Professional Documents

Culture Documents

Formulation and Evaluation of Orodispersive Tablets of "Ebastine" Using Natural Super Disintegrant by Molecular Dispersion Technique

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Formulation and Evaluation of Orodispersive Tablets of "Ebastine" Using Natural Super Disintegrant by Molecular Dispersion Technique

Copyright:

Available Formats

Volume 6, Issue 6, June – 2021 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Formulation and Evaluation of Orodispersive Tablets

of “Ebastine” Using Natural Super Disintegrant by

Molecular Dispersion Technique

Arun Kumar*

Institute of Pharmaceutical Science and Research, Sohramau, Unnao, U.P. India

Postal Address: 17, Moh. Kachcha Katra, P.O. Tilhar, Distt. Shahjahanpur, U.P. India 242307

Shalini Singh Dr. Sambit Kumar Parida Dr. N. Trilochana

(Asst. Professor) (Director – Deptt. of Pharmacy) (Director – Deptt. of Pharmacy)

Institute of Pharmaceutical Science Prof., Institute of Pharmaceutical Institute of Pharmaceutical Science

and Research, Sohramau, Unnao, Science and Research, Sohramau, and Research, Sohramau, Unnao,

U.P. India Unnao, U.P. India U.P. India

Abstract:- Ebastine is a 2nd generation H1 receptor available market products. The determination and

antagonist that is mainly indicated for allergic rhinitis evaluation were made for the most effective type and

and chronic idiopathic urticaria. In allergic conditions optimal amount of “Natural Super Disintegrants’’ for

the patient become panic and will have difficulty to the manufacture of Orodispersive Tablets by molecular

swallow tablet with a glassful of water. In such cases dispersion & direct compression technique.

Orodispersive tablets will be a good solution for patient

compliance and efficient dose regimen. Ebastine tablets I. INTRODUCTION

are available in different strength i.e. 10 mg and 20 mg.

The main objective of this project work was to developed Tablet measurements structure is the most well-known

and designed an Orodispersive tablets (ODTs) medication conveyance frameworks which are viewed as the

containing Ebastine 20 mg, using “Natural Super least demanding and most reasonable method of

Disintegrants’’ by molecular dispersion technique organization of the medication to a patient with the

including various pharmaceutical excipients with utilization of a glass of water. So, tablets are the most best

different strengths to enhance patient compliance and measurements structure involves the biggest and the most

therapeutic value as compare with the available market critical spot as contrast with other dose structures. There are

brands. Orodispersive Tablets of Ebastine were various sizes relating to the portion of the medication which

formulated by molecular dispersion technique and using can be given just as the state of the tablet. A few tablets may

Natural Superdisintegrants such as Agar and Guar gum contain as low as 1 mg or less of the medication, and others

and other excipients like gelatin, sodium lauryl sulphate, contain 1.5 g. of the dynamic medication per tablet, which

microcrystalline cellulose, sweetening agent as Sodium gives an immense scope of medication content. Tablet dose

saccharine, talc and magnesium stearate as lubricants, structures can be made in various sizes and shapes, and the

clove oil and lemon flavor as flavoring agent. Drug - medication fixing may contain 0.1% to 90% of a tablet

excipients compatibility tests performed before start the mass. The assembling of tablets is very simple when

formulation. The selection and the rejection of excipients contrasted with other measurements structure. The

for experimental formulation was considered after soundness issues are extremely less too. Creation yield is

getting the result of drug excipients compatibility study. likewise high and is the most affordable. Especially in the

The flowability of the powder mixtures were evaluated event of present-day mechanical strategies including the

using Carr's index, Angle of Repose and the Hausner’s cycle of Direct Compression Technique (DC).

ratio. The tablets were evaluated according to the

standards prescribed by British Pharmacopoeia like Direct Compression is the most straightforward,

weight variation, thickness, hardness, friability, monetary and financially savvy producing procedure which

disintegration time, a simulated wetting test and in-vitro would now be able to be applied to Orodispersive tablets,

dissolution. Prepared tablets after Optimization showed Fast dissolving Tablets, Mouth dissolving tablets and so on

disintegration time less than 30 seconds and drug due to the accessibility of huge scope of exceptionally

dissolution of about 75% within 30 minutes. The improved excipients like tablet normal super disintegrants,

prepared tablets of optimized batch tested for stability semi engineered disintegrants, manufactured excipients,

40 degree Celsius and 75% RH for 3 months and were strands and sugar-based excipients.

found to be stable. Prepared Orodispersive tablets of

Ebastine 20 mg from optimized batch were found

bioequivalent under fasting and fed conditions with the

IJISRT21JUN839 www.ijisrt.com 928

Volume 6, Issue 6, June – 2021 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

"Orodispersive Tablets" (ODTs) can be characterized Direct compression method was applied to compress the

as strong single-unit measurement structure that is expected tablets due to generally helpful, straightforward, savvy. The

to be set on the tongue where it disintegrates quickly within excipients were utilized in the detailing, for example,

the sight of salivation inside couple of moments and Gelatin, Sod. Lauryl sulfate, Agar, Guar gum,

afterward gulped without the need of water. Quicker the microcrystalline cellulose, Sod. Saccharine, Colloidal

medications breaking down, scattering and disintegration Silicon di oxide and magnesium stearate. The planned tablet

happen, the faster the ingestion and beginning of clinical definitions will be assessed for as indicated by the British

impact. Pharmacopeia for weight variety, thickness, hardness,

friability, breaking down time, a recreated wetting test, and

As indicated by the US-FDA, the ODTs were in-vitro disintegration. The dependability of test item was

characterized as "A strong measurements structure assessed according to the ICH Q8 rules.

containing restorative substances which breaks down

quickly, for the most part inside only seconds, when set Justification of Research

upon the tongue". It has been demonstrated measurably that Super disintegrants are the key material for a

(ODTs) have a few focal points over regular tablets to successful brand and the best therapeutic results in the form

upgrade persistent consistence and acknowledgment in light of Orodispersive tablets. The existing market brands

of its attainability and comfort. Practically half of the containing Ebastine 20 mg or 10 mg were developed and

populace experiences trouble gulping while at the same time designed using superdisintegrants obtained from other than

taking traditional tablets and hard gelatin containers. These natural sources or synthetic sources. In the current research

populaces incorporate pediatric and geriatric populaces who work it has been proven that natural superdisintegrants are

experience issues gulping enormous tablets. So as to defeat superior as compared to superdisintegrants obtained from

these issues, Orodispersive tablets (ODTs) have been synthetic process. Commercially, the Natural

created as elective oral measurements structures. Likewise, Superdisintegrants are freely available in market. The price

ODTs turned into a phenomenal decision as another of Natural superdisintegrants are very competitive and

medication conveyance framework, since they are anything cheaper than synthetic superdisintegrants. Although the

but difficult to regulate and prompt better patient superdisintegrants obtained from natural sources categorized

consistence, particularly in the older and kids. safer ingredients in comparison to synthetic

superdisintegrants. The molecular dispersion technique

The goal of this investigation was to create and plan an utilized to increase the bioavailability of active constituent

Orodispersive tablet dose type of dynamic medication ‘Ebastine’ which is poorly soluble in water. Molecular

Ebastine, utilizing different drug organizations including dispersion of micronized form of Ebastine with gelatin and

super disintegrants from characteristic sources to improve Sodium Lauryl Sulphate increased its solubility which get

tolerant consistence basically for pediatric and geriatric dissolved faster in presence of Natural superdisintegrants

patients. It is a histamine-H1 receptor obstructing specialist when comes in contact with saliva after placing the tablet in

with anticholinergic and narcotic property utilized for its oral cavity and get quick absorbed in blood stream. The

insect unfavorably susceptible properties. Consequently, it is onset of action of drug start faster than a conventional tablet.

basically utilized in the administration of hypersensitivity The preparation of Orodispersive tablets using Natural

manifestations like unfavorably susceptible rhinitis, superdisintegrants by Molecular dispersion technique is

urticaria, skin rashes, irritated/watery eyes, runny nose, and completely satisfies the regulatory requirements and the

regular virus. manufacturing process is commercially feasible. The

optimized formulation was robust, following all the

In the current investigation, Orodispersive tablets parameters of standards and no issues were faced with

(ODTs) of Ebastine was planned utilizing Natural respect to organoleptic attributes, blend uniformity, content

Superdisintegrants by molecular dispersion technique. uniformity, tableting, stability and bioequivalence etc.

