Professional Documents

Culture Documents

Cálculo Flange ASME VIII 1 Apendice 2

Cálculo Flange ASME VIII 1 Apendice 2

Uploaded by

fitobOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cálculo Flange ASME VIII 1 Apendice 2

Cálculo Flange ASME VIII 1 Apendice 2

Uploaded by

fitobCopyright:

Available Formats

G Woods ###

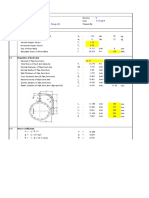

ASME Section VIII Division 1 Appendix 2 Weld Neck Flange Analysis

all US customary units

yellow is input values, green is program calculated values, orange is definition.

I. Flange Description

NPS: 12 Class: 150 Type: WN FLANGE

A: 19.000 dimensions per Section VIII-1 Fig. 2-4 (6)

B: 12.250

C: 17.000

t: 1.190

h: 3.000 Rgsur: is the flange raise face dimension

go: 0.250 R: is calculated by Section VIII equation

g1: 1.065 h t

Rgsur: 15.000 R: 1.31

BD: 0.875 nominal bolt diameter

RD: 0.731 bolt root diameter

#B: 12 number of bolts SR

g1 SH

II. Gasket Dimension & Factors go

C

OD: 14.75 ID: 13.38 m: 3 y: 10000 A

B G

Rgsur

III. Design Conditions

Bolt Diameters

T: 150 F Nominal Root

P: 104 psig 0.500 0.400

F Mat: A105 Sc: 23300 Sf: 22600 0.563 0.454

B Mat: A193-B7 Sa: 25000 Sb: 25000 0.625 0.507

ExMo: 50000 external overturning moment, in-lbs. 0.750 0.620

Pe: 90 0.875 0.731

P+Pe: 194 1.000 0.838

1.125 0.963

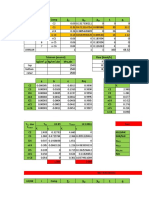

IV. Calculations: 1.250 1.088

1.375 1.213

Location of gasket load reaction: 0.2932 1.500 1.338

N: 0.69 N/2: 0.34 0.25 b: 0.29 1.625 1.463

G: 14.16 1.750 1.588

1.875 1.713

Bolt Loads, lbs. 2.000 1.838

Operating Wm1: 45648 2.250 2.088

Gasket: Wm2: 130376 2.500 2.338

2.750 2.588

Required bolt areas, in2. 3.000 2.838

Am1: 1.826 Am is the greater of Am1 or Am2.

Am2: 5.215 Am: 5.215

Ab: 5.034 Ab is not to be less than Am.

Flange design bolt load operating and gasket seating, lbs.

Oper: 45648

Gask.: 128109

Flange moments, in-lbs.

