Professional Documents

Culture Documents

Effect of Temperature On The Surface Energy of Solids

Uploaded by

Do Ta0 ratings0% found this document useful (0 votes)

38 views2 pagesOriginal Title

Effect of Temperature on the Surface Energy of Solids

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

38 views2 pagesEffect of Temperature On The Surface Energy of Solids

Uploaded by

Do TaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

KRÜSS Application Note AN250e | Page 1 http://www.kruss.

de

Effect of Temperature on the Surface Energy of Solids

Application note: AN250e

Industry section: Adhesives, Lubricants, Metals

Author: Chris Rulison

Augustine Scientific, USA

Date: December 2005

Method: Drop Shape Analysis

System DSA100

Effect of Temperature on the Surface Energy of Solids -

Sometimes It Does Matter

(Probe Liquid Recommendations)

Keywords: Adhesives, Surface Energy, Temperature, Sessile Drop, Contact Angle, Adhesion, Surface

Tension, Metal

Ab st ract

Surface energy values are rarely measured for solids at elevated temperatures. Even when the goal is

understanding spreading and/or adhesion between a molten material (such as a hot melt adhesive) and a solid

surface, most commonly surface energy values for the solid surface are assumed to be those measurable at room

temperature. Here we suggest that such an approach can be problematic particularly when you have finish

coatings on metals or the remnants of drawing and stamping lubricants, which is quite common for metals. So, we

share a probe liquid set (with characterization) which can be used for high temperature solid surface energy in two-

components up to 200oC.

Method on PTFE the following surface energy

characterizations were made for the two probe liquids

The Kruss Drop Shape Analysis System DSA100 is

of interest by Fowkes method.

used along with an elevated temperature chamber to

measure the surface energies of chrome plated steel

and aluminum foil at 40oC and 160o by the Fowkes Temperature 1-bromonaphthalene 1-bromonaphthalene

o

method using contact angles obtained by the sessile C Overall Surface Surface Polarity

drop method. For purposes of making such Tension (%)

measurements, at atmospheric pressure, high boiling (mN/m)

point contact angle probe liquids are necessary and 40

43.93 1.07

must be previously characterized. We used the 60

43.00 1.44

Fowkes method to characterize 1- bromonaphthalene 80

and ethylene carbonate (1,3 dioxlan-2-one) for 42.14 1.78

100

surface tension with polar and dispersive components 41.34 2.09

at a variety of temperatures. Overall surface tensions 120

40.59 2.39

were measured using a Kruss Processor Tensiometer 140

39.88 2.67

K100 and separated into components by testing for 160

39.22 2.94

contact angle against poly(tetrafluoroethylene) 180

(PTFE). The liquids were then put to use at 40oC and 38.60 3.18

200

160o to characterize the chrome plated and aluminum 38.02 3.42

surfaces. Both liquids have boiling points above Table 1: Surface Tension Data – 1-bromonaphthalene

240oC.

Experimental

Based on plate method surface tension

measurements with a Processor Tensiometer K100

and sessile drop contact measurements for the liquids

KRÜSS GmbH • Borsteler Chaussee 85-99a • 22453 Hamburg

Tel.: +49 (40) 51 44 01 - 0 • Fax: +49 (40) 51 44 01 - 98 • eMail: info@kruss.de • http://www.kruss.de

KRÜSS Application Note AN250e | Page 2 http://www.kruss.de

with molten polymer (hot melt) to another polymer film

Temperature ethylene carbonate ethylene carbonate in our customer’s process to make holographic film.

o

C Overall Surface The findings were that the chrome plated steel had

Surface Polarity

Tension (%) very similar surface energy values at 40oC and 160oC.

(mN/m) (42.16 mJ/m2 with 45.11% surface polarity at 40oC)

40 (42.02 mJ/m2 with 45.01% surface polarity at 160oC)

53.74 63.41

60

51.92 60.99 The foil sample on the other hand, decreased

80 substantially in terms of overall surface energy and

50.32 58.98

100

48.84 57.22

surface polarity at 160oC versus at 40oC.

120

47.50 55.68

(45.31 mJ/m2 with 38.19% surface polarity at 40oC)

140 (38.21 mJ/m2 with 29.64% surface polarity at 160oC)

46.27 54.34

160 It is sometimes valid to use solid surface energy data

45.14 53.16

180

at room temperature as a legitimate estimation of the

44.11 52.13 surface energy of the same solid at elevated

200

43.16 51.23 temperature (as with the chrome plated steel above).

