Professional Documents

Culture Documents

60V Two Terminal Constant Current Led Driver Powerdi

Uploaded by

Juan Vicente Hernandez LogytelOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

60V Two Terminal Constant Current Led Driver Powerdi

Uploaded by

Juan Vicente Hernandez LogytelCopyright:

Available Formats

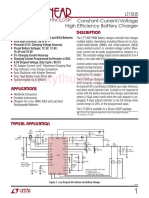

AL5809

60V Two Terminal Constant Current LED Driver

PowerDI

Description Pin Assignments

The AL5809 is a constant current linear LED driver and it provides a

cost-effective two pin solution. It has an excellent temperature 1

stability of 20ppm/°C and the current accuracy ±5% regulated over a IN

wide voltage and temperature range. The AL5809 comes in various

XX Y W X

fixed output current versions removing the need for external current

setting resistors creating a simple solution for the linear driving of

LEDs. It supports both the high-side and low-side driving of LED

AL5809

chains.

The AL5809 turns on when the voltage between IN and OUT swings

from 2.5V up to 60V enabling it drive long LED chains. The floating OUT

ground, 60V Voltage rating between Input and Output pins designed

2

to withstand the high peak voltage incurred in offline applications.

The AL5809 is available in either thermally robust package

PowerDI123 or SOD-123 package.

Features Applications

2.5V to 60V Operating Voltage Between Two Terminals Offline LED Lamps

Robust Power Package Up to 1.2W for PowerDI -123

®

LED Power Supplies

-40°C to +125°C Temperature Range White Goods

±5% LED Current Tolerance Over-Temperature LED Signs

15mA, 20mA, 25mA, 30mA, 40mA, 50mA, 60mA, 90mA, Instrumentation Illumination

100mA, 120mA, and 150mA Available in PowerDI123 Package

15mA, 20mA, 25mA, 30mA, 40mA and 50mA available in SOD-

123 Package, Other Current Options Available by Request

Constant Current with Low Temperature Drift and High Power

Supply Rejection Ratio

Totally Lead-Free & Fully RoHS Compliant (Notes 1 & 2)

Halogen and Antimony Free. “Green” Device (Note 3)

Notes: 1. No purposely added lead. Fully EU Directive 2002/95/EC (RoHS) & 2011/65/EU (RoHS 2) compliant.

2. See http://www.diodes.com/quality/lead_free.html for more information about Diodes Incorporated’s definitions of Halogen- and Antimony-free, "Green"

and Lead-free.

3. Halogen- and Antimony-free "Green” products are defined as those which contain <900ppm bromine, <900ppm chlorine

(<1500ppm total Br + Cl) and <1000ppm antimony compounds.

POWERDI is a registered trademark of Diodes Incorporated.

AL5809 1 of 16 December 2016

Document number: DS36625 Rev. 5 - 2 www.diodes.com © Diodes Incorporated

AL5809

Typical Applications Circuit

VIN VIN

1

IN

Low Side LED String

XX Y W X

AL5809

1

IN

OUT

XX Y W X

2

AL5809

High Side LED String

OUT

2

Pin Descriptions

Pin

Pin

Number Function

Name

(PowerDI123)

LED Current Input Terminal.

In 1 For low side LED string application, connect the LED cathode terminal to the “In” terminal. For high side LED

string application, connect the LED anode terminal to the “Out” terminal.

LED Current Output Terminal.

Out 2 For low side LED string application, connect the LED anode terminal to the “Out” terminal. For high side LED

string application, connect the LED cathode terminal to the “Out” terminal.

Functional Block Diagram

AL5809 2 of 16 December 2016

Document number: DS36625 Rev. 5 - 2 www.diodes.com © Diodes Incorporated

AL5809

Absolute Maximum Ratings

Symbol Parameters Ratings Unit

VInOut “In” Voltage Relative to “Out” Pin -0.3 to +80 V

IInOut LED Current from “In” to “Out” 180 mA

ESD HBM Human Body Model ESD Protection 4 kV

ESD MM Machine Model ESD Protection 400 V

TJ Operating Junction Temperature -40 to +175 °C

TST Storage Temperature -55 to +150 °C

Caution: Stresses greater than the 'Absolute Maximum Ratings' specified above, may cause permanent damage to the device. These are stress ratings only;

functional operation of the device at these or any other conditions exceeding those indicated in this specification is not implied. Device reliability may be

affected by exposure to absolute maximum rating conditions for extended periods of time.

Semiconductor devices are ESD sensitive and may be damaged by exposure to ESD events. Suitable ESD precautions should be taken when

handling and transporting these devices.

AL5809 3 of 16 December 2016

Document number: DS36625 Rev. 5 - 2 www.diodes.com © Diodes Incorporated

AL5809

Package Thermal Data

θJC θJA

PDIS

Package Thermal Resistance Thermal Resistance

Junction-to-Case TA = +25°C, TJ = +125°C

Junction-to-Ambient

PowerDI123 27.15°C/W 148.61°C/W (Note 4) 0.68W

PowerDI123 17.81°C/W 81.39°C/W (Note 5) 1.24W

SOD-123 69.56°C/W 278.42°C/W (Note 6) 0.36W

Recommended Operating Conditions

Symbol Parameter Min Max Unit

VInOut “In” Voltage Range Relative to “Out” Pin 2.5 60 V

IInOut LED Current (Note 7) 15 150 mA

TA Operating Ambient Temperature Range (Note 8) -40 +125 °C

Electrical Characteristics (VInOut = 3.5V) (Note 9)

