Professional Documents

Culture Documents

Inspección Equipo BM 2000 2200 - 2013 - en

Uploaded by

CesarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inspección Equipo BM 2000 2200 - 2013 - en

Uploaded by

CesarCopyright:

Available Formats

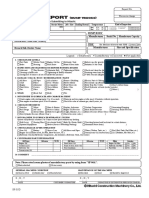

MACHINE INSPECTION Issue

Cold Milling Machine 01/2013

BM 2000...2200/60-2

Kind of machine

Machine type

Year of

Serial number construction:

Operating hours: Hours Date:

last expert inspection Hours Date:

last service Hours Date:

OK

Component yes / no rectified Comment

1. General

If the machine is soiled with oil or dirt, it must be

washed.

Is there corrosion on bearing, functional

components

tight fit of screw connections

Wear of track pads

Wear of rubber parts (conveyor belt, scraper-

discharge)

Accessories:

Operating instructions: correct instructions completely

ex-factory tools are present

2.

Electrics

Lighting : Check front/rear/working lights (if present),

backup alarm, flashing beacon and signal lamps

Battery: check the acid level/clean and grease the

poles, check open-circuit and charge voltage

Read out machine error codes, rectify faults if

necessary

Read out error log and engine control unit, rectify faults

if necessary (trouble shooting in display)

3.

Electrics function test (with the engine shut down)

Self test (display)

Software version

Starter interlock (travel lever, rotor switch, milling tool

replacement switch, PAUSE mode, brake lock/parking

position)

4. Electrics function test (engine running, emergency

shut-down)

EMERGENCY STOP (5x)

Engine air filter

Water separator

Hydraulic oil filter differential pressure switch

Coolant level display

Check coolant concentration and last change, change

coolant, if necessary*, enter the measured actual frost

protection value

_______ °C

Water tank filling level

Fuel system ventilation/starting and running behaviour

5. Filling levels

Engine oil (mark on dipstick)

BOMAG ALL-ROUND CHECK Page 1 of 3

MACHINE INSPECTION Issue

Cold Milling Machine 01/2013

BM 2000...2200/60-2

OK

Component yes / no rectified Comment

Coolant and fuel acc. to display

Check oil level in milling gear

Travel gear oil level

Hydraulic oil, milling gear

6. Function and travel test (observe the general

safety regulations QSA 801)

Check all filling levels visually before driving the

machine. Check travel and steering functions, all

hydraulic functions, milling rotor. Check visually for

leaks.

Condition of frame, transport eyelets.

check all V-belts, replace if necessary*

check power belt of milling rotor drive, replace if necessary*

Check hoses for ageing and damage.

Measurement and setting of components as per

measurement protocol (see below)

7. Electr. functions and operating elements on the

driver's stand

Display units

Sockets

RPM-meter

Signal lamps

Lighting

Operating hour meter

Machine variant

Backup protection

Cold starting facility

Horn

8. Mechanical functions

Travel lever adjustment

Adjustment of both driver's seats

Check driver's seat and seat belt

for function and damage

Running direction of conveyor belt

Check ROPS/FOPS, access steps, stepping areas,

hold-on grips and rods, covers, cladding for

completeness and damage

Check the tension of the tracks and correct the tension

if necessary.

Check the tool change control

Engine hoods/hood locks

Lift/lower the roof, function of emergency pump

Check all cylinder functions for leaks

Function of rear scraper / safety shut-down

Fast speed/milling speed/parking brake response

Check steering cylinder piston rods for leaks

Check front and rear steering, check track and adjust

as necessary, if necessary readjust parameters or

steering correction

Check function of steering modes: Crabwalk, offset,

manually rear

Function and leak tightness of water sprinkling system

(empty)

Condition and cleanliness of water filters and nozzles

AUTO function of sprinkling system and PAUSE mode

BOMAG ALL-ROUND CHECK Page 2 of 3

MACHINE INSPECTION Issue

Cold Milling Machine 01/2013

BM 2000...2200/60-2

OK

Component yes / no rectified Comment

Check left/right steering stops

Routing/identification of hoses and cables

Fill in hydraulic oil (half of inspection glass)

Screw connections (engine mounts, chassis bolts)

