Professional Documents

Culture Documents

670GLC PIN 1FF670GX F690001 Uptime Maintenance Planner

Uploaded by

Nelson Andrade VelasquezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

670GLC PIN 1FF670GX F690001 Uptime Maintenance Planner

Uploaded by

Nelson Andrade VelasquezCopyright:

Available Formats

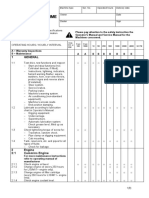

UPTIME MAINTENANCE PLANNER

Service Intervals

670GLC Excavator (PIN: 1FF670GX_ _F690001— )

Service Intervals

Service machine at intervals shown on this chart. Also, perform service on items at multiples of the original requirement. For example: at 500

hours, also service those items (if applicable) listed under 250 hours and 10 hours or daily.

Take fluid samples from each system as indicated on this form. The manufacturer of the fluid analysis kits will provide maintenance

recommendations based upon the results of the fluid analysis and the operating information supplied. Regular fluid sampling extends the

operational life of machine.

As Required

□ Drain fuel tank sump □ Drain primary water separators

□ Remove and clean fuel tank inlet screen □ Drain primary fuel filter and water separators

□ Clean radiator air inlet screen □ Check windshield washer fluid level

□ Check and adjust V-belts □ Check and adjust track sag

□ Clean or replace diesel exhaust fluid (DEF) tank inlet screen □ Clean rear camera lens

□ Clean and tighten battery terminals

Every 10 Hours or Daily

□ Check coolant level in recovery tank □ Lubricate working tool pivots and links

□ Check engine oil level □ Lubricate hydraulic coupler (if equipped)

□ Check hydraulic tank oil level

Every 50 Hours

□ Lubricate front end pin joints

Every 100 Hours

□ Inspect and re-torque track hardware

Every 250 Hours

□ Check hybrid battery electrolyte level (if equipped) □ Check pump drive gear case oil level

□ Check swing gear case oil level □ Drain water and sediment from hydraulic tank sump

□ Check travel gear case oil level □ Take engine oil sample

Every 500 Hours

□ Lubricate swing bearing gear □ Take hydraulic oil sample

□ Drain and refill engine oil and replace filters □ Take swing gear case oil sample

□ Check air intake hoses □ Take travel gear case oil sample

□ Replace primary fuel filter and water separators □ Take pump drive gear case oil sample

□ Replace final fuel filters □ Take diesel fuel sample

□ Lubricate swing bearing □ Take engine coolant sample

□ Clean cab fresh air and cab recirculating air filters (replace every 6 cleanings)

Every 1000 Hours

□ Drain and refill swing gear case oil □ Replace air conditioner V-belt

□ Drain and refill pump drive gear case oil □ Replace air cleaner elements

□ Check coolant condition □ Replace pilot system oil filter

□ Adjust engine valve lash □ Replace hydraulic tank oil filters

□ Replace pump case drain filter

Every 2000 Hours

Continued on next page MB60223,0000468 -19-24APR20-1/2

T364686X19(19AUG21)(ENGLISH) Worldwide Construction

And Forestry Division

PRINTED IN U.S.A.

□ Drain and refill travel gear case oil □ Replace primary water separators

Every 4000 Hours

□ Drain and refill hydraulic tank oil and clean suction screen □ Drain, flush, and refill cooling system

□ Replace hydraulic tank vent cap filter

Every 4500 Hours

□ Replace diesel exhaust fluid (DEF) dosing unit filter □ Replace diesel exhaust fluid (DEF) inlet bag filter

MB60223,0000468 -19-24APR20-2/2

T364686X19(19AUG21)(ENGLISH) Worldwide Construction

And Forestry Division

PRINTED IN U.S.A.

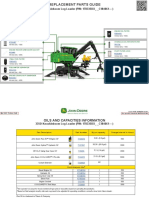

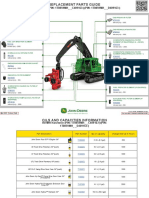

Required Parts

Ensure machine performance and availability; use only genuine John Deere parts. Verify that any associated parts are also on

hand, i.e., filter O-rings.

