Professional Documents

Culture Documents

Quick Reference Guide For Valves

Uploaded by

Ejaz Ahmed RanaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Quick Reference Guide For Valves

Uploaded by

Ejaz Ahmed RanaCopyright:

Available Formats

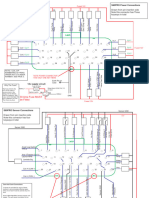

ASME TANK REFURBISH

Quick Reference Guide For Valves

Make sure you are thoroughly trained before you attempt any ASME tank maintenance. Improper

conditions or procedures can cause accidents resulting in property damage and personal injury.

Tank configuration shown is appropriate for tanks built since the mid-1970’s. If yours does not match, please call the

Gas Equipment Company location nearest you and we will be glad to help.

Filler Valve

Chek Lok

ACME Hose Tank Connection

Part #

7550P 7550P

Approximate Connection M. NPT

7647SC

Angle

1 3⁄4” ⁄4”

®

Angle Chek-Lok Inlet Outlet Closing Flow, 3

Valve Valve Connection Connection Liquid GPM Adapters

L7579 1 3⁄4” 1 1⁄4”

Number

7590U 7572-14A

(Propane) L7579

Adapter 7590U-10 7590U 3

⁄4” M.NPT 20 7590U-10 3174-9P Cap

Adapter 1 ⁄8” UNF

3174-93L Cap w/Lanyard

5

7572FC

or 7580FC 7591U 1 1⁄4” M.NPT 35 7590U-20

Chek-Lok ® 7590U Filler Valve Repair Kits:

For L7579: L7579-80

or 7591U

Chek-Lok ®

Contains: Gaskets, seat disc and

retainer assembly and spring.

For 7647: 7647-80

Relief Valves Filler Valve Washers Pkg. of 25 A2697-20R

Start To Flow Capacity SCFM/Air Suitable

Container

Part # Discharge Connection UL ASME for Tanks Rain

Setting (At 120% of (At 120% of w/Surface Caps

PSIG M. NPT

Set Pressure) Set Pressure) Area Up To:

Float Gauge 7583G 3

⁄4” 1980 1806 80 Sq. Ft. 7583-40X

(See Below)

8684G 1” 2620 2565 113 Sq. Ft. 8684-40

250

8685G 4385 4035 212 Sq. Ft. 7583-40X

7583G 1 ⁄4”

1

3132G 4130 - 200 Sq. Ft. 3132-54

To calculate approximate outside surface area (OSSA) in Square Feet: Approximate OSSA

NOTE: Values to be in Feet For Tanks

1. Cylindrical container with hemispherical heads: with hemispherical heads

Area = Overall length X outside diameter X 3.1416 250 gal = 60 S.F.

2. Cylindrical container with semi-ellipsoidal heads: 320 gal = 75 S.F.

500 gal = 98 S.F.

Multivalves

Area = (Overall length + .3 outside diameter) X outside diameter X 3.1416

3. Spherical container: Area = Outside diameter squared x 3.1416 1000 gal = 173 S.F.

Float Fixed Pressure For Use In

Vapor

Container Service Filling Gauge Liquid Relief Containers

Part # Equalizing

Connection Connection Connection Flange Level Vent Valve w/Surface

Connection

Opening Valve Style Setting Area Up To:

83 sq. ft.

Above Ground

G8475RL

Underground

276 sq. ft.

Fits Underground

1 3⁄4” 250

Filler Valve

Multivalve G8475RLW

2 1⁄2” F. NPT

F. POL

M. ACME

1 1⁄4”

“JUNIOR”

Size

PSIG

192 sq. ft.

Above Ground

Knurled 639 sq. ft.