II. MATERIAL AND METHODS

Drug and Excipients used in the formulation

Material Gifted By

Ebastine Bal Pharma Ltd.

Gelatin Bal Pharma Ltd.

Sodium Lauryl Sulphate Bal Pharma Ltd.

Agar Bal Pharma Ltd.

Guargum Bal Pharma Ltd.

Microcrystalline Cellulose Bal Pharma Ltd.

Sod. Saccharine Bal Pharma Ltd.

Clove Oil Bal Pharma Ltd.

Lemon Flavor Bal Pharma Ltd.

Colloidal Silicon-di-Oxide Bal Pharma Ltd.

IJISRT21JUN839 www.ijisrt.com 929

Volume 6, Issue 6, June – 2021 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Equipment and instruments used during formulation

Equipment and instruments Make and Model

Weighing Machine PS6000/C/1 manufactured by LCGC RADWAG

Vibrosifter Gansons Engineering

Electromagnetic Sieve Shaker EM8-08 Plus manufactured by Electrolab

Tap Density Testing Apparatus; ETD-1020 manufactured by Electrolab

Double Cone Blender with interchangeable bowls manufactured by Sams Technomech;

Loss on Drying Mositure Analyzer Model MB 45 manufactured by Ohaus

Comminuting Mill equipped with 0.5mm Screen Manufactured by Cadmach Machinery;

16 Station Single Rotary Tablet Compression Manufactured by Cadmach Machinery

Machine

Hardness Tester Type: TBH 125 manufactured by Erweka

Thickness Tester Vernier Caliper Absolute Dogmatics manufactured by Mitutoyo

Friabilator EF-1W manufactured by Electrolab

Disintegration Test Apparatus Model ED 2L manufactured by Electrolab

6.35 mm Round Flat Faced Bevel Edged Punch manufactured by ACG PAM Pharma Technology

Tooling

pH Meter H12215 manufactured by Hanna Instruments

UV Visisble Spectrophotometer manufactured by Perkin Elmer Lambda 25

Lab Stirrer RQ126D manufactured by Remi

Dissolution Apparatus TDT-08L manufactured by Electrolab

40°C / 75% RH Stability Chamber manufactured by Thermolab Scientific Equipment

Disintegration and dissolution parameters Step – 2:- Manufacturing Process

Disintegration test was performed in USP o Take Gelatin and SLS in a china dish according to the

disintegration test apparatus in purified water at 37+ 0.5- formula and melt at 70 degrees Celsius.

degree celcius. Specification NMT 30 Seconds. Dissolution o Now transfer the whole qty of Ebastin into china dish

is performed in purified water. The parameters include USP- and mix properly.

II (Paddle) 50 RPM, 900 ml, purified water at 37+ 0.5- o Keep the homogenous mixture in a refrigerator for 5-8

degree celcius, Time Points 0, 0.08, 0.16, 0.25, 0.33, 0.41, hrs.

0.5, 0.66, 0.83, 1.0, 2.0, 4.0 and 6.0 minutes. Specification o Cooled mass shall be milled and mixed with previously

NLT 75% (Q) of the labelled amount in 60 minutes. sifted MCC, Agar/Guar gum and blend until proper

mixing of all ingredients.

III. METHOD OF ASSAY, BLEND UNIFORMITY, Step - 3:- Lubrication

CONTENT UNIFORMITY/UNIFORMITY OF o Finally add previously sifted colloidal silicon dioxide,

DOSAGE UNITS AND DISSOLUTION Mag. Stearate, Sod. Saccharine, Flavors and lubricate for

5 min.

Method for Bulk Density, tapped density, Angle of Step – 4:- Compression

Repose and Friability o The lubricated blend is compressed into tablets as per

USP guidelines followed in the measurement of Bulk pre-planned formulation by using a rotary compression

Density, Tapped Density, Compressibility Index, Hausner’s machine.

Ratio, Repose Angle and % Friability measurements. Step – 5:- Analysis

o Compressed tablets shall be analyzed as per the official

Experimental Methodology guidelines for all parameters and a comparative study

Molecular dispersion technique with micronized active shall be done with the existing market brand

drug Ebastin by using Natural superdisintegrants, the

process will be the same for every trial batch from Batch Parameters Fixed for the tablet

No. F1 – Batch No. F13 for the manufacturing of The following parameters were mixed for the final

Orodispersive Tablets. tablets obtained:

Step -1: - Material Sifting Punch size: 7.14 mm

o Ebastin, Sod. Lauryl Sulphate, Guar gum, Agar, Thickness: 3.2 – 3.6 mm

Microcrystalline Cellulose shall be sifted through #60 Hardness: 20 – 100 Newton

separately. Weigh variation: +/- 2 %

o Colloidal silicon dioxide and Magnesium Stearate shall

be sifted through #60 separately.

IJISRT21JUN839 www.ijisrt.com 930

Volume 6, Issue 6, June – 2021 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

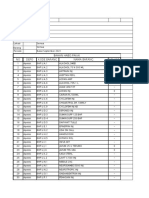

Proposed Formulations For Experiments

(Table 1.0) F1-F6 with Natural Superdisintegrants alone

Unit Formula (mg/tablet)

Sr. No. Ingredients

F-1 F-2 F-3 F-4 F-5 F-6

1 Ebastine 20 20 20 20 20 20

2 Gelatin 1.5 1.5 1.5 1.5 1.5 1.5

3 Sodium Lauryl Sulphate 1.5 1.5 1.5 1.5 1.5 1.5

4 Agar 5 -- 9 -- 13 --

5 Guargum, -- 5 -- 9 -- 13

6 MCC 117 117 113 113 109 109

7 Sod. Saccharine 2 2 2 2 2 2

8 Colloidal Silicon-di-oxide 1.5 1.5 1.5 1.5 1.5 1.5

9 Mag. Stearate 1.5 1.5 1.5 1.5 1.5 1.5

Net Wt. / Tab. in mg 150 150 150 150 150 150

(Table 2.0) F7-F9 with the combination of 2 Natural Super disintegrants

Unit Formula (mg/tablet)

