Professional Documents

Culture Documents

Thumb Rules Vol of Cement Etc

Uploaded by

Nidhi MehtaOriginal Title

Copyright

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThumb Rules Vol of Cement Etc

Uploaded by

Nidhi MehtaDAYANANDA SAGAR COLLEGE OF ENGINEERING, 15/03/17

(An Autonomous Institute Affiliated to VTU, Belagavi)

ShavigeMalleshwara Hills, Kumaraswamy Layout, Bengaluru-560078

Architecture

SQC Notes – CIA II

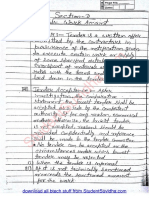

1 Explain the process to calculate the following

a) Volume of cement required for 1m3 of Concrete

Material estimation include sand, cement, coarse aggregate and steel for a particular mix

design. Let us consider a mix design of 1:1.5:3 for our estimation practice. The dry volume

of total materials required is considered as 1.54 times the wet volume of concrete, due to

voids present in sand and aggregates in dry stage. Therefore, for our calculation, we will

consider the total volume of materials required as 1.54 m3 for 1 m3 of wet concrete.

a) Bags of cement required:

Volume of cement required for 1m3 of Concrete = = 0.28 m3

Then number of bags of cement (volume of one bag of cement = 0.0347 m3)

= 8.07 bags of cement.

b) Quantity of steel reinforcement in various building elements eg: Foundation,

columns, beams, roof slab, cement concrete road etc

Estimation of Reinforced Steel:

Quantity of steel required depends on components of structure, i.e. slabs, beams, columns,

foundations, roads etc. To estimate the steel required, there are two methods.

First method is, when we have the drawing available, we can calculate the total weight of

steel required divided by total volume of concrete for different components. This will give

us the weight of reinforcement steel per cubic meter of concrete.

Second method is assuming the percentage of reinforcement for different components.

Following are the percentage of reinforcement steel generally required per different

components. Its values can vary from structure to structure, and can be assumed from past

experiences of similar structure.

For foundation = 0.5 to 0.8% of concrete volume

For slabs = 1.0 % of concrete volume.

For Beam = 2 % concrete volume.

For column = 2.5 % of concrete volume.

For RCC Roads, 0.6% concrete volume

c) Rate Analysis of Brick Masonry work

Rate Analysis of brickwork requires rates of various materials like cement, sand, bricks, and

rates for labour i.e. mason and other labours. The rates of these varies with location and time.

These may be obtained from the schedule of rates of particular location or can be taken from

local market and shall be multiplied with the quantities of materials and labours estimated to

get the rate analysis

For 1m3 of brick masonry, the number of standard size of bricks required is 494.

Labour Estimation for Brick Masonry:

Brick laying mason is required along with, labours for carriage of materials (sand, cement, bricks, and

water), mixing and transporting mortar.

The quantity of labour is expressed as requirement of labour in days for 1m3 of brick masonry.

1. Mason: The quantity of mason required for 1m3 of brickwork is taken as 0.94 days.

2. Labour: The quantity of labour for various works like carriage of materials, mixing of mortar,

transporting of mortar etc. are clubbed. The labour required for 1m3 of brick masonry is for 1.57 days.

The cost of various tools, transportation of materials etc. shall be suitably taken as lump sum for the

given location.

**********************************************************************************************

You might also like

- RCC Rate AnalysisDocument3 pagesRCC Rate AnalysisHari RNo ratings yet

- Quantity and Rate Analysis For Reinforced Concrete ConstructionDocument4 pagesQuantity and Rate Analysis For Reinforced Concrete Constructionvenkateswara rao pothinaNo ratings yet

- Rate AnalysisDocument4 pagesRate Analysisnagaraj_qce3499100% (1)

- How to estimate materials and rods for concrete and plasteringDocument7 pagesHow to estimate materials and rods for concrete and plasteringTanvirNo ratings yet

- Rate Analyses For ConcreteDocument9 pagesRate Analyses For ConcreteLOKESH PUNJNo ratings yet

- Concept of Estimate-ConcreteDocument32 pagesConcept of Estimate-ConcretereymoreNo ratings yet