Every Every Every Every Every Every

Description Part Number 250 500 1000 2000 4000 4500

Hours Hours Hours Hours Hours Hours

Engine Oil Filter Element 8983758600 2 2 2 2 2

Final Fuel Filter Element 8983129180 2 2 2 2 2

Primary Fuel Filter Element 4676385R 2 2 2 2 2

Pump Case Drain Filter Element 4363399 1 1 1

Hydraulic Tank Oil Filter Element 4654745 2 2 2

Pilot System Oil Filter Element 4630525 1 1 1

Primary Air Filter Element AT179371 1 1 1

Secondary Air Filter Element AT179370 1 1 1

Air Conditioner V-Belt 4612763 1 1 1

Engine Rocker Arm Cover Gasket 1111731191 1 1 1

Primary Water Separator Element FYA00002973 2 2

Hydraulic Tank Vent Cap Filter Element 4437838 1

Diesel Exhaust Fluid (DEF) Dosing Unit Filter 8983507160 1

Diesel Exhaust Fluid (DEF) Inlet Bag Filter FYA00051789 1

Cab Fresh Air Filter Element 4S00686R As Required

Cab Recirculating Air Filter Element FYA00001490R As Required

John Deere Plus-50™ II Engine Oil and Pump Drive Gear Case 57.0 L 63.2 L 63.2 L 63.2 L 57.0 L

Oil1 (15.1 gal) (16.7 gal) (16.7 gal) (16.7 gal) (15.1 gal)

API GL-5 Swing Gear Case and Travel Gear Case Oil1 21.0 L 53.0 L 53.0 L

(5.5 gal) (14.0 gal) (14.0 gal)

Hitachi SUPER EX 46HN Hydraulic Oil1 380.0 L

(100.4 gal)

John Deere Cool-Gard™ II Pre-Mix 76.0 L

(20.1 gal)

Fluid Analysis Kits2

Diesel Engine Oil AT346594 1 1 1 1 1 1

Travel Gear Case Oil AT346594 2 2 2 2 2

Hydraulic Oil AT346594 1 1 1 1 1

Swing Gear Case Oil AT346594 1 1 1 1 1

Pump Drive Gear Case Oil AT346594 1 1 1 1 1

Diesel Fuel TY27329 1 1 1 1 1

Engine Coolant TY27787 1 1 1 1 1

1

See operator's manual for recommended oil type and oil viscosities based on operating temperatures.

2

Based on fluid analysis results, intervals may need to be adjusted for operating conditions. Consult an authorized John Deere dealer.

Plus-50 is a trademark of Deere & Company

Cool-Gard is a trademark of Deere & Company

KR46761,00014FE -19-11AUG21-1/1

Original Instructions. All information, illustrations and specifications COPYRIGHT © 2021

in this manual are based on the latest information available at the DEERE & COMPANY

time of publication. The right is reserved to make changes at any All rights are reserved

time without notice. A John Deere ILLUSTRUCTION ® Manual

Previous Edition 2015, 2017, 2019

This page intentionally left blank

You might also like

- Uptime Maintenance Planner: Service IntervalsDocument4 pagesUptime Maintenance Planner: Service IntervalsMauro ArteagaNo ratings yet

- 160GLC PIN 1FF160GX E055001 and 180GLC PIN 1FF180GX E020001 Uptime Maintenance PlannerDocument4 pages160GLC PIN 1FF160GX E055001 and 180GLC PIN 1FF180GX E020001 Uptime Maintenance PlannerNelson Andrade VelasquezNo ratings yet

- Uptime Maintenance Planner: Service IntervalsDocument2 pagesUptime Maintenance Planner: Service IntervalsJohn GrayNo ratings yet

- John Deere 300GLC - T357633X19 Maintenance PlannerDocument2 pagesJohn Deere 300GLC - T357633X19 Maintenance PlannerGeorge PlishkoNo ratings yet

- 200CLC 230CLC 270CLC Excavators Uptime Maintenance PlannerDocument4 pages200CLC 230CLC 270CLC Excavators Uptime Maintenance PlannerJaime MurilloNo ratings yet

- 524K II PIN 1DW524K F677549 Uptime Maintenance PlannerDocument3 pages524K II PIN 1DW524K F677549 Uptime Maintenance PlannerGabriel MarquesNo ratings yet