Table 2: Surface Tension Data – ethylene carbonate However, other times it is not. In the case of metals

this may be due to surface oxidation changes,

The following contact angles were measured and rearrangement of a surface coating, or other aspects

surface energies determined for the surfaces at the not necessary completely understood. We have also

two temperatures of interest. seen the effect in sputter coated surfaces such as

gold, nickel, etc. In the case of polymers passing

glass transition temperatures and secondary transition

Sample Chrome Chrome temperatures, well before the melt point, can also

Plated Plated

Steel Steel change surface energy substantially. These changes

Temperature o o

may well be important to the complete understanding

40 C 160 C

of your adhesion and wetting processes. Please feel

Contact Angle with

1-bromonaphthalene 54.7

o

41.4

o free to use the probe liquids and data above in your

Contact Angle with elevated temperature surface energy evaluations, or

o o

Ethylene Carbonate 42.2 22.6 to contact us if you wish to have such measurements

Overall Surface made on your systems.

2

Energy (mJ/m ) 42.16 42.02

Polar Component

2

S u m ma r y

(mJ/m ) 19.01 18.91

DispersiveComponent Surface energies of solids are most commonly only

2

(mJ/m ) 23.15 23.11 measured at room temperature and assumed to be

Surface Polarity similar at elevated temperatures for most adhesion

(%) 45.11 45.01 energy work. However, it is often the case that

Table 3: Chrome Plated Steel – Surface Energy Data

substantial differences exist with temperature in the

surface energies of real surfaces including metals that

Sample Aluminum Aluminum may contain surface coatings effected by temperature

Foil Foil and polymers. In this note we offer the surface tension

Temperature

components for two surface energy probe liquids

o o

40 C 160 C 1-bromonaphthalene and ethylene carbonate

Contact Angle with (1,3 dioxlan-2-one) which can be used, along with

o o

1-bromonaphthalene 44.1 35.2

Contact Angle with

sessile drop contact angle measurements to

Ethylene Carbonate 39.0

o

38.2

o determine the surface energy of solids up to 200oC.

Overall Surface The example data are for chrome plated steel (of

2

Energy (mJ/m ) 45.31 38.21 interest for a die application) and an aluminum foil (of

Polar Component

2 interest for the formation of holographic film). We find

(mJ/m ) 17.30 11.25

DispersiveComponent the chrome plated steel to have similar surface energy

2

(mJ/m ) 28.01 26.96 at 40oC and 160oC. The aluminium foil, however, is

Surface Polarity found to decrease in surface energy by about 7 mJ/m2

(%) 38.19 29.44 and in surface polarity by about 7% over the same

Table 4: Aluminum Foil – Surface Energy Data

temperature range.

Result s

Literature

The chrome plated steel was of interest for surface

[1] “So you Want to Measure Surface Energy?”

energy analysis at high temperature because it forms

KRÜSS technical note TN306e

the die head for a polymer extrusion process, and it

was desired to have molten polymer adhesion to it be (available for download at www.kruss.de or www.augustinescientific.com)

as low as possible. The aluminum foil sample was of

interest for surface energy because it is to be bonded

KRÜSS GmbH • Borsteler Chaussee 85-99a • 22453 Hamburg

Tel.: +49 (40) 51 44 01 - 0 • Fax: +49 (40) 51 44 01 - 98 • eMail: info@kruss.de • http://www.kruss.de

You might also like

- General Science Grade-7 PDFDocument249 pagesGeneral Science Grade-7 PDFmohammed jimjam100% (6)

- Mold Advance Course BookDocument121 pagesMold Advance Course Bookshahzad afzal100% (6)

- Hydraulic Cal WMDocument104 pagesHydraulic Cal WMWnava CrisNo ratings yet

- Atsc Final Cheat Sheet PDFDocument2 pagesAtsc Final Cheat Sheet PDFManan Shah100% (2)

- Geophysical ProspectingDocument16 pagesGeophysical ProspectingMoulik MehtaNo ratings yet

- Chapter 11 Watershed Management in Nepal: Challenges and ConstraintsDocument11 pagesChapter 11 Watershed Management in Nepal: Challenges and ConstraintsSajeet KarkeeNo ratings yet

