Professional Documents

Culture Documents

LP-463PB 13 01 View

Uploaded by

Juliano DepetrisCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LP-463PB 13 01 View

Uploaded by

Juliano DepetrisCopyright:

Available Formats

DAIMLERCHRYSLER CORPORATION No: LP-463PB-13-01

Laboratory Procedure Date Published: 2002-09-09

Category Code: J-1 Change: D

EASL Req: No THIS DOCUMENT CANNOT BE PRINTED

To receive a copy for printing, please step back to this document in the master list system, click

on "Actions" and choose the “Request Print Access” option.

SILICONE CONTAMINATION OF A PAINTED SURFACE

It is important that this document is not redistributed or reproduced. Please ensure you do not

save this document to another system or to another drive. All external documents are to be

maintained and controlled through our Global External Document Control system.

1.0 GENERAL

This procedure describes the method for determining the presence of silicone or silicone-like contaminants

on rubber, plastic or metal parts. These substances are deemed to be contaminants when, by transfer,

they cause defects on bodies and parts being painted in assembly plants such as cratering, fish-eyeing or

significant film defects.

Unless otherwise specified, both the effect of contaminant under a paint film test and the effect of

contaminant over a wet paint film test shall be performed.

2.0 TEST EQUIPMENT & MATERIALS

The materials listed in Table 1 should be used as required to simulate the coating system being employed

with the candidate part being tested:

TABLE 1: TEST MATERIALS

Name Of Item Description Material Standard

4” X 12” Unpolished Cold Rolled

Steel Test Panels NA

Steel

Pre-Treatment Chemicals Zinc Phosphate Solution PS-4312, PS-3798, or PS-7449

Electrocoat Lead-Free Epoxy Cathodic MS-PB45-1 or equivalent

Primer Liquid or Powder Anti-Chip MS-PB54 –1 or equivalent

MS-PA30-1, MS-PA35-1, or

Topcoat Basecoat/Clearcoat System

equivalent

Cleaning Solvent VM&P Naphtha MS-1316

3.0 SUMMARY OF METHOD

3.1 Effect of Contaminant Under a Paint Film

Rub a phosphated and primed steel panel with the subject contaminant. Topcoat the panel. Panel should

be examined for defects before and after the bake cycle.

3.2 Effect of Contaminant Over a Wet Paint Film

Topcoat a phosphated and primed steel panel. Pass an air scream over the subject contaminant part and

in the direction of the wet top coated test panel. Panel should be examined for defects before and after the

bake cycle.

4.0 SAFETY PRECAUTIONS

LP-463PB-13-01, Change D, 2002-09-09, Page 1

Copyright DaimlerChrysler Corporation 1963

(2002-05-06)

This standard may involve hazardous materials, operations and equipment. This standard does not

purport to address all of the safety problems associated with its use. It is the responsibility of whoever

uses this standard to consult and establish appropriate safety and health practices and determine the

applicability of regulatory limitations prior to use.

5.0 SAMPLING

Refer to the applicable Material Standard.

NOTE: A control should always be run for comparison purposes.

6.0 PROCEDURE

6.1 Effect of Contaminant Under a Paint Film

Lightly rub a phosphated (PS-4312, PS-3798, or PS-7449), electrocoated (MS-PB45-1) and primed (MS-

PB54-1) steel panel with the subject contaminant covering the total surface area.

NOTE: If the subject contaminant part is metal or if it does not lend itself to rubbing directly onto the

panel, the contaminant can be transferred manually by lightly rubbing one's hand over the part and

subsequently rubbing that hand over the panel. If more than one part is being tested per day, it is

necessary that the same technician not be used for each pat when the hand transfer method is being

utilized to avoid cross contamination due to the highly transferable nature of substances such as silicone.

Wipe the bottom half (only) of the panel with VM&P Naphtha (MS-1316).

Topcoat the panel with MS-PA30-1 or MS-PA35-1, as specified, according to PS-962.

Examine the top coated panel before and after the bake cycle and note any evidence of cratering, fish-

eyeing, distortion, or any significant film defects.

