Professional Documents

Culture Documents

Acp Equipment Maintenance Schedule

Uploaded by

Eddie Fernando Catapang0 ratings0% found this document useful (0 votes)

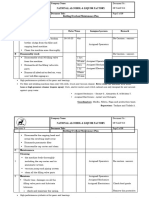

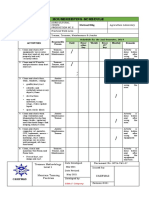

76 views1 pageThe document outlines an ACP equipment maintenance schedule with the following key points:

1) Tasks to be completed every 8 hours include pre-operation checks and cleaning/securing implements.

2) Every 50 hours includes checking fluids, the engine, lights, and exhaust pipe.

3) Every 100 hours includes an oil change, cleaning the electrical panel and exhaust, and checking the battery and pumps.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document outlines an ACP equipment maintenance schedule with the following key points:

1) Tasks to be completed every 8 hours include pre-operation checks and cleaning/securing implements.

2) Every 50 hours includes checking fluids, the engine, lights, and exhaust pipe.

3) Every 100 hours includes an oil change, cleaning the electrical panel and exhaust, and checking the battery and pumps.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

76 views1 pageAcp Equipment Maintenance Schedule

Uploaded by

Eddie Fernando CatapangThe document outlines an ACP equipment maintenance schedule with the following key points:

1) Tasks to be completed every 8 hours include pre-operation checks and cleaning/securing implements.

2) Every 50 hours includes checking fluids, the engine, lights, and exhaust pipe.

3) Every 100 hours includes an oil change, cleaning the electrical panel and exhaust, and checking the battery and pumps.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

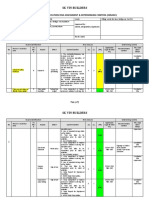

ACP EQUIPMENT MAINTENANCE SCHEDULE

8 HOURS 50 Hours 100 HOURS

• Pre-operation ● Check engine • Check/Clean

check-up of available exhaust pipe if

conducted in ACP functioning well

line with equipment. • Check battery fuel

manufacturer’ ● Check level correct and

s manual. headlights, terminals clean.

• Check plow warning • Change oil

and rotivator light and filter (refer to

by cleaning, side mirrors engine

securing and in good manual for

labeling condition. specifics).

properly. ● Check/Clea • Clean and tighten

• Wipe up oil n exhaust battery

and fuel spills pipe if connections

immediately. functioning ● Clean and

• Check fluid levels well. check

(oil and fuel). ● Note: Refer electrical

• Service the air to Service panel board.

filter (refer to Manual. ● Remove dirt

engine manual from the grass

for specifics). cutter blade

by washing

and brushing

using water

and soap.

● Clean water

pump and

check if it is

functioning

well.

Trainers Methodology Date Developed: Document No. NTTA-TM1-07

Level 1 May 2021 Issued by:

Date Revised:

May 2021

Maintain Training CASIFMAS

Developed by:

Facilities

CASIFMAS EDDIE F. CATAPANG Revision # 001

You might also like

- Land Rover LR3 Owners HandbookDocument349 pagesLand Rover LR3 Owners Handbookbmgeisler100% (9)

- Ophthalmic Dosage FormsDocument40 pagesOphthalmic Dosage Formsabdullah2020No ratings yet

- 007 - Sop (Genset System, Annual) V 1.1Document8 pages007 - Sop (Genset System, Annual) V 1.1Han Htun NaingNo ratings yet

- Iso 1328-1 - Cylindrical - GearsDocument58 pagesIso 1328-1 - Cylindrical - Gearsmauriciovendramin100% (2)

- 05 - Equipment Maintenance ScheduleDocument2 pages05 - Equipment Maintenance ScheduleEddie Fernando CatapangNo ratings yet

- Hirarc Bridge ConstructionDocument9 pagesHirarc Bridge ConstructionAdib Ikhwan100% (3)

- Maintenance and LubricationDocument34 pagesMaintenance and Lubricationtoppen_76100% (1)

- Standby GeneratorDocument11 pagesStandby Generatortecmak AngolaNo ratings yet

- Voss 232 38104 - SuspensionPart - Katalog - Gesamt KomprimiertDocument320 pagesVoss 232 38104 - SuspensionPart - Katalog - Gesamt KomprimiertMatt NagyNo ratings yet

