Professional Documents

Culture Documents

Preventive Maintenance Service

Uploaded by

Jenry JonathanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Preventive Maintenance Service

Uploaded by

Jenry JonathanCopyright:

Available Formats

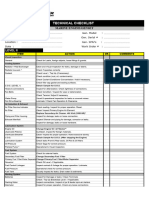

PREVENTIVE MAINTENANCE SERVICE

Asset Name : Maintenance Date :

Service Type : Periodic Engine Hours :

Executor : Next Service :

Status

Item Service Remarks

Satisfactory Unsatisfactory

Check the engine, radiator, and generator for debris, foreign objects,

Visual Check loose or broken fittings, guards, and components. Repair

as necessary.

Belts Check for worn, broken, or loose belts (alternator, fan, drive, etc.).

Cooling System Check and maintain proper coolant level.

Check for proper operation. Maintain 32°C (90°F) coolant

Block Heater

temperature in the block at all times.

Check the indicator. Change the air cleaner elements when the

Air Cleaner Indicator

indicator diaphragm remains locked.

Check the oil level. Maintain the oil level between the add and full

Engine Crankcase

marks on the engine stopped side of the dipstick.

Governor Check and maintain the oil level (if required).

Check for leaks and drain water separator (if equipped). Keep fuel

Fuel System

tank full. Check fuel filter indicator (if equipped).

Air System (II

Drain condensate; check air pressure.

Equipped)

Maintain electrolyte level, clean batteries if necessary, check for tight

Batteries

connections.

Check the condition of all gauges. Repair or replace any broken

Gauges

gauge.

Battery Charger Check for proper operation.

Generator and Visual inspection – check for loose, broken, or damaged wiring or

Control Panel components.

Check the generator operation and the engine starting, lubricating,

and fuel systems as well as overall operation. The checks should take

Engine no longer than five (5) minutes to complete. Longer periods of

operation are not required. A more beneficial test will be performed

with the engine operating under load.

Check for proper operating oil pressure. Refer to the Operation and

Oil Pressure

Maintenance Guide for the correct pressure reading.

Check for proper operating fuel pressure. Refer to the Operation and

Fuel Pressure

Maintenance Guide for the correct pressure reading.

Check the oil level. Maintain the oil level between the add and full

Engine Crankcase

marks on the engine running side of the dipstick.

Check and record readings. NOTE: The operating voltage of a cold

(just started) generator will be slightly higher than the operating

Frequency (rpm) voltage of a generator that has been under load and warm. The full

and Generated load voltage of a generator will decrease a maximum of 1% when

Voltage the generator stabilizes at 100°C (212°F). Most of the voltage

decrease occurs in about 30 minutes. Generally, temperatures of

generators stabilize within two hours.

Radiator Louvers Check for proper operation (able to open and close freely).

Check for leaks and unusual noises. NOTE: Engine must be stopped

Leaks and Noises

before making necessary repairs.

Automatic Switches

Check that all switches are in proper position for automatic start.

(If Equipped)

Fuel Level Check the fuel level refill when below three-fourths full.

Battery Charger Record charging amperage reading.

Malfunctions Report any malfunction and make necessary repairs.

Comments:

Executed by, Acknowledged by, Approved by,

( ) ( ) ( )

You might also like

- Major Process Equipment Maintenance and RepairFrom EverandMajor Process Equipment Maintenance and RepairRating: 4 out of 5 stars4/5 (4)

- Standby Generator Set Pre-Operation Checklist: Before Starting The EngineDocument4 pagesStandby Generator Set Pre-Operation Checklist: Before Starting The EngineMartie ClustersNo ratings yet

- Maintenance Instruction V03Document18 pagesMaintenance Instruction V03Farooq AhmadNo ratings yet

- General InformationDocument111 pagesGeneral Informationkhaledserag23No ratings yet

- Technical Report Checklist - MARINE ENGINESDocument2 pagesTechnical Report Checklist - MARINE ENGINESsary qasimNo ratings yet

- Emergency Generator MaintenanceDocument8 pagesEmergency Generator MaintenanceGerardo Rubio100% (1)

