Professional Documents

Culture Documents

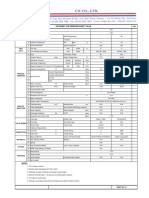

Control Valve Specification Sheet

Uploaded by

jose0 ratings0% found this document useful (0 votes)

49 views1 pageOriginal Title

TERMOCOMPRESOR

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

49 views1 pageControl Valve Specification Sheet

Uploaded by

joseCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Control Valve Specification Sheet

Date 18/06/2014 Quotation Ref - Prepared By Rodrigo Suarez

Sheet - Revision No - Email rodrigo.suarez@ar.spiraxsarco.com

Quantity - AO Number - Telephone -

Customer - Order Number -

Project Type - Location -

Project Name - Project Ref - Job Name -

Model Code 3" LEA43PTSUSS.2 Cv 120 ANSI 150 + PN9233E + EP5 Tag No -

CONTROL VALVE SELECTION

1 Service Application - 5 Max Safe Working Pressure -

2 Hazard Area Class - 6 Pipe Material / Standard -

3 Ambient Air Temperature - 7 Valve Type 2 Port

4 Site Noise Limit 85 dB(A) 8 Design Standard ANSI

DESIGN CONDITIONS SELECTED PIPE SIZE AND VALVE LAGGING

9 Maximum Pressure - 12 Pipe Inlet / Designation 2 1/2" DN65 / Schedule 40

10 Minimum Temperature - 13 Pipe Outlet / Designation 2 1/2" DN65 / Schedule 40

11 Maximum Temperature - 14 Lagging -

PROCESS DATA

15 Media Dry Saturated Steam

16 Process Condition 1 2 3 4

17 Name MIN NOM MAX -

18 State Gas Gas Gas -

19 Mass Flow 1.000,00 kg/h 1.700,00 kg/h 1.850,00 kg/h -

20 Volumetric Flow 194,12 m³/h 330,00 m³/h 359,12 m³/h -

21 Inlet Pressure 9,00 bar gauge 9,00 bar gauge 9,00 bar gauge -

22 Outlet Pressure 8,50 bar gauge 8,50 bar gauge 8,50 bar gauge -

23 Differential Pressure 0,50 bar 0,50 bar 0,50 bar -

24 Temperature 179,95 °C 179,95 °C 179,95 °C -

25 Normal Temperature - - - -

26 Fluid SG 4,28 4,28 4,28 -

27 Vapour Pressure 8,50 bar gauge 8,50 bar gauge 8,50 bar gauge -

28 Viscosity 0,0000150 Pa s 0,0000150 Pa s 0,0000150 Pa s -

29 Critical Pressure 219,63 bar gauge 219,63 bar gauge 219,63 bar gauge -

30 Critical Temperature (Tc) 373,95 °C 373,95 °C 373,95 °C -

31 Specific Heat Ratio 1,29 1,29 1,29 -

32 Compressibility (Z1) 0,92954 0,92954 0,92954 -

33 Required Capacity 20,18 Kv 34,81 Kv 37,97 Kv -

34 Percent Open 58% 72% 74% -

35 Noise Prediction <65 dB(A) <65 dB(A) <65 dB(A) -

36 Power Ratio 0,02 0,03 0,03 -

37 Sigma - - - -

38 SigmaMR - - - -

39 Cavitation None None None -

40 Outlet Velocity 11,29 m/s 19,19 m/s 20,89 m/s -

41 Outlet Mach 0,02 0,04 0,04 -

42 Upstream Pipe Velocity 0,00 m/s 0,00 m/s 0,00 m/s -

43 Downstream Pipe Velocity 0,00 m/s 0,00 m/s 0,00 m/s -

VALVE BODY ASSEMBLY

44 Model Code 3" LEA43PTSUSS.2 Cv 120 ANSI 150 52 Plug Material St.St.431S29

45 Valve Range Spira-Trol 53 Seat Material St.St.431S29

46 Flow Direction Under 54 Seating Type 431 Stainless Steel

47 Characteristic EQ 55 Packing Material PTFE

48 End Connections ANSI 150 56 Balancing Unbalanced

49 Body Material Carbon Steel 57 Bonnet Studs/Nuts ASTM A193 Gr B7 / ASTM A194 Gr 2H