Operating: Mo=MD+MT+MG

MD: 42034

MT: 14575

MG: 21485

MO: 78093

Gasket: Mog: 181678

Calculated Values of T, U, Y, and Z Flange Factor Calculations

K: 1.55102 A: 3.26 C20: 0.167679 E4: 0.646656

T: 1.68859 C: 377.238 C21: -0.17464 E5: -0.00702

U: 5.05244 C1: 0.605 C22: 0.064638 E6: -0.38742

Y: 4.59773 C2: 0.28399 C23: -0.34272

Z: 2.42281 C3: 0.01382 C24: 0.31447

Fig.2-7.6 Value of f C4: 0.09729 C25: -0.09919

g1/go: 4.260 C5: -0.1777 C26: -3.1163

h/ho: 1.71429 C6: 0.02198 C27: -0.61919

f: 1.00 0.12 C7: 0.90557 C28: -0.05268

C8: 0.12457 C29: -9.71131

Fig. 2-7.2 Value of F C9: 0.13469 C30: -30.2633

g1/go: 4.260 C10: -0.1811 C31: 7.611751

h/ho: 1.71429 C11: 0.04852 C32: 0.749823

F: 0.55138 C12: 0.0276 C33: -2.58043

Value of L C13: 0.01267 C34: -0.64286

e: 0.32 C14: -0.0161 C35: 6.623002

Value of V C15: 0.00543 C36: 0.501157

V: 0.02868 C16: 0.00431 C37: 4.78672

Value of d: 19.27 C17: 0.08994 E1: -0.13426

L: 0.90 C18: -0.2188 E2: 0.218799

C19: 0.00825 E3: -0.33206

V. Flange Stress Calculations, psi

Operating Gasket Operating Gasket Allowable

SH: 6233 14501 (SH+SR)/2: 6858 15954 22600

SR: 7482 17407 (SH+ST)/2: 4402 10240 22600

ST: 2570 5979

VI. Allowable Stress Operating and Gasket Seating, psi

Operating Gasket

SH: 33900 34950

SR: 22600 23300

ST: 22600 23300

VII. Flange Rigidity

E: 3E+07 Oper. 3E+07 Gasket Seating, modulus of elasticity

J: 0.13 Oper. 0.35 Gasket Seating

VIII. Probable Bolt Stress: 48107 psi

IX. Leakage Moment, in-lbs.

ML: 394257

ASME Section VIII - Division 1

Appendix 2 Weld Neck Flange Analysis

Project: OxyChem PVC Job No: 31057.01 Cal. by: G Woods Date: ###

Flange Description: NPS 12-150# WN Flange

Flange Location: E-807 Nozzle F at elevation 162'-0 15/16"

I. Design Conditions

Pres.: 104 psig Temp.: 150 F

o

External Moment: 50000 in-lbs Equivalent pressure: 90 psig

Analysis Pressure, P + Pe: 194 psig

II. Flange, Bolt Material and Allowable Stresses

Flange Material: A105 Sc: 23300 psi Sf: 22600 psi

Bolt Material: A193-B7 Sa: 25000 psi Sb: 25000 psi

III. Flange and Bolt Dimensions, inches

Flange: A = 19.000 B = 12.250 C = 17.000 t = 1.190

g1 = 1.065 go = 0.250 h = 3.000

Bolt: Nom. Diameter: 0.875 Root Diameter: 0.731 No. Bolts: 12

IV. Gasket Dimensions and Factors

Dimensions: OD: 14.75 ID: 13.38 inches

Factors: m: 3 y: 10000 b: 0.29 G: 14.16

V. Flange Calculated Factors

K = 1.551 F = 0.551 V = 0.029 e = 0.315 L = 0.902

f = 1.00 T = 1.689 U = 5.052 Y = 4.598 U = 5.052

VI. Flange Design Bolt Loads, lbs., Area, and Moments in-lbs., for Operating and Gasket Seating

Operating Gasket Seating

Bolt: 45648 128109 Bolt Area: 5.034 in2

Moment: 78093 181678 Required Area: 5.215 in2

VII. Flange Operating and Gasket Seating Stress and Allowable Stress

Operate Allowable Gasket Allowable

SH: 6233 33900 14501 34950

SR: 7482 22600 17407 23300

ST: 2570 22600 5979 23300

(SH+SR)/2 6858 22600 15954 23300

(SH+ST)/2 4402 22600 10240 23300

VIII. Flange Modulus of Elasticity, E psi, and Rigidity, J at Operating and Gasket Seating

Operating Gasket

E: 29100000 3E+07

J: 0.13 0.35 J <= 1.0

IX: Probable Bolt Stress at Gasket Seating: 48107 psi

X. Moment to cause Flange Leakage: 394257 in-lbs.

You might also like

- A Leader in Me UK - Big Life JournalDocument7 pagesA Leader in Me UK - Big Life Journalntam100% (1)

- Flange Design: As Per ASME Sect VIII Div. 1, App. 2. 2013. P-373 (435 PDFDocument2 pagesFlange Design: As Per ASME Sect VIII Div. 1, App. 2. 2013. P-373 (435 PDFMuhamad Idris solahuddinNo ratings yet

- CompressDocument14 pagesCompressAnonymous gfR3btyU0% (1)

- 5.7 Asmeviii A-2 & Tema Split Backing RingDocument1 page5.7 Asmeviii A-2 & Tema Split Backing RingpastylNo ratings yet

- Studding Outlet Calculation - PV Elite 2016Document8 pagesStudding Outlet Calculation - PV Elite 2016Liu YangtzeNo ratings yet

- Muhammad Bin QasimDocument15 pagesMuhammad Bin QasimBilal KhanNo ratings yet

- Weld Neck Body Flange Design Calculation: HE-CGI, HE-CG, Spiral Wound Gaskets For Heat ExchangersDocument25 pagesWeld Neck Body Flange Design Calculation: HE-CGI, HE-CG, Spiral Wound Gaskets For Heat ExchangersLipika GayenNo ratings yet

- Using ANSYS For Finite Element Analysis, Volume I A Tutorial For Engineers by Wael A. Altabey, Mohammad Noori, Libin Wang PDFDocument210 pagesUsing ANSYS For Finite Element Analysis, Volume I A Tutorial For Engineers by Wael A. Altabey, Mohammad Noori, Libin Wang PDFNuno Moreira100% (1)

