Professional Documents

Culture Documents

Batch Plant Inspection: DSA Forms DSA Publications

Uploaded by

Michael HaleyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Batch Plant Inspection: DSA Forms DSA Publications

Uploaded by

Michael HaleyCopyright:

Available Formats

IR 17-13

BATCH PLANT INSPECTION

Disciplines: Structural History: Issued 07/28/20

Division of the State Architect (DSA) documents referenced within this publication are available

on the DSA Forms or DSA Publications webpages.

PURPOSE

This Interpretation of Regulations (IR) provides clarification of minimum qualifications and

responsibilities for personnel conducting inspection of transit-mixed batch plant operations for

projects under Division of the State Architect (DSA) jurisdiction.

SCOPE

This IR is applicable to inspection of the batching of transit-mixed concrete, shotcrete, grout and

other cementitious mixtures required to be inspected in accordance with the DSA-approved

construction documents. For applicable reporting requirements, refer to IR 17-12: Special

Inspection Reporting Requirements.

BACKGROUND

The California Building Code (CBC) requires “continuous” inspection of all concrete batching.

CBC also identifies provisions for permitting periodic special inspections of concrete batching

operations, and for certain DSA applications, elimination of batch plant inspections.

1. CONTINUOUS VS. PERIODIC BATCH PLANT INSPECTION

The requirement for continuous batch plant inspection may be waived by the design

professional in responsible charge for qualifying cases noted in CBC Section 1705A.3.3 if

approved by DSA and identified on the form DSA-103: List of Required Structural Tests &

Special Inspections and other appropriate DSA-approved construction documents (e.g.,

drawings, etc.). If waived, “periodic” inspection is required as detailed below. In some cases,

batch plant inspection may be excluded entirely, subject to the requirements and limitations in

CBC Section 1705A.3.3.2.

1.1 Continuous Batch Plant Inspection

Continuous batch plant inspection is required unless the criteria previously described is met.

Continuous inspection requires the inspector be on-site prior to batching to verify the

requirements of Section 4 below, and be physically present at the batching console during all

batching operations every day that such occurs for the project.

1.2 Periodic Batch Plant Inspection

Periodic batch plant inspection requires the inspector be on-site prior to batching to verify the

requirements of Section 4 below, and be physically present at the batching console during the

batching of the first batch of the day for the project. The inspector shall verify that the batch

plant complies with American Standards for Testing and Materials (ASTM) C94, Sections 9 and

10, and holds valid certification from the National Ready Mixed Concrete Association (NRMCA)

or Caltrans Material Plant Quality Program (MPQP).

IR 17-13 (Issued 07/28/20) Page 1 of 4

DIVISION OF THE STATE ARCHITECT DEPARTMENT OF GENERAL SERVICES STATE OF CALIFORNIA

IR 17-13

BATCH PLANT INSPECTON: 2019 CBC

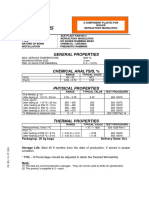

2. MIX DESIGNS

2.1 General

For all mix designs, proportions shall be selected by a registered civil engineer with experience

in mix designs, and shall be determined in accordance with the provisions of American Concrete

Institute (ACI) 318, Section 26.4.3. All mix designs shall be identified by a mix design

identification number. The civil engineer shall prepare and submit a mix design report to the

DSA-accepted testing laboratory for review.

Mix design reports shall include all data required to verify conformance with ACI 318 Sections

26.4.3 and 26.4.4, and the following:

• Mix design identification number

• Purpose or class of concrete

• Cement certification

• Supplementary Cementitious Materials (SCM) certification

• Admixture technical data sheets

• Aggregate test data

• Historic compressive strength data or Three-point water/cement ratio data

The report shall also bear the signature and seal of the registered engineer responsible for

proportioning in accordance with Section 1.1 of IR A-19: Design Professional’s Signature and

Seal (Stamp) on Construction Documents.

2.2 Mix Design Review and Approval Process

An engineer from a DSA-accepted testing laboratory shall review the mix design report, and the

design professional in responsible charge of the project shall approve the mix design.

2.2.1 Review by Laboratory of Record (LOR) Engineer

A qualified civil engineer associated with a DSA-accepted testing laboratory shall review the

report for conformance with ACI 318 Sections 26.4.3.1 and 26.4.4.1. They shall also issue an

evaluation report of findings and recommendation for either acceptance or rejection and forward

their report to the design professional in responsible charge of the project.

