Professional Documents

Culture Documents

Lecture 4 - Worked Out Problems On Involute Spur Gears

Lecture 4 - Worked Out Problems On Involute Spur Gears

Uploaded by

Samawat AhsanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lecture 4 - Worked Out Problems On Involute Spur Gears

Lecture 4 - Worked Out Problems On Involute Spur Gears

Uploaded by

Samawat AhsanCopyright:

Available Formats

Machine Design II Prof. K.Gopinath & Prof. M.M.

Mayuram

Module 2 - GEARS

Lecture – 4: WORKED OUT PROBLEMS ON INVOLUTE SPUR GEARS

Content

4.1 Introduction

4.2 Gear Calculation -Worked example 1

4.3 Gear Calculation -Worked example 2

4.1 INTRODUCTION

In the earlier lectures, the definition of gear, gear terminology, interference, methods of

eliminating interference, standard tooth systems for spur gears, profile shifted gears,

involutometry and design of gear blanks were dealt in detail. With the background of the

above knowledge, solving of simple gear problems will be dealt in this lecture.

4.2 GEAR CALCULATION – Worked out example 1

In a drive, a velocity ratio of 2.5 with a centre distance of 70 mm is desired. (a) Determine

the pitch diameter of the gears with 20o full depth involute teeth; (b) Is there any

interference in the system? If so, how will you avoid it? (c) Determine the contact ratio, (d)

Find the dedendum, addendum, root diameters and the tip clearance, (e) If the centre

distance is increased by 1.5%, what will be the new pressure angle?

• Given Data: i = 2.5; C = 70 mm; φ = 20o;

• It is an involute full depth tooth system ;

• To be found: m = ?; Z1 = ? ; d1 = ?; Interference exists or not ?;

Z2 = ?; d2 = ?; CR = ?

We know that,

C = (r1 +r2) = 0.5 m ( Z1 + Z2) = 0.5 m (Z1 + i Z1) = 70 mm

Indian Institute of Technology Madras

Machine Design II Prof. K.Gopinath & Prof. M.M.Mayuram

From the above, i.e., m x Z1 = 40

• Possible solutions for standard modules as can be seen from the table:

Solution I:

• m = 2mm, Z1 = 20, Z2 = i. Z1 = 2.5 x 20 = 50

• d1 = m Z1 = 2 x 20 = 40 mm

• d2 =i d1 = 2.5 x 40 = 100 mm

STANDARD MODULES IN mm:

0.3 0.4 0.5 0.6 0.7 0.8 1.0

1.25 1.5 1.75 2.0 2.25 2.5 3.0

3.5 4.0 4.5 5.0 5.5 6.0 6.5

7 8 9 10 11 12 13

14 15 16 18 20 22 24

26 28 30 33 36 39 42

45 50 Further increase is in terms of 5 mm

• Minimum number of teeth that can engage with the gear of 50 teeth without

interference is given by,

4k(z2 + k)

z12 + 2 z1 z2 =

sin 2 φ

• For full depth gears, k = 1. Substituting the values Z2 = 50, φ = 20o in the above

equation,

4 x 1( 50 1 )

z12 2 z1 x50

sin 2 20 o

z 2 + 100 z 1744 0

1 1

• i.e., Z1min = 15 is the minimum permissible number of teeth without interference.

Since from the above it is seen that, Z1 > Z1min no interference will occur.