Symbol Parameter Conditions Min Typ Max Unit

VInOut In-Out Supply Voltage - TA = -40°C to +125°C 2.5 - 60 V

AL5809-15S1-7

TA = -40°C to +125°C 14.25 15 15.75

AL5809-15P1-7

AL5809-20S1-7

TA = -40°C to +125°C 19 20 21

AL5809-20P1-7

AL5809-25S1-7

TA = -40°C to +125°C 23.75 25 26.25

AL5809-25P1-7

AL5809-30S1-7

TA = -40°C to +125°C 28.5 30 31.5

AL5809-30P1-7

AL5809-40S1-7

IINOut Current Accuracy TA = -40°C to +125°C 38 40 42

AL5809-40P1-7 mA

IInOut (±5% for over temperature)

AL5809-50S1-7

TA = -40°C to +125°C 47.5 50 52.5

AL5809-50P1-7

AL5809-60P1-7 TA = -40°C to +125°C 57 60 63

AL5809-90P1-7 TA = -40°C to +125°C 85.5 90 94.5

AL5809-100P1-7 TA = -40°C to +125°C 95 100 105

AL5809-120P1-7 TA = -40°C to +125°C 114 120 126

AL5809-150P1-7 TA = -40°C to +125°C 142.5 150 157.5

VInOut = 2.5V to 60V

ILINE IInOut Current Line Regulation TA = +25°C - 1 - %

(Note 10)

VMIN Minimum Power Up Voltage Increase VInOut (Note 11) TA = -40°C to +125°C - 1.5 - V

tON_MIN Minimum On pulse width (Note 12, 13) - 500 - - µS

tOFF_MIN Minimum Off pulse width (Note 12, 13) - 500 - - µS

Junction Temperature

TSHDN Thermal Shutdown - - +165 - °C

(Note 14)

THYS Thermal Shutdown Hysteresis - - - +30 - °C

Notes: 4. Test condition for PowerDI-123: Device mounted on 25.4mm x 25.4mm FR-4 PCB (10mm x 10mm 1oz copper, minimum recommended pad layout on

top layer and thermal vias to bottom layer ground plane). For better thermal performance, larger copper pad for heat-sink is needed.

5. When mounted on 50.8mm x 50.8mm GETEK PCB with 25.4mm x 25.4mm copper pads.

6. Test condition for SOD-123: Device mounted on FR-4 PCB with 50.8mm x 50.8mm 2oz copper, minimum recommended pad layout on top layer and

thermal vias to bottom layer with maximum area ground plane. For better thermal performance, larger copper pad for heat-sink is needed.

7. The LED operating current is determined by the AL5809 current option index XXX, AL5809-XXXS/P1-7.

8. The Maximum LED current is also limited by ambient temperature and power dissipation such that junction temperature should be kept less than or equal

to +125°C.

9. All voltages unless otherwise stated are measured with respect to OUT pin.

10. Measured by the percentage degree of LED current variation when VInOut varies from 2.5V to 60V each current option.

11. Apply the power linearly to the chip until the device starts to turn on.

12. tON_MIN time includes the delay and the rise time needed for IOUT to reach 90% of its final value. tOFF_MIN time is the time needed for IOUT to drop below

10% of its final value.

13. This parameter only guaranteed by design, not tested in production.

14. Ambient temperature at which OTP is triggered may vary depending on application, PCB layout and material used.

AL5809 4 of 16 December 2016

Document number: DS36625 Rev. 5 - 2 www.diodes.com © Diodes Incorporated

AL5809

Application Information

Description

The AL5809 is a constant current Linear LED driver and can be placed in series with LEDs as a High Side or a Low Side constant current

regulator. The AL5809 offers various current settings from 15mA up to 150mA and different current settings available upon request (contact

Diodes local sales office at http://www.diodes.com).

The AL5809 contains a Low-Dropout regulator which provides power to the internal Current regulation control block. A fixed preset LED current

setting resistor sets the reference current of the Current regulation block. The LED current setting resistor varies with each variant of the AL5809.

An accurate current mirror within the Current regulation control block increases the reference current to the preset LED current of the AL5809.

Simple LED String

The AL5809 can be placed in series with LEDs as a Low Side/High Side constant current regulator. The number of the LEDs can vary from one

to as many as can be supported by the input supply voltage. The designer needs to calculate the maximum voltage between In and Out by

taking the maximum input voltage minus the voltage across the LED string (Figures 1 & 2).

VIN VIN

1

IN

Low Side LED String

XX Y W X

AL5809

1

IN

OUT

XX Y W X

2

AL5809

High Side LED String

OUT

2

Figure 1 Low Side LED String Tapping Figure 2 High Side LED String Tapping

The AL5809 can also be used on the high side of the LEDs, see Figure 2. The minimum system input voltage can be calculated by:

VIN(min) = VLED_CHAIN + 2.5V Where VLED_CHAIN is the LED chain voltage.

The LED current can be increased by connecting two or more AL5809 in parallel in Figure 3.

VIN

VIN

1 1

IN IN

...

XX Y W X

XX Y W X

AL5809 AL5809

1 1

IN IN

...

XX Y W X

XX Y W X

OUT OUT

AL5809 AL5809 2 2

OUT OUT

2 2

(a) Low Side Configuration (b) High Side Configuration

Figure 3 Higher LED Current by Parallel Configuration of AL5809

AL5809 5 of 16 December 2016

Document number: DS36625 Rev. 5 - 2 www.diodes.com © Diodes Incorporated

AL5809

Application Information (continued)

PWM Dimming

The AL5809 can be used to provide LED current dimming driving the Out pin via the MOSFET switch to ground (Figure 4a) applying a PWM

signal with a frequency range between 100Hz and 200Hz. The Out pin current is then effectively switched on and off to modulate the output LED

current. The dimming effect can be achieved by varying the PWM signal duty cycle.

