Professional Documents

Culture Documents

Jai Shriram Engineering College Unconventional Machining Processes Test

Uploaded by

Nihal Ashik0 ratings0% found this document useful (0 votes)

7 views2 pagesUCM two marks

Original Title

UCM Two mark questions.

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentUCM two marks

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views2 pagesJai Shriram Engineering College Unconventional Machining Processes Test

Uploaded by

Nihal AshikUCM two marks

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

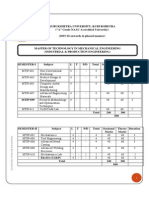

JAI SHRIRAM ENGINEERING COLLEGE, TIRUPUR

DEPARTMENT OF MECHANICAL ENGINEERING

TWO MARKS TEST

SUBJECT NAME: UNCONVENTIONAL MACHINING PROCESSES

YEAR /CLASS: IV YEAR/VII SEMESTER

DATE: 11.06.21

PART-A (25*2=50)

1. What is the need for unconventional machining processes?

2. What are the characteristics of UCM processes?

3. Differentiate the conventional and unconventional machining processes in terms of

principles.

4. What are the various types of energy sources used in non-traditional machining

techniques? Give examples for each.

5. Classify the different types of unconventional machining processes based on the

mechanical energy

6. What is the principle behind abrasive jet machining?

7. What are the major subsystems of AJM? What are the applications of diesel engine

power plant?

8. Why the abrasive particles not reused in the AJM?.

9. Name the abrasive materials that are used for the AJM.

10. Define mixing ratio. What is the effect of mixing ratio on the MRR?

11. What is the principle of Chemical Machining?

12. What is etch factor?

13. What is the purpose of etchant used in CHM? Give some examples

14. What is the purpose of maskant and how is it classified?

15. How are maskants selected?

16. What are the limitations of CHM & PCM?

17. What is ECG? Identify its applications.

18. What is ECD? Identify its applications

19. Name some of the tool material used in EDM?

20. Why is graphite the most preferred electrode material in EDM?

21. What is recast layer?

22. What is the principle of LBM?

23. Compare EBM and LBM.

24. What is the principle of PAM?

25. Identify the essential constituents of the electron gun?

You might also like

- Question Bank: Non Traditional Machining DE/PE-2.0 2 Marks QuestionDocument5 pagesQuestion Bank: Non Traditional Machining DE/PE-2.0 2 Marks QuestionpankajNo ratings yet

- Question Bank UCMDocument6 pagesQuestion Bank UCMSaravanan MathiNo ratings yet

- Our Official Android App - REJINPAUL NETWORK FromDocument1 pageOur Official Android App - REJINPAUL NETWORK FromNick “WWEXTRMEMENATOR” SpartaNo ratings yet

- PPE Two Mark Questions.Document2 pagesPPE Two Mark Questions.Nihal AshikNo ratings yet

- ME2026-Unconventional Machining ProcessesDocument6 pagesME2026-Unconventional Machining ProcessesJagathish JashNo ratings yet

- Me6004 Unconventional Machining Processes Assignment 1,2,3,4,5Document5 pagesMe6004 Unconventional Machining Processes Assignment 1,2,3,4,5BIBIN CHIDAMBARANATHANNo ratings yet

- AdvMan Technology QbankDocument24 pagesAdvMan Technology QbankSandeepKattaNo ratings yet

- UCM Important QuestionsDocument6 pagesUCM Important QuestionsNagarajNo ratings yet

- UCM Question BankDocument7 pagesUCM Question BankAkash KumarNo ratings yet

- MPD ASSIGNMENT-2Document1 pageMPD ASSIGNMENT-2Prinkesh MauryaNo ratings yet

- Ucm-Model Set 1Document1 pageUcm-Model Set 1Kalai ArasanNo ratings yet

- Ucm Two MarksDocument23 pagesUcm Two Marksarun kumarNo ratings yet

- Ucm 2 MarksDocument24 pagesUcm 2 MarksDhana MuruganNo ratings yet

- UNCONVENTIONAL MACHINING PROCESSES - Model Important Questions - CompressedDocument2 pagesUNCONVENTIONAL MACHINING PROCESSES - Model Important Questions - CompressedMuralee DharanNo ratings yet

- ME1001Document5 pagesME1001Dhileepan KumarasamyNo ratings yet

- UCM Course InformationDocument14 pagesUCM Course InformationThiyagu SundaramNo ratings yet

- Unconventional Machining ProcessesDocument6 pagesUnconventional Machining ProcessesMohan ManiNo ratings yet

- Ucmp Assignment QuestionsDocument2 pagesUcmp Assignment QuestionsKalai ArasanNo ratings yet

- Ucm IT-1Document1 pageUcm IT-1Anonymous DQGLUZxHNo ratings yet

- Kingston Pollytechnic College Mechanical Enginneering Advance Manufacturing Process For 3 Year 5 Semester Students AssignmentDocument1 pageKingston Pollytechnic College Mechanical Enginneering Advance Manufacturing Process For 3 Year 5 Semester Students Assignmentsamir boseNo ratings yet