- 260E PIN 1DW260EX F677827 708124 310E PIN 1DW310EX F677827 708124 Uptime Maintenance PlannerDocument4 pages260E PIN 1DW260EX F677827 708124 310E PIN 1DW310EX F677827 708124 Uptime Maintenance PlannerNelson Andrade VelasquezNo ratings yet

- Uptime Maintenance Planner: Service IntervalsDocument2 pagesUptime Maintenance Planner: Service IntervalsJohn GrayNo ratings yet

- Uptime Maintenance Planner: Service IntervalsDocument3 pagesUptime Maintenance Planner: Service IntervalsBrian CareelNo ratings yet

- 210G and 210GLC PIN 1FF210GX E520001 Engine 6068HT086 Uptime Maintenance PlannerDocument2 pages210G and 210GLC PIN 1FF210GX E520001 Engine 6068HT086 Uptime Maintenance PlannerJaime MurilloNo ratings yet

- 310K 310SK 410K 310SKTMC 410KTMC T304355Document2 pages310K 310SK 410K 310SKTMC 410KTMC T304355Denis HernandezNo ratings yet

- 130G PIN 1FF130GX E040001 Uptime Maintenance PlannerDocument2 pages130G PIN 1FF130GX E040001 Uptime Maintenance PlannerGabriel ViniciusNo ratings yet

- 710L PIN 1T0710LX F294268 390995 Uptime Maintenance PlannerDocument4 pages710L PIN 1T0710LX F294268 390995 Uptime Maintenance PlannerNelson Andrade VelasquezNo ratings yet

- 310L 310SL 315SL 325SL and 410L Backhoe Loaders Uptime Maintenance Planner See Document For PINs PDFDocument4 pages310L 310SL 315SL 325SL and 410L Backhoe Loaders Uptime Maintenance Planner See Document For PINs PDFNelson Andrade VelasquezNo ratings yet

- 460E - ADT - Uptime Maintenance PlannerDocument3 pages460E - ADT - Uptime Maintenance PlannerBassieNo ratings yet

- 670D 672D 770D 772D 870D 872D Motor Graders Uptime Maintenance PlannerDocument4 pages670D 672D 770D 772D 870D 872D Motor Graders Uptime Maintenance PlannerNelson Andrade Velasquez100% (1)

- 803M 853M 859M S N F293917 409162 L343918 409162 and 803MH 853MH 859MH S N F293764 409162 L343918 409162 Uptime Maintenance PlannerDocument4 pages803M 853M 859M S N F293917 409162 L343918 409162 and 803MH 853MH 859MH S N F293764 409162 L343918 409162 Uptime Maintenance PlannerNelson Andrade VelasquezNo ratings yet

- 624K 4WD Loader (S.N. - 642634) Engines 6068HDW79 and 6068HDW83Document2 pages624K 4WD Loader (S.N. - 642634) Engines 6068HDW79 and 6068HDW83John Gray100% (1)

- Uptime Maintenance Planner: Service IntervalsDocument2 pagesUptime Maintenance Planner: Service IntervalsJohn GrayNo ratings yet

- Intervalos de ServicioDocument2 pagesIntervalos de ServicioAlejandro ValenzuelaNo ratings yet

- 670GLC (PIN: 1FF670GX - E670001-) : As RequiredDocument2 pages670GLC (PIN: 1FF670GX - E670001-) : As RequiredJohn GrayNo ratings yet

- Catalogo Patrol 672GDocument4 pagesCatalogo Patrol 672GJulio cesarNo ratings yet

- John Deere 724KDocument2 pagesJohn Deere 724KMMM-MMMNo ratings yet

- 120D Uptime Maintenance PlannerDocument2 pages120D Uptime Maintenance PlannerNelson Andrade VelasquezNo ratings yet

- 470GLC (PIN: 1FF470GX - E470001-) : As RequiredDocument2 pages470GLC (PIN: 1FF470GX - E470001-) : As RequiredBrian CareelNo ratings yet

- 544K (PIN: 1DW544KZ - D642685 - ) : As RequiredDocument2 pages544K (PIN: 1DW544KZ - D642685 - ) : As Requiredingcalderon100% (1)