Battery box/stowage space

Brake releasing device

Milling rotor monitoring/reversing

Check the tank lid

Flow divider - function

Function of front hold-down

Function of side plates left/right

Adjustment of milling box (0-position)

Check the milling function

Check the junction box

Check the maintenance position of the rear scrapers,

check the limit switches

Belt tension: Generator, gearbox

Check the height adjustment (quick adjustment,

sensitive adjustment)

Check contamination of radiator, air filter

Check stickers, decals/labelling

General leak test

*Additional work against separate invoicing

Recommended repairs:

Recommended spare parts:

Designation Quantity P/N

Inspection carried out:

Customer Service Engineer: Name: Signature

BOMAG ALL-ROUND CHECK Page 3 of 3

You might also like

- Mac25 Maintenance Section 2Document27 pagesMac25 Maintenance Section 2Wahyu SriharjaNo ratings yet

- AT20 OM906/MD3060 Service ScheduleDocument6 pagesAT20 OM906/MD3060 Service ScheduleFergiKalesaran0% (1)

- Toyota PickupDocument11 pagesToyota Pickupalexberhane3No ratings yet

- Technical Report Checklist - MARINE ENGINESDocument2 pagesTechnical Report Checklist - MARINE ENGINESsary qasimNo ratings yet

- Machine Inspection Form ExcavatorDocument27 pagesMachine Inspection Form ExcavatorAwanNo ratings yet

- 0298 199 0 SV en 300Document56 pages0298 199 0 SV en 300andis_a100% (1)

- A320 Family Line Maintenance Task Card - Weekly Check: CockpitDocument4 pagesA320 Family Line Maintenance Task Card - Weekly Check: CockpitSuman BajracharyaNo ratings yet

- QA10 RF PC210-10MO (5320)Document1 pageQA10 RF PC210-10MO (5320)daffaprastiadwiputeraNo ratings yet

- Checklist PPM AircondDocument6 pagesChecklist PPM AircondsyahirahafiqahNo ratings yet

- Miles - 24 Months ServiceDocument2 pagesMiles - 24 Months ServicePawluchNo ratings yet

- SF-05D Service+report+ (Dump+trucks)Document1 pageSF-05D Service+report+ (Dump+trucks)Yoga SugiNo ratings yet

- Service Ivoco Bus PM Check ListDocument6 pagesService Ivoco Bus PM Check Listalexberhane3No ratings yet

- EMD-003-0 Pre-Used Inspection Checklist For EquipmentsDocument31 pagesEMD-003-0 Pre-Used Inspection Checklist For EquipmentsArjay AlvarezNo ratings yet

- Mercedes PM Check ListsDocument6 pagesMercedes PM Check Listsalexberhane3No ratings yet

- Main Report & InspectionsDocument27 pagesMain Report & Inspectionsyyewin491No ratings yet

- PM. Genset EGS300-6'Document12 pagesPM. Genset EGS300-6'Iqmal WahabNo ratings yet

- Inspection Unit PC 200Lc - 8moDocument28 pagesInspection Unit PC 200Lc - 8moBima AditamaNo ratings yet

- Service Otoyol PM Check ListDocument6 pagesService Otoyol PM Check Listalexberhane3No ratings yet

- 2020 - MU - HTL - 4014 - 4017 - PLATF - 36a-Light - Mif CHECK LISTDocument4 pages2020 - MU - HTL - 4014 - 4017 - PLATF - 36a-Light - Mif CHECK LISTOsscar HerreraNo ratings yet

- Dewa-Pm-Form-325. Daily Maintenance Checksheet Light TruckDocument2 pagesDewa-Pm-Form-325. Daily Maintenance Checksheet Light TruckEdy Gunawan SiagianNo ratings yet

- At22 MaintenanceDocument37 pagesAt22 MaintenancefabuleukalengaNo ratings yet

- Shovel ChecklistDocument2 pagesShovel Checklistjamal motaNo ratings yet

- Jadwal Weekly MaintanaceDocument8 pagesJadwal Weekly Maintanaceardy ansyahNo ratings yet