50 Bonnet Style Standard 58 Finish Standard

51 Trim Type / Reduction Standard / Full Port 59 Shut Off Class Class IV

ACTUATOR

60 Actuator Model PN9233E 74 Finish Standard / Standard

61 Actuator Type Pneumatic 75 Hand Wheel No

62 Control Single Acting 76 Mounting Flange -

63 Travel 30,00 mm 77 Valve Adapter -

64 Fail Position Extend 78 Positioner Card -

65 Spring Range 2,0 - 4,0 bar 79 Position Transmitter -

66 Thrust Available 6,80 kN 80 Local Controller -

67 % Thrust Used 81,68 % 81 3 Way Issolation -

68 Required Force To Close 5,55 kN 82 Fault Indicator Relay -

69 Required Force To Open 0,40 kN 83 Communication Software PSCS -

70 Required Shut Off Differential 9,00 bar 84 Potentiometer -

71 Minimum Air Supply 6,00 bar gauge 85 Auxiliary Switch -

72 Advised Max Differential 11,82 bar 86 Anti-Condensate Heater -

73 % Safety Factor 0 87 High Temperature Kit -

POSITIONER

88 Positioner Model EP5 92 Gauge Type / Part Number 0 - 7 bar / 3701189

89 Product Number 3438996 93 Mounting Kit -

90 Control Signal 4 - 20 mA 94 Mounting Kit Part Number -

91 Enclosure Rating IP65 95 Other : -

OTHER ACCESSORIES

96 Air Instrument Connections No 101 Solenoid Valve No

97 Quick Exhaust No 102 IP Converter No

98 Lockup Valve No 103 Switch Box No

99 Filter Regulator None 104 Booster No

100 Tubing Plastic 105 Other : -

CERTIFICATES AND SPECIAL REQUIREMENTS

106 Material Certs Body Bonnet None 112 Nace No

107 Material Certs Bonnet Bolting None 113 Control Loop Hysteresis No

108 Material Certs Trim None 114 Control Loop Dead Band No

109 Drawings Outline No 115 Paint Report No

110 Drawings GA No 116 ATEX No

111 Drawings Hook Up No 117 Other : -

STANDARD TEST CERTIFICATION

118 Hydrostatic Test No 120 Seat Leakage Test No

119 Functional Test No 121 Positioner Calibration No

MESSAGES AND NOTES

122 -

123 -

124 -

125 -

126 -

You might also like

- 27 July - TVA-TI-P192-01-ENDocument4 pages27 July - TVA-TI-P192-01-ENMalik DaniyalNo ratings yet

- Usonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionDocument3 pagesUsonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionJhonatan RodriguezNo ratings yet

- Datasheet For PSVDocument1 pageDatasheet For PSVlãng duNo ratings yet

- Test Report Certificate Highlights Key Compressor ParametersDocument2 pagesTest Report Certificate Highlights Key Compressor ParametersBùi Việt100% (2)

- SBD 0631 ValveDocument3 pagesSBD 0631 ValvewodrNo ratings yet

- Proyectos de Instrumentaci On "Flotation / Rougher" "Informe N#2"Document4 pagesProyectos de Instrumentaci On "Flotation / Rougher" "Informe N#2"luis alvarezNo ratings yet

- Vacuum Breaker Ruptor Vacuum VB14 TI P019 02 enDocument3 pagesVacuum Breaker Ruptor Vacuum VB14 TI P019 02 encriuvosNo ratings yet

- Usonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionDocument3 pagesUsonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionJhonatan RodriguezNo ratings yet

