Professional Documents

Culture Documents

SF-05D Service+report+ (Dump+trucks)

Uploaded by

Yoga Sugi0 ratings0% found this document useful (0 votes)

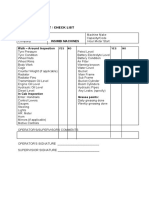

49 views1 pageThis document is a service report for dump trucks that contains sections to record information about a service including: date, customer and distributor details, inspection of fluid levels, wear parts, running tests, and a checklist to mark satisfactory or unsatisfactory results. Key details include the model and serial number, service meter hours, job site, temperatures during inspection, types of service or inspection performed. Sections are included to check for issues like leaks, damage or deterioration, and record information about consumable parts. Photos can be attached and an overall condition of the machine is assessed. Customer and distributor signatures are required with date to sign off the report.

Original Description:

Original Title

SF-05D_SERVICE+REPORT+(DUMP+TRUCKS)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document is a service report for dump trucks that contains sections to record information about a service including: date, customer and distributor details, inspection of fluid levels, wear parts, running tests, and a checklist to mark satisfactory or unsatisfactory results. Key details include the model and serial number, service meter hours, job site, temperatures during inspection, types of service or inspection performed. Sections are included to check for issues like leaks, damage or deterioration, and record information about consumable parts. Photos can be attached and an overall condition of the machine is assessed. Customer and distributor signatures are required with date to sign off the report.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

49 views1 pageSF-05D Service+report+ (Dump+trucks)

Uploaded by

Yoga SugiThis document is a service report for dump trucks that contains sections to record information about a service including: date, customer and distributor details, inspection of fluid levels, wear parts, running tests, and a checklist to mark satisfactory or unsatisfactory results. Key details include the model and serial number, service meter hours, job site, temperatures during inspection, types of service or inspection performed. Sections are included to check for issues like leaks, damage or deterioration, and record information about consumable parts. Photos can be attached and an overall condition of the machine is assessed. Customer and distributor signatures are required with date to sign off the report.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Report No.

SERVICE REPORT (DUMP TRUCKS)

Person in charge

All boxes must be filled up before Submitting to Hitachi.

Model Serial No. Inspection Date Service Meter Job Site Handling Material Temperature Kind of Inspection

D M Y HRS Max ( )°C / ( )°F 1. 1-st Periodic 4. 4-th Periodic 8. Follow up: L/O

2. 2-nd Periodic 5. Additional

Min ( )°C / ( )°F 3. 3-rd Periodic

9. Follow up: Other

Customer Name and Address DUMP BODY

Manufacturer Serial No. Manufacturer Capacity

Distributor Name and Country

TIRE The Machine delivered with TIRE YES NO

Branch/Sub-Dealer Name Manufacturer Size and Specification

Legend : Satisfactory Unsatisfactory Corrected Not applicable

1. CHECK FLUID LEVELS

Fuel Tank Washer Tank Engine Oil Pan Hydraulic Tank Battery specific gravity Transmission (Construction)

Brake Steering Final Drive Front & Rear Axles Radiator & Sub Tank

2. INSPECTION AND MAINTENANCE BEFORE RUNNING ENGINE

Lubricant Tires Pressure Alternator Belt Tightening of Bolts Check and clean the Air Cleaner to prevent from clogging

Cleaning cylinder rods Tightening of Battery terminal Draining water from Fuel Filter

Curing hose & harness (if not assembled the machine) V-Belt Tension (Engine, Alternator, Air-Cond.)

3. DAMAGE / CRACK / RUST / DETERIORATION / PAINT

All Hose All Pipes All cylinders Frames / Building Electric Parts & Wiring All Main Hydraulic Components

CAB Filters Deck / Fender Blower Motor Fuel oil tank cap (Front/Back) Control Cabinet (AC/ DC Drive)

Engine Alternator Accumulator Front/ Rear axle Body Prop Pin / Cable Glass's rubber frame

Final Drive Coolers Travel Motor Bolts / Pins Fuel/ Hydraulic oil tank (inside/ outside)

Fan Glass Urethane Painting Decals Others ( )

4. WEAR Break Pad Body Tire

5. RUN ENGINE TO LUBRICATE AND CHARGE BATTERY

Crank engine with starting motor 5 to 10 seconds. Warm up and run engine at idle speed 10 minutes without operation.