- Certificate of Examination and Test of Engine Generator: Certificate No.:DG/C1 Job No.: ASC-18N-0262Document2 pagesCertificate of Examination and Test of Engine Generator: Certificate No.:DG/C1 Job No.: ASC-18N-0262RavijNo ratings yet

- Service schedule detailsDocument2 pagesService schedule detailsSándor SopronyiNo ratings yet

- Landrover Freelander 2 Maintenance ScheduleDocument2 pagesLandrover Freelander 2 Maintenance Schedulevincent_devine777dNo ratings yet

- MPM 332 01 33Document2 pagesMPM 332 01 33Mousa PetrolNo ratings yet

- Zoom Boom Daily Inspection Checklist - SBIKHADocument1 pageZoom Boom Daily Inspection Checklist - SBIKHAAbdejelil ChokriNo ratings yet

- Maintenance of TransformerDocument4 pagesMaintenance of Transformerdownload4sumitNo ratings yet

- Bobcat Daily Inspection Checklist: Operator's Name: Signature Badge No. BOBCAT Body No.: Model: Project/FacilityDocument1 pageBobcat Daily Inspection Checklist: Operator's Name: Signature Badge No. BOBCAT Body No.: Model: Project/FacilityMuhammad Farooq Awan100% (5)

- JCB VM115 Single Drum RollerDocument9 pagesJCB VM115 Single Drum Roller江柄宏100% (1)

- 4.2 Service SheetDocument2 pages4.2 Service SheetRichard PorterNo ratings yet

- Service Report: GraderDocument3 pagesService Report: Graderainul arifNo ratings yet

- Vehicle Maintenance ManualDocument51 pagesVehicle Maintenance ManualIbaadNo ratings yet

- Initial 250hrs PM HD465-7Document5 pagesInitial 250hrs PM HD465-7Jamyansuren TseveendorjNo ratings yet

- Testing and adjusting PC300, 350-8 excavatorsDocument6 pagesTesting and adjusting PC300, 350-8 excavatorsNaughty VongNo ratings yet

- National irrigation standby generator checklistDocument4 pagesNational irrigation standby generator checklistMartie ClustersNo ratings yet

- Required Manuals and Documentation: Honda Certified Used Cars 150 Point Inspection ChecklistDocument2 pagesRequired Manuals and Documentation: Honda Certified Used Cars 150 Point Inspection ChecklistKaiser Shaikh100% (2)

- Commissioning Form - Crane TruckDocument2 pagesCommissioning Form - Crane TruckKurniawan PriambodoNo ratings yet

- 50H EngineDocument3 pages50H EngineAmirSyafiqNo ratings yet

- Guia 695Document16 pagesGuia 695Elikaty Servicios AereosNo ratings yet

- Periodic Preservice Inspection Sheet Kom PDFDocument2 pagesPeriodic Preservice Inspection Sheet Kom PDFEko FebriyantoNo ratings yet

- Gear InspectionDocument6 pagesGear Inspectionbh hbNo ratings yet

- Daily Fuel Truck ChecklistDocument1 pageDaily Fuel Truck ChecklistTFattah0% (1)

- 5 SM 2200 MaintenanceDocument48 pages5 SM 2200 MaintenancePlr. Baswapur100% (1)

- Maintain Mud Mixing PumpDocument2 pagesMaintain Mud Mixing PumpMousa PetrolNo ratings yet

- PM Schedule Plan For All MachinesDocument32 pagesPM Schedule Plan For All MachineskumaresanNo ratings yet

- Chklist HEXDocument3 pagesChklist HEXluisNo ratings yet

- PS Checklist Motor GraderDocument1 pagePS Checklist Motor Graderyogi ganda pratamaNo ratings yet

- TA2 950G Wheel Loader AYLDocument21 pagesTA2 950G Wheel Loader AYLMekanik Alat Berat100% (2)

- MPM 813 01 04Document2 pagesMPM 813 01 04Mousa PetrolNo ratings yet

- Daily maintenance check sheetDocument5 pagesDaily maintenance check sheetPearlsgodNo ratings yet

- Adt - e - b35 b40 b45 b50 - Qer - New ReleaseDocument1 pageAdt - e - b35 b40 b45 b50 - Qer - New Releasesfe100% (1)