- Es Emp Iocal Colo en 13480Document25 pagesEs Emp Iocal Colo en 13480castibraNo ratings yet

- Calculation of Davit ArmDocument1 pageCalculation of Davit Armpiziyu100% (1)

- Flange DesignDocument6 pagesFlange DesignAKSHAY BHATKARNo ratings yet

- Piping Calculation Program For ASME B31 1 CodeDocument3 pagesPiping Calculation Program For ASME B31 1 CodeAMIT100% (2)

- Solution: WE1 12 Nov 2008Document9 pagesSolution: WE1 12 Nov 2008aauppalNo ratings yet

- Cálculo Flange ASME VIII 1 Apendice 2Document10 pagesCálculo Flange ASME VIII 1 Apendice 2jowarNo ratings yet

- CAP413 - PhraseologyDocument264 pagesCAP413 - PhraseologyGeorge BisdikisNo ratings yet

- STD - Pressure Vessel DrawingDocument138 pagesSTD - Pressure Vessel DrawingChetan PatelNo ratings yet

- AD 2000 Tubes Under Intenal PressureDocument1 pageAD 2000 Tubes Under Intenal Pressuremechengg01No ratings yet

- Dennis R Moss 4th EditionDocument5 pagesDennis R Moss 4th Editionsenthil kumarNo ratings yet

- What Is An ASME Appendix 2 Flange Design PDFDocument1 pageWhat Is An ASME Appendix 2 Flange Design PDFMangesh BanaleNo ratings yet

- Tolerance-E and Chord LengthDocument2 pagesTolerance-E and Chord LengthLcm TnlNo ratings yet

- 'To The Hungry Soul Every Bitter Thing Is Sweet.'soldiers' Food and Cooking in The War For IndependenceDocument91 pages'To The Hungry Soul Every Bitter Thing Is Sweet.'soldiers' Food and Cooking in The War For IndependenceJohn U. Rees90% (10)

- Wind / Seismic Design For Horizontal Vessels: Longitudinal ForcesDocument2 pagesWind / Seismic Design For Horizontal Vessels: Longitudinal ForcesMasoodMiyanNo ratings yet

- Calculation of Pipe Reinforcement ASME B31 3Document5 pagesCalculation of Pipe Reinforcement ASME B31 3Umar Aslam0% (1)

- AD 2000 HesapDocument11 pagesAD 2000 HesapBaşarŞenNo ratings yet

- PDP Example PDFDocument17 pagesPDP Example PDFsaudia686No ratings yet

- Channel Thickness Calculation: 1 Design Data: CO2 Condenser / Liquefier Design Code of ConstructionDocument6 pagesChannel Thickness Calculation: 1 Design Data: CO2 Condenser / Liquefier Design Code of ConstructionGaurav BedseNo ratings yet

- ABS Hull Calculation Rev 12-17-2004Document10 pagesABS Hull Calculation Rev 12-17-2004Anonymous gfR3btyUNo ratings yet

- Saddle v1-5: Fixed Saddle Sliding SaddleDocument9 pagesSaddle v1-5: Fixed Saddle Sliding Saddleduf fuNo ratings yet

- Section VIII CalDocument22 pagesSection VIII CalthodathersNo ratings yet

- ASME FlangeDocument1 pageASME FlangeHanda Bin AdiNo ratings yet

- Skid Calculation Sheet: Reference: Pressure Vessel Handbook, Eugene F. Megyesy MaterialDocument8 pagesSkid Calculation Sheet: Reference: Pressure Vessel Handbook, Eugene F. Megyesy MaterialAzharyanto FadhliNo ratings yet

- 15-501-EP-DS-002 (IG Buffer Vessel Datasheet), Rev.2Document4 pages15-501-EP-DS-002 (IG Buffer Vessel Datasheet), Rev.2Umair A. KhanNo ratings yet

- KuwaitDocument64 pagesKuwaitchhimpayogeshNo ratings yet

- Deaera DesignDocument13 pagesDeaera DesignBhanu K PrakashNo ratings yet

- Check 18Document6 pagesCheck 18Anonymous qBwHKusNo ratings yet

- Ligament Efficiency and Thickness of The Support PlateDocument10 pagesLigament Efficiency and Thickness of The Support PlatePankajDhobleNo ratings yet

- Reinforcement For Multi OpeningsDocument1 pageReinforcement For Multi OpeningsSajal KulshresthaNo ratings yet