Run engine at medium speed 20 to 40 minutes. Check for color of exhaust gas, smell, noise, etc.

6. CHECK INSTRUMENTS

Switches Wiper Horn & Buzzer Display, Indicators Coolant Temperature Generating/Charging

Fuel Gauge Air-cond. Reverse Alarm Engine Oil Pressure Hoist Relief Pressure Steering Relief Pressure

Radio Service Meter Bulbs for Light (Head light, Monitor, etc.) Brake Pressure (Front / Rear / Parking)

Strut Cylinder Pressure (Front / Rear ) Check the error codes ( )

7. RUN MACHINE TO LUBRICATE HYDRAULIC SYSTEM

Operate all hydraulic actuators 3 to 5 times at low speed without any loading.

Shift Lever Steering Wheel Accelerator Pedal Body Up / Down / Hold Traveling forward and backward at a short distance.

Optional Equipments Brakes(Service/ Retarding/ Parking) Abnormal Noise from ( )

8. CHECK LEAKAGE AFTER OPERATION

Gear Oil Battery Grease Line All Hoses and Pipes Water (Washer Tank, etc.) Fuel (Fuel Tank, Fuel Filter, etc.)

Engine Oil (Cylinder head, Oil Pan, Blow-by hose, etc.) Transmission Oil (Construction) LLC (Radiator, Sub Tank, etc.)

Hydraulic Oil (All Hydraulic Components, All Cylinders, Hydraulic Tank, Oil Cooler)

9. CONSUMABLE PARTS INFORMATION

Oil Types Oil name Grade Oil Types Oil name Grade Filter Genuine

Engine Oil Final Drive Oil Engine Oil Filter Yes No

Coolant (LLC) Front & Rear Axles Oil Hydraulic Oil Filter Yes No

Hydraulic Oil Fuel Condition Fuel Filter Yes No

Transmission Oil

10.COMMENT

Note: Please attach some photos of unsatisfactory parts by using form "SF-06A".

Photo attached No necessary

GENERAL MACHINE CONDITION MAINTENANCE OF THE MACHINE

Good as New Satisfactory Unsatisfactory Excellent Good Should be Improved

D -M- Y D -M- Y

- - - -

DATE CUSTOMER’S SIGNATURE DATE SIGNATURE OF DISTRIBUTOR PERSON IN CHARGE

SF-05D

You might also like

- SPARK Technical Specification - AutodataDocument6 pagesSPARK Technical Specification - AutodataAlexey KolmakovNo ratings yet

- Form Inspeksi Alat Berat (Compactor)Document1 pageForm Inspeksi Alat Berat (Compactor)HELMY RUSANDYNo ratings yet

- Engine Training Program Mahindra 2185 GM: 1 Chromelite One Day TrainingDocument25 pagesEngine Training Program Mahindra 2185 GM: 1 Chromelite One Day TrainingAhmad DahlanNo ratings yet

- Vehicle Maintenance ManualDocument51 pagesVehicle Maintenance ManualIbaadNo ratings yet

- Service Ivoco Bus PM Check ListDocument6 pagesService Ivoco Bus PM Check Listalexberhane3No ratings yet

- Mercedes PM Check ListsDocument6 pagesMercedes PM Check Listsalexberhane3No ratings yet

- Vehicle Maintenance PDFDocument58 pagesVehicle Maintenance PDFPethuraj100% (1)

- Water Pump 250 Hrs Service No Unit: Date: HM: ShiftDocument8 pagesWater Pump 250 Hrs Service No Unit: Date: HM: ShiftTLK ChannelNo ratings yet