2.2.2 Approval by the Project Engineer in Responsible Charge

Based on their own review, and the findings and recommendation of the respective LOR

engineer’s evaluation report, the project design professional in responsible charge decides

whether to accept or reject the mix design. They will issue a letter stating their acceptance or

rejection, sending the original letter to DSA, and distributing copies to the project inspector (PI),

LOR and the mix design engineer.

2.2.3 Documentation by the Supplier

The ready-mix supplier shall submit a copy of the approved mix design, cement certification,

SCM certification, admixture technical data sheets, aggregate test data and historic

compressive strength data to the contractor for distribution to the PI and LOR’s responsible

engineer.

3. INSPECTOR QUALIFICATIONS

Batch plant inspectors shall meet all of the following requirements. Qualifications of all batch

plant inspectors shall be verified by the LOR’s engineering manager.

IR 17-13 (Issued 07/28/20) Page 2 of 4

DIVISION OF THE STATE ARCHITECT DEPARTMENT OF GENERAL SERVICES STATE OF CALIFORNIA

IR 17-13

BATCH PLANT INSPECTON: 2019 CBC

• Possess valid certification from ACI as a Concrete Field or Lab Testing Technician and

documented in-house training, or be a California licensed civil engineer. In-house

training records shall document the inspectors general knowledge of materials used to

produce ready-mixed concrete and/or grout, batch plant processes and operation, and

mixing/delivery methods.

• Possess knowledge of the administrative requirements of the California Administrative

Code (CAC), Section 4-335 and concrete batch plant inspection requirements of CBC

Section 1705A.3.3.

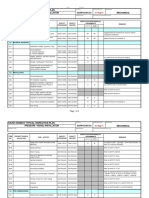

4. INSPECTOR DUTIES

The following duties apply to both continuous and periodic batch plant inspection and shall be

performed and documented on a daily basis. The batch plant inspector shall perform all duties

outlined in Section 4 of this IR.

4.1 Prior to Batching

4.1.1 Review and understand the applicable portions of the approved mix designs, DSA-

approved construction documents, post approval documents and ASTM C94.

4.1.2 Verify and document that the batching facility holds current NRMCA or MPQP

certification. For non-certified plants verify and document that weighing scales and concrete

mixing trucks meet the requirements of ASTM C94.

4.1.3 Verify that material storage areas are separated, clean and free of contaminants.

Aggregate storage areas and stockpiles should be free draining and equipped with water spray

systems to maintain aggregates in a saturated condition. Cementitious materials shall be stored

in weatherproof structures, and admixture materials shall be protected from freezing.

4.1.4 For non-certified plants, verify that scales and other measuring or metering systems

(water and admixtures) appear to be in good working order, are functioning and currently

calibrated.

4.1.5 Verify that fine aggregate moisture meters appear to be in good working order and

functioning. Non-functioning meters require aggregate sampling and moisture “burn-back”

testing by the supplier.

4.2 During Batching

Note: Any deviations to any of the the following subsections of Section 4.2 shall be

immediately reported to the weighmaster.

4.2.1 The batch plant inspector shall be physically present at the batching console during the

batching sequence for each load.

4.2.2 Verify by “back spinning” that the mixing drum does not contain large amounts of wash-

out water from the previous load.

4.2.3 Verify the correct mix is being produced and that the correct truck number is referenced

on the batch ticket.

4.2.4 Verify that material scales start at and return to zero after each weighing cycle.

4.2.5 Verify that fine aggregate moisture contents are being determined, and that batch

quantities of materials are adjusted, to compensate for free moisture in the aggregates.

4.2.6 Verify the type and amount of coarse and fine aggregate, cement, SCMs, admixtures and

water conform to the approved mix design proportions, and are batched and delivered to the

mixer within tolerances specified in ASTM C94.

IR 17-13 (Issued 07/28/20) Page 3 of 4

DIVISION OF THE STATE ARCHITECT DEPARTMENT OF GENERAL SERVICES STATE OF CALIFORNIA

IR 17-13

BATCH PLANT INSPECTON: 2019 CBC

4.2.7 Visually inspect trucks for excess spillage that may have occurred during the loading

process, and if drum revolution limits are specified in the DSA-approved documents verify that

revolution counters are functioning and set to zero.

