Professional Documents

Culture Documents

10.troubleshooting For Relief Valves Used in Hydraulic Systems

10.troubleshooting For Relief Valves Used in Hydraulic Systems

Uploaded by

Hamza NoumanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

10.troubleshooting For Relief Valves Used in Hydraulic Systems

10.troubleshooting For Relief Valves Used in Hydraulic Systems

Uploaded by

Hamza NoumanCopyright:

Available Formats

SCIENTIFIC PROCEEDINGS IX INTERNATIONAL CONGRESS "MACHINES, TECHNOLОGIES, MATERIALS" 2012 ISSN 1310-3946

TROUBLESHOOTING FOR RELIEF VALVES USED IN HYDRAULIC SYSTEMS

Prof. Dr. M. Sc. Pancar Yasar1, Assoc. Prof. Dr. M. Sc. Ergur H. Sevil1

Faculty of Mechanical Engineering – Eskisehir Osmangazi University, Eskisehir1, Turkey.

Abstract: This study relates to the description of a relief valve briefly and troubleshooting due to pressure rise in hydraulic system. In any

hydraulic system, it is essential to limit the maximum pressure generated by the constant displacement pump. For this purpose, usually

pressure relief valve is used and pressure across the relief valve can be balanced. Many of the failures in a hydraulic system show similar

symptoms such as, a gradual or sudden loss of high pressure, resulting in loss of power or speed in the cylinders. Due to possible

malfuntions, the cylinders may stall under light loads or may not move at all. Often the loss of power is accompanied by an increase in

pressure which must be taken away by a relief valve.

Keywords: TROUBLESHOOTING, RELIEF VALVE, PRESSURE-SENSITIVE VALVE, HYDRAULIC SYSTEM.

becomes large enough to provide a force. It causes the valve

1. Introduction to open rapidly because the spring controlling the main

It is believed that the French scientist Denis Papin was the inventor element is light. A relief valve may be installed wherever

of the safety valve at the end of the seventeenth century. The safety there is a need to protect a probably the most common

valve was kept closed by means of either a spring or a lever and a application. It would be protecting a pump against an

movable weight; sliding the weight along the lever to regulate the excessive pressure rise when the motion of an actuator or

pressure. Some believe that, Papin was only the inventor of some motor becomes blocked. Although the load may be

improvements and that safety valves were already being used some 50 abnormal, actuator motions are often blocked deliberately,

years earlier on a steam digester designed by Rudolf Glauber, a German- for example in a clamping application [7].

Dutch alchemist. Timothy Hackworth developed an open-ended safety

valve for the steam trains and boilers that were first being built around

1830 when the starting of the safety valve designs as we use today [1].

Hydraulic systems are used in so many automatic machines. It is

equipped with a pressure relief valve to maintain the operation pressure

of the system at a pre-determined level. Relief valve protects the

hydraulic pump and in turn the prime mover from overload quickly in

case the system is exposed to overpressure. That’s why, characteristics

of such a valve like the other system components are very important in

designing the hydraulic system. The basic pressure relief valve is

dynamically undesirable due to relatively low viscous damping. This

kind of valve provides low damping during upward movement of the

relief valve arbor [2].

Pressure relief valves used in hydraulic systems are spring-loaded

valves designed to open and relieve excess pressure, then immediately

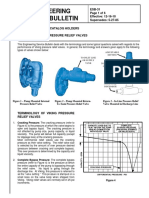

close, preventing any loss of flow of fluid after normal conditions have Fig.1. Pump protection circuit with relief valve [10]

been renovated [3]. They are designed and manufactured to act as a

safety measure in pressurized liquid system. The relief valve is a device

The function of the relief valve is to limit the maximum

utilized to divert excess pressure (sudden surges) in the discharge side of

pressure that can exist in a system [8]. Under ideal

the pump into the suction side. Generally, these changes are so rapidly

condition, the relief valve should provide alternative flow

and of such magnitude, that the pump operator can not correct quickly

path to tank for the system fluid while keeping the system

enough. The properly set and maintained relief valve can make these

pressure constant. There are two types of valves that are

corrections for the operator [4].

commercially available such as, direct and pilot type (9).