- BMW LubrikantiDocument3 pagesBMW LubrikantiNikola PorkiNo ratings yet

- SAU1307Document93 pagesSAU1307jalda srikaranNo ratings yet

- Vehicle Identification: Telephone: Fax: VAT Registration No.Document7 pagesVehicle Identification: Telephone: Fax: VAT Registration No.Adrian MacayaNo ratings yet

- IsuzuDocument1 pageIsuzuFarhan Sheikh100% (1)

- Sepco Arabia: King Salman International Complex For Maritime Industries & Services ProjectDocument1 pageSepco Arabia: King Salman International Complex For Maritime Industries & Services ProjectJamal Mohamed RahamathullahNo ratings yet

- Toyota PickupDocument11 pagesToyota Pickupalexberhane3No ratings yet

- Checklist - BobcatDocument1 pageChecklist - Bobcatsheldon cramerNo ratings yet

- 966H PM10.xls 50.xls 250Document4 pages966H PM10.xls 50.xls 250abdouNo ratings yet

- Service Otoyol PM Check ListDocument6 pagesService Otoyol PM Check Listalexberhane3No ratings yet

- Chklist HEXDocument3 pagesChklist HEXluisNo ratings yet

- Gig-Service Bus PM Check ListDocument6 pagesGig-Service Bus PM Check Listalexberhane3No ratings yet

- Unit I Maintenance of Records and SchedulesDocument19 pagesUnit I Maintenance of Records and Schedulespugal4No ratings yet

- FG Wilson India Operator (2 Cyl) PDFDocument69 pagesFG Wilson India Operator (2 Cyl) PDFviraj arjun ghadageNo ratings yet

- Baleno ManualDocument332 pagesBaleno ManualDeepanjan Ray33% (3)

- Compressed Air LogDocument1 pageCompressed Air LogMd Myul IslamNo ratings yet

- VA 405-Engine Check List FormDocument1 pageVA 405-Engine Check List FormPetrus GunturNo ratings yet

- Caterpillar D8R 250 Hrs Service No Unit: Date: HM: ShiftDocument8 pagesCaterpillar D8R 250 Hrs Service No Unit: Date: HM: ShiftTLK Channel100% (1)

- Mac25 Maintenance Section 2Document27 pagesMac25 Maintenance Section 2Wahyu SriharjaNo ratings yet

- Technical Report Checklist - MARINE ENGINESDocument2 pagesTechnical Report Checklist - MARINE ENGINESsary qasimNo ratings yet

- 5 SM 2200 MaintenanceDocument48 pages5 SM 2200 MaintenancePlr. Baswapur100% (1)

- Cat D8R-T2Document1 pageCat D8R-T2Awet TesafyNo ratings yet

- Pay Loader Monthly Inspection ChecklistDocument1 pagePay Loader Monthly Inspection ChecklistJoy BD60% (5)

- 04 50-90 Predator & 90 SportsmanDocument99 pages04 50-90 Predator & 90 Sportsmannosajseveer100% (1)

- 793D Off Higway Truck FDBDocument28 pages793D Off Higway Truck FDBMelissa TorresNo ratings yet

- Compressed Air Preventative Maintenance: Checklist & LogsDocument3 pagesCompressed Air Preventative Maintenance: Checklist & Logsvibin globalNo ratings yet

- C125D6 Model:: Powered by CumminsDocument2 pagesC125D6 Model:: Powered by CumminsasuhuaneNo ratings yet

- 1.3 CDTI Date TehniceDocument5 pages1.3 CDTI Date TehniceCata Stefan0% (1)

- ServiceTATA Bus PM Check ListDocument7 pagesServiceTATA Bus PM Check Listalexberhane3No ratings yet

- Inspección Equipo BM 2000 2200 - 2013 - enDocument3 pagesInspección Equipo BM 2000 2200 - 2013 - enCesarNo ratings yet