Sr. No. Ingredients

F-7 F-8 F-9

1 Ebastine 20 20 20

2 Gelatin 1.5 1.5 1.5

3 Sodium Lauryl Sulphate 1.5 1.5 1.5

4 Agar 3 5 9

5 Guargum* 3 5 9

6 MCC 116 112 104

7 Sod. Saccharine 2 2 2

8 Colloidal Silicon-di-oxide 1.5 1.5 1.5

9 Mag. Stearate 1.5 1.5 1.5

Net Wt. / Tab. in mg 150 150 150

(Table 3.0) F10-F13 with organoleptic additive

(After getting results of previous formulations from F1 – F9)

Unit Formula (mg/tablet)

Sr. No. Ingredients

F-10 F-11 F-12 F-13

1 Ebastine 20 20 20 20

2 Gelatin 1.5 1.5 1.5 1.5

3 Sodium Lauryl Sulphate 1.5 1.5 1.5 1.5

4 Agar 9 9 9 9

5 Guar gum, 9 9 9 9

6 MCC 101 101 101 101

7 Sod. Saccharine 2 2 2 2

8 Clove Oil 2 -- 3 --

9 Lemon Flavor -- 2 -- 3

10 Colloidal Silicon-di-oxide 1.5 1.5 1.5 1.5

11 Mag. Stearate 1.5 1.5 1.5 1.5

Net Wt. / Tab. in mg 150 150 150 150

Preformulation studies

All the excipients were evaluated with the drug for compactability studies. The preformulation studies were performed

according to the formula and results were recorded based on the data was obtained accordingly.

Characterization of Active Drug

The active drug was evaluated for various parameters through the standard test and accordingly the results have been

mentioned in Table 4.0

IJISRT21JUN839 www.ijisrt.com 931

Volume 6, Issue 6, June – 2021 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Table 4.0 Result analysis of Ebastine

Test Specification Observation Conclusion

Description White color powder White color powder Complied

Odor Odorless Odorless Complied

Solubility Insoluble in water Practically Insoluble in water Complied

Sparingly soluble in methyl alcohol; Practically it is sparingly soluble in methyl alcohol; Complied

freely soluble in methylene chloride. freely soluble in in methylene chloride.

Drug-excipient compatibility studies

The drug was evaluated along with all the excipients for compatibility studies and the results were recorded as per the data

obtained after completion of the studies in Table 5.0.

The FT-IR spectrum of Ebastine and excipient individually and their mixtures of drug and excipient are shown in Fig. 1.0 to

1.10

Table 5.0 Drug-excipient compatibility data

S. No. Drug+ Excipient Condition

Room Hot air oven Freezing

Temperature Temperature

1 EBASTINE (API)* Stable Stable Stable

2 API + GELATIN Stable Stable Stable

3 API + SODIUM LAURYL SULPHATE Stable Stable Stable

4 API + MCC Stable Stable Stable

5 API + AGAR Stable Stable Stable

6 API + GUAR GUM Stable Stable Stable

7 API + COLL. SILI. DI. OXIDE Stable Stable Stable

8 API + MAG. STEARATE Stable Stable Stable

9 API + SOD. SACCHARINE Stable Stable Stable

10 API + CLOVE OIL Stable Stable Stable

11 API + LEMON FLAVOR Stable Stable Stable

Fig. 1.0 FT-IR spectrum of “EBASTINE’’

IJISRT21JUN839 www.ijisrt.com 932

Volume 6, Issue 6, June – 2021 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Fig. 1.1 FT IR spectrum of API+GELATIN

Fig. 1.2 FT IR spectrum of API + SODIUM LAURYL SULPHATE

Fig. 1.3 FT IR spectrum of API+AGAR

IJISRT21JUN839 www.ijisrt.com 933

Volume 6, Issue 6, June – 2021 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Fig. 1.4 FT IR spectrum of API+GUARGUM

Fig. 1.5 FT IR spectrum of API+MICRO CRYSTALLINE CELLULOSE

Fig. 1.6 FT IR spectrum of API + COLLOIDAL SILICON DIOXIDE

IJISRT21JUN839 www.ijisrt.com 934

Volume 6, Issue 6, June – 2021 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Fig. 1.7 FT IR spectrum of API + MAGNESIUM STEARATE

Fig. 1.8 FT IR spectrum of API + SODIUM SACCHARINE

Fig. 1.9 FT IR spectrum of EBASTINE + CLOVE OIL

IJISRT21JUN839 www.ijisrt.com 935

Volume 6, Issue 6, June – 2021 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Fig. 1.10 FT IR spectrum of API + LEMON FLAVOUR

Determination of λmax of Ebastine using a UV spectrometer

The λmax of Ebastine was found to be 252 nm.

Results of pre-compression studies

Precompression studies generally involve the evaluation of the blend in terms of bulk density, tapped density,

compressibility index, Hausner's ratio, and so on (Table 5.3). These also determine the flow property of the powder.

Table 6.0 Physical properties of the prepared blend

BATCH BULK TAPPED ANGLE OF CARR’S INDEX HAUSNER’S

DENSITY DENSITY REPOSE RATIO

F1 0.49+0.002 0.65+0.001 31.96+0.38 24.62 + 0.160 1.33+ 0.003

F2 0.45+0.001 0.60+0.001 32.49+0.80 25.00 + 0.660 1.33+ 0.003

F3 0.49+0.001 0.69+0.001 32.58+0.46 28.99 + 0.360 1.41+ 0.009

F4 0.51+0.002 0.70+0.001 34.81+0.86 27.14 + 0.890 1.37+ 0.016

F5 0.53+0.001 0.71+0.001 34.58+0.58 25.35 + 0.450 1.34+ 0.014

F6 0.52+0.002 0.69+0.001 34.31+0.36 24.64 + 0.860 1.33+ 0.006

F7 0.55+0.001 0.71+0.001 32.58+0.46 22.54 + 0.360 1.29+ 0.009

F8 0.53+0.002 0.73+0.001 34.81+0.86 27.40 + 0.890 1.38+ 0.016

F9 0.50+0.001 0.71+0.001 34.58+0.58 29.58 + 0.450 1.42+ 0.014

F10 0.55+0.002 0.69+0.001 34.31+0.36 20.29 + 0.860 1.25+ 0.006

F11 0.52+0.001 0.73+0.001 34.58+0.58 28.76 + 0.450 1.35+ 0.014

F12 0.52+0.002 0.68+0.001 34.31+0.36 23.53 + 0.860 1.31+ 0.006

F13 0.51+0.001 0.71+0.001 32.58+0.46 28.17 + 0.360 1.39+ 0.009

Results of post compression studies

Orodispersive tablets of all set of batches were evaluated after the compression for several pre-prescribed pharmacopeial and

in-house standards and parameters like average weight, Hardness, Friability, Drug Content, Tablet thickness, dispersion, drug

content, wetting time, water absorption ratio, and in vitro disintegration time.

After the completion of analytical tests, the obtained results are shown in Table 7.0 and 8.0.

In-vitro dissolution rate study is shown in Table. 9.0.