- Monthly PM - EDGDocument3 pagesMonthly PM - EDGMuhammad RosihanNo ratings yet

- A Standby Generator Maintenance ChecklistDocument1 pageA Standby Generator Maintenance ChecklistMelky LumainNo ratings yet

- LV HiluxDocument8 pagesLV HiluxAdie PranataNo ratings yet

- Inspection and Preventive Maintenance: ServicereportDocument2 pagesInspection and Preventive Maintenance: ServicereportMoz KamalNo ratings yet

- Generator MaintenanceDocument1 pageGenerator MaintenancealiNo ratings yet

- Injection Molding MaintainanceDocument28 pagesInjection Molding MaintainanceShubham Chaudhary0% (1)

- Manual Mantenimiento Yanmar 4TNV98TDocument29 pagesManual Mantenimiento Yanmar 4TNV98Tdavid ignacioNo ratings yet

- Recommended Actions: Transmission or Engine Accessories (If Applicable)Document3 pagesRecommended Actions: Transmission or Engine Accessories (If Applicable)sjsshipNo ratings yet

- 50 200 Cylinder Diesel EngineDocument30 pages50 200 Cylinder Diesel EngineFranklin FernandezNo ratings yet

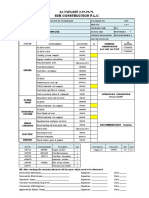

- Item Qty Price/unit Total Engine Maintenance X 2 EnginesDocument2 pagesItem Qty Price/unit Total Engine Maintenance X 2 EnginesMario RimandoNo ratings yet

- Nom de Technicien Signature Durée D'intervention: Ordinary Maintenance 100 H For Forklift Fantuzzi (FDC250)Document8 pagesNom de Technicien Signature Durée D'intervention: Ordinary Maintenance 100 H For Forklift Fantuzzi (FDC250)Peix HichamNo ratings yet

- Method Statement For Testing & Commissioning of DG SetDocument5 pagesMethod Statement For Testing & Commissioning of DG Setaslam shaikh100% (1)

- Precommissioning Procedure For Diesel GeneratorDocument2 pagesPrecommissioning Procedure For Diesel GeneratorBabu100% (1)

- Startup Inspection ChecklistDocument2 pagesStartup Inspection ChecklistMouayed Zeadan100% (1)

- 0298 199 0 SV en 300Document56 pages0298 199 0 SV en 300andis_a100% (1)

- Nissan Certified Pre-Owned Inspection ChecklistDocument2 pagesNissan Certified Pre-Owned Inspection Checklistnuryakhin seNo ratings yet

- (PTM) Maintenance and Trouble ShootingDocument18 pages(PTM) Maintenance and Trouble ShootingdilaNo ratings yet

- MFM Consolidated Preventive Maintenance Ver 2 - 3132017Document201 pagesMFM Consolidated Preventive Maintenance Ver 2 - 3132017Paul CansinoNo ratings yet

- Maintenance Intervals: S SE ER RV Viic CE ES SC CH HE ED DU UL LE EDocument3 pagesMaintenance Intervals: S SE ER RV Viic CE ES SC CH HE ED DU UL LE EROVER RONY VALENCIA CERNANo ratings yet

- Gig-Service Bus PM Check ListDocument7 pagesGig-Service Bus PM Check Listalexberhane3No ratings yet

- JCB VM115 Single Drum RollerDocument9 pagesJCB VM115 Single Drum Roller江柄宏100% (1)

- Pages From 432912277-Manual-Air-Compresor-Atlas Copco-GA75-2-20Document4 pagesPages From 432912277-Manual-Air-Compresor-Atlas Copco-GA75-2-20Tolias EgwNo ratings yet

- Alexander Bubenik Cessna 182Q ChecklistDocument2 pagesAlexander Bubenik Cessna 182Q ChecklistWarrior TempurNo ratings yet

- Wheeloader 980HDocument8 pagesWheeloader 980HAdie PranataNo ratings yet

- DG Operator InterviewDocument24 pagesDG Operator InterviewZez Samuel100% (2)