- Datasheet For Restriction OrificeDocument1 pageDatasheet For Restriction OrificeRajesh Rajesh50% (2)

- PRESSURE SAFETY VALVE DATA SHEETDocument1 pagePRESSURE SAFETY VALVE DATA SHEETBABILIN VNo ratings yet

- Q1Co 3000 Q1Co 3520 3520-LIT - 381Document3 pagesQ1Co 3000 Q1Co 3520 3520-LIT - 381Jhonatan RodriguezNo ratings yet

- Data NX 45-5-1800-4Document1 pageData NX 45-5-1800-4BHILLA TORRESNo ratings yet

- Data Sheet - Rev 01Document158 pagesData Sheet - Rev 01Martin DanzeNo ratings yet

- 150HV051-IFT-Data SheetDocument1 page150HV051-IFT-Data SheetgerardoNo ratings yet

- Pressure Safety Valve Data SheetDocument4 pagesPressure Safety Valve Data SheetŁukasz BolewskiNo ratings yet

- 85000FI610Document1 page85000FI610LibyanManNo ratings yet

- Requisición de equipo para análisis de azufre en gasolinasDocument10 pagesRequisición de equipo para análisis de azufre en gasolinasDesiree MolinaNo ratings yet

- MKI-DS-J-001-A4 - Rev A Data Sheet PCVDocument60 pagesMKI-DS-J-001-A4 - Rev A Data Sheet PCVFIRMANSYAHNo ratings yet

- Desalt Water Distribution RotameterDocument1 pageDesalt Water Distribution RotameterLibyanManNo ratings yet

- 85000FI608Document1 page85000FI608LibyanManNo ratings yet

- Date Tehnice - Regulator Gaz Filtru DN 15 - 65 - MadasDocument8 pagesDate Tehnice - Regulator Gaz Filtru DN 15 - 65 - Madasmishu35No ratings yet

- Data Sheet For Magnetic Flowmeters Rev5Document3 pagesData Sheet For Magnetic Flowmeters Rev5Kandula RajuNo ratings yet

- PVVDocument10 pagesPVVJorge Arturo Rodríguez HerreraNo ratings yet

- Datasheet For Level TransmitterDocument11 pagesDatasheet For Level TransmitterEliyanto E BudiartoNo ratings yet

- Kit Omegas Direct 4cyl CNG 1Document2 pagesKit Omegas Direct 4cyl CNG 1Andres AguirreNo ratings yet

- Emerson Automation Solutions 3950 Greenbriar Stafford TX, 77477 United States (281) 274-4400 Quote NumberDocument2 pagesEmerson Automation Solutions 3950 Greenbriar Stafford TX, 77477 United States (281) 274-4400 Quote Numberdiego veyzagaNo ratings yet

- 2061-MIX-001 Rev1Document2 pages2061-MIX-001 Rev1Emmanuel Ber SNo ratings yet

- 0ZSIRLS001 SAMWONG SERA Contacteur de Niv Data SheetDocument1 page0ZSIRLS001 SAMWONG SERA Contacteur de Niv Data Sheetjean-marie BOGUYNo ratings yet

- Q1Co 3000 Q1Co 3510 3510-LIT - 201: IFC - Issued For ConstructionDocument2 pagesQ1Co 3000 Q1Co 3510 3510-LIT - 201: IFC - Issued For ConstructionJHONATAN RODRIGUEZ VENTONo ratings yet

- Solenoid valve data sheetDocument2 pagesSolenoid valve data sheetHsein WangNo ratings yet

- SGPC-GIZ-HD-002 - Hoja de Datos Medidor Masico (Coriolis) - RevADocument1 pageSGPC-GIZ-HD-002 - Hoja de Datos Medidor Masico (Coriolis) - RevAاليخاندرو اغيليراNo ratings yet

- Milk of lime storage tank discharge valveDocument2 pagesMilk of lime storage tank discharge valveJHONATAN RODRIGUEZ VENTONo ratings yet