VIN

VIN

ON/OFF

Switch

1

IN

XX Y W X

1

IN AL5809

XX Y W X

AL5809

OUT

2

OUT

2

PWM_DIM

(ZXMN6A11Z)

a) PWM Dimming by External MOSFET b) PWM Dimming by Power Supply VIN ON/OFF

Figure 4 PWM Dimming

Recommended PWM Frequency and Dimming Range

Duty Cycle (%)

PWM Frequency (Hz)

Min Max

100 5 95

200 10 90

Test conditions (Figure 4a): PWM frequency 100Hz–200Hz Square wave, 0-4V gate voltage, VIN = 6V, 1 LED, AL5809-30mA

Use the following formula to calculate the Min and Max duty cycle:

Min. Duty cycle (%) = (tON_MIN) / (time period of the PWM signal)

Max. Duty cycle (%) = 100% - ((tOFF_MIN) / (time period of the PWM signal))

Notes: tON_MIN = 0.5mS (Min. value), and tOFF_MIN = 0.5mS (Min. value) are listed in the Electrical Characteristics table on page 4.

AL5809 6 of 16 December 2016

Document number: DS36625 Rev. 5 - 2 www.diodes.com © Diodes Incorporated

AL5809

Application Information (continued)

Dimming Curves

Figure 5 PWM Dimming 30mA vs. Duty Cycle Figure 6 Area Zoom In within Duty Cycle 30% of Figure 5

Recommended Minimum On/Off Pulse Width

Figure 7 Minimum On Pulse Width (tON_MIN) Figure 8 Minimum Off Pulse Width (tOFF_MIN)

AL5809 7 of 16 December 2016

Document number: DS36625 Rev. 5 - 2 www.diodes.com © Diodes Incorporated

AL5809

Application Information (cont.)

Power Dissipation

The maximum ambient temperature range of the AL5809 is determined by its power dissipation and thermal impedance of the PCB onto which it

is mounted. Its junction temperature must be kept equal to or less than +125°C.

The power dissipated is determined by the LED current version that has been selected (15, 20, 25 30, 40, 50, 60, 90, 100, 120 or 150mA) and

the difference between the input voltage and LED chain voltage.

VINOUT * ILED

In a typical 12V system, the input voltage can vary between 11.4V and 12.6V. The recommended minimum V INOUT voltage of 2.5V enables the

AL5809 to drive 2 LED in series from the 12V rail (assuming VLED <3.25V).

The AL5809’s power dissipation under minimum input voltage conditions will be: VINOUT * ILED = (11.4-6.5) * ILED

So for the 20mA AL5809-20PI under these conditions this equals: 4.9V * 20mA = 98mW

Under maximum input conditions (12.6V) the AL5809’s power dissipation will be: VINOUT * ILED = (12.6-6.5) * ILED

So for the 20mA AL5809-20QPI this equals: 6.1V * 20mA = 122mW

So there is a large difference in power dissipation of the Linear LED driver between minimum and maximum battery voltages. And care must be

taken to calculate expected power dissipations and then determine the suitable PCB material and layout. See Figures 9, 10 and 11 for graphs

showing power dissipation and maximum VINOUT, for different currents and PCB material. Maximizing the area and mass of the ground plane and

additional vias between the pad of the OUT pin will improve the thermal impedance (JA) of the AL5809.

Power Dissipation [W] vs. Ambient Temperature [⁰C] Maximum VInOut [V] vs. Ambient Temperature [⁰C] for PDI on FR4

for PDI-123,SOD-123 on FR4, and PDI-123 on Getek Current Options (referred by Apps board FR4, 2-layer, 0.69"x0.76")

1.50

60

PDI on Getek (max Tj=145) PDI on FR4 15mA

PDI on FR4 20mA

1.25

50 PDI on FR4 25mA

PDI on FR4 50mA

PDI on FR4 90mA

Power Dissipation (W)

1.00

40 PDI on FR4 150mA

PDI on FR4 40mA

Maximum VInOut [V]

PDI on FR4 60mA

0.75 PDI on FR4 (max Tj=145) 30

0.50 20

0.25 10

SOD on FR4 (max Tj=145)

0

0.00

0 25 50 75 100 125 150

0 25 50 75 100 125

Ambient Temperature (°C) Ambient Temperature [°C]

Figure 9 Power Dissipation vs. Ambient Temperature Figure 10 Maximum VInOut vs. Temperature

@TJ = +145°C

Maximum VInOut [V] vs. Ambient Temperature [⁰C] for Current Option on PDI

FR4 Board (referred by Apps board FR4, 2-layer, 0.69"x0.76" size)

40

35 SOD on FR4 15mA

SOD on FR4 20mA

30 SOD on FR4 30mA

Maximum VInOut [V]

SOD on FR4 40mA

25 SOD on FR4 50mA

20

15

10

0

0 25 50 75 100 125

Ambient Temperature [°C]

Figure 11 Maximum VInOut vs. Temperature

AL5809 8 of 16 December 2016

Document number: DS36625 Rev. 5 - 2 www.diodes.com © Diodes Incorporated

AL5809

Application Information (cont.)