The pressure relief valve shall safely control increase in pressure by

venting the pressurized liquid from the location. Another application is 3. Types of Relief Valves

to protect equipment from overpressure. The valves are generally “back- 3.1. Direct Acting Type

pressure dependent”, so can be discharged to atmosphere easily. Once a

valve has discharged, replacement is usually adviced, as the set pressure It is usually a poppet, but other geometries such as a ball

can no longer be guaranteed. It is recommended to have a relief valve or a spool may be encountered. During normal system

pressure setting at least 25% higher than the maximum system operating operation, the regulating element is held in a fluid blocking

pressure. One must be sure that set pressure should not be higher than position by a spring. If the system pressure reaches a preset

the design pressure of the hydraulic system [5]. value, the force on the regulating element will equal the

spring preload force. This is called the cracking pressure.

2. Description of Relief Valves Design Further, increase in pressure will cause movement for the

regulating element from its fluid blocking position. Then it

A historic introduction to the pressure relief valve evolution leads to allows fluid to flow to the system reservoir [11].

the definition of the best performance characteristic of pressure relief

valves. The salient features of the valve's best performance characteristic 3.2. Pilot Operated Type

as a combination of the valve ‘best dynamic performance’ and the valve

‘best discharge capacity’ and factors leading to distortions of the best Element can be quite small because this pilot is only

performance characteristics [6]. required to pass a small flow in a hydraulic circuit (see

Figure 2). During the normal closed condition of the valve,

Relief valves are classified in two types. In the direct acting type, the there is no flow through the orifice in the main regulating

pressure to be relieved acts directly on the fluid regulating element. This element, so there is no pressure difference across the main

type is commonly employed in systems with relatively low flow rates. element. Thus, the main element can be held in a closed

For high flow rates, a pilot operated type is commonly employed. In this position by a light spring [11].

type the pressure to be controlled acts on a pilot. As soon as this pilot

allows flow, the pressure difference across the main regulating element

37 YEAR XX, VOLUME 2, P.P. 37-39 (2012)

SCIENTIFIC PROCEEDINGS IX INTERNATIONAL CONGRESS "MACHINES, TECHNOLОGIES, MATERIALS" 2012 ISSN 1310-3946

failure or human error. This exposes the system to a pressure

that exceeds the maximum allowable working pressure. So,

the relief valve is required unless administrative procedures

to control valve closure.

4.1.2. Fire Exposure

Fire may occur in hydraulic systems. So, all

equipments must be protected from overpressure which is

Fig.2. Basic types of relief valves for different operations [5] controlled by pressure relief valves.

4.1.3. Check Valve Failure

4. Operation of Relief Valves in Hydraulic Systems

It is generally placed at a pump outlet. Malfunction of

The machine tolerances are critical and even a small amount of dirt the check valve can lead to overpressure in hydraulic

can cause the relief valve system to malfunction. A good preventive system. When a fluid is pumped into a system, failure of the

maintenance program is essential to prevent the problems in relief valve check valve causes reversal of the liquid flow back to pump.

system. It is important to realize that for the relief valve to function When the liquid is displaced into a suction system and high

properly, the discharge pressure should be at least 3-4 bar greater than pressurizied fluid enters, overpressure is occured.

the suction or incoming pressure. If not, the relief valve opens but the

fluid will not be able to flow from the discharge to the suction area. 4.1.4. Thermal Expansion

It is a common fallacy of some pump operators to think the installed

relief valves protect them under all conditions. Normal relief valve If isolation of a piping on the cold side of system can

systems cannot relieve discharge pressure below the incoming or suction result in overpressure due to heat input from the warm side,

side pressure. Surges such as those encountered in a relay operation, if then the line or cold side of the system must be protected by

not controlled, it will be transmitted to the discharge side of the pump. If a relief valve [12]. Hydraulic systems for the pressure

companies get involved in relay operations over 3 bar, a suction side protection, following categorization can be used for the

relief valve must be installed [12]. These are usually a one-piece unit product standards especially in EU countries.