Indian Institute of Technology Madras

Machine Design II Prof. K.Gopinath & Prof. M.M.Mayuram

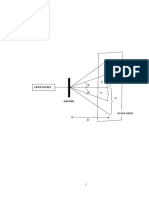

Fig 4.1. Path of Contact

Contact ratio, CR:

Referring to fig. 4.1, the path of contact:

La = ua + ur

L ( r a )2 r 2 cos 2 ( r a )2 r 2 cos 2 ( r r ) sin

a 1 1 2 2 1 2

Substituting the values,

L ( 20 2 ) 2 20 2 cos 2 20o ( 50 2 ) 2 50 2 cos 2 20o ( 20 50 ) sin 20o

a

9.798 mm

Indian Institute of Technology Madras

Machine Design II Prof. K.Gopinath & Prof. M.M.Mayuram

Now CR can be calculated with the formulae below,

L L 9.798 9.798

CR a a 1.660

p cos m cos x 2 x cos 20o 5.901

For full depth tooth, the various values calculated are as shown below:

Addendum: a = 1m = 1x2 = 2mm

Dedendum: b = 1.25m = 1.25x2 = 2.5 mm

Clearance: c = 0.25 m = 0.25x2 = 0.5 mm

Pinion root circle diameter: dr1 = d1- 2b = 40 – 2x2.5 = 35 mm

Pinion addendum diameter: da1 = d1+ 2a = 40 + 2x2 = 44 mm

Gear root circle diameter: dr2 = d2- 2b = 100 – 2x2.5 = 95 mm

Gear addendum diameter: da2 = d2+ 2a = 100 + 2x2 = 104 mm

Solution II:

The centre distance is given by, C = (r1 +r2) = 0.5 m ( Z1 + Z2) = 0.5 m (Z1 + i Z1)

= 70 mm

• Simplifying, m x Z1 = 40

• Another possible solution for standard module from the table is,

m = 2.5 mm, Z1 = 16, Z2 = i x Z1 = 40,

d1 = m Z1 = 2.5x16=40 mm,

d2 = m Z2 = 2.5 x 40 =100 mm

• Minimum number of teeth that can engage the gear of 40 teeth without interference

is given by,

4 k (z2 + k)

z12 + 2 z1 z2 =

sin 2 φ

Indian Institute of Technology Madras

Machine Design II Prof. K.Gopinath & Prof. M.M.Mayuram

• For full depth gears k = 1. Substituting Z2 = 40, φ = 20o, in the above equation,

4(40 + 1 )

z 2 + 2 z x 40 =

1 1 sin2 20o

z 2 + 80 z 1402 0

1 1

• i.e., Z1min = 15 is the minimum permissible without interference.

Since Z1 > Z1min, no interference will occur.

Contact ratio, CR :

Referring to the fig. 4.1, the path of contact is given by,

La = ua + ur

L ( r a )2 r 2 cos 2 ( r a )2 r 2 cos 2 ( r r ) sin

a 1 1 2 2 1 2

Substituting the values,

L ( 20 2.5 )2 20 2 cos 2 20 o ( 50 2.5 )2 50 2 cos 2 20 o ( 20 50 ) sin 20 o

a

11.854 mm

Now CR can be calculated as,

L L 11.854 11.854

CR a a 1.607

p cos m cos x 2.5 x cos 20o 5.901

For full depth tooth the values are,

Addendum : a =1m = 1x2.5 =2.5mm

Dedendum : b =1.25m =1.25x2.5 = 3.125 mm

Indian Institute of Technology Madras

Machine Design II Prof. K.Gopinath & Prof. M.M.Mayuram

Clearance: c = 0.25 m = 0.25x2.5 = 0.625 mm

[Pinion root circle diameter: dr1= d1- 2b = 40 – 2x3.125 = 33.75 mm

Pinion addendum diameter: da1= d1+ 2a = 40+2x2.5 = 45 mm

Gear root circle diameter: dr2= d2- 2b = 100 – 2x3.125 = 93.75 mm

Pinion addendum diameter: da2= d2+ 2a = 100 + 2x2.5 = 105 mm

New Pressure angle Ø when the centre distance C is increased by 1.5% is given by:

Ø = cos-1( r1 cos20o / r1 1.015) = 22.21o

4.3 GEAR CALCULATIONS- Worked out example 2

A 21 teeth gear has 20o full depth involute teeth with a module of 12mm. (a) Calculate the

radii of pitch circle, base circle and addendum circle (b) Determine the tooth thickness at

base circle, pitch circle and addendum circle. Comment on the top land thickness.

rb

r

cos

inv tan

t

t 2 r ( 1 inv inv )

2r

1

Fig 4.2 Involutometry

The terminologies used in the problem are explained in earlier chapters. Hence the figures

referred are self explanatory.