- Chapter 1: Nontraditional MachiningDocument6 pagesChapter 1: Nontraditional MachiningTran Tien AnhNo ratings yet

- Unconventional Machining Processes - Model Important QuestionsDocument3 pagesUnconventional Machining Processes - Model Important Questionsmurugesan_kpm100% (1)

- Assignment 1 and 2 UCMP QDocument1 pageAssignment 1 and 2 UCMP QNagarajNo ratings yet

- Model Exam NTM QPDocument2 pagesModel Exam NTM QPRuby SmithNo ratings yet

- Ucmp-Question Bank - NewDocument4 pagesUcmp-Question Bank - New9966197483No ratings yet

- TE-I Two Mark Questions.Document2 pagesTE-I Two Mark Questions.Nihal AshikNo ratings yet

- Ucmp NotesDocument46 pagesUcmp NotesAnonymous fowICTKNo ratings yet

- Amp Qb.Document6 pagesAmp Qb.svkarthik83No ratings yet

- ME6004 - Unconventional Machining Processes Part-ADocument1 pageME6004 - Unconventional Machining Processes Part-AarunsunderNo ratings yet

- ME6004 - Unconventional Machining Processes Part-ADocument1 pageME6004 - Unconventional Machining Processes Part-AarunsunderNo ratings yet

- VIIIth Semester Scheme and SyllabusDocument21 pagesVIIIth Semester Scheme and SyllabusJitesh DewanganNo ratings yet

- Department of Mechanical Engineering: Acharya Institute of TechnologyDocument1 pageDepartment of Mechanical Engineering: Acharya Institute of Technologysanthosh.k.m SantuNo ratings yet

- 2020/2021 Academic Year 1 Semester Final Exam Paper (A) : Chingqing University of Science and TechnologyDocument4 pages2020/2021 Academic Year 1 Semester Final Exam Paper (A) : Chingqing University of Science and TechnologyAtiqur RahmanNo ratings yet

- UCMDocument6 pagesUCMpradeepNo ratings yet

- Question Bank: Subject Code & Name: Me 6004 Ucm Staff Incharge: M.RavisankarDocument12 pagesQuestion Bank: Subject Code & Name: Me 6004 Ucm Staff Incharge: M.Ravisankarjamunaa83No ratings yet

- Unconventional Machining Processes GuideDocument59 pagesUnconventional Machining Processes GuideAkilesh SNo ratings yet

- Assignment 5Document1 pageAssignment 5utkarshtyagi2307No ratings yet

- PP Syllabus (R2019)Document3 pagesPP Syllabus (R2019)shaikh javedNo ratings yet

- Non-Traditional Machining Processes 2 Marks QuestionsDocument1 pageNon-Traditional Machining Processes 2 Marks QuestionsAbhishek KumarNo ratings yet

- Advance Manufacturing QuestionsDocument7 pagesAdvance Manufacturing Questionsa38659158No ratings yet

- Question Bank Introduction To CAM: Noble Group of Institutions, JunagadhDocument5 pagesQuestion Bank Introduction To CAM: Noble Group of Institutions, JunagadhjanakNo ratings yet

- 1.1 Introduction To Conventional and Non Conventional MachiningDocument42 pages1.1 Introduction To Conventional and Non Conventional MachiningDida KhalingNo ratings yet

- WWW - Manaresults.Co - In: Unconventional Machining ProcessesDocument2 pagesWWW - Manaresults.Co - In: Unconventional Machining ProcessesMohan ReddyNo ratings yet

- 2mark With Answer UCM M.E 6004 PDFDocument22 pages2mark With Answer UCM M.E 6004 PDFl8o8r8d8s8i8v8100% (1)

- Department of Mechanical Engineering: SJB Institute of TechnologyDocument27 pagesDepartment of Mechanical Engineering: SJB Institute of TechnologyChidu KNo ratings yet

- Asg1 Amp Jan2010Document3 pagesAsg1 Amp Jan2010muhamadsaidiNo ratings yet

- Aalim Muhammed Salegh College of Engineering Department of Mechanical EngineeringDocument1 pageAalim Muhammed Salegh College of Engineering Department of Mechanical EngineeringS ABDUR RAHMANNo ratings yet

- Un Conventional Machining Process NotesDocument174 pagesUn Conventional Machining Process Notesban murthy0% (1)

- Advanced Manufacturing ProcessesDocument5 pagesAdvanced Manufacturing Processessagar mhetreNo ratings yet

- M.tech Mechanical Engg. (I &P)Document44 pagesM.tech Mechanical Engg. (I &P)Upender DhullNo ratings yet

- Question Paper Code:: (10×2 20 Marks)Document2 pagesQuestion Paper Code:: (10×2 20 Marks)jastraNo ratings yet

- Working and Applicaions of Esc (Electronic Speed Controller)Document24 pagesWorking and Applicaions of Esc (Electronic Speed Controller)Navin KhatriNo ratings yet

- CM4152 - SFFM Question BankDocument11 pagesCM4152 - SFFM Question BankWork CitNo ratings yet