(entirely separate from those previously discussed) in which pre-settting

the pressure by adjusting a spring-loaded valve. When the pressure rises EN ISO 4126-1: Presssure safety relief valves

above the setting level, the valve opens and dumps the fluid to the tank. EN ISO 4126-2: Bursting disc safety devices

This continues up to the pressure drops below the preset pressure. EN ISO 4126-3: Safety valves and bursting disc safety

Without a suction-type relief valve you are risking the possibility of devices in combination

excess pressure cracking the pump body or, even worse, the inability of EN ISO 4126-4: Pilot operated safety valves

your engineer to be able fully to control discharge pressure. EN ISO 4126-5: Controlled safety pressure relief systems

A conventional pressure relief valve is to be designed to open at a EN ISO 4126-6: Application, selection and installation of

preset liquid pressure. A spring exerts a force on a valve seat via a piston bursting disc safety devices

assembly. At the set pressure, the piston begins to lift resulting in a small DIN EN 12953-8: Shell boilers, safety devices against

amount of flow through the valve and the pressure force. This force acts excessive presssure

on the piston that increases importantly, and overcomes the spring force. DIN EN 764-7: Sizing and spring-Setting

The imbalance of forces cause the valve to fully open. By design, the

difference in pressure from the valve set point to the fully open condition 4.2. Troubleshooting the relief valves

is no more than 10 %. The valve then re-closes at a pressure where the Listed below are the areas that you can troubleshoot the

spring force overcomes the piston force. Under normal system operating relief valves [7]. When working on a specific machine for

conditions, the pressure at the valve inlet is below the set pressure. Only more information technical manual is prefered.

under abnormal operating conditions should the pressure relief valve be

open [12]. The reasons for the usage of relief valves are listed below. If low or erratic pressure occurs for the sake of

(1) Protect system operators troubleshooting, the following items must be

(2) Prevent the demolotion of capital investment considered.

(3) Preserve the production

Adjustment is incorrect.

(4) Reducing downtime of the system

(5) Comply with codes and standards Dirt, chip, or burrs may cause the valve partially

(6) Protect the environment open.

In the daily operation of hydraulic system overpressure can happen Poppets or seats may be worned or damaged.

due to incidents like a blocked discharge, fire exposure, tube rupture, Valve piston in the main body may be sticked.

check valve failure. This can lead to a major incident in plant if the Selection of spring is wrong

pressure relief system is not in place or not functional. It is very Spring ends may be damaged.

important to properly select, size, locate and maintain the pressure relief Valve in the body may be cocked.

systems to prevent or minimize the losses from major incident like fire

or other issues [2]. Orifice or balance hold may be blocked.

If relief valve has no pressure, the following items must

4.1. Causes of overpressure be considered.

Overpressure is significant in preliminary steps of pressure relief Orifice or balance hole may be plugged.

system design. It helps the designer to understand the cause of Poppet does not seat.

overpressure and minimize the effect. It is the result of an unbalance or Valve may have a loose fit.

disruption of the normal flows of material and energy that causes the Spring may be broken.

material or energy, or both, to build up in some part of the system. Dirt, chip, or burrs may cause the the valve

partially open.

4.1.1 Blocked Discharge

Poppet or seat may be worned or damaged.

Blocked discharge can be explained at any system, pump or other Valve in the body may be cocked.

equipment is the closure of blockage at outlet either by mechanical If excessive noise occurs consider the following items;

38 YEAR XX, VOLUME 2, P.P. 37-39 (2012)

SCIENTIFIC PROCEEDINGS IX INTERNATIONAL CONGRESS "MACHINES, TECHNOLОGIES, MATERIALS" 2012 ISSN 1310-3946

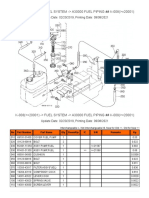

Oil viscosity may be too high. If the shut down for pressurized equipment is reduced,

Poppet or seat may be faulty or worned. the intervals between relief valve examinations need to be

similarly extended, or systems developed to allow the

Line pressure may have an excessive return.

examinations to be carried out on-line [13]. Besides these

Pressure setting is too close to that of another valve in the above mentioned remedies, we also use Figure 3 in order to

circuit. troubleshoot the problem arising in relief valves [14].

Spring may be broken.