Indian Institute of Technology Madras

Machine Design II Prof. K.Gopinath & Prof. M.M.Mayuram

Fig. 4.3 Layout for tooth thickness determination at any point on tooth profile

Given Data: Pressure angle, Ø =20o = 0.349 rad., Z1 = 21, m= 12mm.

Solution:

r1 = 0.5.m.Z1 = 0.5 x 12 x 21=126 mm

rb = r1.CosØ = 126 x cos 20o = 118.4 mm

a = 1m = 1 x 12 = 12 mm

ra = r1 + a = 126 + 12 = 138 mm

p1 = π.m = π. 12 = 37.14 mm

t1 = 0.5 p1 = 0.5 x 37.14 = 18.57 mm

inv Ø = tan Ø - Ø = tan 0.349 – 0.349 = 0.015 rad

Indian Institute of Technology Madras

Machine Design II Prof. K.Gopinath & Prof. M.M.Mayuram

At the base circle Øb= 0, Hence tooth thickness tb at the base circle is:

t

t 2 r ( 1 inv inv )

b b 2r b

1

18.57

2 x 118.4 x( 0.015 0 ) 21.0 mm

2 x126

At the addendum circle the pressure angle is given by,

Øa=cos-1(rb/ra) =cos-1(118.4 /138) =0.54 rad

inv Øa = tan 0.54 – 0.54 = 0.059

Hence tooth thickness ta can be calculated as,

t

t 2 r 1 inv inv

a a 2r a

1

Substituting the values,

18.57

t 2 x 138 x 0.015 0.059 8. 20 mm

a 2 x 126

Minimum recommended top land thickness is,

tamin = 0.25 m = 0.25 x 12 = 3 mm

From the above, we know that, ta > tamin, hence the tip thickness is adequate and

permissible.

-----------------------

Indian Institute of Technology Madras

You might also like

- ATI TEAS Calculation Workbook: 300 Questions to Prepare for the TEAS (2023 Edition)From EverandATI TEAS Calculation Workbook: 300 Questions to Prepare for the TEAS (2023 Edition)No ratings yet

- Answers to Selected Problems in Multivariable Calculus with Linear Algebra and SeriesFrom EverandAnswers to Selected Problems in Multivariable Calculus with Linear Algebra and SeriesRating: 1.5 out of 5 stars1.5/5 (2)

- Instructor's Manual to Accompany CALCULUS WITH ANALYTIC GEOMETRYFrom EverandInstructor's Manual to Accompany CALCULUS WITH ANALYTIC GEOMETRYNo ratings yet

- Calculation of Gear Dimensions - KHK Gears PDFDocument25 pagesCalculation of Gear Dimensions - KHK Gears PDFlawlawNo ratings yet

- NUST Hostel Admission Form New PDFDocument2 pagesNUST Hostel Admission Form New PDFMuhammad Waqas0% (1)

- Introduction To Microelectronic FabricationDocument87 pagesIntroduction To Microelectronic FabricationBhushan Yadav81% (27)

- Machine Design - INHOUSE 3Document28 pagesMachine Design - INHOUSE 3Pia May Torres PablicoNo ratings yet

- Ibong Tiririt (MDSP 1) Machine Design and Shop Practice ProblemsDocument173 pagesIbong Tiririt (MDSP 1) Machine Design and Shop Practice ProblemsRoss AlteaNo ratings yet

- Digital Electronics For Engineering and Diploma CoursesFrom EverandDigital Electronics For Engineering and Diploma CoursesNo ratings yet

- Interference PatternsDocument8 pagesInterference PatternsAsa mathewNo ratings yet