- Salvage Report: Area / Section In-Charge Date Facility Type Part Id RecommendationDocument1 pageSalvage Report: Area / Section In-Charge Date Facility Type Part Id RecommendationEddie Fernando CatapangNo ratings yet

- ARM 1176-JZFS CPU-Based Low-Power SubsystemDocument24 pagesARM 1176-JZFS CPU-Based Low-Power SubsystemJadir Eduardo Souza LucasNo ratings yet

- Qa10 PS GD535-5Document3 pagesQa10 PS GD535-5Andaru GunawanNo ratings yet

- Catia V5 R16 - Part DesignDocument851 pagesCatia V5 R16 - Part DesignHarsh100% (13)

- Maintenance of TransformersDocument15 pagesMaintenance of Transformersmabmanik100% (2)

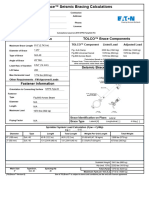

- Manual Servicio Eaton Serie 10 PDFDocument16 pagesManual Servicio Eaton Serie 10 PDFCesar MoraNo ratings yet

- Excavator Instructors NotesDocument31 pagesExcavator Instructors NotesWALTER EMMANUEL FLORES COSCONo ratings yet

- Service Sheet Tadano Cto1Document4 pagesService Sheet Tadano Cto1ainul arifNo ratings yet

- Design ConsiderationsDocument6 pagesDesign ConsiderationssatyacvaNo ratings yet

- Manual Mantenimiento Yanmar 4TNV98TDocument29 pagesManual Mantenimiento Yanmar 4TNV98Tdavid ignacioNo ratings yet

- JCB VM115 Single Drum RollerDocument9 pagesJCB VM115 Single Drum Roller江柄宏100% (1)

- Maintenance Schedule of Stenter Machine: ObjectsDocument14 pagesMaintenance Schedule of Stenter Machine: ObjectsAbel TayeNo ratings yet

- 50 200 Cylinder Diesel EngineDocument30 pages50 200 Cylinder Diesel EngineFranklin FernandezNo ratings yet

- MT55 - Service ScheduleDocument2 pagesMT55 - Service Schedulesernamu85No ratings yet

- Daily MainenanceDocument5 pagesDaily MainenanceChanthol RibeiroNo ratings yet

- Bottling Maintenance Schedule Oct 2023Document19 pagesBottling Maintenance Schedule Oct 2023Tesfaye ejetaNo ratings yet

- Service Program - CE Excapator KOREADocument8 pagesService Program - CE Excapator KOREAtele123No ratings yet

- HEMM Grader01Document9 pagesHEMM Grader01miningnova2100% (1)

- Genset Maintain Time TableDocument2 pagesGenset Maintain Time TableRasheed SiddiquiNo ratings yet

- Machineries Check ListDocument62 pagesMachineries Check ListEyob0% (1)

- Section 2.16 - Life Saving Appliances Maintenance. Maintenance Code N - 1 Month Components Working DescriptionDocument10 pagesSection 2.16 - Life Saving Appliances Maintenance. Maintenance Code N - 1 Month Components Working DescriptionRochmat AdityaNo ratings yet

- Checklists Title: Checklist For Preventive Maintenance of Equipments TG & Bop Maintenance Department Condensate Extraction PumpsDocument1 pageChecklists Title: Checklist For Preventive Maintenance of Equipments TG & Bop Maintenance Department Condensate Extraction Pumpsjp mishraNo ratings yet

- Don Bosco TVET Center-Calauan IncDocument3 pagesDon Bosco TVET Center-Calauan IncJuliet N. Coronado100% (1)

- Service Protocol: Dealer StampDocument4 pagesService Protocol: Dealer Stampanon_844391780No ratings yet

- Service Protocol: Marine Diesel D4, Marine Diesel D6, HS45A, HS63A, HS63IV, HS80A, HS80IV, HS85A, HS85IV, InboardDocument3 pagesService Protocol: Marine Diesel D4, Marine Diesel D6, HS45A, HS63A, HS63IV, HS80A, HS80IV, HS85A, HS85IV, InboardAzael Enrique Vergara GonzalezNo ratings yet