Figure 12 Power Dissipation vs. Ambient Temperature Figure 13 Power Dissipation vs. Junction Temperature

AL5809 9 of 16 December 2016

Document number: DS36625 Rev. 5 - 2 www.diodes.com © Diodes Incorporated

AL5809

Typical Performance Characteristics (15mA, 20mA, 25mA, 30mA, 40mA, 50mA PowerDI options)

15mA 20mA 25mA 30mA 40mA 50mA 15mA 20mA 25mA

60 30mA 40mA 50mA

60

50

50

LED Current [mA]

TA = 25°C

LED Current [mA]

40

40

30

30

20

20

10 TA=25 10

0 0

0 5 10 15 20 25 30 0 0.5 1 1.5 2 2.5 3

VInOut [V] VInOut [V]

Figure 14 LED Current vs. VInOut Figure 15 Startup Minimum Operating Voltage

15mA 20mA 25mA 30mA 40mA 50mA 15mA_25C 15mA_125C 15mA_-40C

60 10

LED Current Accuracy [%] 8

50

6

LED Current [mA]

40 4

2

30 0

-2

20

-4

10 -6

-8

0 -10

-40 -25 -10 5 20 35 50 65 80 95 110 125 0 5 10 15 20 25 30 35 40 45 50 55 60

Temperature [⁰C] VInOut [V]

Figure 16 LED Current vs. Ambient Temperature Figure 17 LED Current Accuracy (%) vs. VInOut across

Temperature

T_Shut Down T_Recovery T_Recovery T_Shut Down

25 45

40

20 35

30

15

25

10 20

15 VInOut=

5 10 3.5V,

VInOut=3.5V

20mA 5

LED Current [mA]

40mA

0

LED Current [mA]

0

-5 -5

100 105 110 115 120 125 130 135 140 145 150 155 160 100 105 110 115 120 125 130 135 140 145 150 155 160

Ambient Temperature [⁰C] Ambient Temperature [⁰C]

Figure 19 THSD of 40mA Current Option

Figure 18 THSD of 20mA Current Option

AL5809 10 of 16 December 2016

Document number: DS36625 Rev. 5 - 2 www.diodes.com © Diodes Incorporated

AL5809

Typical Performance Characteristics (continued) (60mA, 90mA, 150mA PowerDI options)

60mA 90mA 150mA 60mA 90mA 150mA

160 160

140 140

120 120

LED Current [mA]

100 100

80 80

60 60

40

LED Current [mA]

40

TA=25⁰C TA=25⁰C

20 20

C

0 0

0 5 10 15 20 25 30 0 0.5 1 1.5 2 2.5 3

VInOut[V] VInOut [V]

Figure 20 LED Current vs. VInOut Figure 21 Startup Minimum Operating Voltage

VInOut=3.5

Temperature[⁰C]

Figure 22 LED Current across Temperature Figure 23 LED Current Accuracy (%) vs. VInOut across

Temperature

T_Shut Down T_Recovery T_Recovery T_Shut Down

70 160

60 VInOut=3.5V 140

50 60mA 120 VInOut=3.5V

100 150mA

40

80

30

60

20 40

10

LED Current [mA]

20

LED Current [mA]

0 0

-10 -20

100 110 120 130 140 150 160 100 110 120 130 140 150 160

Ambient Tempature [⁰C] Temperature [⁰C]