IJISRT21JUN839 www.ijisrt.com 936

Volume 6, Issue 6, June – 2021 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Table 7.0 Evaluation parameter of the tablet

BATCH Average weight Hardness Friability Drug content Thickness

(mg)* (N)** (%) (%)** (mm)

F1 148.99 34.8±4.57 0.89 98.57 3.26±0.05

F2 149.00 36.8±4.87 0.46 100.52 3.23±0.02

F3 150.02 36.8±2.67 0.51 101.18 3.44±0.04

F4 150.50 41.8±3.17 0.49 102.73 3.34±0.04

F5 151.40 39.8±2.58 0.79 101.34 3.46±0.03

F6 150.20 38.8±3.87 0.76 100.48 3.45±0.04

F7 150.02 36.8±2.67 0.70 99.88 3.24±0.04

F8 150.50 42.8±3.17 0.57 99.43 3.34±0.04

F9 149.40 39.8±2.58 0.59 101.24 3.36±0.03

F10 150.20 37.8±3.87 0.36 100.48 3.35±0.04

F11 150.50 43.8±3.17 0.87 101.33 3.54±0.04

F12 151.40 39.8±2.58 0.49 101.24 3.46±0.03

F13 150.20 37.8±3.87 0.86 99.68 3.34±0.04

* Average weight of 20 tablets was taken into consideration ** Average of 3 readings

Table 8.0 Evaluation parameter of the tablet

Batch Wetting Time (Sec.) Disintegration Time (Sec.)

F1 0.87±0.052 17.0±1.00

F2 2.17±0.032 14.0±1.50

F3 0.67±0.352 17.0±1.20

F4 0.68±0.042 30.0±1.80

F5 0.97±0.059 29.0±1.80

F6 0.67±0.012 23.0±2.10

F7 2.17±0.032 25.0±1.50

F8 0.67±0.352 15.0±1.20

F9 0.47±0.059 12.0±1.80

F10 0.67±0.012 27.0±2.10

F11 0.67±0.012 29.0±2.10

F12 2.17±0.032 19.0±1.50

F13 0.67±0.352 16.0±1.20

**Average of 3 readings

In-Vitro Dissolution Study Results

The result of in vitro dissolution study is given in below Tables

Table 9.0 In-Vitro Dissolution Rate Study

Cumulative Percent Drug Release of All Formulation

Time AGAR AGAR AGAR GUAR GUM GUAR GUM GUAR GUM

(min) (F1) (F2) (F3) F4) (F5) (F6)

0 0 0 0 0 0 0

0.08 4.43±1.96 4.63±1.16 5.93±1.26 5.86±2.96 6.40±0.96 6.43±1.26

0.16 6.43±2.47 6.83±1.47 6.83±1.42 6.93±2.47 7.43±2.47 669±3.67

0.25 13.01±2.19 21.01±1.11 16.01±2.69 6.01±0.19 11.01±2.19 7.96±2.34

0.33 30.27±0.73 42.17±0.13 45.27±1.13 8.07±2.73 14.27±9.78 9.57±9.94

0.41 48.79±8.55 53.79±4.55 63.79±8.55 12.79±7.55 20.79±8.55 15.79±8.55

0.5 71.88±5.49 75.88±6.49 78.88±5.49 16.88±2.49 28.88±1.49 34.88±8.49

0.66 83.95±3.20 87.95±4.60 87.95±3.20 23.95±7.20 51.95±8.20 49.95±6.20

0.83 90.82±2.45 97.82±1.45 92.82±2.45 38.82±5.45 62.82±2.45 66.82±8.45

1 91.40±1.32 92.50±3.32 96.40±1.32 54.40±1.32 74.40±8.32 79.40±7.82

2 96.74±4.89 99.74±1.8 99.74±4.89 79.74±2.89 97.74±9.89 80.74±9.89

4 100.19±5.50 101.19±1.50 101.11±1.50 86.19±1.5 100.1±7.5 87.19±8.5

6 100.9±6.03 102.9±1.03 102.2±7.03 98.9±3.03 101.9±3.03 94.9±0.03

*Average of 2 reading

IJISRT21JUN839 www.ijisrt.com 937

Volume 6, Issue 6, June – 2021 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Market Presence

Brand Name: Ebal 20

Dosage Forms: Fast Dissolving Tablets

Manufacturer: Bal Pharma Ltd.

IV. CONCLUSION swallowing or engaged at such places where it is not easy to

approach water supply. Sometimes the patients may be in a

The Orodispersive tablets of Ebastine were condition like the unconscious, travelers, minors, or old

successfully formulated using various ratios of different aged so fast disintegrating tablets may resolve such issues to

types of natural super disintegrants and the formulation was administer the dose without providing them a sense to

prepared by molecular dispersion and direct compression swallow a drug. Such patients can be given a single tablet to

technique. The natural super disintegrants Agar and keep it in their mouth where the Orodispersive tablet is

Guargum were added in the formulations in various dispersed in a few seconds and starts to absorb in the

concentrations to achieve the optimized batch. The bloodstream.

Orodispersive tablets of Ebastine were prepared using

natural super disintegrants along with the other excipients. Orodispersive tablets are developed and designed for

All the set of product formulation (F1-F13) were evaluated quick dispersion and rapid disintegration in the saliva

for generally less than 30 seconds. ODTs having some major

Pre formulation parameters such as Drug-excipients advantages over other formulations. ODTs disintegrate

compatibility studies. quickly in saliva within few seconds and this is an advantage

For flowability and compressibility analysis pre- that there is no need to take water.

compression parameters such as Bulk & Tapped density

of blend, Carr’s index, Hausner’s ratio, and angle of There were mainly two techniques used to develop

repose obtained. ODTs

Initially, the powder blend for all set of batches was

evaluated for their flowability property. The values The first technique is to use super disintegrants like

obtained through Carr’s index were satisfactory croscarmellose sodium (CCS), sodium starch glycolate

suggested that the blends have good compressibility and (SSG), crospovidone & other polymers as disintegrants.

the values obtained by Hausner’s ratio were showing a And the second technique is increasing the pore size

good sign for flow property for the powder blend. within tablets by freeze-drying or vacuum drying

Other tests like weight variation, hardness, friability, process.

disintegration time, wetting time, dissolution analysis,

drug content uniformity was performed as post- In this present research, Superdisintegrants were used

compression parameters study. from Natural origin. Pre gastric absorption and quick

Finally, the optimized batch was also evaluated for absorption of the drug from an oral cavity after the

accelerated stability studies & bio equibalance study. dispersion of ODTs in saliva may increase the therapeutic

value or bioavailability of drugs. The test formulation

Orodispersive tablets of Ebastine were formulated to containing Ebastine as a model drug is a second-generation

have the adequate mechanical strength to withstand during H1 receptor antagonist. Ebastine is an ethanolamine

their handling, packaging, shipping, storage, and derivative H1 blocker. It competes with the free histamine to

transportation. The tablets were prepared following the bind at the HA receptor site. After placing an Orodispersive

standards as prescribed by guidelines. Formulation F9 were tablet in the oral cavity, it disintegrates within a few seconds

showing fast disintegration and dissolution profile. Drug and quickly gets absorbed in the blood. Orodispersive

dissolution further impact on bioavailability and therapeutic tablets of Ebastine after oral administration has an onset of

effect of formulation. The optimized formulation was action within a few minutes which is present for the next 10-

considered for stability studies. The data obtained from 12 hrs. The elimination of the drug is by the renal and

stability studies demonstrated that Orodispersive tablets of metabolic routes. So it is important to reduce the dose of the

Ebastine were steady and stable under various natural drug for patients having metabolic disorders, kidney, or

environmental storage conditions. renal failure.