- 744J S N 590070 824J S N 590070 Uptime Maintenance PlannerDocument2 pages744J S N 590070 824J S N 590070 Uptime Maintenance PlannerIsma MontoyaNo ratings yet

- 350DLC T221117Document2 pages350DLC T221117Brian CareelNo ratings yet

- 330clc Plan MttoDocument2 pages330clc Plan MttoJuan FloresNo ratings yet

- 644K PIN 1DW644K D658218 PIN 1DW644K C658218 Uptime Maintenance PlannerDocument2 pages644K PIN 1DW644K D658218 PIN 1DW644K C658218 Uptime Maintenance Plannererick huancaya bartraNo ratings yet

- John DeereDocument2 pagesJohn DeereMMM-MMMNo ratings yet

- John Deere 524KDocument2 pagesJohn Deere 524KMMM-MMMNo ratings yet

- 444J 544J 624J Uptime Maintenance PlannerDocument2 pages444J 544J 624J Uptime Maintenance PlannerBryant Legarda GarcésNo ratings yet

- 180CW 210CW Uptime Maintenance PlannerDocument2 pages180CW 210CW Uptime Maintenance PlannerAlex Sandro dos SantosNo ratings yet

- 330G PIN 1T0330G F300253 331G PIN 1T0331G F300253 332G PIN 1T0332G F300253 333G PIN 1T0333G F300253 Uptime Maintenance PlannerDocument2 pages330G PIN 1T0330G F300253 331G PIN 1T0331G F300253 332G PIN 1T0332G F300253 333G PIN 1T0333G F300253 Uptime Maintenance PlannerNelson Andrade VelasquezNo ratings yet

- Uptime Maintenance Planner: Service IntervalsDocument2 pagesUptime Maintenance Planner: Service Intervalsinsincos administrativoNo ratings yet

- Engines 6090HDW01, 6090HDW04 770G, 772G, 770GP, and 772GP Motor Grader (S.N. 634754-)Document2 pagesEngines 6090HDW01, 6090HDW04 770G, 772G, 770GP, and 772GP Motor Grader (S.N. 634754-)Brian Careel100% (1)

- 335D PIN 1T0335DX C184061 and 437D PIN 1T0437DX C254106 Uptime Maintenance PlannerDocument2 pages335D PIN 1T0335DX C184061 and 437D PIN 1T0437DX C254106 Uptime Maintenance PlannerNelson Andrade VelasquezNo ratings yet

- 310G, 310SG and 315SG: As RequiredDocument2 pages310G, 310SG and 315SG: As Requiredp0t2g047No ratings yet

- 310J, 310SJ, 315SJ and 410J: As RequiredDocument2 pages310J, 310SJ, 315SJ and 410J: As Requiredhannelore.fineman8327100% (1)

- 850J Uptime T224253Document2 pages850J Uptime T224253Jose Luis Rojas AzuaNo ratings yet

- Mantenimiento 120C 160C LCDocument2 pagesMantenimiento 120C 160C LCGustavo Gonzalez100% (1)

- 724K John Deere MantenimientoDocument2 pages724K John Deere MantenimientoErwin Castro100% (1)

- Lubrication and Maintenance: General InformationDocument1,896 pagesLubrication and Maintenance: General InformationTonyNo ratings yet

- 12-20T MAINTENANCE MANUAL ZoomlionDocument23 pages12-20T MAINTENANCE MANUAL ZoomlionAbas AbasariNo ratings yet

- PM 4000 SeriesDocument3 pagesPM 4000 SeriesmohamedNo ratings yet

- PC1250 1000HR LUBICATIONDocument5 pagesPC1250 1000HR LUBICATIONJamyansuren TseveendorjNo ratings yet

- Dongfeng Dfa1063dj10 14 301 303 Service Manual 2006 09Document10 pagesDongfeng Dfa1063dj10 14 301 303 Service Manual 2006 09gary100% (51)

- PC 1250 500 HR Service SheetDocument5 pagesPC 1250 500 HR Service SheetJamyansuren TseveendorjNo ratings yet

- Marine Diesel Engine Service RecordsDocument3 pagesMarine Diesel Engine Service RecordsAzael Enrique Vergara GonzalezNo ratings yet