Figure 24 THSD of 60mA Current Option Figure 25 THSD of 150mA Current Option

AL5809 11 of 16 December 2016

Document number: DS36625 Rev. 5 - 2 www.diodes.com © Diodes Incorporated

AL5809

Ordering Information

LED Current Package 7” Tape and Reel

Part Number Packaging

Opion Code Quantity Part Number Suffix

AL5809-15P1-7 P1 PowerDI123 3,000/ Tape & Reel -7

15mA

AL5809-15S1-7 S1 SOD-123 3,000/ Tape & Reel -7

AL5809-20P1-7 P1 PowerDI123 3,000/ Tape & Reel -7

20mA

AL5809-20S1-7 S1 SOD-123 3,000/ Tape & Reel -7

AL5809-25P1-7 P1 PowerDI123 3,000/ Tape & Reel -7

25mA

AL5809-25S1-7 S1 SOD-123 3,000/ Tape & Reel -7

AL5809-30P1-7 P1 PowerDI123 3,000/ Tape & Reel -7

30mA

AL5809-30S1-7 S1 SOD-123 3,000/ Tape & Reel -7

AL5809-40P1-7 P1 PowerDI123 3,000/ Tape & Reel -7

40mA

AL5809-40S1-7 S1 SOD-123 3,000/ Tape & Reel -7

AL5809-50P1-7 P1 PowerDI123 3,000/ Tape & Reel -7

50mA

AL5809-50S1-7 S1 SOD-123 3,000/ Tape & Reel -7

AL5809-60P1-7 60mA P1 PowerDI123 3,000/ Tape & Reel -7

AL5809-90P1-7 90mA P1 PowerDI123 3,000/ Tape & Reel -7

AL5809-100P1-7 100mA P1 PowerDI123 3,000/ Tape & Reel -7

AL5809-120P1-7 120mA P1 PowerDI123 3,000/ Tape & Reel -7

AL5809-150P1-7 150mA P1 PowerDI123 3,000/ Tape & Reel -7

AL5809 12 of 16 December 2016

Document number: DS36625 Rev. 5 - 2 www.diodes.com © Diodes Incorporated

AL5809

Marking Information

Part Number Package Identification Code

AL5809-15P1-7 PowerDI123 C1

AL5809-20P1-7 PowerDI123 C2

AL5809-25P1-7 PowerDI123 CA

AL5809-30P1-7 PowerDI123 C3

AL5809-40P1-7 PowerDI123 C4

AL5809-50P1-7 PowerDI123 C5

AL5809-60P1-7 PowerDI123 C6

AL5809-90P1-7 PowerDI123 C7

AL5809-100P1-7 PowerDI123 CB

AL5809-120P1-7 PowerDI123 C8

AL5809-150P1-7 PowerDI123 C9

AL5809-15S1-7 SOD-123 D1

AL5809-20S1-7 SOD-123 D2

AL5809-25S1-7 SOD-123 DA

AL5809-30S1-7 SOD-123 D3

AL5809-40S1-7 SOD-123 D4

AL5809-50S1-7 SOD-123 D5

Package Outline Dimensions

Please see http://www.diodes.com/package-outlines.html for the latest version.

PowerDI123 (Type B)

PowerDI123

C E Type B

Dim Min Max Typ

B

A 3.50 3.90 3.70

H B 2.60 3.00 2.80

C 1.63 1.93 1.78

D

D 0.93 1.00 0.98

E 0.85 1.25 1.00

L H 0.15 0.25 0.20

L 0.50 0.80 0.65

All Dimensions in mm

E

AL5809 13 of 16 December 2016

Document number: DS36625 Rev. 5 - 2 www.diodes.com © Diodes Incorporated

AL5809

Package Outline Dimensions (continued)

Please see http://www.diodes.com/package-outlines.html for the latest version.

SOD123

0

.10

° R0 100

Al

l7 All ll R0.

A

SOD123

A Dim Min Max Typ

a

A 1.00 1.35 1.05

A1 0.00 0.10 0.05

c L All 7 A1 b 0.52 0.62 0.57

° c 0.10 0.15 0.11

D 1.40 1.70 1.55

He E 2.55 2.85 2.65

E He 3.55 3.85 3.65

L 0.25 0.40 0.30

a 0º 8º --

All Dimensions in mm

b D

Suggested Pad Layout

Please see http://www.diodes.com/package-outlines.html for the latest version.

PowerDI123 (Type B)

Value

Dimensions

(in mm)

Y G 2.000

X 1.050

X1 4.100

G Y 1.500

X1

SOD123

X1

Dimensions Value (in mm)

X 0.900

Y X1 4.050

Y 0.950

AL5809 14 of 16 December 2016

Document number: DS36625 Rev. 5 - 2 www.diodes.com © Diodes Incorporated

AL5809

Taping Orientation

The taping orientation of the other package type can be found on our website at http://www.diodes.com/datasheets/ap02007.pdf.

PowerDI123 (Type B)

SOD123

AL5809 15 of 16 December 2016

Document number: DS36625 Rev. 5 - 2 www.diodes.com © Diodes Incorporated

AL5809

IMPORTANT NOTICE

DIODES INCORPORATED MAKES NO WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, WITH REGARDS TO THIS DOCUMENT,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE

(AND THEIR EQUIVALENTS UNDER THE LAWS OF ANY JURISDICTION).

Diodes Incorporated and its subsidiaries reserve the right to make modifications, enhancements, improvements, corrections or other changes

without further notice to this document and any product described herein. Diodes Incorporated does not assume any liability arising out of the

application or use of this document or any product described herein; neither does Diodes Incorporated convey any license under its patent or

trademark rights, nor the rights of others. Any Customer or user of this document or products described herein in such applications shall assume

all risks of such use and will agree to hold Diodes Incorporated and all the companies whose products are represented on Diodes Incorporated

website, harmless against all damages.

Diodes Incorporated does not warrant or accept any liability whatsoever in respect of any products purchased through unauthorized sales channel.

Should Customers purchase or use Diodes Incorporated products for any unintended or unauthorized application, Customers shall indemnify and

hold Diodes Incorporated and its representatives harmless against all claims, damages, expenses, and attorney fees arising out of, directly or

indirectly, any claim of personal injury or death associated with such unintended or unauthorized application.

Products described herein may be covered by one or more United States, international or foreign patents pending. Product names and markings

noted herein may also be covered by one or more United States, international or foreign trademarks.

This document is written in English but may be translated into multiple languages for reference. Only the English version of this document is the

final and determinative format released by Diodes Incorporated.

LIFE SUPPORT

Diodes Incorporated products are specifically not authorized for use as critical components in life support devices or systems without the express

written approval of the Chief Executive Officer of Diodes Incorporated. As used herein:

A. Life support devices or systems are devices or systems which:

1. are intended to implant into the body, or

2. support or sustain life and whose failure to perform when properly used in accordance with instructions for use provided in the

labeling can be reasonably expected to result in significant injury to the user.

B. A critical component is any component in a life support device or system whose failure to perform can be reasonably expected to cause the

failure of the life support device or to affect its safety or effectiveness.

Customers represent that they have all necessary expertise in the safety and regulatory ramifications of their life support devices or systems, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products and any

use of Diodes Incorporated products in such safety-critical, life support devices or systems, notwithstanding any devices- or systems-related

information or support that may be provided by Diodes Incorporated. Further, Customers must fully indemnify Diodes Incorporated and its

representatives against any damages arising out of the use of Diodes Incorporated products in such safety-critical, life support devices or systems.