Repair Kit Vapor E qualizing (CGA 510) M. ACME

8475-80 Repair Kit Underground

8475-81A PG8475RL N/A

Service Valve 7556R12.0 3

⁄4” M. NPT N/A N/A N/A N/A

Repair Kit

8593AR16.0 1 1⁄2” M. NPT 1 3⁄4” N/A N/A N/A

19104-50 M. ACME

Fixed Liquid Service Valve Repair Kit for G8475RL — 19104-50 —

8593AR16.0

Level Gauge Contains: MultiBonnet assembly, handwheel, nameplate, and self-tapping screw.

3165C

Service Valve Repair Kit Prior to 1962 — 8100-50 — Contains: Bonnet assembly.

G8475RL/RLW 7556R12.0 Service Valve Repair Kit for 1470, 1480 Series, 2593/K, 2594/K Series —3100-81K

PG8475RL — Contains: Bonnet and stem assembly

DOMESTIC TANK GAUGES

How to Order A Gauge Or Build Your Own With The NEW R3G

1. Determine Tank Type

Adjustable Liquid Level Gauge

In Jun ior ™ & Se nior ™ Sizes

o Above Ground Here is an adjustable, magnetic, liquid-level gauge which makes it a snap to quickly and econom-

o Under Ground ically replace non-functional LP Gas gauges in the field. Because the NEW R3G adjustable

gauges fit many tanks, the R3G Gauge greatly reduces the number of spare gauges you need to

stock. The R3G Gauge is UL listed for LP gas service.

2. Determine Gauge Head Type

1. Select the Gauge Support Assembly

Junior™, 4-Bolt Adjustable Gauges

Part # Tank Diameter Application

B0049S02159 24” to 37.5”

Above Ground

B0049S02170 41”

o JR - 4 bolt o SR - 4 bolt o 1-1/4” Thread o 1” Thread Senior™, 4-Bolt Adjustable Gauges

A = 2-1/32 A = 2-1/2

3. Determine Tank Diameter

Part # Tank Diameter Application

0049S02207 24” to 37.5”

Above Ground

D = _______ “ 0049S02208 41”

From Tank Data Plate or Junior™ Brass Threaded Adjustable Gauge

Measure Circumference (in inches) 1 1⁄4" NPT Threaded

and divide by 3.14

Or the KIT

Option:

Part # Tank Diameter Application

B0049S02203 24” to 37.5”

4. Determine Riser Height: H = ________ “ Above Ground

B0049S02204 41”

Part #6287-00001K

Note: Riser height is the distance, in inches,

from tank surface to top of mounting flange or 1" NPT Threaded

coupling for gauge. Includes: 1 Support

Part # Tank Diameter Application Assembly (Jr. 4-Bolt) and

B0049S02160 24” to 37.5” 4 Float Assemblies to fit

Above Ground

B0049S02167 41” one 24”, 30”, 32” or 37.5”

2. Select a Float above ground tank.

Common Junior™ & Senior™

5. Determine Mounting Position

Float Assemblies - Top Mount

Part # Tank Diameter

6857S11009 24”

6857S13759 30”

o Top Mount

6810S14379 32”

o Angle Mount 6857S17009 37.5”

o Side Mount 6857S18509 41”

o End Mount 3. Put It Together

Note: P ivot point of float must be at center line Assembly Instructions

of tank. Located to the right of the gauge.

SINCE 1937

Atlanta GA Dallas TX Fayetteville NC Houston TX Indianapolis IN

(800) 241-4155 (800) 821-1829 (800) 447-1625 (800) 334-7816 (800) 241-1971

Kansas City MO Little Rock AR Orlando FL Richmond VA St. Louis MO

(800) 821-5062 (800) 643-8222 (800) 821-0631 (800) 368-4013 (800) 423-4685

www.gasequipment.com Gas Equipment Co. TV / www.youtube.com/GasEquipmentTV

P1 CEDed0513

You might also like

- 20K inDocument1 page20K inossoskiNo ratings yet

- Rego 7572fc Drenaje LiquidoDocument1 pageRego 7572fc Drenaje LiquidoDaniel MaldonadoNo ratings yet