- DfsDocument8 pagesDfsupadhyaysanuNo ratings yet

- Involute Spur Gear ProblemsDocument6 pagesInvolute Spur Gear ProblemsChiragJansari100% (1)

- Test-9 - ME - Production & MSDocument11 pagesTest-9 - ME - Production & MSJatin prasad TandanNo ratings yet

- Cc19 Group 1 Lab Report 9Document12 pagesCc19 Group 1 Lab Report 9PHƯỚC DƯƠNG THANHNo ratings yet

- Dme II Test 1 Set 3Document7 pagesDme II Test 1 Set 3Vamshi ReddyNo ratings yet

- Sri Chaitanya IIT Academy., India.: A Right Choice For The Real AspirantDocument11 pagesSri Chaitanya IIT Academy., India.: A Right Choice For The Real AspirantUppu EshwarNo ratings yet

- Design of Machine Elements - Chapter 20: A M (Q+ ZDocument6 pagesDesign of Machine Elements - Chapter 20: A M (Q+ ZAditya Varma YalamanchiliNo ratings yet

- TST2601 - Minor Test 1 - Memo - 2022Document8 pagesTST2601 - Minor Test 1 - Memo - 2022Johan PienaarNo ratings yet

- 002 Deep Drawing GuidelinesDocument34 pages002 Deep Drawing GuidelinesMohit WaniNo ratings yet

- Laboratory Report PHYS 194 Fall 2019: AbsentDocument6 pagesLaboratory Report PHYS 194 Fall 2019: AbsentAbdulNo ratings yet

- Tolerance For ThreadDocument15 pagesTolerance For ThreadthilipkumarNo ratings yet

- Vibration Cat 2 MSDocument4 pagesVibration Cat 2 MSkalu kioNo ratings yet

- Visit Us At: WWW - Nodia.co - In: GATE Previous Year Solved Paper For Mechanical EngineeringDocument1 pageVisit Us At: WWW - Nodia.co - In: GATE Previous Year Solved Paper For Mechanical EngineeringSameerChauhanNo ratings yet

- Kinds of GearsDocument51 pagesKinds of GearsIrfanNo ratings yet

- Steel Structure - Solutions - Batch AbDocument7 pagesSteel Structure - Solutions - Batch AbAvinash ChoudharyNo ratings yet

- Meng 149 - Machine Design Learning Task No.2 Shear Stress Collano, Noel Rogie M. Class Schedule: Monday (8:00am - 10:00) AmDocument2 pagesMeng 149 - Machine Design Learning Task No.2 Shear Stress Collano, Noel Rogie M. Class Schedule: Monday (8:00am - 10:00) AmCollano M. Noel RogieNo ratings yet

- Experiment Report 6Document4 pagesExperiment Report 6Cuber HCNo ratings yet

- SRG SPS-19 07 Dec SoDocument2 pagesSRG SPS-19 07 Dec Sotechnicalfacts31No ratings yet

- Experiment 6Document6 pagesExperiment 6ntuanhung322No ratings yet

- Experimental-Report-1 FixDocument3 pagesExperimental-Report-1 FixNguyễn Quốc HưngNo ratings yet

- XII - Maths - CirclesDocument12 pagesXII - Maths - CirclesNaveen GargNo ratings yet

- Nodia and Company: Gate Solved Paper Mechanical Engineering 2012Document39 pagesNodia and Company: Gate Solved Paper Mechanical Engineering 2012Arif AliNo ratings yet

- Module - 2Document20 pagesModule - 2Rockstar AnilNo ratings yet

- 11 Mrs. Sadia Patka Dda Line Drawing AlgorithmDocument21 pages11 Mrs. Sadia Patka Dda Line Drawing Algorithmsova jettoNo ratings yet

- PHPG ICLu 0Document47 pagesPHPG ICLu 0rockybear11111No ratings yet

- JEE Advanced 2021 Paper 1 and 2 Paper - SolutionDocument71 pagesJEE Advanced 2021 Paper 1 and 2 Paper - SolutionSfhhjjNo ratings yet