Copyright © 2016, Diodes Incorporated

www.diodes.com

AL5809 16 of 16 December 2016

Document number: DS36625 Rev. 5 - 2 www.diodes.com © Diodes Incorporated

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

Diodes Incorporated:

AL5809-50P1-7 AL5809-50S1-7 AL5809-40P1-7 AL5809-20S1-7 AL5809-15P1-7 AL5809-90P1-7 AL5809-20P1-7

AL5809-30S1-7 AL5809-30P1-7 AL5809-40S1-7 AL5809-150P1-7 AL5809-120P1-7 AL5809-15S1-7 AL5809-

60P1-7

You might also like

- AL8805 Description Pin Assignments: Not Recommended For New Design USE ORDocument18 pagesAL8805 Description Pin Assignments: Not Recommended For New Design USE ORlakshmananNo ratings yet

- AL8862QDocument17 pagesAL8862QIvo MatosNo ratings yet

- LT3932-3932-1-36V, 2A SynchronousDocument30 pagesLT3932-3932-1-36V, 2A Synchronousjustinvil1103No ratings yet

- AL5815EV1 User GuideDocument8 pagesAL5815EV1 User GuideJuan Vicente Hernandez LogytelNo ratings yet

- SC4541 Rev.2.1Document19 pagesSC4541 Rev.2.1Akhil GargNo ratings yet

- Branch Panel Mounted Surge Protective Device (SPD) : Cat. Nos. 51120-1 & 51120-3Document2 pagesBranch Panel Mounted Surge Protective Device (SPD) : Cat. Nos. 51120-1 & 51120-3Rober BlanquitoNo ratings yet

- AP1509Document12 pagesAP1509Андрей ОлененкоNo ratings yet

- 3 A, 2 MHZ Buck-Regulating Led Driver: Description Features and BenefitsDocument12 pages3 A, 2 MHZ Buck-Regulating Led Driver: Description Features and BenefitsElizabet VallejoNo ratings yet

- AD52580B Audio AmplifierDocument3 pagesAD52580B Audio Amplifierhamada13No ratings yet

- lt8356 1-2955993Document27 pageslt8356 1-2955993chawkigenieNo ratings yet

- AL8860EV2 User GuideDocument8 pagesAL8860EV2 User GuideHans ClarinNo ratings yet

- AL9910/ AL9910A/ AL9910-5/ AL9910A-5: Universal High Voltage High Brightness Led DriverDocument15 pagesAL9910/ AL9910A/ AL9910-5/ AL9910A-5: Universal High Voltage High Brightness Led DrivernareshNo ratings yet

- Ω Ω Ω Ω Ω, 1.3A Power Switch with Programmable Current LimitDocument14 pagesΩ Ω Ω Ω Ω, 1.3A Power Switch with Programmable Current LimitSurendra SharmaNo ratings yet

- White LED Driver With PWM Brightness Control in Small PackageDocument24 pagesWhite LED Driver With PWM Brightness Control in Small PackageRamíro ChocotecóNo ratings yet

- AL8861EV1 User GuideDocument8 pagesAL8861EV1 User GuideHans ClarinNo ratings yet

- A2 Inverter Guide for 0.75-30kW ModelsDocument24 pagesA2 Inverter Guide for 0.75-30kW ModelsEdgardo PaoliniNo ratings yet

- ZXLD1374: Thermal PadDocument39 pagesZXLD1374: Thermal PadAdrian WongNo ratings yet

- Acpl 337J 500eDocument18 pagesAcpl 337J 500eAandk NovaNo ratings yet

- LM3500 Synchronous Step-Up DC/DC Converter For White LED ApplicationsDocument26 pagesLM3500 Synchronous Step-Up DC/DC Converter For White LED ApplicationsIngenieria MultifuncionalNo ratings yet

- IID_4771_Datasheet SL2711 09-2020Document2 pagesIID_4771_Datasheet SL2711 09-2020apusica.wwhNo ratings yet

- AP3019ADocument12 pagesAP3019ARadu MititeluNo ratings yet

- TPS5125Document21 pagesTPS5125Shaun Dwyer Van HeerdenNo ratings yet

- LT1510 LINAR TECNOLOGY IC - 1510fc PDFDocument16 pagesLT1510 LINAR TECNOLOGY IC - 1510fc PDFmaxonetNo ratings yet

- Hysteretic Boost-Buck (Ćuk) LED Driver IC: Features General DescriptionDocument16 pagesHysteretic Boost-Buck (Ćuk) LED Driver IC: Features General DescriptionJohnNo ratings yet

- Descriptio Features: LT1505 Constant-Current/Voltage High Efficiency Battery ChargerDocument16 pagesDescriptio Features: LT1505 Constant-Current/Voltage High Efficiency Battery ChargerCarlos Henrique RibasNo ratings yet

- Features Description: 1997 Burr-Brown Corporation PDS-1412A Printed in U.S.A. May, 1998Document13 pagesFeatures Description: 1997 Burr-Brown Corporation PDS-1412A Printed in U.S.A. May, 1998Umair MansoorNo ratings yet

- AL1676Document15 pagesAL1676nareshNo ratings yet

- ACPL-C87AT/ACPL-C87BT: Data SheetDocument16 pagesACPL-C87AT/ACPL-C87BT: Data SheetMattias RahmNo ratings yet

- Richtekusainc Rt906950gb Datasheets 6616Document15 pagesRichtekusainc Rt906950gb Datasheets 6616JayR VillaNo ratings yet

- Tp5089 DTMF (Touch-Tone) GeneratorDocument5 pagesTp5089 DTMF (Touch-Tone) GeneratorHanilen CatamaNo ratings yet