- Pembandingan Pelaksanaan Pekerjaan Pelat Lantai Menggunakan Tulangan Kromo Dengan Tulangan Dua Lapis Di Tinjau Dari Aspek Biaya Dan WaktuDocument12 pagesPembandingan Pelaksanaan Pekerjaan Pelat Lantai Menggunakan Tulangan Kromo Dengan Tulangan Dua Lapis Di Tinjau Dari Aspek Biaya Dan WaktuMuhammad OkiNo ratings yet

- F. F. F. F. O. Okafor O. Okafor O. Okafor O. Okafor and and and and D. D. D. D. E. Ewa E. Ewa E. Ewa E. EwaDocument7 pagesF. F. F. F. O. Okafor O. Okafor O. Okafor O. Okafor and and and and D. D. D. D. E. Ewa E. Ewa E. Ewa E. EwaYashika Bhathiya JayasingheNo ratings yet

- Quantity and Rate Analysis For Reinforced Concrete ConstructionDocument12 pagesQuantity and Rate Analysis For Reinforced Concrete Constructionvaishali0100% (1)

- The Open Civil Engineering JournalDocument13 pagesThe Open Civil Engineering JournalPREM NAIDUNo ratings yet

- Designing, Proposing and Comparing The Methods Predicting The Compressive Strength of The Ferrocement MortarDocument10 pagesDesigning, Proposing and Comparing The Methods Predicting The Compressive Strength of The Ferrocement MortarAnis ShatnawiNo ratings yet

- Lab Assignment 1Document7 pagesLab Assignment 1Sayed YusufNo ratings yet

- Effect of Aggregate Type On Compressive Strength of ConcreteDocument10 pagesEffect of Aggregate Type On Compressive Strength of ConcreteamelialoritaNo ratings yet

- Civil Engineering Interview QuestionsDocument123 pagesCivil Engineering Interview QuestionsSoni Mishra Tiwari89% (9)

- Why Don't We Deduct The Steel Volume While Calculating The Concrete Volume in RCC StructuresDocument5 pagesWhy Don't We Deduct The Steel Volume While Calculating The Concrete Volume in RCC StructuressitaracommercialcomplexNo ratings yet

- Characteristic Strength of Machine Made First Class Bricks Found in Different Parts of ManipurDocument7 pagesCharacteristic Strength of Machine Made First Class Bricks Found in Different Parts of ManipurleGionNo ratings yet

- GUIDELINES ON USE OF READY MIXED CONCRETE MIX DESIGNDocument14 pagesGUIDELINES ON USE OF READY MIXED CONCRETE MIX DESIGNRaju Shetty CjNo ratings yet

- L.D College of Engineering: A Report On Construction Site VisitDocument15 pagesL.D College of Engineering: A Report On Construction Site VisitNeel TurkhiyaNo ratings yet

- Tek 04-02aDocument8 pagesTek 04-02aFeyisa GuyeNo ratings yet

- Civil Thumb RulesDocument8 pagesCivil Thumb RulesNasreen khushi muhammad Nasree100% (1)

- Effect Time-Casting Second Layer ConcDocument11 pagesEffect Time-Casting Second Layer ConcVikash PeerthyNo ratings yet

- !! 06 Spek 1D Pekerjaan Batu EngDocument12 pages!! 06 Spek 1D Pekerjaan Batu EngJawaraWasisNo ratings yet

- Lesson 2. Concreting Works 2024Document17 pagesLesson 2. Concreting Works 2024Paul Justin MangatNo ratings yet

- CE3410 Tests On Concrete Lab Manual 3Document15 pagesCE3410 Tests On Concrete Lab Manual 3SUBHAM SAGARNo ratings yet

- EstimationDocument48 pagesEstimationcdawan dawanNo ratings yet

- Nagpur Metro Rail Project ExploredDocument29 pagesNagpur Metro Rail Project ExploredSumit BhagatNo ratings yet

- On Partial Replacement of Sand and AggregateDocument19 pagesOn Partial Replacement of Sand and Aggregatemohammedzeeshan0% (2)

- New Level 1Document15 pagesNew Level 1Habtamu HaileNo ratings yet

- UNITEC-engineering Project 6299 2013 s2Document7 pagesUNITEC-engineering Project 6299 2013 s2donNo ratings yet

- Ceng 125 Learning Hand Out 2Document11 pagesCeng 125 Learning Hand Out 2edmar limNo ratings yet