4.2.8 Record the total amount of wash down water added to each load inspected, and

calculate and report the maximum quantity of water permitted to be added at the project site.

4.2.9 Provide a batch plant inspection certificate or report for each load inspected, clearly

detailing basic load information and permitted quantity of site-added water. The inspection

certificate shall be sent with the load or be electronically transmitted to the PI prior to discharge.

Certificates shall include the name of the inspector and a statement that the specific load(s)

were duly inspected and met the requirements of the approved mix design or, when applicable,

provide details of non-conformining aspects of the batch.

5. REPORTING

5.1 The batch plant inspector shall prepare and provide detailed daily inspection reports, that

clearly describe the work inspected in accordance with IR 17-12 and CAC Section 4-335(f)4, to

parties indicated to receive such reports. All reports shall be transmitted to the PI within one day

of the date the inspections were performed and shall document all inspection duties listed in

Section 4 above. Reports of non-conforming materials shall be forwarded immediately to the PI

and others indicated to receive such reports.

6. FAILURE TO PERFORM

Failure to inspect the work in a professional and competent manner, prepare and distribute all

required reports in a truthful and timely manner (including reports of defective work) or fulfill any

other duties defined by CAC may result in withdrawal of DSA acceptance of the batch plant

inspector and/or LOR (reference CAC, § 4-335.1[c]). This includes but is not limited to

withdrawal of acceptance or approval to work on any current or future projects under DSA

jurisdiction.

REFERENCES:

California Code of Regulations (CCR) Title 24

Part 1: California Administrative Code (CAC), Section 4-335

Part 2: California Building Code (CBC), Section 1705A.3.3

This IR is intended for use by DSA staff and by design professionals to promote statewide consistency for review and

approval of plans and specifications as well as construction oversight of projects within the jurisdiction of DSA, which

includes State of California public schools (K‒12), community colleges and state-owned or state-leased essential

services buildings. This IR indicates an acceptable method for achieving compliance with applicable codes and

regulations, although other methods proposed by design professionals may be considered by DSA.

This IR is subject to revision at any time. Please check DSA’s website for currently effective IRs. Only IRs listed on

the webpage at https://www.dgs.ca.gov/dsa/publications at the time of project application submittal to DSA are

considered applicable.

IR 17-13 (Issued 07/28/20) Page 4 of 4

DIVISION OF THE STATE ARCHITECT DEPARTMENT OF GENERAL SERVICES STATE OF CALIFORNIA

You might also like

- Structural Welding Inspection: 2019 CBC: DSA Forms DSA PublicationsDocument3 pagesStructural Welding Inspection: 2019 CBC: DSA Forms DSA PublicationsfracevNo ratings yet

- Readymix 2Document6 pagesReadymix 2melatyplamoniaNo ratings yet

- APP143Document6 pagesAPP143Kwok MorrisNo ratings yet

- AEP1152Document10 pagesAEP1152walitedisonNo ratings yet

- Cast in Situ Pile Method StatementDocument18 pagesCast in Situ Pile Method StatementManal Patel100% (2)

- Sampling, Testing and Tagging of Reinforcing Bars: DSA Forms DSA PublicationsDocument4 pagesSampling, Testing and Tagging of Reinforcing Bars: DSA Forms DSA PublicationsMichael HaleyNo ratings yet

- Ship RepairDocument56 pagesShip Repairganda irvanNo ratings yet

- Concrete Method StatementDocument14 pagesConcrete Method StatementWufei Chang95% (21)

- Sampling, Testing and Tagging of Rebar Ir-17 PDFDocument3 pagesSampling, Testing and Tagging of Rebar Ir-17 PDFKidd Torno100% (1)

- Inspection of Underground Precast Concrete Utility StructuresDocument2 pagesInspection of Underground Precast Concrete Utility Structuresmohammed ;arasnehNo ratings yet

- Fall Arrest Spec PDFDocument6 pagesFall Arrest Spec PDFAnonymous I8nZsDqlmhNo ratings yet

- Buildings Department Practice Note For Authorized Persons, Registered Structural Engineers and Registered Geotechnical Engineers APP-45Document3 pagesBuildings Department Practice Note For Authorized Persons, Registered Structural Engineers and Registered Geotechnical Engineers APP-45anon_78207244No ratings yet

- Cargo Container Conversion To Modular School Buildings: Disciplines: HistoryDocument6 pagesCargo Container Conversion To Modular School Buildings: Disciplines: Historycarlos.caceresNo ratings yet