- Example1.1.: I. Uncracked Section PropertiesDocument13 pagesExample1.1.: I. Uncracked Section PropertiesOlesea NesterencoNo ratings yet

- PMLLH Kqko9Document18 pagesPMLLH Kqko9Jelly SurbaktiNo ratings yet

- Diffraction at A Slit and Heisenberg'S Uncertainty PrincipleDocument10 pagesDiffraction at A Slit and Heisenberg'S Uncertainty PrincipleĐào Lương Duy AnhNo ratings yet

- Tasks 1.5Document2 pagesTasks 1.5Aly Sherif AhmedNo ratings yet

- Group Assignment ORDocument13 pagesGroup Assignment ORYeabsira DawitNo ratings yet

- Square FootingDocument21 pagesSquare FootingRakesh ShresthaNo ratings yet

- Seri Omega Private & International School: To View The Video For This Worksheet, ClickDocument24 pagesSeri Omega Private & International School: To View The Video For This Worksheet, ClickShean LimNo ratings yet

- ERROR Cheat CodeDocument9 pagesERROR Cheat Codeazamchishty796No ratings yet

- Charts and Tables PDFDocument2 pagesCharts and Tables PDFAbdoNo ratings yet

- Mathcad - CONICOS - 2Document15 pagesMathcad - CONICOS - 2Entrerriano de CorzonNo ratings yet

- Example 9.1Document17 pagesExample 9.1Sarah HaiderNo ratings yet

- Laser - Particle Size DeterminationDocument8 pagesLaser - Particle Size Determinationdharshankannan22No ratings yet

- ME 358 Homework Solution 1: Problem 1Document12 pagesME 358 Homework Solution 1: Problem 1Neo TarunNo ratings yet

- EE 164 Problem Set 5 SolutionDocument2 pagesEE 164 Problem Set 5 SolutionnenasukaNo ratings yet

- Part 2. Desiging Chain DriveDocument3 pagesPart 2. Desiging Chain Drivekhang.trieuk13t6u3002No ratings yet

- Results Phy Exp. 1Document3 pagesResults Phy Exp. 1NurmazillaZainalNo ratings yet

- XColumn Paal ENDocument4 pagesXColumn Paal ENAlem LoajnerNo ratings yet

- ME GATE-12Document45 pagesME GATE-12Monu SharmaNo ratings yet

- Calculation of Gear DimensionsDocument22 pagesCalculation of Gear DimensionsdressfeetNo ratings yet

- Gear DesignDocument37 pagesGear DesignAayush ShahNo ratings yet

- Lec 41Document16 pagesLec 41Mayuresh AtramNo ratings yet

- Fluid Assignment 2016Document8 pagesFluid Assignment 2016TlhologeloNo ratings yet

- Microwave Engineering Pozar Chapter 05 Exercise 09 PDFDocument11 pagesMicrowave Engineering Pozar Chapter 05 Exercise 09 PDFJohn Bofarull GuixNo ratings yet

- Ten-Decimal Tables of the Logarithms of Complex Numbers and for the Transformation from Cartesian to Polar Coordinates: Volume 33 in Mathematical Tables SeriesFrom EverandTen-Decimal Tables of the Logarithms of Complex Numbers and for the Transformation from Cartesian to Polar Coordinates: Volume 33 in Mathematical Tables SeriesNo ratings yet

- HW 8Document1 pageHW 8Muhammad WaqasNo ratings yet

- Fire Damper PDFDocument20 pagesFire Damper PDFMuhammad WaqasNo ratings yet

- Ishq Ka SheenDocument271 pagesIshq Ka Sheenroadsign100% (3)

- Spur GearDocument12 pagesSpur GearIsrael CeballosNo ratings yet

- Gear Lecturers2 - 10Document17 pagesGear Lecturers2 - 10Muhammad WaqasNo ratings yet

- Shiglay SM ch17Document33 pagesShiglay SM ch17Muhammad WaqasNo ratings yet