SUMMARY Orodispersive Tablets (ODTs) of Ebastine were

prepared by using natural super disintegrants with different

Orodispersive Tablets (ODTs) drug-delivery systems concentrations such as Agar, Guar gum. Gelatine, Sodium

were developed for patient compliance, especially for lauryl sulfate, Micro Crystalline Cellulose, Sodium

pediatric, geriatric, dysphagia, tremor, or physically disabled saccharine, Lemon Flavor, Clove Oil, Colloidal silicon

and travelers. Sometimes it is impractical to access water dioxide, Magnesium Stearate were used in formulations as

which is required to administer the drug in the form of a other excipients. A total of 13 formulations were designed

tablet or capsules. Those patients who feel difficulty in with molecular dispersion. To compress Orodispersive

IJISRT21JUN839 www.ijisrt.com 938

Volume 6, Issue 6, June – 2021 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

tablets, the direct compression method was preferred. All the proven with the existing study. ODTs with natural super

set of batches were evaluated for Pre formulation parameters disintegrants were found stable during Drug Excipients

like stability studies. Disintegration time and dissolution profiles

were found more challenging as compared with the available

Precompression Studies ODTs with synthetic disintegrants. The optimized batch can

Drug excipients compatibility studies, Angle of repose be considered for human trials to investigate the In-vivo

for flowability of powder blend, bulk, and tapped drug release. Bioequivalence studies can be done for test

density of powder blend, compressibility index, formulation with the brand drug “Ebay 20” or with other

Hausner's ratio was analyzed for each formulation. brands as available in the market.

REFERENCES

Compression Parameters Studies

Similar conditions were followed for all the sets of [1]. Arya, A., Sharma, S., Kumar, J., Jaiswal, P., Chandra,

formulations. The average weight of Orodispersive A., 2010. Formulation and Evaluation of Mouth

tablets was within the range of 149.99 to 150.4 mg. Dissolving Tablets of Ranitidine HCl. International

Other parameters were found within the prescribed Journal of PharmTech. Research, Vol. 2, pp. 1574-

limits such as weight variation, friability within the 1577.

range 0.36 – 0.89 % of all formulation. [2]. Aithal, K., Harish, N. M., Rathnanand, M., Shirwaikar,

A., Dutta, M., 2006. Once-daily fast dissolving tablets

The hardness of tablets from all set of 13 batches was

of granisetron hydrochloride formulation and in vitro

found satisfactory and within the range of 34.8 to 43.8

evaluation. Indian Drugs, Vol. 43, Issue 7, pp. 576-

Newton.

581.

Disintegration time is most of the important parameter

[3]. Ahmed, I. S., Nafadi, M. M., Fatahalla F. A., 2006.

for ODT’s, quick dispersion or disintegration help in

Formulation of a fast-dissolving ketoprofen tablet

swallowing of dispersed tablets & drug absorption in the

using freeze-drying in blisters technique. Drug Dev

oral cavity, thus promoting therapeutic value by

Ind. Pharm., Vol. 32, pp. 437-442.

increasing bioavailability of the drug.

[4]. Ahire, B., Gaikwad, P., Banker, V., Pawar, S., 2012.

ODTs showing disintegration time within the time limit. Mouth Dissolving Tablet and Its Applications.

Practically the values were observed within the range of International Journal of Drug Delivery, Issue 4, pp.

12 sec to 30 seconds. The percent drug content of the 89-94.

Orodispersive tablet of formulation F9 was found to the [5]. Ashish, P., et al., A Review-Formulation of mouth

98.57%, which has the best percent drug content among dissolving tablet. International journal of

all the sets of formulations & Formulation F4 was found pharmaceutical and clinical science, 2011. 1(1): p. 1-

with the percent drug content of 54.40%, which has the 8.

least percent drug content among all the formulations. In [6]. Brown, D., 2001. Orally disintegrating tablets: Taste

vitro dissolution studied of ODT’s was performed in the over speed. Drug Delivery Technology Vol. 3, Issue 6,

0.1N HCL using the USP paddle-type dissolution pp. 58-61.

apparatus. It was observed that formulations with the [7]. Bradoo, R., 2001. Fast Dissolving Drug Delivery

natural super disintegrants in optimum concentration Systems. JAMA India, Vol. 4 Issue 10, pp.27-31.

having better drug release as compared to the product [8]. Bagul, U., Gujar, K., Patel, N., Aphale, S., Dhat, S.,

with super disintegrants from synthetic sources due to 2010. Formulation and Evaluation of Sublimed Fast

the swelling and wicking effect of its combination. The Melt Tablets of Levocetirizine Dihydrochloride,

best in-vitro dissolution profile was obtained from the International Journal of Pharmaceutical Sciences,

formulations containing super disintegrants from the Vol. 2, and Issue 2, pp. 76-80.

natural origin when the results were compared with the [9]. Bhandari, S., Mittapalli, R. K., Gannu, R., Rao, Y. M.,

preexisting formulations containing super disintegrants 2008. Orodispersible tablet: An overview. Asian

from the synthetic origin. The optimized batch F9 was Journal of Pharmaceutics, Vol. 2, pp. 2-11.

considered for a long time on stress conditions to [10]. Bedi, N., Kalia, A., Khurana, S., 2009. Formulation &

determine the shelf life of the product. evaluation of mouth dissolving tablet of

Oxcarbazepine. International Journal of Pharmacy &

Pharmaceutical Science, Vol. 1, Issue 1, pp. 12- 23.

FUTURE PROSPECTS OF CURRENT RESEARCH [11]. Bhowmik, D., Chiranjib, B., Krishna, K., Pankaj,

WORK, BIOEQUIVALENCE STUDY AND CLINICAL Chandira, R. M., 2009. Fast Dissolving Tablet: An

TRIAL Overview. Journal of Chemical and Pharmaceutical

Research, Vol. 1, Issue 1, pp. 163-177.

The prospects of Orodispersive formulations are [12]. Bagul, U., Bagul, N., Kulkarni, M., Sawant, S., Gujar,

promising and the market demand is increasing day by day. K., Bidkar, A., 2006 [Online]. Current status of tablet

Several techniques were applied with different kinds of disintegrant: a review. Available at:

material that were used to formulate the ODTs. Natural Pharmainfonet.html, Vol. 4, and Issue 4.

Superdisintegrants are the best option to produce

satisfactory and safer ODT formulation which has been

IJISRT21JUN839 www.ijisrt.com 939

Volume 6, Issue 6, June – 2021 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

[13]. Cirri, M., Valleri, M., Mura, P., Maestrelli, F.,

Ballerini, R., Development of fast-dissolving tablets of

flurbiprofen cyclodextrin complexes. Drug Dev Ind.

Pharm., Vol. 3 Issue 1, pp. 697-707.

[14]. Chang, R., Guo, X., Burnside, B. A., Couch, R., 2000.

Fast-Dissolving Tablets. Pharmaceutical Technology,

Vol. 24, Issue 6, pp.52-58.

[15]. Chandy, A., Gupta, S., Manigauha, A., Thakur, Singh,

A., 2010. Comparatively evaluated disintegration in

the orodispersible tablet of famotidine. International

Journal of Current Pharmaceutical Research, Vol. 2,

Issue 3, pp. 44-46.

[16]. Saccharine" reference.com. Archived from the original

on 2007-03-03.

[17]. Saccharine". etymonline.com. Archived from the

original on 2006-03-23.

[18]. ^ "Sweetener Comparisons". Food Ingredient Series.