If adjustment of the relief valve can not be achieved properly, 5. Conclusion

consider the following items;

Spring may be broken. As with all troubleshooting techniques, knowledge of

components and their function in a system is vitally

Fatique for spring material may come across.

important. It is probably fair to say that, when all the

Improper spring may have been used. components of a hydraulic system have been identified, their

Drain line in system may be restricted. function determined and the operation of the system as a

whole understood, the troubleshooter has gone 51% of the

4. 3. Relief Valve Failures and Remedies way towards finding the problem. It is important to make the

Hydraulic valves are precision-made and must be very accurate in use of advices given for relief valves effectively, a good

controlling a fluid pressure, direction, and volume within a hydraulic understanding of the basic principles of relief valves with a

system. Contaminants, such as dirt, in the oil are the major problems in knowledge of the operation and application of them.

valve failures. Small amounts of dirt, lint, rust, or sludge can cause Hydraulic systems are getting more and more complex

annoying malfunctions and extensively damage valve parts. Such as methods of controlling machines become increasingly

material will cause a valve to stick, plug small openings, or abrade the developed. Technological advances in many hydraulic

mating surfaces until a valve leaks. Only the specified oils must be used system components such as, relief valves were exhibited in

in a hydraulic system. the last twenty years. The object of this study is to provide

Following recommendations are advisable before servicing a relief procedure for a logical approach on troubleshooting which

valve [1]. can be extended when necessary to cover specific machines

in all areas of industry either using the advices or flow charts

Disconnect the electrical power source before removing a

given. In order to control pressure of flow, the fundamentals

hydraulic relief valve's components.

for this procedure must be developed.

Release the system's hydraulic pressure before disconnecting

any hydraulic valve components. The main problem in philosophy of the troubleshooting

Lower all hydraulic working units to the ground before procedure is determining the aspects of the hydraulic

disconnecting any parts. system, such as fault, flow, pressure or direction. By

Clean a valve and its surrounding area before removing any consulting the circuit diagram, a list of possible causes can

part for service. be drawn up. The next stage is to search for the obvious

remedy. Certain controls that are achieved on a hydraulic

Paint thinner or acetone for cleaning is not advisable.

system using the human senses of sight, touch and hearing

which can be carried out very quickly.

6. References

[1] M. Hellemans, The Safety Relief Valve Handbook, Design and

Use of Process Safety Valves to ASME and International Codes

and Standards, (1st edition, Macmillan Company, 2009).

[2] J. Watton, The Design of a Single-Stage Relief Valve with

Directional Damping, The Journal of Fluid Control Including

Fluidics Vol. 18, n. 2, pp. 22–35, 1988.

[3] K. Dasgrupta, R. Karmakar, Modelling and Dynamics of Single-

Stage Pressure Relief Valve with Directional Damping,

Simulation Modelling Practise and Theory, Vol. 10, n. 1-2, pp.

51-67, 2002.

[4] www.haleproducts.com.

[5] Y. Pancar, H.S. Ergur, Hydraulic Circuits, Design and

Application, (Lecture notes, ESOGU, Eng. Faculty, Mech. Eng.

Dept., 2009).

[6] N. G. Gavrila, S. Sethi, Best Performance Characteristic of

Pressure Relief Valves and The Amount of Lost Product, Journal

of Loss Prevention in the Process Industries, Vol. 4, n. 4, pp.

265-271, 1991.

[7] F. C. Parry, Relief System Handbook, (Institution of Chemical

Engineers, ICE, 1992).

[8] K. Dasgupta, R. Karmakar, Dynamic Analysis of Pilot Operated

Fig.3. Troubleshooting nomogram for hydraulic system with relief valve Pressure Relief Valve, Simulation Modelling Practice and Theory

Vol. 10, pp. 35–49, 2002.

The following must be fulfilled when disassembling a valve. [9] A. Misra, K. Behdinanb, W.L. Cleghorna, Self-Excited Vibration

of a Control Valve due to Fuid–Structure Interaction, Journal of

Maintenance operator must be certain that all tools are clean Fluids and Structures Vol. 16, n. 5, pp. 649-665, 2002.

[10] S. Hayashi, K. Ohi, Global Stability of a Poppet Valve Circuit,

and free of grease and dirt. Journal of Fluid Control, Vol. 21, n. 4, pp. 48-63. 1999.