- Reverse Engagement Valve Kit: Ford 5R55S, 5R55WDocument1 pageReverse Engagement Valve Kit: Ford 5R55S, 5R55WJefithoCortezNo ratings yet

- S60 Wiring DiagramDocument9 pagesS60 Wiring Diagramhashim sohailNo ratings yet

- Solenoid Modulator Valve Kit: Toyota/Lexus U140E, U140F, U240E, U241EDocument1 pageSolenoid Modulator Valve Kit: Toyota/Lexus U140E, U140F, U240E, U241EossoskiNo ratings yet

- 5 EvacOnlineMax-TechnicalDetailsDocument1 page5 EvacOnlineMax-TechnicalDetailsJose LiraNo ratings yet

- TF-80/81SC, TF-60SN: OmplaintDocument1 pageTF-80/81SC, TF-60SN: Omplaintramon baronaNo ratings yet

- Qa 7 Wa380-3 Demand - ValveDocument1 pageQa 7 Wa380-3 Demand - ValveEndraNo ratings yet

- 11KDocument1 page11KAlli YantiNo ratings yet

- 45rfe 545rfe 65rfe 66rfe 68rfe Zip-11k-InDocument1 page45rfe 545rfe 65rfe 66rfe 68rfe Zip-11k-InHenry SilvaNo ratings yet

- Multivalvula - 8593arDocument1 pageMultivalvula - 8593arCarlos Rafael Rondon AbreuNo ratings yet

- GEMS bilge water level switches provide reliable operation in contaminated liquidsDocument1 pageGEMS bilge water level switches provide reliable operation in contaminated liquidsAhmed EmamNo ratings yet

- Lockup Clutch Control Plunger Valve Kit: Aisin AW TF-60SN, TF-80SC, TF-81SC Mini 6F21WA VW/Audi 09G, 09K, 09MDocument1 pageLockup Clutch Control Plunger Valve Kit: Aisin AW TF-60SN, TF-80SC, TF-81SC Mini 6F21WA VW/Audi 09G, 09K, 09Mkurupt486 ekbxsfkjxddNo ratings yet

- Excess Flow Valves - General InformationDocument7 pagesExcess Flow Valves - General Informationtranhonghakd5533No ratings yet

- 02K inDocument1 page02K inAbbode HoraniNo ratings yet

- Renegade Gunite Skimmers Maximize FlowDocument2 pagesRenegade Gunite Skimmers Maximize FlowChhomNo ratings yet

- A750E A750F Rebuild ManualDocument100 pagesA750E A750F Rebuild ManualKhamkhoun Phanthavong100% (1)

- A760E F H VBL InteractiveDocument1 pageA760E F H VBL InteractivehaddadiNo ratings yet

- A760E-F-H VBL Interactive PDFDocument1 pageA760E-F-H VBL Interactive PDFchoco84No ratings yet

- Oversized Kit Valvula Lock Up AmarokDocument1 pageOversized Kit Valvula Lock Up AmarokautomaticosbrasilNo ratings yet

- Notes Piping Symbols Pipe Components Cont. Pipe Components Pipe ComponentsDocument1 pageNotes Piping Symbols Pipe Components Cont. Pipe Components Pipe ComponentsMohd KhaidirNo ratings yet

- Vent Valve PDFDocument1 pageVent Valve PDFIqra AngelsNo ratings yet

- A750EDocument100 pagesA750ERICARDO TAVERA100% (7)

- Pressure Regulator Boost Sleeve: Jatco/Nissan RE4F02A, RL4F02ADocument1 pagePressure Regulator Boost Sleeve: Jatco/Nissan RE4F02A, RL4F02Aflash_24014910No ratings yet

- Oversized Lockup Control Valve Kit: Jatco/Nissan JF011E (RE0F10A)Document1 pageOversized Lockup Control Valve Kit: Jatco/Nissan JF011E (RE0F10A)SAMADNo ratings yet