- New Rich Text DocumentDocument23 pagesNew Rich Text DocumentRubina FatimaNo ratings yet

- Rate Analysis of Plastering With Cement Mortar - Quantity CalculationDocument4 pagesRate Analysis of Plastering With Cement Mortar - Quantity CalculationwaynectwNo ratings yet

- EQ12 ADocument83 pagesEQ12 Ahram_phdNo ratings yet

- 4 Final Text Book Quantity SurveyingDocument6 pages4 Final Text Book Quantity SurveyingNIKHIL MATHURNo ratings yet

- Chapter 1Document15 pagesChapter 1New LearnersNo ratings yet

- Project Cost EstimationDocument8 pagesProject Cost Estimationmamuka kassaNo ratings yet

- BLASTING APPLICATION IN KOSOVO MOTORWAY PROJECTDocument8 pagesBLASTING APPLICATION IN KOSOVO MOTORWAY PROJECTFrasher BrahimajNo ratings yet

- Effect of Rock Mass Quality On Construction Time in A Road TunnelDocument8 pagesEffect of Rock Mass Quality On Construction Time in A Road TunnelCamila Contreras CarrascoNo ratings yet

- Teorija - Experimental Determination Mechanical Properties Clay Brick MasonryDocument19 pagesTeorija - Experimental Determination Mechanical Properties Clay Brick Masonrypedja0% (1)

- Word File 2 QSC MaterialDocument22 pagesWord File 2 QSC MaterialShakti DubeyNo ratings yet

- CE8701 Estimation, Costing and Valuation Engineering Notes 2Document32 pagesCE8701 Estimation, Costing and Valuation Engineering Notes 2Raja Siddu100% (1)

- Three Equations Method For Normal Concrete Mix DesignDocument5 pagesThree Equations Method For Normal Concrete Mix DesignSEP-PublisherNo ratings yet

- Bored Tunnel Lining Design in Soft Soils - Analytical vs NumericalDocument7 pagesBored Tunnel Lining Design in Soft Soils - Analytical vs NumericalDEBASISNo ratings yet

- Estimation NotesDocument32 pagesEstimation NotesSrinivas P50% (2)

- Cube Tests Doc-20181030-Wa0009Document6 pagesCube Tests Doc-20181030-Wa0009kundayi shavaNo ratings yet

- Process of Ready Mixed ConcreteDocument27 pagesProcess of Ready Mixed ConcreteN P SrinivasaraoNo ratings yet

- School Building Structural ReportDocument51 pagesSchool Building Structural ReportNabin Acharya100% (1)

- SCC Development, Applications and InvestigationsDocument5 pagesSCC Development, Applications and InvestigationslauravoineagNo ratings yet

- Recycled Concrete: Sumia Alghlam Mostafa Jweli Nagat MaramiDocument21 pagesRecycled Concrete: Sumia Alghlam Mostafa Jweli Nagat MaramiSumia AlghlamNo ratings yet

- Practical Training Presentation on Box Culvert ConstructionDocument30 pagesPractical Training Presentation on Box Culvert ConstructionVineet SinghNo ratings yet

- Chapter 1 - BQDocument14 pagesChapter 1 - BQSaidatul SazwaNo ratings yet

- Bottom Feed Stone Column (Dry)Document3 pagesBottom Feed Stone Column (Dry)volkanNo ratings yet

- Sp171-21 - Construction of RCC Dam ConcreteDocument12 pagesSp171-21 - Construction of RCC Dam ConcretesunilbauchkarNo ratings yet

- Project Cost EstimationDocument8 pagesProject Cost EstimationBESAYE ROBA100% (1)

- 8 Construction: 8.1 Construction Phases and ProceduresDocument23 pages8 Construction: 8.1 Construction Phases and Proceduresechono johnNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Civil Engineering Structures According to the Eurocodes: Inspection and MaintenanceFrom EverandCivil Engineering Structures According to the Eurocodes: Inspection and MaintenanceNo ratings yet

- Elastic, Plastic and Yield Design of Reinforced StructuresFrom EverandElastic, Plastic and Yield Design of Reinforced StructuresNo ratings yet