6.2 Effect of Contaminant Over a Wet Paint Film

Topcoat a phosphated (PS-4312, PS-3798, or PS-7449), electrocoated (MS-PB45-1) and primed (MS-

PB54-1) steel panel with MS-PA30-1 or MS-PA35-1, as specified, according to PS-962.

WITHIN 30 SECONDS AFTER APPLICATION OF THE COLOR COAT, pass a 347 to 414 kPa (50 to 60

psi) air stream over the subject contaminant part and in the direction of the wet top coated test panel.

NOTE: The subject part must be rotated to insure that the air stream hits all surfaces and the wet painted

surface of the test panel should be from 2 to 3 feet from the subject part.

Examine the top coated panel before and after the bake cycle and note any evidence of cratering, fish-

eyeing, distortion, or any significant film defects.

7.0 REPORT

The report shall include the test procedure used, and shall describe the coating and silicon materials used

i.e. source, color, curing process, etc.

The report shall describe the results of all inspections i.e. existence of cratering, fish-eyeing, distortion or

significant coating film defects etc.

8.0 GENERAL INFORMATION

LP-463PB-13-01, Change D, 2002-09-09, Page 2

Copyright DaimlerChrysler Corporation 1963

(2002-05-06)

Three asterisks “***” after the section/paragraph header denotes multiple technical changes to the

section/paragraph. A triple asterisk before and after a string of text (***text***) identifies a single change.

Certain important information relative to this Laboratory Procedure has been included in separate

standards. To assure the materials submitted meet all of DaimlerChrysler requirements, it is mandatory

that the requirements in the following standards be met.

CS-9800 - Application of this procedure, the subscription service, and approved sources

CS-9003 - Regulated substances and recyclability

For specific information on this document, please refer to the contact person shown in the "Publication

Information" Section of this document. For general information on obtaining Engineering Standards and

Laboratory Procedures, see CS-9800 or contact the Engineering Standards Department at

engstds@dcx.com.

9.0 REFERENCES

CS-9800 MS-PA30-1 MS-PB54-1 PS-3798

CS-9003 MS-PA35-1 PS-962 PS-7449

MS-1316 MS-PB45-1 PS-4312

10.0 PUBLICATION INFORMATION

Contact/Phone No: Kim Scarlet (248) 576-7433

Alternate Contact/Phone No: Kim Remer (248) 576-0652

Dept. Name & Dept. No./Tech Club/Organization: Body Materials Engineering, Dept. 5820

Date Procedure Originally (Initially) Published: 1963-05-28

Date Published: 2002-09-09

Change Notice: NA

Description of Change: New Format

#####

LP-463PB-13-01, Change D, 2002-09-09, Page 3

Copyright DaimlerChrysler Corporation 1963

(2002-05-06)

You might also like

- Corrosion Inhibitor Injection System Data Sheet Surface Facility EPC Services Phase-4 Development ProjectDocument11 pagesCorrosion Inhibitor Injection System Data Sheet Surface Facility EPC Services Phase-4 Development ProjectNesrine MhedhbiNo ratings yet

- Interior Fluid Resistant Epoxy Primer: Technical Data SheetDocument5 pagesInterior Fluid Resistant Epoxy Primer: Technical Data SheetPannha LangNo ratings yet

- Five Finger Scratch Resistance Test Method: 1.0 GeneralDocument3 pagesFive Finger Scratch Resistance Test Method: 1.0 GeneralJuliano DepetrisNo ratings yet

- Special Provision To Specal Specification Marine StructuresDocument47 pagesSpecial Provision To Specal Specification Marine StructuresRodolfoMarínNo ratings yet

- Field Painting and Coating: Standard Work Process ProcedureDocument16 pagesField Painting and Coating: Standard Work Process ProcedureMelih SENTURKNo ratings yet

- Mil C 53072Document43 pagesMil C 53072Valerie Schmid BurnsNo ratings yet

- Durashield 110 61Document6 pagesDurashield 110 61huicholeNo ratings yet

- MS-4005 - Rev - DDocument5 pagesMS-4005 - Rev - DEngenharia APedroNo ratings yet

- Ain Tsila Development Main EPC Contract A-CNT-CON-000-00282 Subcontract N°: JI-2045/07-002BDocument15 pagesAin Tsila Development Main EPC Contract A-CNT-CON-000-00282 Subcontract N°: JI-2045/07-002BAslaouiNo ratings yet