- Effect of - Irradiation On The Properties of Rubber-Based Conductive Blend CompositesDocument10 pagesEffect of - Irradiation On The Properties of Rubber-Based Conductive Blend CompositesDr. Ahmed Abdel-HakimNo ratings yet

- Bi (PB) SR Ca Cu O (2223) Superconductor Prepared by Improved Sol Gel TechniqueDocument8 pagesBi (PB) SR Ca Cu O (2223) Superconductor Prepared by Improved Sol Gel TechniqueGökçen Aslan AydemirNo ratings yet

- Dielectric Relaxation BehaviourDocument7 pagesDielectric Relaxation BehaviourMisael Abdias Millan AlonzoNo ratings yet

- Crude Oil Fouling in A Pilot-Scale Parallel Tube ApparatusDocument10 pagesCrude Oil Fouling in A Pilot-Scale Parallel Tube Apparatusemi222222No ratings yet

- Analysis of Surface Finish in Burnishing of Brass and CopperDocument4 pagesAnalysis of Surface Finish in Burnishing of Brass and CopperFIRST FAST ASSOCIATESNo ratings yet

- The Use of Utilizable Explosives To Increase The Efficiency of An ExplosionDocument4 pagesThe Use of Utilizable Explosives To Increase The Efficiency of An ExplosionAnonymous sn5PGOsD53No ratings yet

- Using Thermal Analysis Methods To Better Understand Asphalt RheologyDocument6 pagesUsing Thermal Analysis Methods To Better Understand Asphalt RheologyNatalia KovalovaNo ratings yet

- A Study of Frequency and Temperature Effects On Fatigue Crack Growth Resistance of CPVCDocument11 pagesA Study of Frequency and Temperature Effects On Fatigue Crack Growth Resistance of CPVCIdung ChristopherNo ratings yet

- Technical Bulletin: Chloroprene RubberDocument5 pagesTechnical Bulletin: Chloroprene RubberPrashantha NandavarNo ratings yet

- Processing and Characterizations of BNT-KNN Ceramics For Actuator ApplicationsDocument6 pagesProcessing and Characterizations of BNT-KNN Ceramics For Actuator ApplicationsM CHANDRASEKHARNo ratings yet

- Jurnal Boraks 2Document7 pagesJurnal Boraks 2418003 ADI SAPUTRONo ratings yet

- The Experimental Investigation of Concrete Carbonation DepthDocument8 pagesThe Experimental Investigation of Concrete Carbonation DepthasdfghNo ratings yet

- Chaapter 4 PEMDDocument13 pagesChaapter 4 PEMDPradhunya KambleNo ratings yet

- 1043-Article Text-4043-1-10-20140214Document10 pages1043-Article Text-4043-1-10-20140214Peter RhoadsNo ratings yet

- (Datasheet) Eriks - Ketron Peek-1000Document2 pages(Datasheet) Eriks - Ketron Peek-1000Carlos AlbertoNo ratings yet

- Sintering of Ceramics-Overview PDFDocument83 pagesSintering of Ceramics-Overview PDFEstelle Maurice-ArgentNo ratings yet

- Applsci 07 00429Document12 pagesApplsci 07 00429Rahul MeenaNo ratings yet

- Arai Et Al (2005) - Study On The Visualization of Soil Turbulence Surrounding The Model Pile Using ThermographyDocument5 pagesArai Et Al (2005) - Study On The Visualization of Soil Turbulence Surrounding The Model Pile Using ThermographyMatthew KemmyNo ratings yet

- Surface Modification of Polycarbonate Using Mesh Electrode at Atmospheric Pressure Discharge at 50 HZDocument5 pagesSurface Modification of Polycarbonate Using Mesh Electrode at Atmospheric Pressure Discharge at 50 HZArun Kumar ShresthaNo ratings yet

- Convective Heat Transfer in Impinging-Gas - Jet ArrangementsDocument13 pagesConvective Heat Transfer in Impinging-Gas - Jet ArrangementsArlez HernandezNo ratings yet

- Direct Measurements of Laser Absorptivity During Metal Melt Pool Formation Associated With Powder Bed Fusion Additive Manufacturing ProcessesDocument5 pagesDirect Measurements of Laser Absorptivity During Metal Melt Pool Formation Associated With Powder Bed Fusion Additive Manufacturing ProcessesLi KLNo ratings yet