One must be careful to identify the parts when disassembling [11] J. S. Cundiff, Fluid Power Circuits and Controls, (1st edition,

for later reassembly. The valve sections to be reassembled in the same CRC Pres LLC, 2002).

order. [12] www.grothcorp.com

[13] T. Nicholls, Benefits of On-line Relief Valve Testing, World

If possible, use a vise equipped with lead or brass jaws, or Pumps, Vol. 2004, n. 456, pp. 50-54, 2004.

protect the component by wrapping component in a protective covering. [14] Guide to Industrial Hydraulics, Maintanence Manual, (Vickers,

Sealing all the valve's housing openings to remove the 1998)

components during service work is advisable.

39 YEAR XX, VOLUME 2, P.P. 37-39 (2012)

You might also like

- 318B HydDocument2 pages318B Hydkelmal KELMALLNo ratings yet

- API STD 521-Control Valve FailureDocument1 pageAPI STD 521-Control Valve Failuremuhammad_asim_10100% (1)

- Tyco Control Valve ManualDocument55 pagesTyco Control Valve Manualtxlucky80100% (1)

- Technical Guide Introduction To Liquid Pipeline Surge Relief Daniel en 43822 PDFDocument20 pagesTechnical Guide Introduction To Liquid Pipeline Surge Relief Daniel en 43822 PDFVrbank KrabNo ratings yet

- Troubleshooting For Relief Valves Used in Hydraulic SystemsDocument3 pagesTroubleshooting For Relief Valves Used in Hydraulic SystemspradipNo ratings yet

- Pressure Safety ValvesDocument15 pagesPressure Safety Valvesh_abdullah100% (2)

- Overpressure Protection Methods: Figure ADocument6 pagesOverpressure Protection Methods: Figure AJohn Jairo ValenciaNo ratings yet

- Micro Project: D.Y.Patil Polytechnic, Ambi (0996)Document14 pagesMicro Project: D.Y.Patil Polytechnic, Ambi (0996)Mruganesh Sonar0% (2)

- Surge Relief Valve Definition Function Types Sizing SelectionDocument6 pagesSurge Relief Valve Definition Function Types Sizing Selectionkamala 123100% (1)

- Systems Notes Final 2Document139 pagesSystems Notes Final 2Shreshth ChaddaNo ratings yet

- Hydraulic Control Valves - Sg. STANCU CosminDocument36 pagesHydraulic Control Valves - Sg. STANCU Cosminstancu cosminNo ratings yet

- An Engineer's Guide To Selecting A Pressure Relief Valve (Updated 3.3.21)Document17 pagesAn Engineer's Guide To Selecting A Pressure Relief Valve (Updated 3.3.21)Joseph JoseNo ratings yet

- Control - Pressure Control ValveDocument4 pagesControl - Pressure Control Valvesajad jasmNo ratings yet

- Fps Report PDFDocument7 pagesFps Report PDFShridhar KoriNo ratings yet

- Water Hammer ReferenceDocument5 pagesWater Hammer ReferenceAmit SawantNo ratings yet

- Pressure-Control Valves PDFDocument15 pagesPressure-Control Valves PDFRagab Abulmagd100% (1)

- SIS Lab - Practical - (7) 3Document3 pagesSIS Lab - Practical - (7) 3Hardik BhadouriyaNo ratings yet

- Pressure Control Design GuideDocument10 pagesPressure Control Design GuideMarkNo ratings yet

- AircraftSystems Lesson-4-5Document7 pagesAircraftSystems Lesson-4-5Yves CaraangNo ratings yet

- Relief Valves and Relief SystemsDocument10 pagesRelief Valves and Relief Systemsmatteo2009No ratings yet

- Reliable - Dry Pipe Valve SystemDocument8 pagesReliable - Dry Pipe Valve Systemmina elromanyNo ratings yet

- PSV ManualDocument55 pagesPSV Manualioan.tsiamisNo ratings yet

- Control Valve - Surge Relief Valve Selection GuideDocument20 pagesControl Valve - Surge Relief Valve Selection GuideSriya PetikiriarachchigeNo ratings yet

- Industrial Hydraulic CircuitsDocument43 pagesIndustrial Hydraulic CircuitsFidel Garcia GarciaNo ratings yet

- 4 TH Unit ValvesDocument43 pages4 TH Unit ValvesBahaa EmadNo ratings yet

- Safety Valve SelectionDocument56 pagesSafety Valve Selectionganesh82No ratings yet

- Task 1: Fluid Power DevicesDocument6 pagesTask 1: Fluid Power Devicesmaitham100No ratings yet