- Daily Equipment Safety ChecklistDocument5 pagesDaily Equipment Safety ChecklistArturo Ramos AlvezoNo ratings yet

- AT2403 Vehicle Maintenance RecordsDocument58 pagesAT2403 Vehicle Maintenance RecordsPethuraj100% (1)

- Periodical Service Check Sheet Compactor Volvo SD 100 KDocument8 pagesPeriodical Service Check Sheet Compactor Volvo SD 100 Kkkmech100% (1)

- WG - F436 Vehicle-Equipment Maintenance Service SheetDocument3 pagesWG - F436 Vehicle-Equipment Maintenance Service Sheetnalanliyanage008No ratings yet

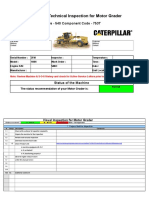

- TA-2 Visual & Technical Inspection For Motor Grader: SMCS - Job Code - 540 Component Code - 753TDocument18 pagesTA-2 Visual & Technical Inspection For Motor Grader: SMCS - Job Code - 540 Component Code - 753THebert TrujilloNo ratings yet

- PT6A Engine Inspection Guidelines After Propeller Strike or Sudden StoppageDocument3 pagesPT6A Engine Inspection Guidelines After Propeller Strike or Sudden StoppageVagner OliveiraNo ratings yet

- Desarmado y ArmadoDocument136 pagesDesarmado y ArmadoAlex Robledo Olarte100% (1)

- Fogging Machine User ManualDocument10 pagesFogging Machine User ManualCesarNo ratings yet

- Great Wall Service ManualDocument484 pagesGreat Wall Service ManualJeison Isaza100% (1)

- MDR65 Version 011001Document24 pagesMDR65 Version 011001CesarNo ratings yet

- O&m D475a-5eo 30001-Up Ten00132-00d PDFDocument333 pagesO&m D475a-5eo 30001-Up Ten00132-00d PDFLuis Añanca LoayzaNo ratings yet

- C11 C13 C15 Electrical GuideDocument232 pagesC11 C13 C15 Electrical GuideCesar Ego-Aguirre Calderon80% (5)

- Aw60 40le Zip BookDocument8 pagesAw60 40le Zip BookMohamd Fadel Hassan80% (5)

- SM-E2B Series PDFDocument140 pagesSM-E2B Series PDFAndres Florentin Pizarro Lazarte100% (1)

- 2AZ-FE ToyotaDocument11 pages2AZ-FE ToyotaCesar50% (2)

- 2010 505sxatvparts ManualDocument50 pages2010 505sxatvparts ManualCesarNo ratings yet

- Product DirectoryDocument39 pagesProduct DirectoryAngel BernabeNo ratings yet

- Inspección Equipo WZ - HTW - 2013 - enDocument3 pagesInspección Equipo WZ - HTW - 2013 - enCesarNo ratings yet

- Safety and Operating Instructions: Hydraulic BreakersDocument72 pagesSafety and Operating Instructions: Hydraulic BreakersRizwan KhanNo ratings yet

- XMT 425 CC CV Parts ListDocument12 pagesXMT 425 CC CV Parts ListCesar0% (1)

- Sport AgeDocument23 pagesSport AgeCesarNo ratings yet

- MR453X7913B000 PDFDocument202 pagesMR453X7913B000 PDFmilerk100% (2)

- SpamDocument2 pagesSpamAshutosh SinghNo ratings yet

- 2) Coa-Vitamin-Dsm-Lot # XW91707139-146 PDFDocument16 pages2) Coa-Vitamin-Dsm-Lot # XW91707139-146 PDFNaeem AnjumNo ratings yet

- Sub-Zero Icing Your Testicles For Increased Male Performance - MyBioHack Unlock Your Maximus PotentialDocument7 pagesSub-Zero Icing Your Testicles For Increased Male Performance - MyBioHack Unlock Your Maximus PotentialfortnitediscordbgweeNo ratings yet

- Global Leader: in Glass IonomerDocument2 pagesGlobal Leader: in Glass IonomerAnggini ZakiyahNo ratings yet