- TT C 490FDocument25 pagesTT C 490FMichael SkrableNo ratings yet

- Mil DTL 53072CDocument43 pagesMil DTL 53072CMichael SkrableNo ratings yet

- Airblast Coating Inspection Equipment - The Guide - LR PDFDocument20 pagesAirblast Coating Inspection Equipment - The Guide - LR PDFMohsen Halweni100% (2)

- PS 80 2000Document6 pagesPS 80 2000陳相如No ratings yet

- Sigma PC ManualDocument339 pagesSigma PC ManualSarisha Harrychund100% (2)

- Surface Insulation Resistance Testing of - CompressDocument10 pagesSurface Insulation Resistance Testing of - CompressRobert MartosNo ratings yet

- iRAN SPECIFICATIONSDocument12 pagesiRAN SPECIFICATIONSSarwat Naim SiddiquiNo ratings yet

- West Qurna 1 Building Upgrades & Facilities WorkDocument19 pagesWest Qurna 1 Building Upgrades & Facilities WorkNoor A QasimNo ratings yet

- SSPC-SP 27.00Document6 pagesSSPC-SP 27.00manoses100% (1)

- Mil C 53072BDocument47 pagesMil C 53072Bv65magnaNo ratings yet

- TMS6900Document14 pagesTMS6900Josue Garcia QuiniNo ratings yet

- WSS M1P87 BXDocument6 pagesWSS M1P87 BXShu Fu100% (1)

- Mil PRF 87937DDocument23 pagesMil PRF 87937DmurphygtNo ratings yet

- Bridge-railing-powder-coating-qualification-procedure (Tiêu Chuẩn Kiểm Tra Sơn Bằng Ngoại Quan)Document9 pagesBridge-railing-powder-coating-qualification-procedure (Tiêu Chuẩn Kiểm Tra Sơn Bằng Ngoại Quan)Nguyen Le Truong HaiNo ratings yet

- Document Transmittal: SAW-CWCO-TR149 15 January 2013Document8 pagesDocument Transmittal: SAW-CWCO-TR149 15 January 2013Budi IndraNo ratings yet

- Jotafloor EP SL Uni - Abrasion & Impact ResistDocument6 pagesJotafloor EP SL Uni - Abrasion & Impact Resistangelito bernalNo ratings yet

- ID-PRC 19 - PE Coating RepairDocument7 pagesID-PRC 19 - PE Coating Repaircloud23No ratings yet

- DP B58W00610Document4 pagesDP B58W00610tangouzeNo ratings yet

- Carta FuturaDocument3 pagesCarta FuturaCarlosSánchezNo ratings yet

- MS Pa1 1Document8 pagesMS Pa1 1Felipe De la cruzNo ratings yet

- MS-4052 Rev. HDocument4 pagesMS-4052 Rev. HGuri GuriNo ratings yet

- Blasting & Coating Procedure For Fabricated Steel StructureDocument8 pagesBlasting & Coating Procedure For Fabricated Steel Structurejasmineamma100% (1)

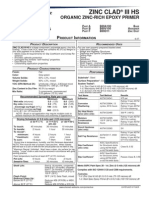

- Zinc Clad IIIDocument4 pagesZinc Clad IIIScott Van PeltNo ratings yet

- MX 4926N M.CDocument4 pagesMX 4926N M.Csubham chakrabortyNo ratings yet

- Sae Ams 1320aDocument5 pagesSae Ams 1320achris nelsonNo ratings yet

- Painting Cycle: Document TitleDocument8 pagesPainting Cycle: Document TitleMaffone NumerounoNo ratings yet

- Bgas Grade-1 - Model Exam No: 3Document8 pagesBgas Grade-1 - Model Exam No: 3Shamim AlamNo ratings yet

- Mil I 25135e PDFDocument37 pagesMil I 25135e PDFDuy NguyenNo ratings yet

- GS 19-1-2 - MainbodyDocument50 pagesGS 19-1-2 - MainbodyDhanushNo ratings yet

- MS45xx Series Application NoteDocument9 pagesMS45xx Series Application Notescribd5714No ratings yet