- TB21 ValvesDocument4 pagesTB21 ValvesMONANo ratings yet

- Comating Droop in Self-Contained Pressure Regulators (CVR408)Document5 pagesComating Droop in Self-Contained Pressure Regulators (CVR408)HectorNo ratings yet

- Hydraulic SystemDocument28 pagesHydraulic SystemSamiha Maysoon Nooria0% (1)

- Tailoring The Specifications For Pressure Reducing ValvesDocument13 pagesTailoring The Specifications For Pressure Reducing ValvesSuperstarVirgoNo ratings yet

- Control Valve Common Interview QuestionsDocument10 pagesControl Valve Common Interview QuestionsMustafa MehdiNo ratings yet

- Final Control ElementDocument16 pagesFinal Control ElementSanchit KhannaNo ratings yet

- Section 30 - Relief ValvesDocument17 pagesSection 30 - Relief ValveshammamiNo ratings yet

- Pressure Relief Valve: Definition, Types, Working, Location, Sizing, Codes and StandardsDocument18 pagesPressure Relief Valve: Definition, Types, Working, Location, Sizing, Codes and StandardsMalcolm MooreNo ratings yet

- Emergency Shutdown ValveDocument6 pagesEmergency Shutdown ValveCepi Sindang KamulanNo ratings yet

- Final Control ValveDocument19 pagesFinal Control Valveahmad wahideeNo ratings yet

- Study and Testing of PRVDocument4 pagesStudy and Testing of PRVBhargava S PadmashaliNo ratings yet

- Control Valves Interview QuestionsDocument7 pagesControl Valves Interview QuestionsDerbel WalidNo ratings yet

- VALVE TYPES AssignmentDocument10 pagesVALVE TYPES Assignmentbabe100% (3)

- Automatic Sprinkler (Control, Gauges & Alarms)Document6 pagesAutomatic Sprinkler (Control, Gauges & Alarms)rmaffireschoolNo ratings yet

- Lab Report: Basic Hydraulic Linear Circuit: Mechanical Engineering Department Djj40153 Pneumatics and HyraulicsDocument6 pagesLab Report: Basic Hydraulic Linear Circuit: Mechanical Engineering Department Djj40153 Pneumatics and Hyraulicszairil izuwanNo ratings yet

- Cenários Sobrepressão Conforme API RP 521Document3 pagesCenários Sobrepressão Conforme API RP 521Adilmar E. NatãnyNo ratings yet

- Relief Valve: Flare Header or Relief Header To A Central, Elevated Gas Flare Where It Is UsuallyDocument3 pagesRelief Valve: Flare Header or Relief Header To A Central, Elevated Gas Flare Where It Is UsuallyKhaled RabeaNo ratings yet

- Safety ValvesDocument65 pagesSafety Valvesserturkbudak_3448365No ratings yet

- Safety Valve IntroductionDocument88 pagesSafety Valve Introductionbhuvi_patu12100% (3)

- 12 Oxler VW Weight Loaded ActuatorDocument2 pages12 Oxler VW Weight Loaded ActuatorDachyiNo ratings yet

- Deal With The Function of The Pressure Control Valves in Hydraulic Power SystemsDocument6 pagesDeal With The Function of The Pressure Control Valves in Hydraulic Power Systems666667No ratings yet

- Aeroplane Visual Landing Gear System With Tyre Inflation SystemDocument48 pagesAeroplane Visual Landing Gear System With Tyre Inflation SystemANAND KRISHNANNo ratings yet

- Microsoft Word - SVDocument62 pagesMicrosoft Word - SVaftabulalamNo ratings yet

- Microsoft Word - SV - Part1Document6 pagesMicrosoft Word - SV - Part1aftabulalamNo ratings yet

- Safety ValveDocument10 pagesSafety ValveVignesh War100% (1)

- Fisher - Compressor Anti Surge ValveDocument3 pagesFisher - Compressor Anti Surge ValveAlexa MouawadNo ratings yet

- Topic No 2 Hydraulics UpdatedDocument21 pagesTopic No 2 Hydraulics UpdatedSamarth SNo ratings yet

- Demonstration of Relief Valve in Hydraulic and Pneumatic SystemsDocument2 pagesDemonstration of Relief Valve in Hydraulic and Pneumatic SystemsAbraham OmomhenleNo ratings yet