- AL3353Document15 pagesAL3353JonathanTaclindoNo ratings yet

- Features Description: LT3755/LT3755-1/LT3755-2 40V, 75V LED ControllersDocument28 pagesFeatures Description: LT3755/LT3755-1/LT3755-2 40V, 75V LED ControllersMick Thomson RcNo ratings yet

- OB3372 On BrightDocument13 pagesOB3372 On BrightPedro Leandro SilvaNo ratings yet

- WS3620-LED Coor Const LAMP - WinsemiDocument7 pagesWS3620-LED Coor Const LAMP - WinsemivmsaNo ratings yet

- AP2120 Description Pin Assignments: High Speed, Extremely Low Noise Ldo RegulatorDocument19 pagesAP2120 Description Pin Assignments: High Speed, Extremely Low Noise Ldo RegulatorHitesh GambhavaNo ratings yet

- 2981 8chanel Surce DriverDocument8 pages2981 8chanel Surce DriverTb303No ratings yet

- Strato 35 Series and 70 Series :: ROAL Living EnergyDocument5 pagesStrato 35 Series and 70 Series :: ROAL Living EnergyMinhNo ratings yet

- Pam 8320Document11 pagesPam 8320Darko GoracinskiNo ratings yet

- LT3990 Demo Circuit 1471 Quick Start Guide LT3990 62V, 350ma Step-Down Regulator With 2.5 A Quiescent Current and Integrated DiodesDocument3 pagesLT3990 Demo Circuit 1471 Quick Start Guide LT3990 62V, 350ma Step-Down Regulator With 2.5 A Quiescent Current and Integrated DiodesDmitryNo ratings yet

- Ap7354 1381523Document19 pagesAp7354 1381523elctronicaCoNo ratings yet

- SM2082D DatasheetDocument12 pagesSM2082D Datasheetmetinprivat01No ratings yet

- Triple Output LED DriverDocument20 pagesTriple Output LED DriverFernando BalseiroNo ratings yet

- XL6009 DC DC Converter DatasheetDocument12 pagesXL6009 DC DC Converter DatasheetGFGHJHKNo ratings yet

- Pepprl Fuchs Barrier Switch AmpDocument4 pagesPepprl Fuchs Barrier Switch AmpShabeer CVNo ratings yet

- PDF LR8 MicrochipDocument16 pagesPDF LR8 MicrochipElijah MathewNo ratings yet

- Features: Lt1375/Lt1376 1.5A, 500Khz Step-Down Switching RegulatorsDocument29 pagesFeatures: Lt1375/Lt1376 1.5A, 500Khz Step-Down Switching RegulatorsSergio MuriloNo ratings yet

- (Top View) : High Performance Boost Led ControllerDocument15 pages(Top View) : High Performance Boost Led ControllerJavier Mendoza CastroNo ratings yet

- 4420 FaDocument26 pages4420 Fazvh48588No ratings yet

- Stib1060dm2t LDocument23 pagesStib1060dm2t LРуслан КаргиевNo ratings yet

- Ad52060 EsmtDocument23 pagesAd52060 EsmtRoel GloriosoNo ratings yet

- Features Applications: MicroDocument14 pagesFeatures Applications: Microjorgeortiz1982No ratings yet

- Ina122 PDFDocument11 pagesIna122 PDFFer Martinez de la RivaNo ratings yet

- Ina122 PDFDocument14 pagesIna122 PDFCDDSANo ratings yet

- INA122Document14 pagesINA122runar libraryNo ratings yet

- AP62200/AP62201/AP62200T: 4.2V To 18V Input, 2A Low Iq Synchronous Buck ConverterDocument24 pagesAP62200/AP62201/AP62200T: 4.2V To 18V Input, 2A Low Iq Synchronous Buck ConverterAarsol AdvanceNo ratings yet

- AP7331Document13 pagesAP7331a.escalant.tNo ratings yet

- Very Low Dropout 3.0 Amp Regulator With Enable: Power Management Features DescriptionDocument10 pagesVery Low Dropout 3.0 Amp Regulator With Enable: Power Management Features DescriptionmitusharmaNo ratings yet

- RT8059Document10 pagesRT8059Bijan AmiriNo ratings yet

- 5v and 12v 1a Output Power Supply With Onboard Transformer 1Document1 page5v and 12v 1a Output Power Supply With Onboard Transformer 1Sundar KrishNo ratings yet

- Conect OresDocument44 pagesConect OrescrazysergioNo ratings yet

- Automotive Fuse-Holders: ATO Sealed 30 A In-LineDocument1 pageAutomotive Fuse-Holders: ATO Sealed 30 A In-LineJuan Vicente Hernandez LogytelNo ratings yet

- 97 SeriesDocument37 pages97 SeriesAbdou_AENo ratings yet

- IDS-87 Gray ZnNiDocument2 pagesIDS-87 Gray ZnNiJuan Vicente Hernandez LogytelNo ratings yet

- 97 SeriesDocument37 pages97 SeriesAbdou_AENo ratings yet

- Datasheet IRFZ48Document9 pagesDatasheet IRFZ48demostenessNo ratings yet

- TQ Relays: FeaturesDocument11 pagesTQ Relays: FeaturesDongTaNo ratings yet

- CC 3 - 05 05 S F - E Features Model-Naming Method: Insulation Type DC-DC ConverterDocument26 pagesCC 3 - 05 05 S F - E Features Model-Naming Method: Insulation Type DC-DC ConverterJuan Vicente Hernandez LogytelNo ratings yet

- Quick Start Guide: Apple Carplay™Document3 pagesQuick Start Guide: Apple Carplay™Juan Vicente Hernandez LogytelNo ratings yet