- Case StudyDocument8 pagesCase StudyNidhi MehtaNo ratings yet

- U Value ExplainedDocument3 pagesU Value ExplainedNidhi MehtaNo ratings yet

- Tropical ClimatesDocument12 pagesTropical ClimatesNidhi MehtaNo ratings yet

- What Is Nature Cure Center?Document2 pagesWhat Is Nature Cure Center?Nidhi MehtaNo ratings yet

- Wind Ele of Climate-1Document12 pagesWind Ele of Climate-1Nidhi MehtaNo ratings yet

- History of Architecture - III - by Shanmuga SirDocument118 pagesHistory of Architecture - III - by Shanmuga SirKarthik Suresh50% (2)

- Escalator's Arrangement 1. A Single Escalator Arrangement: August 2016 SemesterDocument10 pagesEscalator's Arrangement 1. A Single Escalator Arrangement: August 2016 SemesterUmang SoniNo ratings yet

- Evolution of High RiseDocument8 pagesEvolution of High RiseNidhi MehtaNo ratings yet

- U-Values of ElementsDocument21 pagesU-Values of ElementsNidhi MehtaNo ratings yet

- Marcus Vitruvius Pollio Roman Architect and AuthorDocument3 pagesMarcus Vitruvius Pollio Roman Architect and AuthorNidhi Mehta100% (1)

- Material Security in SpecificationDocument2 pagesMaterial Security in SpecificationNidhi MehtaNo ratings yet

- Indvidual Case Study: Space in To PlaceDocument9 pagesIndvidual Case Study: Space in To PlaceNidhi MehtaNo ratings yet

- Role of An Architect in Monitoring SpecDocument1 pageRole of An Architect in Monitoring SpecNidhi MehtaNo ratings yet

- Notes On Detailed & Approximate EstimatesDocument4 pagesNotes On Detailed & Approximate EstimatesNidhi Mehta100% (1)

- Section B e CostingDocument32 pagesSection B e CostingNidhi MehtaNo ratings yet

- M-5 Estimation and Costing - Rakesh RDocument10 pagesM-5 Estimation and Costing - Rakesh RNidhi MehtaNo ratings yet

- BUILDING SERVICES-I: SANITARY FIXTURES, FITTINGS & WELLNESSDocument48 pagesBUILDING SERVICES-I: SANITARY FIXTURES, FITTINGS & WELLNESSVidya Hitti100% (2)

- Specifications NotesDocument1 pageSpecifications NotesNidhi MehtaNo ratings yet

- E Costing Sec DDocument27 pagesE Costing Sec DNidhi MehtaNo ratings yet

- Module 1 (2 Part)Document46 pagesModule 1 (2 Part)Nidhi MehtaNo ratings yet

- Percentage Reinforcement Calculation For Miscellaneous RCC Works BBPDocument1 pagePercentage Reinforcement Calculation For Miscellaneous RCC Works BBPNidhi MehtaNo ratings yet

- Muncipal, Garden, Organic & Inorganic Waste: Done By: Amrutha M.S. B.Akshata Delma Susan Biju Nikkitha VenugopalDocument10 pagesMuncipal, Garden, Organic & Inorganic Waste: Done By: Amrutha M.S. B.Akshata Delma Susan Biju Nikkitha VenugopalNidhi MehtaNo ratings yet

- Disinfection of WaterDocument24 pagesDisinfection of WaterNidhi MehtaNo ratings yet

- BUILDING SERVICES-I INTRODUCTIONDocument37 pagesBUILDING SERVICES-I INTRODUCTIONNidhi MehtaNo ratings yet

- Module 1 (2 Part)Document46 pagesModule 1 (2 Part)Nidhi MehtaNo ratings yet

- PLUMBING SYSTEMS GUIDEDocument39 pagesPLUMBING SYSTEMS GUIDENidhi MehtaNo ratings yet

- Modul 1Document18 pagesModul 1Nidhi MehtaNo ratings yet

- Sewerage System Module 2Document31 pagesSewerage System Module 2Nidhi MehtaNo ratings yet

- Estimation Sec-C NotesDocument13 pagesEstimation Sec-C NotesNidhi MehtaNo ratings yet

- PDF 12689Document52 pagesPDF 12689ktroarsNo ratings yet

- Library of Muyinga in Northeast BurundiDocument1 pageLibrary of Muyinga in Northeast BurundiTanishka ChavanNo ratings yet