- Excess Flow Valves For Flange Mounting in Container Service A3500 Series and A4500 SeriesDocument1 pageExcess Flow Valves For Flange Mounting in Container Service A3500 Series and A4500 SeriesLPG Equipment Consulting and ServicesNo ratings yet

- g8475rDocument1 pageg8475rmohsen fatemiNo ratings yet

- Oversized Volumetric Flow Rate Kit: Audi 01J, 01TDocument1 pageOversized Volumetric Flow Rate Kit: Audi 01J, 01TАндрей ЛозовойNo ratings yet

- A 750e PDFDocument100 pagesA 750e PDFMarcos MontesNo ratings yet

- A 750e PDFDocument100 pagesA 750e PDFTaymazNo ratings yet

- Instruction Manual: Installation - Operation - MaintenanceDocument13 pagesInstruction Manual: Installation - Operation - MaintenanceNamer HajiNo ratings yet

- 6-mm Metric Powder Feed PumpsDocument1 page6-mm Metric Powder Feed Pumpsjorgeeu88No ratings yet

- A1100 Overfill Prevention Valve (5162) .PDF NuevoDocument2 pagesA1100 Overfill Prevention Valve (5162) .PDF NuevolauraNo ratings yet

- Installation/Service Manual: Slow Exhaust Autoclave & Rapid Exhaust AutoclaveDocument35 pagesInstallation/Service Manual: Slow Exhaust Autoclave & Rapid Exhaust Autoclavebiomed systechNo ratings yet

- AMT 16 Lesson 10Document12 pagesAMT 16 Lesson 10Jashi SiñelNo ratings yet

- Prince Hydraulics Wolverine Adjustable Flow Control Valve Offered by PRC Industrial SupplyDocument1 pagePrince Hydraulics Wolverine Adjustable Flow Control Valve Offered by PRC Industrial SupplyPRC Industrial SupplyNo ratings yet

- Light Oil PumpsDocument2 pagesLight Oil PumpsBach Vu CongNo ratings yet

- Weldtec WT-17 TIG Torch PartsDocument2 pagesWeldtec WT-17 TIG Torch PartsCarlos Eduardo Castillo LanderosNo ratings yet

- PC210LC-11 Sen06695-01 Troubleshooting For Hydraulic and MechanicalDocument70 pagesPC210LC-11 Sen06695-01 Troubleshooting For Hydraulic and MechanicaldatphuongNo ratings yet

- JATCO JF506E / Mazda 5F31J: FWD 5 SpeedDocument6 pagesJATCO JF506E / Mazda 5F31J: FWD 5 SpeedAdrian PhillipsNo ratings yet

- JF506E 5-Speed Transmission ManualDocument6 pagesJF506E 5-Speed Transmission ManualAdrian PhillipsNo ratings yet

- Toyota A761E Transmission Repair Manual RM1050UDocument107 pagesToyota A761E Transmission Repair Manual RM1050Uparti di automobili100% (1)

- Inground Pool Skimmer Instructions: Operation For All SkimmersDocument3 pagesInground Pool Skimmer Instructions: Operation For All SkimmersRAKESH REDDYNo ratings yet

- RCH 2 - Williams Model IP-1000Document2 pagesRCH 2 - Williams Model IP-1000Chris Alfa PalaNo ratings yet

- Permanent gauging blocks installation guideDocument2 pagesPermanent gauging blocks installation guideJaime RichardsonNo ratings yet

- Oversized Solenoid Modulator Valve Kit: Aisin AW TF-80/81SCDocument1 pageOversized Solenoid Modulator Valve Kit: Aisin AW TF-80/81SCramon baronaNo ratings yet

- Centrifugal End Suction Firepump NFPA 20Document5 pagesCentrifugal End Suction Firepump NFPA 20huseeeNo ratings yet