- AD 2000 Head Under Extenal PressureDocument2 pagesAD 2000 Head Under Extenal Pressuremechengg01100% (1)

- .Document7 pages.Darshan Panchal100% (1)

- Full Face Flange With Metal To Metal Contact (11.10) EN 13445-3Document5 pagesFull Face Flange With Metal To Metal Contact (11.10) EN 13445-3met-calcNo ratings yet

- AD 2000 Head Under Intenal PressureDocument3 pagesAD 2000 Head Under Intenal Pressuremechengg01No ratings yet

- News Letter For Expansion Bellow PDFDocument4 pagesNews Letter For Expansion Bellow PDFAsma Khan100% (1)

- Operations & Training Risk Management Plan: ObjectiveDocument3 pagesOperations & Training Risk Management Plan: ObjectiveSunderNo ratings yet

- Din 28044Document3 pagesDin 28044amoldholeNo ratings yet

- IBR - 1950 - Reg. 366Document2 pagesIBR - 1950 - Reg. 366Vijay ParmarNo ratings yet

- WEP Standard For Reference OnlyDocument37 pagesWEP Standard For Reference OnlyKiran NikateNo ratings yet

- Garlock GYLON Style 3501 - Spec Sheet - (NA) 2016-12 enDocument1 pageGarlock GYLON Style 3501 - Spec Sheet - (NA) 2016-12 ennmosilvaNo ratings yet

- Toriconical Head Ver 1.1Document4 pagesToriconical Head Ver 1.1Iqbal AhmadsNo ratings yet

- Trunnion 6 TonDocument3 pagesTrunnion 6 TonEngr Khurram Jaan RamayNo ratings yet

- How To Consider Sea Transportation LoadDocument7 pagesHow To Consider Sea Transportation LoadSharun SureshNo ratings yet

- Sa 420Document10 pagesSa 420Widya widyaNo ratings yet

- TEMA Shell Bundle Entrance and Exit AreasDocument3 pagesTEMA Shell Bundle Entrance and Exit AreasArunkumar MyakalaNo ratings yet

- Modeling An API 661 Air Cooler - Intergraph CADWorx & AnalysisDocument2 pagesModeling An API 661 Air Cooler - Intergraph CADWorx & AnalysisdhurjatibhuteshNo ratings yet

- Pan Volume CalculationDocument11 pagesPan Volume CalculationNagaraj BabuNo ratings yet

- Fallacon 15Document1 pageFallacon 15Roma99No ratings yet

- API 650 (Modified) - N5Document1 pageAPI 650 (Modified) - N5Guochao SongNo ratings yet

- Project Job Number EngineerDocument1 pageProject Job Number EngineerGirindraDamarNo ratings yet

- Memoria VigaDocument1 pageMemoria VigaKarina Manjarres VergaraNo ratings yet

- Onsms03751 1 PDFDocument4 pagesOnsms03751 1 PDFKevin DumbravaNo ratings yet

- Intercambiadores de Calor Plantas Opcion 2Document130 pagesIntercambiadores de Calor Plantas Opcion 2Julian PiratobaNo ratings yet

- Beams & Columns & Slabs According To ECPDocument15 pagesBeams & Columns & Slabs According To ECPmahmoud mahmoudNo ratings yet

- ETABSDocument1 pageETABSJasser BerriosNo ratings yet

- MCH-Fluids Properties ExcercisesDocument2 pagesMCH-Fluids Properties ExcercisesRafraf Ezdine100% (1)

- MDM 2DLDocument6 pagesMDM 2DLMicah Elaine BorjaNo ratings yet

- PIPEMILL - Piping Engineering, Design and AnalysisDocument1 pagePIPEMILL - Piping Engineering, Design and Analysisfahid masoodNo ratings yet

- LK/HK I Comp: I, F I, D I, B I IDocument13 pagesLK/HK I Comp: I, F I, D I, B I IMuhammad Putra RamadhanNo ratings yet

- METODA HARDY-CROSS (Head Balance Loop Method)Document10 pagesMETODA HARDY-CROSS (Head Balance Loop Method)Tineu AprilliaNo ratings yet

- Side FrameDocument15 pagesSide FrameGayleNo ratings yet

- Project Job Number EngineerDocument1 pageProject Job Number EngineerbenjipaulNo ratings yet

- Ridha Rahmi Khairani - Latihan IX - Hidrolika ADocument2 pagesRidha Rahmi Khairani - Latihan IX - Hidrolika AridhaNo ratings yet