- V. Design, Application, Maintenance & Operation Technical RequirementsDocument7 pagesV. Design, Application, Maintenance & Operation Technical Requirementstillu basheerNo ratings yet

- Generaror Inspection ChecklistDocument1 pageGeneraror Inspection Checklistyibelta abebeNo ratings yet

- Series 10 Dual Displacement: Parts and Repair InformationDocument20 pagesSeries 10 Dual Displacement: Parts and Repair InformationAлександрNo ratings yet

- Standby Generator Set Pre-Operation Checklist: Before Starting The EngineDocument4 pagesStandby Generator Set Pre-Operation Checklist: Before Starting The EngineMartie ClustersNo ratings yet

- Reactor Maintenance: Before Batch Daily Weekly Monthly 3 Month 6 Month Yearly Maintenance FrequencyDocument1 pageReactor Maintenance: Before Batch Daily Weekly Monthly 3 Month 6 Month Yearly Maintenance FrequencyUrvashiNo ratings yet

- Machineries Check ListDocument59 pagesMachineries Check Listabrham negashNo ratings yet

- Check Sheet PS Pc78uu-6 EditDocument3 pagesCheck Sheet PS Pc78uu-6 EditToko SerbaNo ratings yet

- IMEE-6 Maintenance PDFDocument8 pagesIMEE-6 Maintenance PDFHirakNo ratings yet

- ABL-74T Machine MaintenanceDocument1 pageABL-74T Machine MaintenanceChris McNairNo ratings yet

- 3 EPT20-15ET Daily Maintenance List - 20181115 - 133154Document3 pages3 EPT20-15ET Daily Maintenance List - 20181115 - 133154Lacatusu MirceaNo ratings yet

- Maintenance ScheduleDocument33 pagesMaintenance SchedulesfsdffdsdfsdfsdfNo ratings yet

- Maintenance Check Sheet - DISCOVERY 3 4 ARMOURED DIESEL MODELS - MilesDocument2 pagesMaintenance Check Sheet - DISCOVERY 3 4 ARMOURED DIESEL MODELS - MilesCristiano DellazariNo ratings yet

- United Proarc Corporation: Engineering Department Technique DirectiveDocument3 pagesUnited Proarc Corporation: Engineering Department Technique DirectiveIrving Israel IrvingNo ratings yet

- BB6 Annual Maintenance PlanDocument1 pageBB6 Annual Maintenance PlanFoued DridiNo ratings yet

- Service Protocol: Marine Diesel D11, InboardDocument3 pagesService Protocol: Marine Diesel D11, Inboardtomo776No ratings yet

- 670GLC PIN 1FF670GX F690001 Uptime Maintenance PlannerDocument4 pages670GLC PIN 1FF670GX F690001 Uptime Maintenance PlannerNelson Andrade VelasquezNo ratings yet

- Cashman EM Solutions Brochure 3 16Document2 pagesCashman EM Solutions Brochure 3 16jov100% (1)

- RT Inspection & Lubrication Service Log 242-00Document46 pagesRT Inspection & Lubrication Service Log 242-00hananmeliani79No ratings yet

- Mooney M20 100hour PDFDocument2 pagesMooney M20 100hour PDFsplyn100% (1)

- 05 Equipment Maintenance ScheduleDocument2 pages05 Equipment Maintenance ScheduleMagda MargaNo ratings yet

- Preventive Maintenance ServiceDocument1 pagePreventive Maintenance ServiceJenry JonathanNo ratings yet

- 4.2 Service SheetDocument2 pages4.2 Service SheetRichard PorterNo ratings yet

- Lincoln Welding Machine ChecklistDocument1 pageLincoln Welding Machine ChecklistEjike Francis ChizobaNo ratings yet

- 330clc Plan MttoDocument2 pages330clc Plan MttoJuan FloresNo ratings yet

- Maintenance Table - 6161Document2 pagesMaintenance Table - 6161Kushal KarNo ratings yet

- Transformer Maintenance PDFDocument10 pagesTransformer Maintenance PDFJIMMYNo ratings yet