- I Repfiir Piirts I: Silentvane@Twinvane@ Adaptor For Tandem MountingDocument6 pagesI Repfiir Piirts I: Silentvane@Twinvane@ Adaptor For Tandem MountingEng-Mohammed SalemNo ratings yet

- Curva ASH 10x10SRH C4-2302Document1 pageCurva ASH 10x10SRH C4-2302BM Thaís100% (2)

- 1545 Q 15 Mva 66 - 11.55 KV Aet-1374Document1 page1545 Q 15 Mva 66 - 11.55 KV Aet-1374shravan Kumar SinghNo ratings yet

- Low Pressure Regulator Settings GuideDocument1 pageLow Pressure Regulator Settings GuideEmanuelCalmaYandocNo ratings yet

- Relief Valves For Transports and Delivery TrucksDocument8 pagesRelief Valves For Transports and Delivery Truckswilfredo macoNo ratings yet

- Installation and Maintenance: Al Is To Be Give Nto The e ND Us ErDocument12 pagesInstallation and Maintenance: Al Is To Be Give Nto The e ND Us ErM. ShaatNo ratings yet

- Jatco/Nissan JF011E (RE0F10A), JF015E (RE0F11A), JF016E (RE0F10D), JF017E (RE0F10E)Document1 pageJatco/Nissan JF011E (RE0F10A), JF015E (RE0F11A), JF016E (RE0F10D), JF017E (RE0F10E)SAMAD50% (2)

- Effective Pump Swap Maximizing Production and Well Uptime: Through Tubing Conveyed ESPDocument14 pagesEffective Pump Swap Maximizing Production and Well Uptime: Through Tubing Conveyed ESPMustafa NaithelNo ratings yet

- Oversized Pressure Reducing Valve Kit: Hyundai/Kia A4CF1, A4CF2Document1 pageOversized Pressure Reducing Valve Kit: Hyundai/Kia A4CF1, A4CF2belchior0% (1)

- Dish Ends Calculator For Pressure Vessel FabricationDocument8 pagesDish Ends Calculator For Pressure Vessel FabricationEjaz Ahmed RanaNo ratings yet

- Risk Based Leak Analysis of An LPG Stora PDFDocument28 pagesRisk Based Leak Analysis of An LPG Stora PDFEjaz Ahmed RanaNo ratings yet

- LPG Road Tankers and ISO Tank ContainersDocument12 pagesLPG Road Tankers and ISO Tank ContainersEjaz Ahmed RanaNo ratings yet

- What Is A Material Test Certificate (Mill Test Certificate) - HQTSDocument5 pagesWhat Is A Material Test Certificate (Mill Test Certificate) - HQTSEjaz Ahmed RanaNo ratings yet

- Bulk LPG TT - Safety in Design & OperationDocument35 pagesBulk LPG TT - Safety in Design & OperationNilambar Bariha100% (1)

- Optech Density Correction Values Calculated As Per ASTMDocument14 pagesOptech Density Correction Values Calculated As Per ASTMEjaz Ahmed RanaNo ratings yet

- Gas flow calculations: mass to volume conversionsDocument2 pagesGas flow calculations: mass to volume conversionsPangestu Try WibowoNo ratings yet

- VCF Propane510Document5 pagesVCF Propane510Ejaz Ahmed RanaNo ratings yet

- LPG Road Tankers and ISO Tank ContainersDocument12 pagesLPG Road Tankers and ISO Tank ContainersEjaz Ahmed RanaNo ratings yet

- Sa 517Document2 pagesSa 517Ejaz Ahmed RanaNo ratings yet

- Ms0162f Flowsolv v5.3 Pro Getting Started Guide Sd000092 201120Document2 pagesMs0162f Flowsolv v5.3 Pro Getting Started Guide Sd000092 201120Ejaz Ahmed RanaNo ratings yet