- How To Use This Spreadsheet: Acrobat DocumentDocument13 pagesHow To Use This Spreadsheet: Acrobat DocumentAnonymous gfR3btyUNo ratings yet

- Interactive Course On Hydrodynamics in Ship Design': 3-Day Training Program, Shanghai, 15 - 17 May 2018Document2 pagesInteractive Course On Hydrodynamics in Ship Design': 3-Day Training Program, Shanghai, 15 - 17 May 2018Anonymous gfR3btyUNo ratings yet

- AA V5 I2 Full VersionDocument52 pagesAA V5 I2 Full VersionQuan Dieu LinhNo ratings yet

- White Sugar: Dalda Cooking Oil Kaalar Super Basmati RiceDocument8 pagesWhite Sugar: Dalda Cooking Oil Kaalar Super Basmati RiceAnonymous gfR3btyUNo ratings yet

- Directions To Shad Bagh, Lahore District, Pakistan 10.6 KM - About 20 MinsDocument5 pagesDirections To Shad Bagh, Lahore District, Pakistan 10.6 KM - About 20 MinsAnonymous gfR3btyUNo ratings yet

- Construction MethodologyDocument39 pagesConstruction MethodologyAbhimanyu KumarNo ratings yet

- List Besaran Diskon Maksimal Per Produk: NO Kode Produk Komposisi Kemasan HNADocument10 pagesList Besaran Diskon Maksimal Per Produk: NO Kode Produk Komposisi Kemasan HNAapotekerNo ratings yet

- Background of The Study: Future Founders: Understanding The Next Generation of EntrepreneursDocument4 pagesBackground of The Study: Future Founders: Understanding The Next Generation of EntrepreneursCarol PasiwatNo ratings yet

- Waiting and The Will of God: Series: The Spreading FlameDocument4 pagesWaiting and The Will of God: Series: The Spreading FlameGeorgie StephenNo ratings yet

- Cat thermoMETER Infrared enDocument56 pagesCat thermoMETER Infrared ensrinathgudur11No ratings yet

- 10 55290-Steam 1349238-3359324Document29 pages10 55290-Steam 1349238-3359324g-ipgp29205499No ratings yet

- Final Proposal 26.8.2023Document63 pagesFinal Proposal 26.8.2023Wycliff VuziguNo ratings yet

- The Implementation of A Data-Accessing Platform Built From Big Data Warehouse of Electric LoadsDocument6 pagesThe Implementation of A Data-Accessing Platform Built From Big Data Warehouse of Electric LoadsEttaoufik AbdelazizNo ratings yet

- Internet of Things: Anum NaseemDocument24 pagesInternet of Things: Anum NaseemMuqadar AliNo ratings yet

- Final Pre-Training Teacher Assessment Literacy InventoryDocument25 pagesFinal Pre-Training Teacher Assessment Literacy InventoryEL Filibusterisimo Paul CatayloNo ratings yet

- Presentation Robert Burmanjer 13july11Document10 pagesPresentation Robert Burmanjer 13july11Anonymous kHjswl6No ratings yet

- Organic Kiwifruit ProductionDocument2 pagesOrganic Kiwifruit Productionaryan jainNo ratings yet

- Laboratory 5 - The Convolution IntegralDocument10 pagesLaboratory 5 - The Convolution IntegralOsama AlqahtaniNo ratings yet

- Natural Beauty of BangladeshDocument10 pagesNatural Beauty of BangladeshpallabmphrmduNo ratings yet

- Solis 1 5k 2g Manual v2 2Document20 pagesSolis 1 5k 2g Manual v2 2Luz Mariel Serrano CastilloNo ratings yet

- Wool FolkDocument3 pagesWool FolkHendra Septian DalimuntheNo ratings yet

- TSS-TS-004 - Marker Pens For Tank Coatings and LiningsDocument5 pagesTSS-TS-004 - Marker Pens For Tank Coatings and LiningsJacoboNo ratings yet

- MCQ On Job CostingDocument11 pagesMCQ On Job CostingSocial SectorNo ratings yet

- Auditing Chp. 3 Flashcards - QuizletDocument9 pagesAuditing Chp. 3 Flashcards - Quizletglt0No ratings yet

- Timesheet Access & Filling Process DocumentDocument3 pagesTimesheet Access & Filling Process DocumentMANOJ M BNo ratings yet

- Introductory Pamphlet To Tzu ChiDocument84 pagesIntroductory Pamphlet To Tzu ChiTzuchi100% (2)