- Multi Mill SOPDocument14 pagesMulti Mill SOPDilraj KohliNo ratings yet

- BlastingtDocument1 pageBlastingtArjuna GamingNo ratings yet

- Triptico OriginalDocument2 pagesTriptico OriginalAaron LopezNo ratings yet

- Chick ListDocument1 pageChick ListahmedNo ratings yet

- Safety Measures and Maintenace of Power PackDocument2 pagesSafety Measures and Maintenace of Power Packsameer singhNo ratings yet

- 120D Uptime Maintenance PlannerDocument2 pages120D Uptime Maintenance PlannerNelson Andrade VelasquezNo ratings yet

- Service ManuelDocument28 pagesService ManuelTushar BhowarNo ratings yet

- Tuneup Engine Form PDFDocument2 pagesTuneup Engine Form PDFYan SaputraNo ratings yet

- Operational ProcedureDocument1 pageOperational ProcedureEddie Fernando CatapangNo ratings yet

- 12-Waste Segregation ListDocument2 pages12-Waste Segregation ListEddie Fernando Catapang100% (1)

- 08 - Work RequestDocument1 page08 - Work RequestEddie Fernando CatapangNo ratings yet

- 07 - Tag Out IndexDocument2 pages07 - Tag Out IndexEddie Fernando CatapangNo ratings yet

- Housekeeping Schedule: Qualification Station/Bldg Area/Section In-Charge Schedule For The 2nd Semester, 2019Document3 pagesHousekeeping Schedule: Qualification Station/Bldg Area/Section In-Charge Schedule For The 2nd Semester, 2019Eddie Fernando CatapangNo ratings yet

- 9701 s09 QP 2Document25 pages9701 s09 QP 2Hubbak KhanNo ratings yet

- LateralDocument2 pagesLateralDeddy TambunanNo ratings yet

- Fan Tom TwisterDocument18 pagesFan Tom TwisterRainNo ratings yet

- J616V21 enDocument4 pagesJ616V21 enMartin KratkyNo ratings yet

- Diesel Injection System Naturally AspiratedDocument346 pagesDiesel Injection System Naturally AspiratedGreg Hanna100% (1)

- Simulation in Terminated SystemsDocument17 pagesSimulation in Terminated SystemsSaleem AlmaqashiNo ratings yet

- Raghunath AnDocument68 pagesRaghunath AnRagunathan NarayananNo ratings yet

- Cathodic Protection Level I - INDOCOR Training and Certification FJM 2015 PDFDocument2 pagesCathodic Protection Level I - INDOCOR Training and Certification FJM 2015 PDFCimotNo ratings yet

- 10 Frequently Asked SQL Query Interview Questions - Java67Document26 pages10 Frequently Asked SQL Query Interview Questions - Java67renegade78No ratings yet

- Practical File TaskDocument7 pagesPractical File TaskRakim SajdadNo ratings yet

- Ranchi: Organization Study at Heavy Engineering Corporation LTDDocument6 pagesRanchi: Organization Study at Heavy Engineering Corporation LTDruchisinghnovNo ratings yet

- Umts CourseDocument19 pagesUmts CourseJesvin RochaNo ratings yet

- Test For B.tech StudentsDocument5 pagesTest For B.tech StudentsAniketh Pradhan50% (2)

- 777D.Schematic ElectricDocument2 pages777D.Schematic ElectricDedeNo ratings yet

- Chem Unit 1Document34 pagesChem Unit 1Ismaeel ShamsiNo ratings yet

- Goulds PumpsDocument44 pagesGoulds PumpscridavarNo ratings yet

- Cameron Type U BoppdfDocument1 pageCameron Type U BoppdfAly Kamal SabbahNo ratings yet

- Yarn Trading Mechanism FullDocument68 pagesYarn Trading Mechanism FullSasi MurugesanNo ratings yet

- BV NR 467Document280 pagesBV NR 467teacgNo ratings yet

- Renewable Energy System: Simulation of Fuel Cell ForDocument30 pagesRenewable Energy System: Simulation of Fuel Cell ForVinayak KhandareNo ratings yet

- Reza Mokhtari (Mechanical Engineer) N0.52 Golestan 8Document4 pagesReza Mokhtari (Mechanical Engineer) N0.52 Golestan 8korosh_mokhtariNo ratings yet