- A307 Ius Uv DS 1201Document2 pagesA307 Ius Uv DS 1201smartravi222No ratings yet

- 141014.datasheet For PSV-1323Document2 pages141014.datasheet For PSV-1323ocanhthuNo ratings yet

- Control Valve Technical Specification Sheet Globe Service: GasDocument1 pageControl Valve Technical Specification Sheet Globe Service: Gassiddhesh_guessNo ratings yet

- Essence Mixing Tank Technical Bid Evaluation: Kg/batch Bar (G) Bar (G) °C °CDocument3 pagesEssence Mixing Tank Technical Bid Evaluation: Kg/batch Bar (G) Bar (G) °C °CHaries Bugarin GarciaNo ratings yet

- Level ControllerDocument1 pageLevel Controllerkhasim15No ratings yet

- Cam Characteristic Air Consumption: Control Valve Air Act. Instrument Data SheetDocument2 pagesCam Characteristic Air Consumption: Control Valve Air Act. Instrument Data SheetJHONATAN RODRIGUEZ VENTONo ratings yet

- Sectional directional control valves overviewDocument101 pagesSectional directional control valves overviewIstenio Cassiano NetoNo ratings yet

- MQ13 02 DS 3510 Inhv142b - R0Document2 pagesMQ13 02 DS 3510 Inhv142b - R0JHONATAN RODRIGUEZ VENTONo ratings yet

- BE-WI-248-01-F19 Datasheet Breather ValveDocument3 pagesBE-WI-248-01-F19 Datasheet Breather Valvemika cabelloNo ratings yet

- 150FV002-IFT-Data SheetDocument1 page150FV002-IFT-Data SheetgerardoNo ratings yet

- KSB MIL Controls Limited Valve Specification SheetDocument2 pagesKSB MIL Controls Limited Valve Specification SheetPablo TorresNo ratings yet

- RELOAD - 0025M - 12418 - MEIP Rev.3Document2 pagesRELOAD - 0025M - 12418 - MEIP Rev.3Claudio AmoneNo ratings yet

- Instrument Data For Coriolis Flow TransmitterDocument2 pagesInstrument Data For Coriolis Flow Transmitterdilip matalNo ratings yet

- RIM20Document10 pagesRIM20GeorgeNo ratings yet

- CONTROL VALVE DATA SHEETDocument2 pagesCONTROL VALVE DATA SHEETMateus EliasNo ratings yet

- Endsdwr Ge51r0519Document22 pagesEndsdwr Ge51r0519bgbbNo ratings yet

- Pure Epoxy Primer (Zinc and Lead Free) 1 X 50 M Micaceous Iron Oxide 2 Pack Epoxy 2 X 100 M Polyurethane-Acrylic 1 X 50 M Total 300 MDocument2 pagesPure Epoxy Primer (Zinc and Lead Free) 1 X 50 M Micaceous Iron Oxide 2 Pack Epoxy 2 X 100 M Polyurethane-Acrylic 1 X 50 M Total 300 MTrịnh Đức HạnhNo ratings yet

- DP27T and DP27TE Pilot Operated Pressure Temperature Control Valves With SG Iron BodiesDocument12 pagesDP27T and DP27TE Pilot Operated Pressure Temperature Control Valves With SG Iron BodiesDiegoNo ratings yet

- FRG - 2M - 16617 DungDocument14 pagesFRG - 2M - 16617 DungSauro GordiniNo ratings yet

- Reguladora Primera Etapa 2BAR PDFDocument14 pagesReguladora Primera Etapa 2BAR PDFEdwin QuicenoNo ratings yet

- RG2MC Low Pressure DN15to100 PDFDocument42 pagesRG2MC Low Pressure DN15to100 PDFAdministratorNo ratings yet

- DELUGE VALVES DATASHEET Rev.01Document1 pageDELUGE VALVES DATASHEET Rev.01moodydoodyNo ratings yet