- Service Manual: DONGFENG DFA1063DJ10 (14) - 301/303Document142 pagesService Manual: DONGFENG DFA1063DJ10 (14) - 301/303Yonny ColqueNo ratings yet

- Check Sheet PS Pc78uu-6 EditDocument3 pagesCheck Sheet PS Pc78uu-6 EditToko SerbaNo ratings yet

- Service Program - CE Excapator KOREADocument8 pagesService Program - CE Excapator KOREAtele123No ratings yet

- Uptime Maintenance Planner: Service IntervalsDocument2 pagesUptime Maintenance Planner: Service IntervalsJohn Gray100% (1)

- TOPIC 10 LubricationDocument29 pagesTOPIC 10 LubricationVLADIMIR VERA VELARDE100% (1)

- SB 063 Issue 2 - 4000 Series - Preventive Maintenance ScheduleDocument3 pagesSB 063 Issue 2 - 4000 Series - Preventive Maintenance Scheduleaung minhtetNo ratings yet

- PC 1250 5000 HR Service SheetDocument5 pagesPC 1250 5000 HR Service SheetJamyansuren TseveendorjNo ratings yet

- Bobcat S630 maintenance schedule and filter guideDocument4 pagesBobcat S630 maintenance schedule and filter guideMohamed SaiedNo ratings yet

- Major Process Equipment Maintenance and RepairFrom EverandMajor Process Equipment Maintenance and RepairRating: 4 out of 5 stars4/5 (4)

- Analysis of Engineering Cycles: Power, Refrigerating and Gas Liquefaction PlantFrom EverandAnalysis of Engineering Cycles: Power, Refrigerating and Gas Liquefaction PlantNo ratings yet

- 310L Backhoe Loader Engine 4045HT082 4045HT096 PIN 1T0310LX F273920 390995 IntroductionDocument7 pages310L Backhoe Loader Engine 4045HT082 4045HT096 PIN 1T0310LX F273920 390995 IntroductionFelipe FarfanNo ratings yet

- 260E PIN 1DW260EX F677827 708124 310E PIN 1DW310EX F677827 708124 Uptime Maintenance PlannerDocument4 pages260E PIN 1DW260EX F677827 708124 310E PIN 1DW310EX F677827 708124 Uptime Maintenance PlannerNelson Andrade VelasquezNo ratings yet

- 330G PIN 1T0330G F300253 331G PIN 1T0331G F300253 332G PIN 1T0332G F300253 333G PIN 1T0333G F300253 Uptime Maintenance PlannerDocument2 pages330G PIN 1T0330G F300253 331G PIN 1T0331G F300253 332G PIN 1T0332G F300253 333G PIN 1T0333G F300253 Uptime Maintenance PlannerNelson Andrade VelasquezNo ratings yet

- 6601 Pull Type Combine IntroductionDocument4 pages6601 Pull Type Combine IntroductionNelson Andrade VelasquezNo ratings yet

- 310E 310SE and 315SE Backhoe Loaders IntroductionDocument5 pages310E 310SE and 315SE Backhoe Loaders IntroductionJhonny GarciaNo ratings yet

- 310E PIN 1DW310EX F677827 708124 Replacement Parts GuideDocument5 pages310E PIN 1DW310EX F677827 708124 Replacement Parts GuideNelson Andrade VelasquezNo ratings yet

- 310E Articulated Dump Truck PIN 1DW310EX F677827 708124 IntroductionDocument6 pages310E Articulated Dump Truck PIN 1DW310EX F677827 708124 IntroductionNelson Andrade VelasquezNo ratings yet

- 335D Knuckleboom Log Loader PIN 1T0335DX C184061 Replacement Parts GuideDocument3 pages335D Knuckleboom Log Loader PIN 1T0335DX C184061 Replacement Parts GuideNelson Andrade VelasquezNo ratings yet

- 470GLC PIN 1FF470GX E470001 Uptime Maintenance PlannerDocument4 pages470GLC PIN 1FF470GX E470001 Uptime Maintenance PlannerNelson Andrade VelasquezNo ratings yet

- 670D 672D 770D 772D 870D 872D Motor Graders Uptime Maintenance PlannerDocument4 pages670D 672D 770D 772D 870D 872D Motor Graders Uptime Maintenance PlannerNelson Andrade Velasquez100% (1)