- C3. Paint Specification (WSS-M64J39-A1) v1Document7 pagesC3. Paint Specification (WSS-M64J39-A1) v1Chandrajeet ShelkeNo ratings yet

- City of PearlandDocument6 pagesCity of PearlandAshwin DSNo ratings yet

- Mil-Std-171f - Finishing of Metal and Wood Surfaces (31may2011)Document65 pagesMil-Std-171f - Finishing of Metal and Wood Surfaces (31may2011)JumpfastNo ratings yet

- Surlyn® - 8660Document3 pagesSurlyn® - 8660Alan FerreiraNo ratings yet

- STP1238 Eb.1415051 1 PDFDocument141 pagesSTP1238 Eb.1415051 1 PDFpaola100% (1)

- 24T3 Series TDSDocument5 pages24T3 Series TDSFernando CarmonaNo ratings yet

- Mil PRF 24712BDocument18 pagesMil PRF 24712Bchristopher.j.morris20.civNo ratings yet

- Materials System SpecificationDocument7 pagesMaterials System SpecificationAjeetKumarNo ratings yet

- Es805-001 Rev 4 Decorative Chrome PlatingDocument7 pagesEs805-001 Rev 4 Decorative Chrome PlatingFrancisco BocanegraNo ratings yet

- Polyflex UltrachemDocument2 pagesPolyflex UltrachemBraulio Candela NoriegaNo ratings yet

- VP 31a Product Data Met L CheckDocument2 pagesVP 31a Product Data Met L CheckTopoilServNo ratings yet

- MS-4052 - Rev - CDocument4 pagesMS-4052 - Rev - CEngenharia APedroNo ratings yet

- Ammonia Piping InsulationDocument46 pagesAmmonia Piping InsulationshahgardezNo ratings yet

- Powercrete R150Document2 pagesPowercrete R150welbert001No ratings yet

- Terostat Ms 930Document3 pagesTerostat Ms 930Kristin SimpsonNo ratings yet

- INS-000-SPE-0002 Rev.3 Specification For Painting and Coating, Structural Steel of Marine FacilitiesDocument25 pagesINS-000-SPE-0002 Rev.3 Specification For Painting and Coating, Structural Steel of Marine FacilitiesenriqueNo ratings yet

- Technology Update No. 5: SSPC: The Society For Protective Coatings Accelerated Testing of Industrial Protective CoatingsDocument11 pagesTechnology Update No. 5: SSPC: The Society For Protective Coatings Accelerated Testing of Industrial Protective CoatingsachusanachuNo ratings yet

- Coal Tar PDFDocument4 pagesCoal Tar PDFMohammadreza AsheghNo ratings yet

- Return To TOC: Dowty Propellers Standard Practices ManualDocument11 pagesReturn To TOC: Dowty Propellers Standard Practices ManualNicolás PiratovaNo ratings yet

- TT-P-28H Paint Aluminum, Heat ResistingDocument18 pagesTT-P-28H Paint Aluminum, Heat ResistingmiguelmosquerabNo ratings yet

- Circumcision Photo Guide: What To Expect After Surgery: Patient and Family EducationDocument2 pagesCircumcision Photo Guide: What To Expect After Surgery: Patient and Family EducationJashanjot SinghNo ratings yet

- Major Issues of Health Care System in The United States - EditedDocument4 pagesMajor Issues of Health Care System in The United States - EditedDanNo ratings yet

- Hygiene Supervisor Training Course Hygiene Supervisor Training Course Hygiene Supervisor Training Course Hygiene Supervisor Training CourseDocument2 pagesHygiene Supervisor Training Course Hygiene Supervisor Training Course Hygiene Supervisor Training Course Hygiene Supervisor Training CourseBoyka KirovNo ratings yet

- Etiqa Accredited Providers As of DecDocument36 pagesEtiqa Accredited Providers As of DecDonny ィ ۦۦNo ratings yet

- Amber Gemstone Can Amazingly Transform Negativity Into PositivityDocument3 pagesAmber Gemstone Can Amazingly Transform Negativity Into PositivityMustafa AliNo ratings yet