- VCF Propane510Document5 pagesVCF Propane510Ejaz Ahmed RanaNo ratings yet

- Different Types of Pipe Support Clamps & Hangers - Make Piping EasyDocument20 pagesDifferent Types of Pipe Support Clamps & Hangers - Make Piping EasyEjaz Ahmed RanaNo ratings yet

- Endress-Hauser LPGmass 8FE enDocument4 pagesEndress-Hauser LPGmass 8FE enEjaz Ahmed RanaNo ratings yet

- 2020-2021 MEC Catalog REV B - LowresDocument228 pages2020-2021 MEC Catalog REV B - LowresEjaz Ahmed RanaNo ratings yet

- pressureProcedTest PDFDocument7 pagespressureProcedTest PDFfaizal azizNo ratings yet

- MS0162F FLOWSOLV V5.3 Datasheet SD000195 201009Document1 pageMS0162F FLOWSOLV V5.3 Datasheet SD000195 201009Ejaz Ahmed RanaNo ratings yet

- A Presentation On Pipe Stress Analysis - Make Piping EasyDocument16 pagesA Presentation On Pipe Stress Analysis - Make Piping EasyEjaz Ahmed RanaNo ratings yet

- Reinforcement Pad Calculation For Branch Connection - Make Piping EasyDocument16 pagesReinforcement Pad Calculation For Branch Connection - Make Piping EasyEjaz Ahmed RanaNo ratings yet

- Blackmer Autogas HandbookDocument32 pagesBlackmer Autogas HandbookMuhammad ImranNo ratings yet

- Pump Cavitation - Causes, Effects, & Preventive Actions - Make Piping EasyDocument14 pagesPump Cavitation - Causes, Effects, & Preventive Actions - Make Piping EasyEjaz Ahmed RanaNo ratings yet

- Pipe Sizing Guide for Chemical ProcessesDocument3 pagesPipe Sizing Guide for Chemical ProcessesEjaz Ahmed RanaNo ratings yet

- Control Station and Control Valve in The Process Piping - Make Piping EasyDocument15 pagesControl Station and Control Valve in The Process Piping - Make Piping EasyEjaz Ahmed RanaNo ratings yet

- Pump Installation: Inlet Piping Discharge PipingDocument1 pagePump Installation: Inlet Piping Discharge PipingEjaz Ahmed RanaNo ratings yet

- Pipe Sizing Guide for Chemical ProcessesDocument3 pagesPipe Sizing Guide for Chemical ProcessesEjaz Ahmed RanaNo ratings yet

- Pressure DropDocument81 pagesPressure Drophamzashafiq1100% (1)

- Brass Fittings: Call Toll Free For Prices On Copper TubingDocument1 pageBrass Fittings: Call Toll Free For Prices On Copper TubingEjaz Ahmed RanaNo ratings yet

- Quick Reference Guide For Repair KitsDocument1 pageQuick Reference Guide For Repair KitsEjaz Ahmed RanaNo ratings yet

- Forklift Cylinder Maintenance: Quick Reference Guide For ValvesDocument1 pageForklift Cylinder Maintenance: Quick Reference Guide For ValvesEjaz Ahmed RanaNo ratings yet

- Basic Instrumentation: An IntroductionDocument136 pagesBasic Instrumentation: An IntroductionJuan MurriaNo ratings yet

- Differential Pressure Switch For Air Up To 5000 Pa: Position SectionDocument2 pagesDifferential Pressure Switch For Air Up To 5000 Pa: Position SectionИльяNo ratings yet

- Walnut Filter IOM RevA2Document12 pagesWalnut Filter IOM RevA2Ledavid Leonel Flores RiveraNo ratings yet

- Project Report InstrumentationDocument51 pagesProject Report InstrumentationUtkarsh ShuklaNo ratings yet

- Heat Capacity of GasesDocument9 pagesHeat Capacity of Gasesismail100% (1)

