Professional Documents

Culture Documents

Sa 517

Uploaded by

Ejaz Ahmed RanaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sa 517

Uploaded by

Ejaz Ahmed RanaCopyright:

Available Formats

[page_title]

Overview

This quenched and tempered grade is used primarily in pressure vessel applications.

The elevated physicals of this alloy grade is applicable for environments where

added strength is required.

Chemical Requirements

*Elements represented in percentage

Elements Grade A % Grade B % Grade E % Grade F % Grade H % Grade P % Grade Q % Grade S %

Carbon

Heat

0.15-0.21 0.15-0.21 0.12-0.20 0.10-0.20 0.12-0.21 0.12-0.21 0.14-0.21 0.10-0.20

analysis

Product

0.13-0.23 0.13-0.23 0.10-0.22 0.08-0.22 0.10-0.23 0.10-0.23 0.12-0.23 0.10-0.22

analysis

Manganese

Heat

0.80-1.10 0.70-1.00 0.40-0.70 0.60-1.00 0.95-1.30 0.45-0.70 0.95-1.30 1.10-1.50

analysis

Product

0.74-1.20 0.64-1.10 0.35-0.78 0.55-1.10 0.87-1.41 0.40-0.78 0.87-1.41 1.02-1.62

analysis

Phosphorus,

0.025 0.025 0.025 0.025 0.025 0.025 0.025 0.025

max

Sulfur, max 0.025 0.025 0.025 0.025 0.025 0.025 0.025 0.025

Silicon

Heat

0.40-0.80 0.15-0.35 0.10-0.40 0.15-0.35 0.15-0.35 0.20-0.35 0.15-0.35 0.15-0.40

analysis

Product

0.34-0.86 0.13-0.37 0.08-0.45 0.13-0.37 0.13-0.37 0.18-0.37 0.13-0.37 0.13-0.45

analysis

Nickel

Heat

– – – 0.70-1.00 0.30-0.70 1.20-1.50 1.20-1.50 –

analysis

Product

– – – 0.67-1.03 0.27-0.73 1.15-1.55 1.15-1.55 –

analysis

Chromium

Heat

0.50-0.80 0.40-0.65 1.40-2.00 0.40-0.65 0.40-0.65 0.85-1.20 1.00-1.50 –

analysis

Product

0.46-0.84 0.36-0.69 1.34-2.06 0.36-0.69 0.36-0.69 0.79-1.26 0.94-1.56 –

analysis

Elements Grade A % Grade B % Grade E % Grade F % Grade H % Grade P % Grade Q % Grade S %

Molybdenum

Heat

0.18-0.28 0.15-0.25 0.40-0.60 0.40-0.60 0.20-0.30 0.45-0.60 0.40-0.60 0.10-0.35

analysis

Tensile Requirements

2.50 in. [65 mm] and Over 2.50 to 6 in. [65

Under to 150 mm]

Tensile strength 115-135 [795-930] 105-135 [725-930]

Yield strength, min, ksi [MPa] 100 [690] 90 [620]

Elongation in 2 in. [50 mm], min, % 16 14

Reduction of area, min, %:

Rectangular specimens 35 –

Round specimens 45 45

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Risk Based Leak Analysis of An LPG Stora PDFDocument28 pagesRisk Based Leak Analysis of An LPG Stora PDFEjaz Ahmed RanaNo ratings yet

- What Is A Material Test Certificate (Mill Test Certificate) - HQTSDocument5 pagesWhat Is A Material Test Certificate (Mill Test Certificate) - HQTSEjaz Ahmed RanaNo ratings yet

- Dish Ends Calculator For Pressure Vessel FabricationDocument8 pagesDish Ends Calculator For Pressure Vessel FabricationEjaz Ahmed RanaNo ratings yet

- VCF Propane510Document5 pagesVCF Propane510Ejaz Ahmed RanaNo ratings yet

- LPG Road Tankers and ISO Tank ContainersDocument12 pagesLPG Road Tankers and ISO Tank ContainersEjaz Ahmed RanaNo ratings yet

- Endress-Hauser LPGmass 8FE enDocument4 pagesEndress-Hauser LPGmass 8FE enEjaz Ahmed RanaNo ratings yet

- Optech Density Correction Values Calculated As Per ASTMDocument14 pagesOptech Density Correction Values Calculated As Per ASTMEjaz Ahmed RanaNo ratings yet