- Generator Set Test (DMG)Document4 pagesGenerator Set Test (DMG)amrnasser008No ratings yet

- Gig-Service Bus PM Check ListDocument7 pagesGig-Service Bus PM Check Listalexberhane3No ratings yet

- Pre - Post Start Checklist - Hydrostatic RigDocument9 pagesPre - Post Start Checklist - Hydrostatic Rigmnscsc713321No ratings yet

- Technical Specifica OnsDocument8 pagesTechnical Specifica OnsNakkeeran NNo ratings yet

- Cummins Report of New Engine Inspection: Claim DataDocument4 pagesCummins Report of New Engine Inspection: Claim Datafarizns90No ratings yet

- TTT Inspection SheetDocument9 pagesTTT Inspection Sheetkhaled fathyNo ratings yet

- Backhoe Safety Inspection ChecklistDocument1 pageBackhoe Safety Inspection ChecklistImran Alam100% (1)

- FD35 Lubricant ListDocument2 pagesFD35 Lubricant ListErsa RahmandaNo ratings yet

- Model Identification: 1999 Toyota RAV4 1999 Toyota RAV4Document28 pagesModel Identification: 1999 Toyota RAV4 1999 Toyota RAV4skilleddragonNo ratings yet

- SZ Crde Ems 01 2005 v0Document99 pagesSZ Crde Ems 01 2005 v0luisxdNo ratings yet

- Vehicle TIDocument2 pagesVehicle TIBacolod PS SevenNo ratings yet

- TA1 Visual Inspection Form Master - Track-Type Tractor (Hydrostatic)Document8 pagesTA1 Visual Inspection Form Master - Track-Type Tractor (Hydrostatic)CarlosNo ratings yet

- Troubleshooting Data SheetDocument3 pagesTroubleshooting Data SheetRicardo La CruzNo ratings yet

- Hitachi - Group 2 - 5-16-2013Document104 pagesHitachi - Group 2 - 5-16-2013Jhonald Lanz Lossada100% (1)

- 362214Document59 pages362214Anderson BombistaNo ratings yet

- 4 h50 TicDocument129 pages4 h50 Ticpatrick.wirtzNo ratings yet

- Om615 616 617 PDFDocument221 pagesOm615 616 617 PDFAnonymous wpUyixsj100% (1)

- CRDeDocument97 pagesCRDeluisxdNo ratings yet

- Fully Automatic A.T.F Changer: Operation & Maintenance ManualDocument16 pagesFully Automatic A.T.F Changer: Operation & Maintenance ManualMed ChetNo ratings yet

- Report Genset TimbanganDocument4 pagesReport Genset TimbanganmahmudiNo ratings yet

- 140H Motor Grader XZHDocument18 pages140H Motor Grader XZHHebert Trujillo100% (2)

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityFrom EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityRating: 3 out of 5 stars3/5 (4)

- Code Manual For Hitachi Service Report FormDocument37 pagesCode Manual For Hitachi Service Report FormYoga SugiNo ratings yet

- Hose & FittingDocument124 pagesHose & FittingYoga Sugi100% (1)

- Muster 2 PresentationINDDocument106 pagesMuster 2 PresentationINDYoga SugiNo ratings yet

- Preventive - Maintenance ZX350H-5GDocument27 pagesPreventive - Maintenance ZX350H-5GYoga SugiNo ratings yet

- Transitive & Intransitive Verbs: Grammar PracticeDocument5 pagesTransitive & Intransitive Verbs: Grammar PracticeSzeman YipNo ratings yet

- Integrated Chinese Vol 4 TextbookDocument444 pagesIntegrated Chinese Vol 4 Textbookcuriousbox90% (10)

- Be1-Flex (Uub)Document2 pagesBe1-Flex (Uub)Eliyanto E BudiartoNo ratings yet

- CMMI DAR Effectively Apply The Decision Analysis and Resolution (DAR) ProcessDocument26 pagesCMMI DAR Effectively Apply The Decision Analysis and Resolution (DAR) Processjgonzalezsanz8914100% (1)