NCSU. 2006. Archived from the original on 2019-01-

20

[19]. Payen, Anselme (1859) "Sur la gelose et le nids de

salangane" (On agar and swiftlet nests), Comptes

rendus …, 49: 521–530, appended remarks 530–532.

[20]. "Agar-Agar". Botanical.com. Retrieved 22

January 2017.

IJISRT21JUN839 www.ijisrt.com 940

You might also like

- IMS Jurisprudence Exam QuestionsDocument26 pagesIMS Jurisprudence Exam QuestionsKalpesh Varma88% (8)

- 4 Preeti PDFDocument15 pages4 Preeti PDFBaru Chandrasekhar RaoNo ratings yet

- Review On "Mouth Dissolving Tablet As Fast Dissolving Drug Delivery System"Document13 pagesReview On "Mouth Dissolving Tablet As Fast Dissolving Drug Delivery System"Editor IJTSRDNo ratings yet

- Review On The Superdisintigrant and There PhenomenonDocument12 pagesReview On The Superdisintigrant and There PhenomenonNepjune RxNo ratings yet

- Formulation and Evaluation of Orodispersible Tablets of CelecoxibDocument8 pagesFormulation and Evaluation of Orodispersible Tablets of CelecoxibdadaNo ratings yet

- Literature SurveyDocument6 pagesLiterature SurveyVaibhav KaleNo ratings yet

- 2404-Article Text-7186-1-10-20190315 PDFDocument7 pages2404-Article Text-7186-1-10-20190315 PDFnelisaNo ratings yet

- Formulation Development and in Vitro Evaluation of Capecitabine Immediate Release TabletsDocument9 pagesFormulation Development and in Vitro Evaluation of Capecitabine Immediate Release TabletsEditor IJTSRDNo ratings yet

- Formulation and Evaluation of Cefixime Trihydrate Dispersible TabletsDocument10 pagesFormulation and Evaluation of Cefixime Trihydrate Dispersible TabletsEditor IJTSRDNo ratings yet

- Ondansetron Formulation-Archives of Pharmacal ResearchDocument13 pagesOndansetron Formulation-Archives of Pharmacal ResearchJenk JenkNo ratings yet

- Jchps 6 (4) 15 Page 286-292 MsreddyDocument7 pagesJchps 6 (4) 15 Page 286-292 MsreddydwahyusafriNo ratings yet

- Formulation, Optimization and Evaluation of Eslicarbazepine AcetateDocument6 pagesFormulation, Optimization and Evaluation of Eslicarbazepine AcetateBaru Chandrasekhar RaoNo ratings yet

- Formulation and Evaluation of ValsartanDocument15 pagesFormulation and Evaluation of Valsartanningsih rezekiNo ratings yet

- Formulation and Evaluation of Orally Disintegrating Tablets of SertralineDocument7 pagesFormulation and Evaluation of Orally Disintegrating Tablets of SertralineDinesh BabuNo ratings yet

- Formulation and Evaluation of Mouth Dissolving Film Containing RofecoxibDocument7 pagesFormulation and Evaluation of Mouth Dissolving Film Containing RofecoxibSathish SizzyNo ratings yet

- Phytochemical Screening and TLC Fingerprinting Formulation and Evaluation of Fast Disintegrating Tablets of FenofibrateDocument8 pagesPhytochemical Screening and TLC Fingerprinting Formulation and Evaluation of Fast Disintegrating Tablets of FenofibrateBaru Chandrasekhar RaoNo ratings yet

- 2 Vol.2 11 IJPSR RE 351 2011 Paper 2Document14 pages2 Vol.2 11 IJPSR RE 351 2011 Paper 2anomsawitriNo ratings yet

- An Alternative To The USP Disintegration Test For Orally Disintegrating TabletsDocument12 pagesAn Alternative To The USP Disintegration Test For Orally Disintegrating TabletsJurusan Farmasi Poltekkes MedanNo ratings yet

- Formulation, Development and Evalution of An Immediate Release Tablet of MethotrexateDocument22 pagesFormulation, Development and Evalution of An Immediate Release Tablet of MethotrexateDarlianaMelloSouzaNo ratings yet

- Article WJPR 1400475907Document13 pagesArticle WJPR 1400475907miserable1995No ratings yet

- Mouth Dissolving Tablets A ReviewDocument9 pagesMouth Dissolving Tablets A ReviewEditor IJTSRDNo ratings yet

- Formulation Development and Characterization of Fast Dissolving Acetaminophen TabletsDocument5 pagesFormulation Development and Characterization of Fast Dissolving Acetaminophen TabletsAshok KoshtaNo ratings yet

- FORMULATION AND IN-VITRO EVALUATION OF ZOLMITRIPTAN ORO-DISPERSIBLE TABLETS Arigela Bharathi, Vemugunta Ramakrishna, Baratam Anupama, Chukkapalli ManishaDocument9 pagesFORMULATION AND IN-VITRO EVALUATION OF ZOLMITRIPTAN ORO-DISPERSIBLE TABLETS Arigela Bharathi, Vemugunta Ramakrishna, Baratam Anupama, Chukkapalli ManishaiajpsNo ratings yet

- A Review On Chewable TabletsDocument11 pagesA Review On Chewable TabletsThuận TVNo ratings yet

- New Formulation and Evaluation of Domperidone SuspensionDocument18 pagesNew Formulation and Evaluation of Domperidone SuspensionethylenepluschlorineNo ratings yet

- JHP-4-102Formulation and Evaluation of Orally Disintegrating Tablet of Ondansetron Using Natural SuperdisintegrantDocument8 pagesJHP-4-102Formulation and Evaluation of Orally Disintegrating Tablet of Ondansetron Using Natural SuperdisintegrantIrfan SetiyawanNo ratings yet

- Formulation Development and Evaluation of Tablet Formulation Containing Ibuprofen HCL With Castor OilDocument9 pagesFormulation Development and Evaluation of Tablet Formulation Containing Ibuprofen HCL With Castor OilEditor IJTSRDNo ratings yet

- Formulation and Evaluation of Mouth Dissolving Tablets of Losartan PotassiumDocument10 pagesFormulation and Evaluation of Mouth Dissolving Tablets of Losartan PotassiumEditor IJTSRDNo ratings yet

- Formulation Development and Evaluation of Mouth Dissolving Tablet of ThiocolchicosideDocument18 pagesFormulation Development and Evaluation of Mouth Dissolving Tablet of ThiocolchicosideEditor IJTSRDNo ratings yet

- Bilayer Tablet Formulation ThesisDocument6 pagesBilayer Tablet Formulation Thesisbseb81xq100% (2)

- Formulation and Evaluation of Fast Disintegrating Tablet of Solid Dispersion of Carvedilol A ResearchDocument15 pagesFormulation and Evaluation of Fast Disintegrating Tablet of Solid Dispersion of Carvedilol A ResearchEditor IJTSRDNo ratings yet

- Formulation and Optimization of Taste Masked Zinc Sulphate TabletsDocument7 pagesFormulation and Optimization of Taste Masked Zinc Sulphate TabletsmulazimhNo ratings yet

- Fast dissolving Aceclofenac tabletsDocument13 pagesFast dissolving Aceclofenac tabletsMaria Carmen Rivera PorrasNo ratings yet

- Formulation and Evaluation of Fast Dissolving Tablets of Aceclofenac by Using Ispaghula Husk Powder As Natural Super DisintegrantDocument9 pagesFormulation and Evaluation of Fast Dissolving Tablets of Aceclofenac by Using Ispaghula Husk Powder As Natural Super DisintegrantBaru Chandrasekhar RaoNo ratings yet