- FM HydraulicsDocument4 pagesFM HydraulicsOnkar KakadNo ratings yet

- Activity No.1 AMT 121Document2 pagesActivity No.1 AMT 121Lion ManabatNo ratings yet

- Study The Water Hammer Phenomena It's Causes and Solutions: M.SC. Mudafer Kadum Kredi M.SC. Lammia'a Abdulrudah AbdDocument25 pagesStudy The Water Hammer Phenomena It's Causes and Solutions: M.SC. Mudafer Kadum Kredi M.SC. Lammia'a Abdulrudah AbdYazNo ratings yet

- HighBeam Research Article APR 13 2016Document14 pagesHighBeam Research Article APR 13 2016Sílvio MonteiroNo ratings yet

- Technical Data Sheet: High Pressure Dry System: 1. DescriptionDocument7 pagesTechnical Data Sheet: High Pressure Dry System: 1. DescriptionDjapaNo ratings yet

- Best Practices in Machinery InstallationDocument2 pagesBest Practices in Machinery InstallationHamzaNoumanNo ratings yet

- Balance Plot FormDocument1 pageBalance Plot FormHamzaNoumanNo ratings yet

- The ABC of NDTDocument5 pagesThe ABC of NDTHamzaNoumanNo ratings yet

- 2005 Nondestructive Testing GuideDocument8 pages2005 Nondestructive Testing GuideHamzaNoumanNo ratings yet

- H Hole MesaurmentDocument2 pagesH Hole MesaurmentHamzaNoumanNo ratings yet

- Helium Leak Detector Vs Pressure Decay Leak DetectionDocument2 pagesHelium Leak Detector Vs Pressure Decay Leak DetectionHamzaNoumanNo ratings yet

- Nbo-Tc NewDocument24 pagesNbo-Tc NewHamzaNoumanNo ratings yet

- Mechanical Workshop: Inspection & Test PlanDocument4 pagesMechanical Workshop: Inspection & Test PlanHamzaNoumanNo ratings yet

- MC LiftRigBestPractices Poster 11X17Document1 pageMC LiftRigBestPractices Poster 11X17HamzaNoumanNo ratings yet

- Bayyinat ArticleDocument4 pagesBayyinat ArticleHamzaNoumanNo ratings yet

- Onboarding Checklist IGDocument1 pageOnboarding Checklist IGHamzaNoumanNo ratings yet

- FNDWRRDocument2 pagesFNDWRRHamzaNoumanNo ratings yet

- COVID-19 VACCINATION REGISTRATION DATA - June18Document11 pagesCOVID-19 VACCINATION REGISTRATION DATA - June18HamzaNoumanNo ratings yet

- Rigging and Lifting Plan GTG-2 GenratorDocument4 pagesRigging and Lifting Plan GTG-2 GenratorHamzaNoumanNo ratings yet

- Scaffolding: Submitted By, Akhilesh.A Production Operator (TR), Forbes Bumiarmada LimitedDocument42 pagesScaffolding: Submitted By, Akhilesh.A Production Operator (TR), Forbes Bumiarmada LimitedHamzaNoumanNo ratings yet

- PC Help Desk Form: Pakarab Fertilizers Ltd. MultanDocument1 pagePC Help Desk Form: Pakarab Fertilizers Ltd. MultanHamzaNoumanNo ratings yet

- Pak-Arab Fertilizer: Khanewal Road Multan Comparative StatementDocument1 pagePak-Arab Fertilizer: Khanewal Road Multan Comparative StatementHamzaNoumanNo ratings yet

- Updated Rigging and Lifting Plan GTG 2 OverhaulingDocument2 pagesUpdated Rigging and Lifting Plan GTG 2 OverhaulingHamzaNoumanNo ratings yet

- 50L Liquid Nitrogen GeneratorTech-ProposalDocument13 pages50L Liquid Nitrogen GeneratorTech-ProposalHamzaNouman0% (1)

- 01 Rigging and Lifting Plan GTG-2 GeneratorDocument2 pages01 Rigging and Lifting Plan GTG-2 GeneratorHamzaNoumanNo ratings yet