- Preparation of Pt-Ru Bimetallic Anodes by Galvanostatic Pulse Electrodeposition: Characterization and Application To The Direct Methanol Fuel CellDocument6 pagesPreparation of Pt-Ru Bimetallic Anodes by Galvanostatic Pulse Electrodeposition: Characterization and Application To The Direct Methanol Fuel Cellkrishna_saroNo ratings yet

- Gum Rosin-Acetone System As An Analogue To The Degassing Behaviour of Hydrated MagmasDocument6 pagesGum Rosin-Acetone System As An Analogue To The Degassing Behaviour of Hydrated MagmasAlbert RahardjoNo ratings yet

- Friction Coe Cient in Hot Compression of Cylindrical Sample: Yunping Li, Emi Onodera and Akihiko ChibaDocument6 pagesFriction Coe Cient in Hot Compression of Cylindrical Sample: Yunping Li, Emi Onodera and Akihiko ChibaKaren OrtegaNo ratings yet

- Disintegrating Supercritical Jets in A Subcritical EnvironmentDocument10 pagesDisintegrating Supercritical Jets in A Subcritical EnvironmentVictor CardosoNo ratings yet

- ICCM22 Full PaperDocument9 pagesICCM22 Full PaperAnonymous wTBMNUNo ratings yet

- Bo2002.pdf Surface Characteristics in The Ultrasonic Ductile Honing of ZrO2 Ceramics Using Coarse GritsDocument7 pagesBo2002.pdf Surface Characteristics in The Ultrasonic Ductile Honing of ZrO2 Ceramics Using Coarse Gritsmoharb996No ratings yet

- 1 s2.0 S0272884215002552 MainDocument5 pages1 s2.0 S0272884215002552 MainirmamendoNo ratings yet

- The Physical Properties of Pressure Sensitive Rubber CompositesDocument7 pagesThe Physical Properties of Pressure Sensitive Rubber CompositesRonald Lucas Silva Lefundes OliveiraNo ratings yet

- Azizian, Bashavard - 2005 - Surface Tension of Dilute Solutions of Linear Alcohols in Benzyl AlcoholDocument5 pagesAzizian, Bashavard - 2005 - Surface Tension of Dilute Solutions of Linear Alcohols in Benzyl AlcoholTatiana VargasNo ratings yet

- Styrene StyreneDocument22 pagesStyrene StyrenedeboNo ratings yet

- Study of Ferromagnetic and Ferroelectric Properties of Nanocrystalline Bi MN ODocument11 pagesStudy of Ferromagnetic and Ferroelectric Properties of Nanocrystalline Bi MN ODeym GómezNo ratings yet

- Porositas KatalisDocument8 pagesPorositas KatalisYoga PratamaNo ratings yet

- Tekure 2021Document18 pagesTekure 2021Liviu BadeaNo ratings yet

- Ali Take ItDocument14 pagesAli Take ItAlyaa TahirNo ratings yet

- Watermark Operating Instructions 2Document8 pagesWatermark Operating Instructions 2Pedro Salazar RojasNo ratings yet

- CAL - Lei Dos Gases IdeaisDocument5 pagesCAL - Lei Dos Gases Ideaisjrfisico2011No ratings yet

- Thermography Imaging Based On Equivalent Wave Field Transform For ClientDocument28 pagesThermography Imaging Based On Equivalent Wave Field Transform For Clientcarlito79No ratings yet

- Controlled Lowering of Graphitization Temperature of Electrospun Poly (Acrylonitrile) Based Carbon Fiber by Carbon Nanotube EmbedmentDocument4 pagesControlled Lowering of Graphitization Temperature of Electrospun Poly (Acrylonitrile) Based Carbon Fiber by Carbon Nanotube EmbedmentPhysics MPSTMENo ratings yet

- AltoCiclo SciencedirectDocument10 pagesAltoCiclo SciencedirectLeonardo LimaNo ratings yet

- 90 PDFDocument12 pages90 PDFBrandon HenryNo ratings yet

- FRB and Ebr at FireDocument9 pagesFRB and Ebr at Firesantosh bharathyNo ratings yet

- Isobaric Vapor Liquid Equilibria of The Water 2-Propanol System at 30, 60, and 100 KpaDocument4 pagesIsobaric Vapor Liquid Equilibria of The Water 2-Propanol System at 30, 60, and 100 KpaRafael HenriqueNo ratings yet