- ServiceTATA Bus PM Check ListDocument7 pagesServiceTATA Bus PM Check Listalexberhane3No ratings yet

- EMD-003-0 Pre-Used Inspection Checklist For EquipmentsDocument31 pagesEMD-003-0 Pre-Used Inspection Checklist For EquipmentsArjay AlvarezNo ratings yet

- Fuel Truck Operator's Daily ChecklistDocument1 pageFuel Truck Operator's Daily ChecklistTFattah0% (1)

- Initial 250hrs PM HD465-7Document5 pagesInitial 250hrs PM HD465-7Jamyansuren TseveendorjNo ratings yet

- Failure ReportDocument3 pagesFailure ReportCrisdiantoNo ratings yet

- Chklist HEXDocument3 pagesChklist HEXluisNo ratings yet

- Check Sheet PS Pc78uu-6 EditDocument3 pagesCheck Sheet PS Pc78uu-6 EditToko SerbaNo ratings yet

- Sec 15C (4HL1)Document9 pagesSec 15C (4HL1)Susilo purwanggiNo ratings yet

- Cat D8R-T2Document1 pageCat D8R-T2Awet TesafyNo ratings yet

- Maintenance and LubricationDocument34 pagesMaintenance and Lubricationtoppen_76100% (1)

- Generators Expected ServicesDocument3 pagesGenerators Expected Servicesmoaz zahidNo ratings yet

- Excavadora Oruga HX85A Maintenance StandardsDocument37 pagesExcavadora Oruga HX85A Maintenance StandardscmhNo ratings yet

- Fire Pump Acceptance Testing CriteriaDocument6 pagesFire Pump Acceptance Testing Criteriadaniel benitezNo ratings yet

- Commissioning Procedure For Diesel GeneratorDocument3 pagesCommissioning Procedure For Diesel Generatorthilanka0650% (4)

- 15C (4JA1) enDocument5 pages15C (4JA1) enARIF RACHMANNo ratings yet

- Inspección Equipo BM 2000 2200 - 2013 - enDocument3 pagesInspección Equipo BM 2000 2200 - 2013 - enCesarNo ratings yet

- Gig-Service Bus PM Check ListDocument6 pagesGig-Service Bus PM Check Listalexberhane3No ratings yet

- Engstrom CarestationDocument24 pagesEngstrom CarestationmaruthaiNo ratings yet

- Generator PM ChecklistDocument2 pagesGenerator PM ChecklistYan's Senora Bescoro100% (3)

- Manual de Instruçao CondensadoraDocument55 pagesManual de Instruçao CondensadoraMatheus PestanaNo ratings yet

- Ame PDFDocument26 pagesAme PDFH R VALANo ratings yet

- PC 1250 Initial 100 HR Service SheetDocument4 pagesPC 1250 Initial 100 HR Service SheetJamyansuren TseveendorjNo ratings yet

- Engine Controls and Fuel (ALL Diagnostic Trouble Codes (DTC) ) - ALLDATA RepairP0507Document4 pagesEngine Controls and Fuel (ALL Diagnostic Trouble Codes (DTC) ) - ALLDATA RepairP0507Juan Antonio Ochoa PadronNo ratings yet

- Rexton Y200Document1,627 pagesRexton Y200Xuân Hùng NguyễnNo ratings yet

- General Information: Section 0BDocument3,772 pagesGeneral Information: Section 0BLeandro Lcar AutomotivoNo ratings yet

- Qa10 PS GD535-5Document3 pagesQa10 PS GD535-5Andaru GunawanNo ratings yet

- Generator PM SOWsbsDocument1 pageGenerator PM SOWsbsVinay ThakurNo ratings yet

- Maintenance Trouble Shooting of Voith CouplingDocument20 pagesMaintenance Trouble Shooting of Voith CouplingPRAMOD KUMAR NANDANo ratings yet

- Sample Chapter II - Related LiteraturesDocument13 pagesSample Chapter II - Related LiteraturesKevin Adrian ZorillaNo ratings yet