- Formulation and Evaluation of Risperidone Fast Dissolving TabletsDocument11 pagesFormulation and Evaluation of Risperidone Fast Dissolving TabletsAmik TuladharNo ratings yet

- Oral Dispersible Tablets - A ReviewDocument8 pagesOral Dispersible Tablets - A ReviewSriram NagarajanNo ratings yet

- Paper 8695Document9 pagesPaper 8695IJARSCT JournalNo ratings yet

- Formulation and Evaluation of Voglibose Mouth Dissolving Tablets by Direct Compression MethodDocument5 pagesFormulation and Evaluation of Voglibose Mouth Dissolving Tablets by Direct Compression Methodanto_pharma7784No ratings yet

- Formulation and evaluation of pulsatile release tablets of celecoxibDocument19 pagesFormulation and evaluation of pulsatile release tablets of celecoxibSiva PrasadNo ratings yet

- A Review On Effervescent TabletDocument6 pagesA Review On Effervescent TabletInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Thesis Presentation - NiluDocument48 pagesThesis Presentation - NiluJay SahNo ratings yet

- Formulation and Evaluation of Multiunit Pellet System of Venlafaxine HydrochlorideDocument12 pagesFormulation and Evaluation of Multiunit Pellet System of Venlafaxine HydrochloridevbadsNo ratings yet

- Final ProjectDocument59 pagesFinal Projectvidya gantaNo ratings yet

- Lozenges DetailDocument9 pagesLozenges Detailankur guptaNo ratings yet

- MDIw MTMy MJ U5Document5 pagesMDIw MTMy MJ U5Zeyad A AbdullahNo ratings yet

- Orally Disintegrating TabletDocument5 pagesOrally Disintegrating TabletVenkat SwamyNo ratings yet

- Formulation and Evaluation of Amlodipine Fast Dissolving TabletsDocument9 pagesFormulation and Evaluation of Amlodipine Fast Dissolving TabletsEditor IJTSRDNo ratings yet

- Bisoprolol NehaDocument16 pagesBisoprolol NehasadafNo ratings yet

- 22A6761 - 222203.final ResarchDocument31 pages22A6761 - 222203.final Resarchrameshwar9595kNo ratings yet

- 10-Formulation and Evaluation of Effervescent Tablets of ParacetamolDocument30 pages10-Formulation and Evaluation of Effervescent Tablets of ParacetamolRodrigo InostrozaNo ratings yet

- Abstract Fast Dissolving TabletsDocument7 pagesAbstract Fast Dissolving TabletsRamakant SharmaNo ratings yet

- Valsartan Orodispersible Tablets Formulation in VIDocument9 pagesValsartan Orodispersible Tablets Formulation in VIRosa MarquezNo ratings yet

- DiclofenacDocument56 pagesDiclofenacVikas Sharma0% (1)

- Dissertation On Fast Dissolving TabletsDocument6 pagesDissertation On Fast Dissolving TabletsPaperWriterServicesCanada100% (1)

- Ijrpb 2 (1) 8 Bharathi 982-987Document6 pagesIjrpb 2 (1) 8 Bharathi 982-987dini hanifaNo ratings yet

- 3Document5 pages3Isma UddinNo ratings yet

- Formulation and Evaluation of Floating Tablet of Metoprolol SuccinateDocument13 pagesFormulation and Evaluation of Floating Tablet of Metoprolol SuccinateEditor IJTSRDNo ratings yet

- 1745-Article Text-6947-2-10-20200624Document14 pages1745-Article Text-6947-2-10-20200624Gaurav AdhikariNo ratings yet

- Literature Review of Fast Dissolving TabletsDocument13 pagesLiterature Review of Fast Dissolving Tabletsc5pjg3xh100% (1)

- Design and Manufacture of Pharmaceutical TabletsFrom EverandDesign and Manufacture of Pharmaceutical TabletsRating: 3.5 out of 5 stars3.5/5 (6)

- Parenteral Products: The Preparation and Quality Control of Products for InjectionFrom EverandParenteral Products: The Preparation and Quality Control of Products for InjectionNo ratings yet

- An Analysis on Mental Health Issues among IndividualsDocument6 pagesAn Analysis on Mental Health Issues among IndividualsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Insights into Nipah Virus: A Review of Epidemiology, Pathogenesis, and Therapeutic AdvancesDocument8 pagesInsights into Nipah Virus: A Review of Epidemiology, Pathogenesis, and Therapeutic AdvancesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Compact and Wearable Ventilator System for Enhanced Patient CareDocument4 pagesCompact and Wearable Ventilator System for Enhanced Patient CareInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Smart Cities: Boosting Economic Growth through Innovation and EfficiencyDocument19 pagesSmart Cities: Boosting Economic Growth through Innovation and EfficiencyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Implications of Adnexal Invasions in Primary Extramammary Paget’s Disease: A Systematic ReviewDocument6 pagesImplications of Adnexal Invasions in Primary Extramammary Paget’s Disease: A Systematic ReviewInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Parkinson’s Detection Using Voice Features and Spiral DrawingsDocument5 pagesParkinson’s Detection Using Voice Features and Spiral DrawingsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Relationship between Teacher Reflective Practice and Students Engagement in the Public Elementary SchoolDocument31 pagesThe Relationship between Teacher Reflective Practice and Students Engagement in the Public Elementary SchoolInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Harnessing Open Innovation for Translating Global Languages into Indian LanuagesDocument7 pagesHarnessing Open Innovation for Translating Global Languages into Indian LanuagesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Air Quality Index Prediction using Bi-LSTMDocument8 pagesAir Quality Index Prediction using Bi-LSTMInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Investigating Factors Influencing Employee Absenteeism: A Case Study of Secondary Schools in MuscatDocument16 pagesInvestigating Factors Influencing Employee Absenteeism: A Case Study of Secondary Schools in MuscatInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Advancing Healthcare Predictions: Harnessing Machine Learning for Accurate Health Index PrognosisDocument8 pagesAdvancing Healthcare Predictions: Harnessing Machine Learning for Accurate Health Index PrognosisInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Exploring the Molecular Docking Interactions between the Polyherbal Formulation Ibadhychooranam and Human Aldose Reductase Enzyme as a Novel Approach for Investigating its Potential Efficacy in Management of CataractDocument7 pagesExploring the Molecular Docking Interactions between the Polyherbal Formulation Ibadhychooranam and Human Aldose Reductase Enzyme as a Novel Approach for Investigating its Potential Efficacy in Management of CataractInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Dense Wavelength Division Multiplexing (DWDM) in IT Networks: A Leap Beyond Synchronous Digital Hierarchy (SDH)Document2 pagesDense Wavelength Division Multiplexing (DWDM) in IT Networks: A Leap Beyond Synchronous Digital Hierarchy (SDH)International Journal of Innovative Science and Research TechnologyNo ratings yet