- Android Auto Quick Start GuideDocument3 pagesAndroid Auto Quick Start GuideJuan Vicente Hernandez LogytelNo ratings yet

- Android Auto User GuideDocument15 pagesAndroid Auto User GuideJuan Vicente Hernandez LogytelNo ratings yet

- AN202Document28 pagesAN202Anonymous GmUbEhBknUNo ratings yet

- Apple Carplay User GuideDocument15 pagesApple Carplay User GuideJuan Vicente Hernandez LogytelNo ratings yet

- 1814 d01 PDFDocument20 pages1814 d01 PDFteletrabbiesNo ratings yet

- Generator Honda EP2500CX1Document50 pagesGenerator Honda EP2500CX1Syamsul Bahry HarahapNo ratings yet

- Jitante Stotram v4 PDFDocument71 pagesJitante Stotram v4 PDFRamadevaNo ratings yet

- RPT Mathematics Year 5Document24 pagesRPT Mathematics Year 5Anonymous wirViz1tyoNo ratings yet

- Landmark Church School WBSDocument4 pagesLandmark Church School WBSbayoNo ratings yet

- Its Raining Idioms A Figurative Language ActivityDocument11 pagesIts Raining Idioms A Figurative Language ActivityTyrone MoogNo ratings yet

- CHE135 - Ch1 Intro To Hazard - MII - L1.1Document26 pagesCHE135 - Ch1 Intro To Hazard - MII - L1.1SyafiyatulMunawarahNo ratings yet

- 2016 Practical Theory Questions SolutionDocument36 pages2016 Practical Theory Questions Solutionsheeess gaadaNo ratings yet

- VachanamruthaDocument5 pagesVachanamruthaypraviNo ratings yet

- The Most Efficient and Effective Ways To Address New Literacies FDocument61 pagesThe Most Efficient and Effective Ways To Address New Literacies FAlpha MoontonNo ratings yet

- Appointment Slip: 2 X 2 ID PictureDocument1 pageAppointment Slip: 2 X 2 ID PictureDarwin Competente LagranNo ratings yet

- Excel Case Study 1 - DA - Questions With Key AnswersDocument56 pagesExcel Case Study 1 - DA - Questions With Key AnswersVipin AntilNo ratings yet

- Product Brand Management 427 v1Document484 pagesProduct Brand Management 427 v1Adii AdityaNo ratings yet

- Office AutomationDocument12 pagesOffice AutomationMad GirlNo ratings yet

- Ms - 1294 - Part3 - 1993 - WALL AND FLOOR TILING PART 3 - CODE OF PRACTICE FOR THE DESIGN AND INSTALLATION OF CERAMIC FLOOR AND MOSAICSDocument7 pagesMs - 1294 - Part3 - 1993 - WALL AND FLOOR TILING PART 3 - CODE OF PRACTICE FOR THE DESIGN AND INSTALLATION OF CERAMIC FLOOR AND MOSAICSeirenatanNo ratings yet

- Assurance Question Bank 2013 PDFDocument168 pagesAssurance Question Bank 2013 PDFIan RelacionNo ratings yet

- Final Research Dossier - Joey KassenoffDocument11 pagesFinal Research Dossier - Joey Kassenoffapi-438481986No ratings yet

- Electrode ChemDocument17 pagesElectrode Chemapi-372366467% (3)

- SG CD FR 175 Levelness V 531 Lmi 001 Firmar SellarDocument1 pageSG CD FR 175 Levelness V 531 Lmi 001 Firmar SellarLuis VelazcogarciaNo ratings yet

- Rethinking Classroom Assessment With Purpose in MindDocument112 pagesRethinking Classroom Assessment With Purpose in MindlykkhaiNo ratings yet

- Body Condition Scoring of Dairy Cattle A Review - 2 PDFDocument8 pagesBody Condition Scoring of Dairy Cattle A Review - 2 PDFfrankyNo ratings yet

- KF2.5-200 - With-M-C - GB - 03-15 KRACHT Bomba PDFDocument8 pagesKF2.5-200 - With-M-C - GB - 03-15 KRACHT Bomba PDFJairo Andrés FA100% (1)

- 1.0sg Equations and Inequalities - Study GuideDocument1 page1.0sg Equations and Inequalities - Study Guiderad58No ratings yet

- Creutzfeldt JakobDocument6 pagesCreutzfeldt JakobErnesto Ochoa MonroyNo ratings yet

- Hydrolics Final Year ProjectDocument23 pagesHydrolics Final Year ProjectHarsha VardhanaNo ratings yet

- Soften, Soothe, AllowDocument1 pageSoften, Soothe, AllowTatiannaMartinsNo ratings yet

- ADP Pink Diamond Investment Guide 2023Document47 pagesADP Pink Diamond Investment Guide 2023sarahNo ratings yet

- China VS1-24 Series Indoor High Voltage Vacuum Circuit Breaker Factory and Manufacturers - GhoritDocument6 pagesChina VS1-24 Series Indoor High Voltage Vacuum Circuit Breaker Factory and Manufacturers - GhoritKalidass BackNo ratings yet

- Scalable Machine-Learning Algorithms For Big Data Analytics: A Comprehensive ReviewDocument21 pagesScalable Machine-Learning Algorithms For Big Data Analytics: A Comprehensive ReviewvikasbhowateNo ratings yet

- Cazul Cyril Burt 3Document3 pagesCazul Cyril Burt 3Cosmina MihaelaNo ratings yet