- Figure 8 - Dimensions of PN 16 FlangesDocument3 pagesFigure 8 - Dimensions of PN 16 FlangesSamir TahaNo ratings yet

- 2 iPLEX uPVC Pipes and FittingsDocument17 pages2 iPLEX uPVC Pipes and FittingsP YeungNo ratings yet

- Pressure Relief Valves PDFDocument6 pagesPressure Relief Valves PDFroyert80No ratings yet

- Sizing of Restriction OrificesDocument4 pagesSizing of Restriction OrificesYakubuNo ratings yet

- THERMOVACDocument31 pagesTHERMOVACWira Technic UtamaNo ratings yet

- Cryogenic Valves For Industrial Gas Applications PDFDocument88 pagesCryogenic Valves For Industrial Gas Applications PDFmhientbNo ratings yet

- HVAC Piping SystemDocument86 pagesHVAC Piping Systemmohd farhan ariff zaitonNo ratings yet

- Reactor HOJA DE DATOSDocument4 pagesReactor HOJA DE DATOSRodrigo GraciaNo ratings yet

- Quick Change Valve Heads For G1316C and G1170ADocument6 pagesQuick Change Valve Heads For G1316C and G1170Anine starNo ratings yet

- P&ID CWP Rev 2Document1 pageP&ID CWP Rev 2Ajeng OctaviaNo ratings yet

- FW-02 HD-EC-TF-P5076-002: Name Signature DateDocument1 pageFW-02 HD-EC-TF-P5076-002: Name Signature DateAnonymous AdofXEYAgENo ratings yet

- BLANK RISK ASSESSMENT-Trace Analytics-CSnewDocument1 pageBLANK RISK ASSESSMENT-Trace Analytics-CSnewLucero MarinNo ratings yet

- Eaton Hydraulics 2000 Steve Skinner, Eaton Hydraulics, Havant, UKDocument63 pagesEaton Hydraulics 2000 Steve Skinner, Eaton Hydraulics, Havant, UKbatuhan kılıçNo ratings yet

- TX402 Thermostatic Mixing Valve. Tectite Push-Fit ConnectionsDocument18 pagesTX402 Thermostatic Mixing Valve. Tectite Push-Fit ConnectionsShishan AhmadNo ratings yet

- Turbomaquinas - Eduardo BrizuelaDocument164 pagesTurbomaquinas - Eduardo BrizuelaEnrique Melgar100% (1)

- VCR Theory NewDocument18 pagesVCR Theory NewPranay TinkuNo ratings yet

- K-008 ( 20001) - Fuel System - A30000 Fuel Piping ## K-008 ( 20001)Document2 pagesK-008 ( 20001) - Fuel System - A30000 Fuel Piping ## K-008 ( 20001)Martin LindbergNo ratings yet

- An Overboosted Mitsubishi l200Document3 pagesAn Overboosted Mitsubishi l200Joao SilvaNo ratings yet

- Bryton Cycle PDFDocument9 pagesBryton Cycle PDFEddyNo ratings yet

- Us Army Aviation Course Gas Turbine EnginesDocument477 pagesUs Army Aviation Course Gas Turbine EnginesMassimo DercoNo ratings yet

- Intro Propulsion Lect 33Document30 pagesIntro Propulsion Lect 33VyakulShahNo ratings yet

- MSS SP 45Document12 pagesMSS SP 45Allan SousaNo ratings yet

- TT US Logics PDFDocument13 pagesTT US Logics PDFxxshNo ratings yet

- Rowell Repollo Laput: Personal DataDocument6 pagesRowell Repollo Laput: Personal DataHarry DemeterioNo ratings yet

- Outlines: Theory Calculation Conclusion ReferencesDocument31 pagesOutlines: Theory Calculation Conclusion ReferencesYè Paing Oo100% (3)

- Open Storage Water Sprinkler Calculation - ExampleDocument4 pagesOpen Storage Water Sprinkler Calculation - ExampleBagus PrambudiNo ratings yet

- Pury P168tlmu A Bs 208 230v ProductdatasheetDocument2 pagesPury P168tlmu A Bs 208 230v ProductdatasheetLee ChorneyNo ratings yet

- (1952) Válv. Ventosa Dav-Ms DorotDocument3 pages(1952) Válv. Ventosa Dav-Ms DorotHOSMANNo ratings yet