- Concrete Batch PlantDocument9 pagesConcrete Batch Plantjana0926No ratings yet

- Procedure For Fabrication and Erection of HP Piping Extract From Tata Cons - LTDDocument12 pagesProcedure For Fabrication and Erection of HP Piping Extract From Tata Cons - LTDSushanta NaikNo ratings yet

- Qcs 2010 Part 10 Pipeline Cleaning and Inspection SurveyDocument18 pagesQcs 2010 Part 10 Pipeline Cleaning and Inspection SurveyRotsapNayrbNo ratings yet

- Enquiry ValveDocument4 pagesEnquiry ValvePradnyesh DivekarNo ratings yet

- Plant Certification ChecklistDocument26 pagesPlant Certification ChecklistAndy Rogers100% (2)

- Under Slab Piping Drawing and Specs PDFDocument71 pagesUnder Slab Piping Drawing and Specs PDFjfl2096100% (1)

- BP - Survey Vessel XS6001Document10 pagesBP - Survey Vessel XS6001Kurniawan PriambodoNo ratings yet

- No.6 Low Voltage Cubicle Switchboard InstallationDocument23 pagesNo.6 Low Voltage Cubicle Switchboard InstallationHang WanNo ratings yet

- National Board Pressure Relief Device Certification Administrative RequirementsDocument3 pagesNational Board Pressure Relief Device Certification Administrative RequirementsHaroltAlexisLeonTripulNo ratings yet

- Dangerous Goods Guidance Note 10 PDFDocument3 pagesDangerous Goods Guidance Note 10 PDFDan DumbravescuNo ratings yet

- Technical SpecificayionDocument40 pagesTechnical SpecificayionDebjit KunduNo ratings yet

- Vol-III of IV - Laying - HPCLDocument527 pagesVol-III of IV - Laying - HPCLbolinagNo ratings yet

- 994 Structural PDF BookletDocument20 pages994 Structural PDF BookletRommel Abenoja100% (2)

- Revised Draft Ammendment To IRS T29 MAR13Document11 pagesRevised Draft Ammendment To IRS T29 MAR13Shipra MishraNo ratings yet

- Civil Quality Control ProcedureDocument37 pagesCivil Quality Control ProcedureRen Salazar100% (2)

- Abs Type Approval1 - TeamDocument5 pagesAbs Type Approval1 - TeamRogério FreitasNo ratings yet

- 2011 Mcs FinalDocument62 pages2011 Mcs FinalhendjoNo ratings yet

- Technical Specifications FOR Plumbing Works (Internal & External)Document40 pagesTechnical Specifications FOR Plumbing Works (Internal & External)Mac ShaikNo ratings yet

- Excavaciones AmbientalDocument20 pagesExcavaciones AmbientalCindy JulianaNo ratings yet

- QA QC Manual 2008Document86 pagesQA QC Manual 2008netomeller100% (2)

- Do - 253 - s2003 Asphalt and Concrete Batching PlantsDocument12 pagesDo - 253 - s2003 Asphalt and Concrete Batching PlantsrubydelacruzNo ratings yet

- Itn 2017 04Document64 pagesItn 2017 04yathi sNo ratings yet

- BIW Ref: 00-SP-03-3000 Rev 03Document46 pagesBIW Ref: 00-SP-03-3000 Rev 03niuxiaoliangNo ratings yet

- 2PW046 SOW (Elevator Modernization, B120)Document5 pages2PW046 SOW (Elevator Modernization, B120)thang_phan_54No ratings yet

- Qcs 2010 Part 28.02 Irrigation System SpecificationsDocument38 pagesQcs 2010 Part 28.02 Irrigation System SpecificationsRotsapNayrb100% (1)

- NRMCA Plant Certification: Items The Company Should Have Ready Prior To Requesting An InspectionDocument2 pagesNRMCA Plant Certification: Items The Company Should Have Ready Prior To Requesting An Inspectioncah_mbuhNo ratings yet

- Precast Concrete Technician Study GuideDocument37 pagesPrecast Concrete Technician Study Guidefree4bruceNo ratings yet

- Polymer SpecifcatiionDocument7 pagesPolymer SpecifcatiionSunny RohillaNo ratings yet