- The Making of Object Recognition Eyeglasses for the Visually Impaired using Image AIDocument6 pagesThe Making of Object Recognition Eyeglasses for the Visually Impaired using Image AIInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Utilization of Date Palm (Phoenix dactylifera) Leaf Fiber as a Main Component in Making an Improvised Water FilterDocument11 pagesThe Utilization of Date Palm (Phoenix dactylifera) Leaf Fiber as a Main Component in Making an Improvised Water FilterInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Impact of Digital Marketing Dimensions on Customer SatisfactionDocument6 pagesThe Impact of Digital Marketing Dimensions on Customer SatisfactionInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- A Survey of the Plastic Waste used in Paving BlocksDocument4 pagesA Survey of the Plastic Waste used in Paving BlocksInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Diabetic Retinopathy Stage Detection Using CNN and Inception V3Document9 pagesDiabetic Retinopathy Stage Detection Using CNN and Inception V3International Journal of Innovative Science and Research TechnologyNo ratings yet

- Formulation and Evaluation of Poly Herbal Body ScrubDocument6 pagesFormulation and Evaluation of Poly Herbal Body ScrubInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Comparatively Design and Analyze Elevated Rectangular Water Reservoir with and without Bracing for Different Stagging HeightDocument4 pagesComparatively Design and Analyze Elevated Rectangular Water Reservoir with and without Bracing for Different Stagging HeightInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Terracing as an Old-Style Scheme of Soil Water Preservation in Djingliya-Mandara Mountains- CameroonDocument14 pagesTerracing as an Old-Style Scheme of Soil Water Preservation in Djingliya-Mandara Mountains- CameroonInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Explorning the Role of Machine Learning in Enhancing Cloud SecurityDocument5 pagesExplorning the Role of Machine Learning in Enhancing Cloud SecurityInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Auto Encoder Driven Hybrid Pipelines for Image Deblurring using NAFNETDocument6 pagesAuto Encoder Driven Hybrid Pipelines for Image Deblurring using NAFNETInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Cyberbullying: Legal and Ethical Implications, Challenges and Opportunities for Policy DevelopmentDocument7 pagesCyberbullying: Legal and Ethical Implications, Challenges and Opportunities for Policy DevelopmentInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- A Review: Pink Eye Outbreak in IndiaDocument3 pagesA Review: Pink Eye Outbreak in IndiaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Design, Development and Evaluation of Methi-Shikakai Herbal ShampooDocument8 pagesDesign, Development and Evaluation of Methi-Shikakai Herbal ShampooInternational Journal of Innovative Science and Research Technology100% (3)

- Electro-Optics Properties of Intact Cocoa Beans based on Near Infrared TechnologyDocument7 pagesElectro-Optics Properties of Intact Cocoa Beans based on Near Infrared TechnologyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Hepatic Portovenous Gas in a Young MaleDocument2 pagesHepatic Portovenous Gas in a Young MaleInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Navigating Digitalization: AHP Insights for SMEs' Strategic TransformationDocument11 pagesNavigating Digitalization: AHP Insights for SMEs' Strategic TransformationInternational Journal of Innovative Science and Research Technology100% (1)

- Automatic Power Factor ControllerDocument4 pagesAutomatic Power Factor ControllerInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- 103 230 1 PBDocument13 pages103 230 1 PBMkf FaridliNo ratings yet

- Immacule Product List - Injectables UpdatedDocument1 pageImmacule Product List - Injectables Updatedsanjay_gawaliNo ratings yet

- Panadol Osteo Product InformationDocument5 pagesPanadol Osteo Product Informationsalema2No ratings yet

- Dosage CalculationsDocument21 pagesDosage CalculationsHaley P100% (2)

- NMT 04209 - Basic Pharmacology-1Document126 pagesNMT 04209 - Basic Pharmacology-1Rubeni VENANSI chisiNo ratings yet

- Pharmacokinetics principles applicationDocument10 pagesPharmacokinetics principles applicationahsan naeemNo ratings yet

- Pharmacy Paper I & II TopicsDocument2 pagesPharmacy Paper I & II TopicsShadman RhamanNo ratings yet

- Pharmaceutical Interview Questions and AnswerDocument7 pagesPharmaceutical Interview Questions and Answergeusaa91No ratings yet

- Pharmacy Bulletin Aug11Document6 pagesPharmacy Bulletin Aug11Rema Panickar SugunanNo ratings yet

- Laporan Kartu Stok Semua Barang Bulan SeptemberDocument23 pagesLaporan Kartu Stok Semua Barang Bulan Septemberklinik stiesiaNo ratings yet

- National Drug Register of Uganda - Human Medicines - August 2020 PDFDocument1,337 pagesNational Drug Register of Uganda - Human Medicines - August 2020 PDFKman SoorNo ratings yet

- Day1.2 - Young - An Overview of The Draft Guidance For Industry - ANDA Submissions RTRDocument42 pagesDay1.2 - Young - An Overview of The Draft Guidance For Industry - ANDA Submissions RTRMarkbot1999No ratings yet

- Dr.b. Santosh Kumar ResumeDocument2 pagesDr.b. Santosh Kumar ResumeSureshNo ratings yet

- Drug Calculations For NursesDocument4 pagesDrug Calculations For NursesynottripNo ratings yet

- Stok Obat Apotik Per 22 Juni 2018Document314 pagesStok Obat Apotik Per 22 Juni 2018Jefry AjaNo ratings yet

- E Catalog ObatDocument2 pagesE Catalog ObatInna MarsanNo ratings yet

- ARV Coverage - May 2020Document10 pagesARV Coverage - May 2020ilhamNo ratings yet

- Practicals in Pharmaceutical Technology - Prescription PharmacyDocument260 pagesPracticals in Pharmaceutical Technology - Prescription PharmacyAngel Stojanov100% (1)

- Question Paper ProDocument13 pagesQuestion Paper ProselvaprabaNo ratings yet

- Comparative Dossier Filling Procedure in The Asean, Cis and The GCC RegionDocument35 pagesComparative Dossier Filling Procedure in The Asean, Cis and The GCC Regionsandeepver88100% (1)

- UntitledDocument63 pagesUntitledD'Clair ChannelNo ratings yet

- Aq - Minimal Stok ApotekDocument30 pagesAq - Minimal Stok ApotekSifa Septiani PutriNo ratings yet

- Laporan Pemakaian Dan Lembar Permintaan Obat (Lplpo) PuskesmasDocument7 pagesLaporan Pemakaian Dan Lembar Permintaan Obat (Lplpo) PuskesmasNoviana Kurnia AmbarwatiNo ratings yet

- Laporan Stok Harian 27 JANUARI 2022Document64 pagesLaporan Stok Harian 27 JANUARI 2022HakimNo ratings yet

- Analisis Kebutuhan Tenaga Berdasarkan Beban Kerja Sebagai Dasar Perencanaan SDM Di Instalasi Farmasi RS. X SemarangDocument7 pagesAnalisis Kebutuhan Tenaga Berdasarkan Beban Kerja Sebagai Dasar Perencanaan SDM Di Instalasi Farmasi RS. X SemarangNYONGKERNo ratings yet

- Multiple Dosage Regimens ExplainedDocument36 pagesMultiple Dosage Regimens ExplainedRafay Sarwar MughalNo ratings yet

- Management of Malaria in Children: Update 2008: GuidelinesDocument5 pagesManagement of Malaria in Children: Update 2008: GuidelinesSaumilNo ratings yet

- Routes of Drug AdministrationDocument42 pagesRoutes of Drug AdministrationRiddhi JainNo ratings yet

- Medicines Administration 1 Understanding Routes of AdministrationDocument3 pagesMedicines Administration 1 Understanding Routes of AdministrationJosa Camille BungayNo ratings yet