- English 1000 Most Repeated MCQs by Learning With Rizwan - 083731Document145 pagesEnglish 1000 Most Repeated MCQs by Learning With Rizwan - 083731Athleteboy7No ratings yet

- Sika Poxitar FDocument3 pagesSika Poxitar FBudhi KurniawanNo ratings yet

- Cavab - kartı - numune (копия) (копия) (копия) (копия)Document2 pagesCavab - kartı - numune (копия) (копия) (копия) (копия)Javid NovruzovNo ratings yet

- Pradhan Mantri Gram Sadak Yojana Pradhan Mantri Gram Sadak YojanaDocument19 pagesPradhan Mantri Gram Sadak Yojana Pradhan Mantri Gram Sadak Yojanapriyajaiswal428No ratings yet

- Practical-2 Simulation of ReactorsDocument2 pagesPractical-2 Simulation of ReactorsniralNo ratings yet

- Cs Varnavrat Land SlideDocument7 pagesCs Varnavrat Land SlideBIJAY KRISHNA DASNo ratings yet

- Catalogue Perkins 4012 46TAG1A 46TAG2ADocument18 pagesCatalogue Perkins 4012 46TAG1A 46TAG2AAbdoul-aziz Ben Ousmanou100% (1)

- Diesel Engine Operation and DiagDocument76 pagesDiesel Engine Operation and DiagHafiezul Hassan100% (3)

- SG Salary Guide 2021-22Document66 pagesSG Salary Guide 2021-22Gilbert ChiaNo ratings yet

- IB Student's Soil Systems GuideDocument7 pagesIB Student's Soil Systems GuideYohanes Sumantri RatnodiyantoNo ratings yet

- Hospital Acquired Infections-IIDocument52 pagesHospital Acquired Infections-IIFATHIMA ANo ratings yet

- Sectors of The Indian EconomyDocument5 pagesSectors of The Indian EconomyhavejsnjNo ratings yet

- Complete Dummy's Guide to a Diffusion Pumped Vacuum SystemDocument4 pagesComplete Dummy's Guide to a Diffusion Pumped Vacuum Systemjokerbuddy01No ratings yet

- Which Statement On Physical Development of Infants and Toddlers Is TRUEDocument9 pagesWhich Statement On Physical Development of Infants and Toddlers Is TRUEKristylle Renz100% (1)

- Vegetarianism A Salvation Issue?Document7 pagesVegetarianism A Salvation Issue?ChetiweKapilaNo ratings yet

- F 856 - 97 - Rjg1ni05nw - PDFDocument7 pagesF 856 - 97 - Rjg1ni05nw - PDFRománBarciaVazquezNo ratings yet

- Letter From Springfield Mayor Sarno To License Commission Re: Late Night Hours.Document12 pagesLetter From Springfield Mayor Sarno To License Commission Re: Late Night Hours.Patrick JohnsonNo ratings yet

- Electricity Merit Badge Class 1 2017Document34 pagesElectricity Merit Badge Class 1 2017RoshanNo ratings yet

- Palm Kernel Oil Mill ProjectDocument8 pagesPalm Kernel Oil Mill Projectsjr141071100% (2)

- G.V. Black's Classification and Class I Cavity PreparationDocument57 pagesG.V. Black's Classification and Class I Cavity PreparationPrakuz Harmony SubedifiedNo ratings yet

- Personal Development Course for Senior High StudentsDocument7 pagesPersonal Development Course for Senior High StudentsLucelle PalarisNo ratings yet

- Transformer Protection Techniques for Fault DetectionDocument32 pagesTransformer Protection Techniques for Fault DetectionshashankaumNo ratings yet

- Managing Hypertension and Insomnia Through Family Nursing Care PlansDocument4 pagesManaging Hypertension and Insomnia Through Family Nursing Care PlansChristian UmosoNo ratings yet

- 4801-Article Text-19217-1-10-20110701Document8 pages4801-Article Text-19217-1-10-20110701David BriggsNo ratings yet

- MWRC Policies & Procedures Manual 2020Document10 pagesMWRC Policies & Procedures Manual 2020Emma RyersonNo ratings yet

- Standardized Recipes - Doc2Document130 pagesStandardized Recipes - Doc2epic failNo ratings yet