- AiscDocument3 pagesAiscvo thi kim xuyenNo ratings yet

- Schedule Q - Attachment VIDocument8 pagesSchedule Q - Attachment VISIVANo ratings yet

- Supplemental Requirements For Fabricators of Steel Bridges (SBR, IBR, ABR)Document6 pagesSupplemental Requirements For Fabricators of Steel Bridges (SBR, IBR, ABR)Roberto ParionaNo ratings yet

- Elaborated By: Arturo LlanosDocument59 pagesElaborated By: Arturo LlanosSuryaprakashNo ratings yet

- Acceptance Test Reports of Ready Mixed Concrete: Who Should Get Them?Document4 pagesAcceptance Test Reports of Ready Mixed Concrete: Who Should Get Them?ZELALEMNo ratings yet

- SECTION 03 45 00 Precast Architectural ConcreteDocument30 pagesSECTION 03 45 00 Precast Architectural ConcreteJuanPaoloYbañezNo ratings yet

- AHJ Correections-Requirements For Struc Eng Laundromat B23-12520Document1 pageAHJ Correections-Requirements For Struc Eng Laundromat B23-12520Rhem Aldrin CordovaNo ratings yet

- SRMCA Concrete Production Facilities Certification Program Checklist - Fifth Edition Rev Nov. 2013 PDFDocument23 pagesSRMCA Concrete Production Facilities Certification Program Checklist - Fifth Edition Rev Nov. 2013 PDFSumit OmarNo ratings yet

- QCS 2010 Section 28 Part 2Document38 pagesQCS 2010 Section 28 Part 2Saif Abdulla0% (1)

- Tank Specification - Fiberglass Tanks 0408Document13 pagesTank Specification - Fiberglass Tanks 0408shankarkl100% (2)

- Materials and Qualification Procedures For Ships: Book CDocument18 pagesMaterials and Qualification Procedures For Ships: Book CDinar OjakNo ratings yet

- Appendix G Construction Inspection Checklists and Asbuilt CertificationsDocument30 pagesAppendix G Construction Inspection Checklists and Asbuilt CertificationsMehdi RezougNo ratings yet

- TR Foam Tank Crude PumpDocument3 pagesTR Foam Tank Crude PumpirfanlarikhotmailcomNo ratings yet

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeFrom EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNo ratings yet

- Bioprocessing Piping and Equipment Design: A Companion Guide for the ASME BPE StandardFrom EverandBioprocessing Piping and Equipment Design: A Companion Guide for the ASME BPE StandardNo ratings yet

- California Infrastructure Projects: Legal Aspects of Building in the Golden StateFrom EverandCalifornia Infrastructure Projects: Legal Aspects of Building in the Golden StateNo ratings yet

- Identification, Sampling and Testing of Threaded Steel Anchor Bolts and Anchor RodsDocument6 pagesIdentification, Sampling and Testing of Threaded Steel Anchor Bolts and Anchor RodsMichael HaleyNo ratings yet

- Aci Renewel DateDocument1 pageAci Renewel DateMichael HaleyNo ratings yet

- Hazard Identification: 1. Position The Yellow Arm Guard Directly Below The HammerDocument2 pagesHazard Identification: 1. Position The Yellow Arm Guard Directly Below The HammerMichael HaleyNo ratings yet

- Special Inspection Reporting Requirements: DSA PublicationsDocument3 pagesSpecial Inspection Reporting Requirements: DSA PublicationsMichael HaleyNo ratings yet

- Adobe Scan Jun 01 2021Document1 pageAdobe Scan Jun 01 2021Michael HaleyNo ratings yet

- Reinforced Concrete Information-1 PDFDocument5 pagesReinforced Concrete Information-1 PDFnotevaleNo ratings yet

- Sop 003Document1 pageSop 003Michael HaleyNo ratings yet

- Sampling, Testing and Tagging of Reinforcing Bars: DSA Forms DSA PublicationsDocument4 pagesSampling, Testing and Tagging of Reinforcing Bars: DSA Forms DSA PublicationsMichael HaleyNo ratings yet

- Mechanical Drives 1 Lap 3Document77 pagesMechanical Drives 1 Lap 3j.bbarnesNo ratings yet

- Sans2001-Ct2-2011 - Ed1.2-Struct Timber RoofDocument35 pagesSans2001-Ct2-2011 - Ed1.2-Struct Timber RoofRoland BritzNo ratings yet