- Thermal Analysis of Low Cost Refrigeration System With LPG: Rajkiya Engineering College MainpuriDocument12 pagesThermal Analysis of Low Cost Refrigeration System With LPG: Rajkiya Engineering College MainpuriGAURAV KUMARNo ratings yet

- Operating Manual: Edition: 01 / 2016Document91 pagesOperating Manual: Edition: 01 / 2016Juan Manuel Llorente VaraNo ratings yet

- Durashock Overview - ENG PDFDocument2 pagesDurashock Overview - ENG PDFmaria jose rodriguez lopezNo ratings yet

- N M (Joules) FT LB Newton LB M FT: Inhinyero Review CenterDocument4 pagesN M (Joules) FT LB Newton LB M FT: Inhinyero Review CenterAngelo PlumosNo ratings yet

- Fluid Statics Chapter SummaryDocument56 pagesFluid Statics Chapter SummaryNur KamiliaNo ratings yet

- Intern Report LongerDocument57 pagesIntern Report LongerAnonymous 50Qv66BjNo ratings yet

- Xc-500 Series: Source Sampler ConsolesDocument4 pagesXc-500 Series: Source Sampler ConsolesSaleh UISNo ratings yet

- Integrity Testing of Hydrophilic Membrane Filters: Figure 1 - Wetting & Integrity Test SetupDocument4 pagesIntegrity Testing of Hydrophilic Membrane Filters: Figure 1 - Wetting & Integrity Test SetupVijay Kumar NandagiriNo ratings yet

- Instrumentation Design EngineeringDocument4 pagesInstrumentation Design EngineeringAwneesh Kumar100% (1)

- مبادئ1Document132 pagesمبادئ1assatpute0% (1)

- Hydraulics ProblemsDocument88 pagesHydraulics ProblemsG-Joy Fajilan100% (1)

- Sugar Engineering Certificate Course First Year (S.E.C.C.) Subject: Sugar Technology (Theory) CODE: EC/101 Max. Marks: 50Document9 pagesSugar Engineering Certificate Course First Year (S.E.C.C.) Subject: Sugar Technology (Theory) CODE: EC/101 Max. Marks: 50Robert BahatiNo ratings yet

- SPARES Part NumbersDocument4 pagesSPARES Part NumbersariyakkannaaNo ratings yet

- Generalized Measurement System PDFDocument24 pagesGeneralized Measurement System PDFdeerajNo ratings yet

- 4 - Gas Flow MeasurementDocument46 pages4 - Gas Flow MeasurementHashem HashemNo ratings yet

- Annex B BSMarE Course Specifications For Basic Control EngineeringDocument9 pagesAnnex B BSMarE Course Specifications For Basic Control EngineeringMarvin Carillo NatividadNo ratings yet

- Process Fluid MechanicsDocument38 pagesProcess Fluid Mechanicsmir shifayatNo ratings yet

- Secador TZ100Document45 pagesSecador TZ100nestor coaquiraNo ratings yet

- Theory19 PDFDocument54 pagesTheory19 PDFRoman SinghNo ratings yet

- s540 Flue Gas Analyser Maxilyzer NG PlusDocument2 pagess540 Flue Gas Analyser Maxilyzer NG Plusisraelnogueira3No ratings yet

- Pressure Measurement FundamentalsDocument10 pagesPressure Measurement FundamentalsDr.AhmedNo ratings yet

- QDR-GCS-ESJ-SPC-1000 RevADocument28 pagesQDR-GCS-ESJ-SPC-1000 RevAshaheen iqbal100% (1)

- MDX - Uk DP Gauge Bourdon HaeniDocument2 pagesMDX - Uk DP Gauge Bourdon HaeniKUSNONo ratings yet

- ASS Build Wika WerefedDocument2 pagesASS Build Wika WerefedXZXDEATHNo ratings yet

- Pressure Measurement Trainer ManualDocument20 pagesPressure Measurement Trainer ManualRajaNo ratings yet