- Acknowledgement: E.M.C. Anajaneylu, M. Tech For His Important and Moral Support During TheDocument3 pagesAcknowledgement: E.M.C. Anajaneylu, M. Tech For His Important and Moral Support During TheYashwanth ReddyNo ratings yet

- Syllabus PDF 1Document3 pagesSyllabus PDF 1gowrisankar32No ratings yet

- Unconvetional Machining ProcessDocument2 pagesUnconvetional Machining ProcessmaheshNo ratings yet

- Universiti Teknologi Mara Final Examination: Confidential EM/JAN 2012/MEM561/KJP516/470Document4 pagesUniversiti Teknologi Mara Final Examination: Confidential EM/JAN 2012/MEM561/KJP516/470Nasri JamaludinNo ratings yet

- PP-I Syllabus (SH2019)Document2 pagesPP-I Syllabus (SH2019)Vishwa RohindNo ratings yet

- Electrochemical Micromachining for Nanofabrication, MEMS and NanotechnologyFrom EverandElectrochemical Micromachining for Nanofabrication, MEMS and NanotechnologyRating: 4 out of 5 stars4/5 (1)

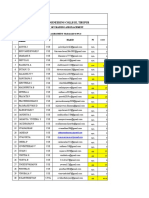

- Jai Shriram Engineering College placement records and training modulesDocument9 pagesJai Shriram Engineering College placement records and training modulesNihal AshikNo ratings yet

- Est 000911Document2 pagesEst 000911Nihal AshikNo ratings yet

- SEATING ArrangementDocument32 pagesSEATING ArrangementAnonymous 11TijG2aNo ratings yet

- 7.2.II QualitativeDocument3 pages7.2.II QualitativeNihal AshikNo ratings yet

- Jai Shriram Engineering CollegeDocument4 pagesJai Shriram Engineering CollegeNihal AshikNo ratings yet

- Jai Shriram Engg CollegeDocument2 pagesJai Shriram Engg CollegeNihal AshikNo ratings yet

- Technical AssessmentDocument16 pagesTechnical AssessmentNihal AshikNo ratings yet

- Comfortable Driving with Ventilated Steering WheelDocument6 pagesComfortable Driving with Ventilated Steering WheelNihal AshikNo ratings yet

- JAI SHRIRAM ENGINEERING COLLEGE Results Analysis for Hydraulics and PneumaticsDocument4 pagesJAI SHRIRAM ENGINEERING COLLEGE Results Analysis for Hydraulics and PneumaticsNihal AshikNo ratings yet

- Index For English DebateDocument1 pageIndex For English DebateNihal AshikNo ratings yet

- JAI SHRIRAM ENGINEERING COLLEGE Model Exam Analysis ME Hydraulics PneumaticsDocument17 pagesJAI SHRIRAM ENGINEERING COLLEGE Model Exam Analysis ME Hydraulics PneumaticsNihal AshikNo ratings yet

- Dr. Yamunadevi M.E., Ph.D. PublicationsDocument1 pageDr. Yamunadevi M.E., Ph.D. PublicationsNihal AshikNo ratings yet

- Jai Shriram Engineering College Technical Assessment ReportDocument63 pagesJai Shriram Engineering College Technical Assessment ReportNihal AshikNo ratings yet

- Social Welfare ManualDocument165 pagesSocial Welfare ManualNihal AshikNo ratings yet

- Anna University affiliated colleges academic performance April/May 2015 examsDocument19 pagesAnna University affiliated colleges academic performance April/May 2015 examsMartin De Boras PragashNo ratings yet

- TE-I Two Mark Questions.Document2 pagesTE-I Two Mark Questions.Nihal AshikNo ratings yet

- JAI SHRIRAM ENGINEERING COLLEGE Results Analysis for Hydraulics and PneumaticsDocument4 pagesJAI SHRIRAM ENGINEERING COLLEGE Results Analysis for Hydraulics and PneumaticsNihal AshikNo ratings yet

- Television: Operating InstructionsDocument2 pagesTelevision: Operating InstructionsNihal AshikNo ratings yet

- S.D Worksheet For Lesson 2Document1 pageS.D Worksheet For Lesson 2Nihal AshikNo ratings yet

- Presence of Mind and Communication Skills of Dr. C. N. AnnaduraiDocument10 pagesPresence of Mind and Communication Skills of Dr. C. N. AnnaduraiNihal AshikNo ratings yet

- Letter of IntentDocument3 pagesLetter of IntentNihal AshikNo ratings yet

- ME8493 Important Questions PDFDocument6 pagesME8493 Important Questions PDFNihal AshikNo ratings yet

- Wp-Content Uploads 2013 12 UNIVERSITY-QPDocument6 pagesWp-Content Uploads 2013 12 UNIVERSITY-QPNihal AshikNo ratings yet

- Affiliated Institutions Anna University of Technology Chennai:: Chennai 600 113 Curriculum 2010Document12 pagesAffiliated Institutions Anna University of Technology Chennai:: Chennai 600 113 Curriculum 2010Gowri ShankarNo ratings yet

- Unit IiiDocument20 pagesUnit IiiNihal AshikNo ratings yet

- ThermodynamicsDocument139 pagesThermodynamicsaravindaero123No ratings yet