- DSNHP00197140000690828 2022Document2 pagesDSNHP00197140000690828 2022Vidya SagarNo ratings yet

- Chapter 5 - Adlerian TherapyDocument28 pagesChapter 5 - Adlerian TherapyRhalf100% (1)

- Workshop Manual Transporter 2016 1-29Document167 pagesWorkshop Manual Transporter 2016 1-29samueleNo ratings yet

- Electronic Transformer For 12 V Halogen LampDocument15 pagesElectronic Transformer For 12 V Halogen LampWin KyiNo ratings yet

- He 2011Document11 pagesHe 2011DarshilNo ratings yet

- System 9898XT Service ManualDocument398 pagesSystem 9898XT Service ManualIsai Lara Osoria100% (3)

- Courses Offered in Spring 2015Document3 pagesCourses Offered in Spring 2015Mohammed Afzal AsifNo ratings yet

- Steinway Sons 1210010201644895 8Document41 pagesSteinway Sons 1210010201644895 8Nadia ShamiNo ratings yet

- Literature & MedicineDocument14 pagesLiterature & MedicineJoyce LeungNo ratings yet

- Codel: Monitoring SolutionsDocument4 pagesCodel: Monitoring SolutionsCindy HenaoNo ratings yet

- Assignment / Tugasan HBEF3703 Introduction To Guidance and Counselling / May 2021 SemesterDocument8 pagesAssignment / Tugasan HBEF3703 Introduction To Guidance and Counselling / May 2021 SemesterTHURGANo ratings yet

- Final Examination SEMESTER 1, SESSION 2014/2015: SKAA 2722 1Document10 pagesFinal Examination SEMESTER 1, SESSION 2014/2015: SKAA 2722 1Hanis SyafiqNo ratings yet

- Fractions Math 6 DLP 1Document13 pagesFractions Math 6 DLP 1Dess DotimasNo ratings yet

- Web Development Internship TaskDocument12 pagesWeb Development Internship TaskradhaNo ratings yet

- Or Or: Correlation Between Carbon Residue and Molecular WeightDocument4 pagesOr Or: Correlation Between Carbon Residue and Molecular WeightNiranjana Murthy PNo ratings yet

- 20years Cultural Heritage Vol2 enDocument252 pages20years Cultural Heritage Vol2 enInisNo ratings yet

- Using GPS, GIS, and Accelerometer Data To Predict Transportation ModesDocument7 pagesUsing GPS, GIS, and Accelerometer Data To Predict Transportation ModesAdanely Escudero BarrenecheaNo ratings yet

- Punjab Medical Faculty Registration Form: Personal DetailsDocument2 pagesPunjab Medical Faculty Registration Form: Personal DetailsAamir Khan PtiNo ratings yet

- Improve Basic Visualization SkillDocument29 pagesImprove Basic Visualization Skillpatrick.schoenkaesNo ratings yet

- Honeywell S4565 CVI Ignition ControlDocument66 pagesHoneywell S4565 CVI Ignition ControlcarlosNo ratings yet

- Crushing and Screening Equipment Handbook (Low Res)Document46 pagesCrushing and Screening Equipment Handbook (Low Res)Jayesh NairNo ratings yet

- Bahasa Inggris Teknik Individual Assignment 3Document5 pagesBahasa Inggris Teknik Individual Assignment 3Khaiza SyNo ratings yet

- Atiq E-AI On AuditDocument20 pagesAtiq E-AI On AuditShahid MahmudNo ratings yet

- Mixed Conditionals Gap Filling Exercise 2Document3 pagesMixed Conditionals Gap Filling Exercise 2Amanda MaccarroneNo ratings yet

- The Differences Between OHS Management System StandardsDocument27 pagesThe Differences Between OHS Management System StandardsRommel100% (2)

- ANSYS SimplorerDocument2 pagesANSYS Simplorerahcene2010No ratings yet