- Low Temperature Deformation of The R-Phase in A NiTiFe Shape Memory AlloyDocument4 pagesLow Temperature Deformation of The R-Phase in A NiTiFe Shape Memory AlloyLive LivedNo ratings yet

- Heat P 2019Document5 pagesHeat P 2019JakeNo ratings yet

- Improvement in The Efficiency of Thermally-Induced Ultrasonic Emission From Porous Silicon by Nano-Structural ControlDocument1 pageImprovement in The Efficiency of Thermally-Induced Ultrasonic Emission From Porous Silicon by Nano-Structural ControlNaser AlrawiNo ratings yet

- Analysis of Microstructure in Soft Zone and Precipitation Zone of Dissimilar Cr-Mo Steels WeldmentDocument8 pagesAnalysis of Microstructure in Soft Zone and Precipitation Zone of Dissimilar Cr-Mo Steels WeldmentMahsaNo ratings yet

- Shear Parameters of Rammed Earth Material ResultsDocument10 pagesShear Parameters of Rammed Earth Material ResultsJalal KeNo ratings yet

- Additive Manufacturing: SciencedirectDocument5 pagesAdditive Manufacturing: Sciencedirectpurrab divakarNo ratings yet

- Comparison of Three Types of Carbon Composite Coatings With Exceptional Load-Bearing Capacity and High Wear ResistanceDocument5 pagesComparison of Three Types of Carbon Composite Coatings With Exceptional Load-Bearing Capacity and High Wear ResistanceDaniel ToaderNo ratings yet

- Applied Thermal Engineering: D. Meresse, S. Harmand, M. Siroux, M. Watremez, L. DubarDocument9 pagesApplied Thermal Engineering: D. Meresse, S. Harmand, M. Siroux, M. Watremez, L. DubarYemane TesfayeNo ratings yet

- Microwave-Assisted Hydrothermal Synthesis and Characterization ofDocument3 pagesMicrowave-Assisted Hydrothermal Synthesis and Characterization ofVanessa NielyNo ratings yet

- Deformation Mechanism Map of Cu/Nb Nanoscale Metallic Multilayers As A Function of Temperature and Layer ThicknessDocument20 pagesDeformation Mechanism Map of Cu/Nb Nanoscale Metallic Multilayers As A Function of Temperature and Layer ThicknessMiguel MonclusNo ratings yet

- Al Hayan2006Document5 pagesAl Hayan2006Samyak DhutaleNo ratings yet

- (2001) The Thermal Degradation of Poly (Vinyl Alcohol)Document9 pages(2001) The Thermal Degradation of Poly (Vinyl Alcohol)Nam Huu TranNo ratings yet

- An Investigation of The Structures and Molecular Dynamics of Natural WaxesDocument9 pagesAn Investigation of The Structures and Molecular Dynamics of Natural WaxesCarolina AyalaNo ratings yet

- Effect of Crosslinking On The MechanicalDocument8 pagesEffect of Crosslinking On The MechanicalThoại Nguyễn QuốcNo ratings yet

- Comparativestudyoftheuseof Hoek Brownandequivalent Mohr CoulombparametersintunnelexcavationDocument16 pagesComparativestudyoftheuseof Hoek Brownandequivalent Mohr CoulombparametersintunnelexcavationAhmed NoeNo ratings yet

- SSRN Id4427163Document36 pagesSSRN Id4427163Do TaNo ratings yet

- Apply in ShipDocument6 pagesApply in ShipDo TaNo ratings yet

- Pipe FlowDocument15 pagesPipe FlowDo TaNo ratings yet

- Investigation of Boat Hull Performance With Superhydrophobic CoatDocument51 pagesInvestigation of Boat Hull Performance With Superhydrophobic CoatDo TaNo ratings yet

- Immersed Superhydrophobic SurfacesDocument6 pagesImmersed Superhydrophobic SurfacesDo TaNo ratings yet

- CNT Drag ReductionDocument6 pagesCNT Drag ReductionDo TaNo ratings yet

- Dynamic Air Layer On Textured Superhydrophobic SurfacesDocument8 pagesDynamic Air Layer On Textured Superhydrophobic SurfacesDo TaNo ratings yet