- Bulk LPG TT - Safety in Design & OperationDocument35 pagesBulk LPG TT - Safety in Design & OperationNilambar Bariha100% (1)

- Gas flow calculations: mass to volume conversionsDocument2 pagesGas flow calculations: mass to volume conversionsPangestu Try WibowoNo ratings yet

- LPG Road Tankers and ISO Tank ContainersDocument12 pagesLPG Road Tankers and ISO Tank ContainersEjaz Ahmed RanaNo ratings yet

- MS0162F FLOWSOLV V5.3 Datasheet SD000195 201009Document1 pageMS0162F FLOWSOLV V5.3 Datasheet SD000195 201009Ejaz Ahmed RanaNo ratings yet

- Pressure DropDocument81 pagesPressure Drophamzashafiq1100% (1)

- 2020-2021 MEC Catalog REV B - LowresDocument228 pages2020-2021 MEC Catalog REV B - LowresEjaz Ahmed RanaNo ratings yet

- Ms0162f Flowsolv v5.3 Pro Getting Started Guide Sd000092 201120Document2 pagesMs0162f Flowsolv v5.3 Pro Getting Started Guide Sd000092 201120Ejaz Ahmed RanaNo ratings yet

- VCF Propane510Document5 pagesVCF Propane510Ejaz Ahmed RanaNo ratings yet

- Pump Cavitation - Causes, Effects, & Preventive Actions - Make Piping EasyDocument14 pagesPump Cavitation - Causes, Effects, & Preventive Actions - Make Piping EasyEjaz Ahmed RanaNo ratings yet

- pressureProcedTest PDFDocument7 pagespressureProcedTest PDFfaizal azizNo ratings yet

- A Presentation On Pipe Stress Analysis - Make Piping EasyDocument16 pagesA Presentation On Pipe Stress Analysis - Make Piping EasyEjaz Ahmed RanaNo ratings yet

- Different Types of Pipe Support Clamps & Hangers - Make Piping EasyDocument20 pagesDifferent Types of Pipe Support Clamps & Hangers - Make Piping EasyEjaz Ahmed RanaNo ratings yet

- Reinforcement Pad Calculation For Branch Connection - Make Piping EasyDocument16 pagesReinforcement Pad Calculation For Branch Connection - Make Piping EasyEjaz Ahmed RanaNo ratings yet

- Forklift Cylinder Maintenance: Quick Reference Guide For ValvesDocument1 pageForklift Cylinder Maintenance: Quick Reference Guide For ValvesEjaz Ahmed RanaNo ratings yet

- Pipe Sizing Guide for Chemical ProcessesDocument3 pagesPipe Sizing Guide for Chemical ProcessesEjaz Ahmed RanaNo ratings yet

- Blackmer Autogas HandbookDocument32 pagesBlackmer Autogas HandbookMuhammad ImranNo ratings yet

- Control Station and Control Valve in The Process Piping - Make Piping EasyDocument15 pagesControl Station and Control Valve in The Process Piping - Make Piping EasyEjaz Ahmed RanaNo ratings yet

- Pipe Sizing Guide for Chemical ProcessesDocument3 pagesPipe Sizing Guide for Chemical ProcessesEjaz Ahmed RanaNo ratings yet

- Pump Installation: Inlet Piping Discharge PipingDocument1 pagePump Installation: Inlet Piping Discharge PipingEjaz Ahmed RanaNo ratings yet

- Brass Fittings: Call Toll Free For Prices On Copper TubingDocument1 pageBrass Fittings: Call Toll Free For Prices On Copper TubingEjaz Ahmed RanaNo ratings yet

- Quick Reference Guide For ValvesDocument1 pageQuick Reference Guide For ValvesEjaz Ahmed RanaNo ratings yet

- Quick Reference Guide For Repair KitsDocument1 pageQuick Reference Guide For Repair KitsEjaz Ahmed RanaNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Welding Inspection Handbook PDF 1623987530Document29 pagesWelding Inspection Handbook PDF 1623987530Dross AlssNo ratings yet

- Compression Fittings Technical SpecDocument12 pagesCompression Fittings Technical SpecTerex14253No ratings yet