- NSP/004/109 (OHI 9) Guidance On Anti-Climbing Devices, Safety Signs and Labels Required On Overhead Line SupportsDocument25 pagesNSP/004/109 (OHI 9) Guidance On Anti-Climbing Devices, Safety Signs and Labels Required On Overhead Line SupportsMuhammad BilalNo ratings yet

- QP - PDF Class XIth MathsDocument7 pagesQP - PDF Class XIth MathsSivakumar NairNo ratings yet

- Alternative Strategies - CorporateDocument35 pagesAlternative Strategies - CorporateFungJingYun VivianNo ratings yet

- Factors Affecting Online Buying BehaviorDocument17 pagesFactors Affecting Online Buying BehaviorJohn DoeNo ratings yet

- An Introduction To Mathematical ReasoninDocument3 pagesAn Introduction To Mathematical ReasoninGero Nimo100% (1)

- 16b. Present Continuous TenseDocument9 pages16b. Present Continuous TenseGung PanjiNo ratings yet

- Proposal For Improvement of Infant Toddler Weighing ScaleDocument6 pagesProposal For Improvement of Infant Toddler Weighing ScaleYuna-chan KatsuraNo ratings yet

- Business Branding - The Art of War in The Marketing World With Jun WuDocument1 pageBusiness Branding - The Art of War in The Marketing World With Jun Wusundevil2010usa4605No ratings yet

- The Secret Behind 432Hz Tuning - Attuned VibrationsDocument2 pagesThe Secret Behind 432Hz Tuning - Attuned VibrationsAdityaCaesarNo ratings yet

- Wave AlphaDocument116 pagesWave AlphaListedlee LeeNo ratings yet

- Ti ArgusDocument54 pagesTi ArgusVio ViorelNo ratings yet

- MMS - ZTE Network - MO and MT - SGSN TraceDocument25 pagesMMS - ZTE Network - MO and MT - SGSN TraceSunny Girija SapruNo ratings yet

- MG100-M85 Reference Design - 20140815Document3 pagesMG100-M85 Reference Design - 20140815Defrian SupriadyNo ratings yet

- Cloze Test: Complete The Text Wtih The Correct WordsDocument2 pagesCloze Test: Complete The Text Wtih The Correct WordsSo ToysNo ratings yet

- Microsoft PPT - Module4 - OrganisationChart&GraphDocument8 pagesMicrosoft PPT - Module4 - OrganisationChart&GraphOnez WanNo ratings yet

- Independent Auditor's ReportDocument9 pagesIndependent Auditor's Reporttidomam303No ratings yet

- ART in AsiaDocument3 pagesART in AsiaMark Joseph Corum EsmenioNo ratings yet

- Syllabus Statistiek 3 UMDocument65 pagesSyllabus Statistiek 3 UMyuripiosikNo ratings yet

- Noc22 bt10Document2 pagesNoc22 bt10Asmita MoulickNo ratings yet

- Module 1Document14 pagesModule 1Sungha Jhun0% (1)

- Character Personality ClothesDocument3 pagesCharacter Personality ClothesMelania AnghelusNo ratings yet

- Codecon Tito Jankowski Apr18Document14 pagesCodecon Tito Jankowski Apr18titojankowskiNo ratings yet

- Electrical Power Distribution & Utilization EE-359Document36 pagesElectrical Power Distribution & Utilization EE-359MarwaNo ratings yet

- Saurashtra University B. Sc. IT (English) 2019Document3 pagesSaurashtra University B. Sc. IT (English) 2019Aditya PatelNo ratings yet

- Concept of Statistical Quality ControlDocument51 pagesConcept of Statistical Quality ControlTehmeena BegumNo ratings yet

- Mock Test Mock TestDocument9 pagesMock Test Mock TestQUANG DUNG DENIS LAINo ratings yet

- XXXVI. Paper and Board For Food Contact: As of 01.04.2022Document17 pagesXXXVI. Paper and Board For Food Contact: As of 01.04.2022刘佳奇No ratings yet

- Grading Dam Spillway Civil 3dDocument18 pagesGrading Dam Spillway Civil 3dmqueroNo ratings yet

- Topic 4.4 FormativeDocument2 pagesTopic 4.4 FormativebubbleteaNo ratings yet