- ERSA010-DSM-001 Rev.0 DS Boquillas RociadorasDocument1 pageERSA010-DSM-001 Rev.0 DS Boquillas RociadorasAdrian Andres Quilodran MirandaNo ratings yet

- DP27S Ti Ibr16 26inDocument7 pagesDP27S Ti Ibr16 26inMUHAMMAD AIMAN BIN MOHD YUSOFNo ratings yet

- Cam Characteristic Air Consumption: Control Valve Air Act. Instrument Data SheetDocument2 pagesCam Characteristic Air Consumption: Control Valve Air Act. Instrument Data SheetJHONATAN RODRIGUEZ VENTONo ratings yet

- Data Sheet - Rotary Gas Meter: RRPL-OGD-DOC-NO:-GGL-RPD-150-003 Sheet 1 of 1Document1 pageData Sheet - Rotary Gas Meter: RRPL-OGD-DOC-NO:-GGL-RPD-150-003 Sheet 1 of 1akshay bahalNo ratings yet

- Datasheet For Pressure TransmitterDocument8 pagesDatasheet For Pressure TransmitterVenkatesan ManikandanNo ratings yet

- Spare Parts: Unique Single Seat Valve - StandardDocument20 pagesSpare Parts: Unique Single Seat Valve - StandardjoseNo ratings yet

- Spare Parts: LKB Automatic and Manual Butterfly ValveDocument40 pagesSpare Parts: LKB Automatic and Manual Butterfly ValvejoseNo ratings yet

- Spare Parts: LKC-2 Non-Return ValveDocument10 pagesSpare Parts: LKC-2 Non-Return ValvejoseNo ratings yet

- Vapour Compression Refrigeration PDFDocument5 pagesVapour Compression Refrigeration PDFjose100% (1)

- Trepko XPG40 Packing Machine ButterDocument177 pagesTrepko XPG40 Packing Machine Butterjose100% (1)

- Instruction Manual SMP BC Mixproof Valve Ese02255enDocument46 pagesInstruction Manual SMP BC Mixproof Valve Ese02255enjoseNo ratings yet

- Dosing Pumps, Measurement & Control and Disinfection SystemsDocument16 pagesDosing Pumps, Measurement & Control and Disinfection SystemsjoseNo ratings yet

- WRV Manual de ServicioDocument4 pagesWRV Manual de ServiciojoseNo ratings yet

- Sustaining Performance of Condensate Recovery SystemsDocument24 pagesSustaining Performance of Condensate Recovery SystemsjoseNo ratings yet

- New 2024 Hyundai N Vision 74Document2 pagesNew 2024 Hyundai N Vision 74luxury life wishesNo ratings yet

- Himel Variable Speed DrivesDocument17 pagesHimel Variable Speed DriveszibrahimiNo ratings yet

- Manual de Taller CF150 PDFDocument190 pagesManual de Taller CF150 PDFMotorcycles Workshop Amigos PulsarNo ratings yet

- Td122 Engine Tighteting RorquesDocument2 pagesTd122 Engine Tighteting RorquesFilipposNo ratings yet

- Catalog + Fiber Laser Welding Machine + XT Laser AbelDocument13 pagesCatalog + Fiber Laser Welding Machine + XT Laser AbelLuciano Añorga ArmestarNo ratings yet

- Investigation on Super Lift DC/AC Inverters Using Photovoltaic EnergyDocument6 pagesInvestigation on Super Lift DC/AC Inverters Using Photovoltaic EnergySuresh JKNo ratings yet

- Process Applications: Selecting EvaporatorsDocument8 pagesProcess Applications: Selecting EvaporatorsRaul TejedaNo ratings yet

- Roland Rolled Over The Floor in Order To Put Off The Fire That Caught Her Clothes. Which Principle Explains This?Document3 pagesRoland Rolled Over The Floor in Order To Put Off The Fire That Caught Her Clothes. Which Principle Explains This?Rovz GC BinNo ratings yet