- RSC Advances: PaperDocument8 pagesRSC Advances: PaperDo TaNo ratings yet

- A Numerical Study of Drag Reduction of Superhydrophobic Surfaces in Shipping IndustryDocument5 pagesA Numerical Study of Drag Reduction of Superhydrophobic Surfaces in Shipping IndustryDo TaNo ratings yet

- Waste Management: Marco Tomasi Morgano, Hans Leibold, Frank Richter, Dieter Stapf, Helmut SeifertDocument9 pagesWaste Management: Marco Tomasi Morgano, Hans Leibold, Frank Richter, Dieter Stapf, Helmut SeifertCarlos AlvarezNo ratings yet

- Unit The Natural World: Environmental Impacts of LoggingDocument7 pagesUnit The Natural World: Environmental Impacts of LoggingnbjnNo ratings yet

- Values of Safe Bearing CapacityDocument2 pagesValues of Safe Bearing CapacityChee Soon LeeNo ratings yet

- Student Exploration: Limiting ReactantsDocument2 pagesStudent Exploration: Limiting ReactantsaefNo ratings yet

- The Differences Between Green Energy, Renewable Energy and MoreDocument1 pageThe Differences Between Green Energy, Renewable Energy and MoreroopakNo ratings yet

- Class 4-Social Studies-Digital Module 1-15-11th June 2020Document10 pagesClass 4-Social Studies-Digital Module 1-15-11th June 2020stephen_george_29No ratings yet

- Atomic Structure: Protons, Neutrons & ElectronsDocument2 pagesAtomic Structure: Protons, Neutrons & ElectronsAdam JensenNo ratings yet

- Question Answer: Free Knowledge Sharing WebsiteDocument8 pagesQuestion Answer: Free Knowledge Sharing Websitezohaib inksarNo ratings yet

- Wilson Cloud Chamber: How Does It WorkDocument3 pagesWilson Cloud Chamber: How Does It WorkNaveed AhmedNo ratings yet

- Icpep 4 AbstractDocument254 pagesIcpep 4 AbstractshonapinkiNo ratings yet

- AdsorptionDocument3 pagesAdsorptionali105No ratings yet

- Ee2303 Newlp ADocument3 pagesEe2303 Newlp ARavi KannappanNo ratings yet

- LPO of SPIRADocument2 pagesLPO of SPIRAFuqingliNo ratings yet

- VICONDocument6 pagesVICONBukhori TamamNo ratings yet

- You Searched For - SimpAsianDocument1 pageYou Searched For - SimpAsianZayar LwinNo ratings yet

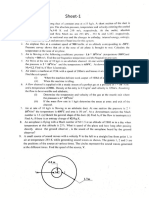

- Problem Sheets 1 2 3 4Document12 pagesProblem Sheets 1 2 3 4AshutoshNo ratings yet

- Steam Circuit Diagram PDFDocument1 pageSteam Circuit Diagram PDFAgeng Firstyan BagaskoroNo ratings yet

- Environmental Sustainability Action PlanDocument15 pagesEnvironmental Sustainability Action PlanIvana NikolicNo ratings yet

- Taxonomy Test Review With ANSDocument4 pagesTaxonomy Test Review With ANSdani abrahaNo ratings yet

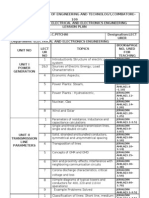

- Power Plant Engineering: TME-801 Unit-IDocument2 pagesPower Plant Engineering: TME-801 Unit-IRe AdhityNo ratings yet

- Module 3 Lesson 1Document37 pagesModule 3 Lesson 1Juvy Jane DuarteNo ratings yet

- The Shepherd of Banbury's Rules To Judge of The Changes of The Weather, Grounded On Forty Years' Experience by Claridge, JohnDocument30 pagesThe Shepherd of Banbury's Rules To Judge of The Changes of The Weather, Grounded On Forty Years' Experience by Claridge, JohnGutenberg.org100% (1)

- AQM M1 Ktunotes - inDocument25 pagesAQM M1 Ktunotes - inBala GopalNo ratings yet

- Chemistry: Ogun State School of Nursing Practice Questions For Enterance EXAMS 2022Document103 pagesChemistry: Ogun State School of Nursing Practice Questions For Enterance EXAMS 2022mariamojelade5No ratings yet