- Laser Micro Welding: Presented By: PAVAN PATEL (18BME082) & JIGAR MODI (18BME037)Document17 pagesLaser Micro Welding: Presented By: PAVAN PATEL (18BME082) & JIGAR MODI (18BME037)Pavan PatelNo ratings yet

- Test Bank, G 10Document48 pagesTest Bank, G 10abdullah.1723006No ratings yet

- (English) SDS PERTAMINA GRISKLINDocument13 pages(English) SDS PERTAMINA GRISKLINaudreyNo ratings yet

- MS 1462-2-2-2010 (Confirmed 2015) SoilDocument12 pagesMS 1462-2-2-2010 (Confirmed 2015) SoilGan Chin Phang0% (1)

- GemDocument9 pagesGemRam Prasidh AnaswaraNo ratings yet

- Metals & Non-MetalsDocument16 pagesMetals & Non-Metalseditsnaruto106100% (2)

- MDB Lecture Simple StrainDocument9 pagesMDB Lecture Simple StrainAura Paige Montecastro-RevillaNo ratings yet

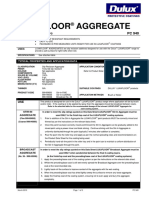

- Luxafloor Aggregate: Slip Resistant AdditiveDocument3 pagesLuxafloor Aggregate: Slip Resistant AdditivelivefreakNo ratings yet

- Velten Et Al-2002-Journal of Biomedical Materials ResearchDocument11 pagesVelten Et Al-2002-Journal of Biomedical Materials ResearchjeffreylopezNo ratings yet

- Materials & Finishes Catalog 2014Document32 pagesMaterials & Finishes Catalog 2014Constructora MAS100% (2)

- Fire Cable EL SewedyDocument3 pagesFire Cable EL SewedyMotaz AliNo ratings yet

- DDS 03b (20190620) Final Structural Drawings-2Document11 pagesDDS 03b (20190620) Final Structural Drawings-2Kevin RojasNo ratings yet

- Construction Materials and TestingDocument145 pagesConstruction Materials and TestingrajeshwaridasondhiNo ratings yet

- Digimat HCDocument2 pagesDigimat HCyokartikNo ratings yet

- 3632r 98 PDFDocument18 pages3632r 98 PDFFred PrzNo ratings yet

- Synthesis and Characterization of Comb-Like Copolymer Dispersant With Methoxy Poly (Ethylene Oxide) Side ChainsDocument9 pagesSynthesis and Characterization of Comb-Like Copolymer Dispersant With Methoxy Poly (Ethylene Oxide) Side ChainsGeorgeThorogoodNo ratings yet

- Use of Alternative Materials and Technology For Roads PDFDocument10 pagesUse of Alternative Materials and Technology For Roads PDFDwijendra ChanumoluNo ratings yet

- Exp - 2, Extraction Lab - 97-2003Document16 pagesExp - 2, Extraction Lab - 97-2003venu11chemistNo ratings yet

- Polymer StructureDocument34 pagesPolymer StructureQaz ZaqNo ratings yet

- Penetrant Product Brochure EMEARDocument8 pagesPenetrant Product Brochure EMEARChoice OrganoNo ratings yet

- Nihonto Summary PDFDocument54 pagesNihonto Summary PDFtogakure0880No ratings yet

- Welding Galvanized SteelDocument6 pagesWelding Galvanized SteelmperelmuterNo ratings yet

- Dissolves Marine Growth Calcium Rust Mussels SafelyDocument2 pagesDissolves Marine Growth Calcium Rust Mussels SafelyIvan TonjaNo ratings yet

- Conversion of Waste Plastics Into FuelsDocument7 pagesConversion of Waste Plastics Into FuelsEvans KasondeNo ratings yet

- HQ091EN Balinit® ALNOVADocument2 pagesHQ091EN Balinit® ALNOVAMari BraatzNo ratings yet

- Grade 12 Enzyme LabDocument25 pagesGrade 12 Enzyme LabKrystalLovejoyNo ratings yet

- Stainless Steel Grade Selection Rev Sep 2008Document11 pagesStainless Steel Grade Selection Rev Sep 2008rastogi18100% (1)

- Sika Waterbar® WP AF-600 AT: Product Data SheetDocument4 pagesSika Waterbar® WP AF-600 AT: Product Data SheetKhin Sandi KoNo ratings yet