- Hal 79 EnglishDocument6 pagesHal 79 EnglishUmiyanti AzizahNo ratings yet

- Care Shield: Add-On Cover With Retail PoliciesDocument13 pagesCare Shield: Add-On Cover With Retail PoliciesShefali HegdeNo ratings yet

- Petrofac: Job Safety AnalysisDocument3 pagesPetrofac: Job Safety AnalysisMon Trang Nguyễn100% (5)

- Frequency Table: Data Kesehatan Ibu 1) Ibu HamilDocument9 pagesFrequency Table: Data Kesehatan Ibu 1) Ibu HamilEka OktaviaNo ratings yet

- One Hip SurgeonDocument1 pageOne Hip SurgeonMike McGuire100% (1)

- Call If... : How To Help Someone Having A SeizureDocument1 pageCall If... : How To Help Someone Having A SeizureZin KoNo ratings yet

- UNIT 3 - IP Organizational ChartDocument5 pagesUNIT 3 - IP Organizational ChartYesenia Havana 7thNo ratings yet

- Argumentative Text 2 - Zayyina Chamaladina Hanfin - 30101900210Document2 pagesArgumentative Text 2 - Zayyina Chamaladina Hanfin - 30101900210Anonymous iTstegX2No ratings yet

- Data Sheet Sample For SlaeemDocument3 pagesData Sheet Sample For SlaeemmuhannadNo ratings yet

- The Practice of Oral MedicineDocument40 pagesThe Practice of Oral Medicineامجد شاكرNo ratings yet

- SOP Material InstructionsDocument1 pageSOP Material Instructionspankajbhatt376100% (1)

- Plaque of Exemplary Service: Lorraine G. Jungco-Nery, RN, MD, MhaDocument5 pagesPlaque of Exemplary Service: Lorraine G. Jungco-Nery, RN, MD, MhaEastwest BoundNo ratings yet

- Assignment 11 - Sanitary Landfill PDFDocument2 pagesAssignment 11 - Sanitary Landfill PDFJohn Feil JimenezNo ratings yet

- LESSON PLAN ON OCCUPATION HEALTH (Ritesh)Document4 pagesLESSON PLAN ON OCCUPATION HEALTH (Ritesh)Sunil Patel100% (1)

- Girls Chart Head Circumference For Age Birth To 13 Weeks (Percentile)Document1 pageGirls Chart Head Circumference For Age Birth To 13 Weeks (Percentile)Nia Tri MulyaniNo ratings yet

- TEIPL-JSA-022 Hydra (Farana) and Crane Operation R1Document7 pagesTEIPL-JSA-022 Hydra (Farana) and Crane Operation R1ba ratnaparkhe0% (1)

- Item No. Item Description Item Type As of Balance Qty UnitDocument8 pagesItem No. Item Description Item Type As of Balance Qty UnitNurma Annisa FitriaNo ratings yet

- JHA - Manual TorquingDocument6 pagesJHA - Manual TorquingMohamadSyahmiNo ratings yet

- Perawatan Diri Ibu Primipara Selama Periode Nifas (Revisi)Document24 pagesPerawatan Diri Ibu Primipara Selama Periode Nifas (Revisi)FerdilaDilaAmandaNo ratings yet

- N95 Vs FFP3 & FFP2 Masks - What's The DifferenceDocument1 pageN95 Vs FFP3 & FFP2 Masks - What's The DifferenceRobert SmoothopNo ratings yet

- AAA Consent FormDocument3 pagesAAA Consent FormAlex LamNo ratings yet

- Mobiltemp Series Product Data SheetDocument3 pagesMobiltemp Series Product Data SheetRonaldo RossiNo ratings yet

- Empanelled Hospital List - Maharashtra: SR No Hospital Location CityDocument72 pagesEmpanelled Hospital List - Maharashtra: SR No Hospital Location CityNishant ThakkarNo ratings yet

- Sterile Urethral Catheters For Single Use: British Standard Bs en 1616: 1997Document18 pagesSterile Urethral Catheters For Single Use: British Standard Bs en 1616: 1997JoannaJames67% (3)

- SRS Bulletin-2018Document3 pagesSRS Bulletin-2018Roshan Singh100% (1)