- 544E and 624E Loaders 544E TC Tool Carriers and 544E LL Log Loader IntroductionDocument10 pages544E and 624E Loaders 544E TC Tool Carriers and 544E LL Log Loader IntroductionNelson Andrade VelasquezNo ratings yet

- 710L PIN 1T0710LX F294268 390995 Uptime Maintenance PlannerDocument4 pages710L PIN 1T0710LX F294268 390995 Uptime Maintenance PlannerNelson Andrade VelasquezNo ratings yet

- 333G Compact Track Loader PIN 1T0333G F300253 Replacement Parts GuideDocument3 pages333G Compact Track Loader PIN 1T0333G F300253 Replacement Parts GuideNelson Andrade VelasquezNo ratings yet

- 335D Knuckleboom Log Loader PIN 1T0335DX C184061 IntroductionDocument7 pages335D Knuckleboom Log Loader PIN 1T0335DX C184061 IntroductionNelson Andrade VelasquezNo ratings yet

- 335D PIN 1T0335DX C184061 and 437D PIN 1T0437DX C254106 Uptime Maintenance PlannerDocument2 pages335D PIN 1T0335DX C184061 and 437D PIN 1T0437DX C254106 Uptime Maintenance PlannerNelson Andrade VelasquezNo ratings yet

- 410G Uptime Maintenance PlannerDocument2 pages410G Uptime Maintenance PlannerNelson Andrade VelasquezNo ratings yet

- Uptime Maintenance Planner: Service IntervalsDocument2 pagesUptime Maintenance Planner: Service Intervalsluis eduardo corzo enriquezNo ratings yet

- 803M 853M 859M S N F293917 409162 L343918 409162 and 803MH 853MH 859MH S N F293764 409162 L343918 409162 Uptime Maintenance PlannerDocument4 pages803M 853M 859M S N F293917 409162 L343918 409162 and 803MH 853MH 859MH S N F293764 409162 L343918 409162 Uptime Maintenance PlannerNelson Andrade VelasquezNo ratings yet

- 120D Uptime Maintenance PlannerDocument2 pages120D Uptime Maintenance PlannerNelson Andrade VelasquezNo ratings yet

- 859MH Tracked Harvester PIN 1T0859MH F293764 409162 PIN 1T0859MH L343926 409162 Replacement Parts GuideDocument5 pages859MH Tracked Harvester PIN 1T0859MH F293764 409162 PIN 1T0859MH L343926 409162 Replacement Parts GuideNelson Andrade VelasquezNo ratings yet

- 909M Tracked Feller Buncher PIN 1T0909MX C271505 PIN 1T0909MX D271505 Replacement Parts GuideDocument3 pages909M Tracked Feller Buncher PIN 1T0909MX C271505 PIN 1T0909MX D271505 Replacement Parts GuideNelson Andrade VelasquezNo ratings yet

- Uptime Maintenance Planner: Service IntervalsDocument2 pagesUptime Maintenance Planner: Service Intervalsluis eduardo corzo enriquezNo ratings yet

- 330G PIN 1T0330G F300253 Replacement Parts GuideDocument3 pages330G PIN 1T0330G F300253 Replacement Parts GuideNelson Andrade VelasquezNo ratings yet

- 318G Skid Steer Loader PIN 1T0318G J288093 Replacement Parts GuideDocument3 pages318G Skid Steer Loader PIN 1T0318G J288093 Replacement Parts GuideNelson Andrade VelasquezNo ratings yet

- 333G Compact Track Loader PIN 1T0333G F387881 Replacement Parts GuideDocument3 pages333G Compact Track Loader PIN 1T0333G F387881 Replacement Parts GuideNelson Andrade VelasquezNo ratings yet

- 759JH Tracked Feller Buncher Harvester Leveling PIN 1T0759JH C220452 Replacement Parts GuideDocument3 pages759JH Tracked Feller Buncher Harvester Leveling PIN 1T0759JH C220452 Replacement Parts GuideNelson Andrade Velasquez100% (1)