- FIRST مسرحDocument1 pageFIRST مسرحAbdelhamed MedhatNo ratings yet

- Fatigue and Bond Properties For High Performance ConcreteDocument23 pagesFatigue and Bond Properties For High Performance ConcretesakolkongNo ratings yet

- Bharat BhavanDocument14 pagesBharat BhavanNareegara NimeshNo ratings yet

- Ace Plast Ram Bs2Document1 pageAce Plast Ram Bs2pulakjaiswal85No ratings yet

- Bsi BS en 12602+a1 - 2013Document190 pagesBsi BS en 12602+a1 - 2013alferedNo ratings yet

- Civil Engineering Reviewer - Soil and FoundationDocument8 pagesCivil Engineering Reviewer - Soil and Foundationmark_torreon100% (4)

- ASME B31.1 Power PipingDocument1 pageASME B31.1 Power Pipingslxanto25% (4)

- SATIP D 001 01 (Revision 4)Document3 pagesSATIP D 001 01 (Revision 4)Anonymous 4e7GNjzGW100% (1)

- Buehler Technotes - Indentation Testing MappingDocument3 pagesBuehler Technotes - Indentation Testing Mappingdev-nullNo ratings yet

- 03 Bridge HydraulicsDocument35 pages03 Bridge HydraulicsMichael DixonNo ratings yet

- ScaffoldingDocument24 pagesScaffoldingAzrulZamriNo ratings yet

- Upheaval Buckling PipelineDocument11 pagesUpheaval Buckling PipelineRYZKI EFENDI SIMANULANGNo ratings yet

- Mountain and Agricultural SettlementsDocument66 pagesMountain and Agricultural SettlementsArianne Joy Quiba DullasNo ratings yet

- Roles and Responsibilities of Project Managers: BSS666: LECT 3Document21 pagesRoles and Responsibilities of Project Managers: BSS666: LECT 3Ahmad Muzakkir Ahmad FauziNo ratings yet

- 550r 96 PDFDocument8 pages550r 96 PDFFred PrzNo ratings yet

- CV. Gentur Maladi - Inspector 10Document6 pagesCV. Gentur Maladi - Inspector 10abdurrahman warsyahNo ratings yet

- Standard Materials Price List For Infrastructure: Capital Province: Year: 2016 2-BattambangDocument8 pagesStandard Materials Price List For Infrastructure: Capital Province: Year: 2016 2-BattambangsamehNo ratings yet

- İMÜ331 - Soil Mechanics I: SeepageDocument18 pagesİMÜ331 - Soil Mechanics I: SeepageCagdas AydınNo ratings yet

- Experimental Research of Hollow Concrete Block Mas PDFDocument7 pagesExperimental Research of Hollow Concrete Block Mas PDFmayasNo ratings yet

- Steel Grade Diameter Tensile Strength (RM) YIE Point (RP0.2) Elongation (A5) Hardness Impact Test (J at - 20°C)Document1 pageSteel Grade Diameter Tensile Strength (RM) YIE Point (RP0.2) Elongation (A5) Hardness Impact Test (J at - 20°C)Kuya Fabio VidalNo ratings yet

- Eastman Industries - BoqDocument6 pagesEastman Industries - BoqcivilNo ratings yet

- Lts Product Liner 1Document2 pagesLts Product Liner 1claudio godinezNo ratings yet

- PDF Ems Engine Management System PPTX Repaired DDDocument56 pagesPDF Ems Engine Management System PPTX Repaired DDmuhammad dzakiNo ratings yet

- Cummins Engine Service Manual Cum S H NHDocument11 pagesCummins Engine Service Manual Cum S H NHWalter Lazo50% (2)

- Performance-Based Seismic Design of Bridges: A Global Perspective and Critical Review of Past, Present and Future DirectionsDocument25 pagesPerformance-Based Seismic Design of Bridges: A Global Perspective and Critical Review of Past, Present and Future DirectionsYati TankNo ratings yet

- Manual Lava Louça CCR200 - MDIK80-00 LIVRETO PDFDocument132 pagesManual Lava Louça CCR200 - MDIK80-00 LIVRETO PDFJulyanorigoniNo ratings yet

- Indian Standard For LiftsDocument11 pagesIndian Standard For LiftsSomnath DasNo ratings yet

- PM 293598 001 1800 PartsDocument663 pagesPM 293598 001 1800 Partsgilberto isrrael roman saviñonNo ratings yet