- Power Boost BulletinDocument3 pagesPower Boost BulletinBrianHazeNo ratings yet

- AKSA Battery ChargerDocument2 pagesAKSA Battery ChargerTTIBCCANo ratings yet

- 38 661 000 Flushing Cistern GD 2: Product DescriptionDocument2 pages38 661 000 Flushing Cistern GD 2: Product DescriptionAnuj AggarwalNo ratings yet

- Compact EOCR-SSD overload relay protects motors in narrow spacesDocument5 pagesCompact EOCR-SSD overload relay protects motors in narrow spacesashraf hafiziNo ratings yet

- Engine Mechanical - 5.7LDocument426 pagesEngine Mechanical - 5.7LjisuuuNo ratings yet

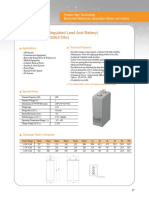

- (Valve Regulated Lead Acid Battery) ESG 200 (2V, 200AH/10hr)Document1 page(Valve Regulated Lead Acid Battery) ESG 200 (2V, 200AH/10hr)RosiinNo ratings yet

- Surge Protector and Filter Specifications: Technical DataDocument16 pagesSurge Protector and Filter Specifications: Technical DataJuan Esteban Benjumea BenjumeaNo ratings yet

- Governing system animation for HP turbineDocument25 pagesGoverning system animation for HP turbinesaratchandranbNo ratings yet

- Stellar nucleosynthesis and nuclear fusionDocument4 pagesStellar nucleosynthesis and nuclear fusionKim Labastida MolinaNo ratings yet

- Topic-Questions-Mass WeightDocument10 pagesTopic-Questions-Mass WeightJoe Y. MathewNo ratings yet

- SEBF9050 - Applied Failure Analysis - Engine Valve Failure Modes (1100, 1105)Document14 pagesSEBF9050 - Applied Failure Analysis - Engine Valve Failure Modes (1100, 1105)Rodolfo WongNo ratings yet

- Mga Sagot Ni Ashe Montage Gen Physics1Document4 pagesMga Sagot Ni Ashe Montage Gen Physics1Valencia AngieNo ratings yet

- Airtek Air DryerDocument12 pagesAirtek Air DryerMarcelo NoirNo ratings yet

- Page 47-54 Immobiliser and DiagnosisDocument13 pagesPage 47-54 Immobiliser and DiagnosisDaniel Mamani Paredez100% (1)

- Investigation and Characterization of Gamma Radiation Shielding Capacity of Heavy Minerals-Based Composite MaterialsDocument9 pagesInvestigation and Characterization of Gamma Radiation Shielding Capacity of Heavy Minerals-Based Composite MaterialsMd.Helal HossainNo ratings yet

- Year 10 Physics - MotionDocument18 pagesYear 10 Physics - MotionKevin XiaoNo ratings yet

- Aug 2022 Spotlight Merged Lyst4330Document147 pagesAug 2022 Spotlight Merged Lyst4330Nitika VermaNo ratings yet

- IPCC AR6 WGI Chapter07Document132 pagesIPCC AR6 WGI Chapter07Mario MontejoNo ratings yet

- 2A Ultra Low Dropout Linear Regulator TJ4320Document20 pages2A Ultra Low Dropout Linear Regulator TJ4320Rizky GultomNo ratings yet

- Man - Ge - Tables de FiliationDocument13 pagesMan - Ge - Tables de FiliationSaid HajjamiNo ratings yet

- Unit 3 Problem With SvaDocument6 pagesUnit 3 Problem With SvaFatih DebenefitsNo ratings yet

- Vertical Axis Wind Turbine For Remote Power GenerationDocument75 pagesVertical Axis Wind Turbine For Remote Power GenerationGeet DeokateNo ratings yet