- 316GR Skid Steer Loader PIN 1T0316G G298752 Replacement Parts GuideDocument3 pages316GR Skid Steer Loader PIN 1T0316G G298752 Replacement Parts GuideNelson Andrade Velasquez100% (1)

- Parts Manual Cat 420eDocument5 pagesParts Manual Cat 420eNelson Andrade VelasquezNo ratings yet

- AiNEX 2015 Brochure - Form - RulesDocument3 pagesAiNEX 2015 Brochure - Form - Ruleskabuto riderNo ratings yet

- Lane Departure AssistDocument3 pagesLane Departure AssistMartynas RamanauskasNo ratings yet

- Ansoff MatrixDocument1 pageAnsoff MatrixManveen ArnejaNo ratings yet

- ToLiss AirbusA321 V1.3.1 TutorialDocument109 pagesToLiss AirbusA321 V1.3.1 TutorialBattle Saga100% (1)

- Engine 1104d Euro 3 - 120cvDocument304 pagesEngine 1104d Euro 3 - 120cvKaloyanNo ratings yet

- SAFETY-manual Mobile CraneDocument84 pagesSAFETY-manual Mobile CraneLuffy11No ratings yet

- Cesabb 300 B 400Document8 pagesCesabb 300 B 400BeyzaNo ratings yet

- Ahu SpecificationDocument8 pagesAhu SpecificationUzair QuraishiNo ratings yet

- Roots Easyair X2: Factory Blower Package SystemDocument8 pagesRoots Easyair X2: Factory Blower Package SystemAndrey GyrychNo ratings yet

- FERNANDODocument4 pagesFERNANDOFernando FiorilloNo ratings yet

- Toyota FM 2632 6x4 Cab Chassis SpecsDocument4 pagesToyota FM 2632 6x4 Cab Chassis SpecspendiNo ratings yet

- Parts & Service Manual MODEL 1750-CDocument57 pagesParts & Service Manual MODEL 1750-CEric GrunstNo ratings yet

- Tesla Utilization of Robotics Process AutomationDocument8 pagesTesla Utilization of Robotics Process AutomationAlexander KimaniNo ratings yet

- Diagrama Eléctrico Chevrolet s10 - Luv 2.2Document6 pagesDiagrama Eléctrico Chevrolet s10 - Luv 2.2Luis PerezNo ratings yet

- Combination Tool WFTDocument11 pagesCombination Tool WFTCarlos HolguinNo ratings yet

- Parts & Accessories CatalogDocument56 pagesParts & Accessories CatalogGiri DanuartoNo ratings yet

- Jaguar Land Rover ReportDocument3 pagesJaguar Land Rover ReportAmar narayanNo ratings yet

- Technical Bulletin #065: Lugs The EngineDocument3 pagesTechnical Bulletin #065: Lugs The EngineMario MastronardiNo ratings yet

- 8) O & M Manual PristineDocument2 pages8) O & M Manual PristineWan HaikalNo ratings yet

- 1 Description and OperationDocument67 pages1 Description and OperationangelNo ratings yet

- Divertor DamperDocument53 pagesDivertor DamperfaisalnadimNo ratings yet

- Lecture 6Document39 pagesLecture 6Kashka IraniNo ratings yet

- BMW M57D30 EngineDocument5 pagesBMW M57D30 EngineCallum Smith83% (6)

- Iso 6195 - 2013eDocument24 pagesIso 6195 - 2013eDeivson SILVANo ratings yet

- Supermach UTV700 Service Manual WholeDocument361 pagesSupermach UTV700 Service Manual WholeWillie Fowler75% (8)

- 2016 SunnySedan Owner ManualDocument386 pages2016 SunnySedan Owner ManualA QanasNo ratings yet

- ABB manual for induction motors and generatorsDocument146 pagesABB manual for induction motors and generatorsRama Samy100% (2)

- 6991 5374 62b Explorac E100 PDFDocument360 pages6991 5374 62b Explorac E100 PDFJoseAntonioQuintanillaPoncedeLeon75% (4)

- Furniture Catalogue 2014Document54 pagesFurniture Catalogue 2014Sharmadave SubramaniamNo ratings yet

- KTA50 ESN 25329037 Parts ListDocument8 pagesKTA50 ESN 25329037 Parts ListNikkikumarNo ratings yet