- HOT1-Medieval ArchitectureDocument23 pagesHOT1-Medieval ArchitectureRowena NabarteNo ratings yet

- Module 3 SAYYID AND LODIDocument38 pagesModule 3 SAYYID AND LODIAzra Shahal100% (1)

- Audi A4 Current Flow Diagram No. 1Document1 pageAudi A4 Current Flow Diagram No. 1Dezrobitu ClaudiuNo ratings yet

- Fire and Smoke Fire - and - Smoke - Tight - Sliding - Doorstight Sliding Doors Mutli Purpose Doors 86038 enDocument32 pagesFire and Smoke Fire - and - Smoke - Tight - Sliding - Doorstight Sliding Doors Mutli Purpose Doors 86038 enAna GainaNo ratings yet

- Building on sloped terrainDocument9 pagesBuilding on sloped terrainImam MuslihNo ratings yet

- 3.high Rise Building StandardsDocument12 pages3.high Rise Building Standardssneha haridasNo ratings yet

- Mr. Talal Saleh Al Baker VillaDocument1 pageMr. Talal Saleh Al Baker VillaCharlton JimenezNo ratings yet

- Sverre Fehn: Villa Schreiner, Villa Bødtker, Villa BuskDocument26 pagesSverre Fehn: Villa Schreiner, Villa Bødtker, Villa Buskxu chen100% (1)

- DoorDocument1 pageDoorDexter PeraltaNo ratings yet

- Byzantine ArchitectureDocument2 pagesByzantine ArchitectureAnushkaNo ratings yet

- Standard One-Storey School Building: (2 - Classrooms)Document16 pagesStandard One-Storey School Building: (2 - Classrooms)Prime Agritech EngineeringNo ratings yet

- Aksha Elegance - 1 BHK Properties For Sale in Kudalwadi, Chikhali, Pune.Document4 pagesAksha Elegance - 1 BHK Properties For Sale in Kudalwadi, Chikhali, Pune.akshaNo ratings yet

- Arteriors 2021 Catalog SingleDocument320 pagesArteriors 2021 Catalog SingleTruongKhanh ArcNo ratings yet

- Annex-A (4 5%)Document3 pagesAnnex-A (4 5%)Naveed KhanNo ratings yet

- CM Exam Prep Notes PDFDocument119 pagesCM Exam Prep Notes PDFEnr L100% (5)

- Rencana Anggaran Biaya: (Penawaran)Document8 pagesRencana Anggaran Biaya: (Penawaran)Pavilium JoyNo ratings yet

- List of Publications in The American Concrete Institute Kansas Chapter LibraryDocument14 pagesList of Publications in The American Concrete Institute Kansas Chapter LibraryGabriel Paolo CañeteNo ratings yet

- Comparative Price List: AmountsDocument1 pageComparative Price List: AmountsMuhammad irfan javaidNo ratings yet

- Warm Interiors and Pristine Glass at Harbin Opera HouseDocument11 pagesWarm Interiors and Pristine Glass at Harbin Opera HouseNisanth Menon67% (3)

- Taj Decor ProfileDocument6 pagesTaj Decor ProfileTAJ DECORNo ratings yet

- Plans, Sections and ElevationsDocument16 pagesPlans, Sections and ElevationsDilshad Jaf100% (1)

- Aluminium Partitioning Systems Quick Reference GuideDocument58 pagesAluminium Partitioning Systems Quick Reference GuideShreyas soniNo ratings yet

- Solar LED Street Light BrochureDocument13 pagesSolar LED Street Light Brochuresetyo mercuadiNo ratings yet

- Byzantine and Romanesque Architecture v2 PDFDocument450 pagesByzantine and Romanesque Architecture v2 PDFBùi Thắng100% (2)

- Temples of The IndusDocument189 pagesTemples of The IndusRuhiNo ratings yet

- Structural Analysis and Design Structural Loadings Dead LoadDocument22 pagesStructural Analysis and Design Structural Loadings Dead LoadMckent V. EntienzaNo ratings yet

- Indo Sarcenic BuildingDocument8 pagesIndo Sarcenic Buildingajay dalalNo ratings yet

- Page-1 R4Document1 pagePage-1 R4Jana jerodyNo ratings yet