Professional Documents

Culture Documents

Non Conformance Report (NCR) : Disposition Quantity Department (Dept.) Pen Id Comments / Confirmation

Uploaded by

Mangesh MohiteOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Non Conformance Report (NCR) : Disposition Quantity Department (Dept.) Pen Id Comments / Confirmation

Uploaded by

Mangesh MohiteCopyright:

Available Formats

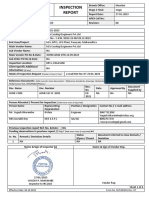

NON CONFORMANCE REPORT (NCR) NC NO.

: 844

(FORM QF-U-003) DATE : 12.05.21

Section (Please tick)

A QMS / EMS / OHSAS NA C Customer Complaints Yes

rd

B Audit (FSL / 3 Party) NA D QC Inspection NA

For Section A & B For Section C & D

ISO / BS Clause : NA Inspection lot Number : 010003742363

Process / Procedure :- Part number / code : 2H-160321

Sub Process : NA Part description : Plan 52

SOP / OCP No. : NA Offered quantity :3

Supplier Code : DD6198 Complaint quantity :2

Audit No. : NA Accepted quantity :1

For SAP F3 Notification only For SAP F2 Notification only

Production Order : NA Purchase Order : 6100079435

Device data : NA PO Line item :3

Defect location : NA Material document : 5001371965

Cell : NA Supplier code : DG0010

Cause code : NA Supplier name : Gauges Bourdon(India)Pvt Ltd

Cause text : NA Raw material heat code : -

Details of Non conformance

Problem statement / Auditor observation / Complaint

SAP Notification Short text : NA

SAP Notification Long text : NA

Reported by : LK3

Disposition Quantity Department (Dept.) PEN ID Comments / Confirmation

Machining defectives

Concession Engg / BT

Deviation Engg / BT

Rework Engg / BT / Dept.

Rejection Engg / BT / Dept.

Material defectives

Concession Engineering / BT

Rework Engg / BT / Dept.

Rejection Engg / BT / Dept.

Corrective Action Details

CAPA Report Number : 844

Flowserve Sanmar Ltd CAPA No. : 844

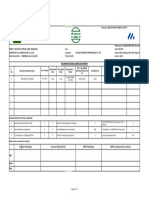

CORRECTIVE / PREVENTIVE

Date : 12.05.21

147, Karapakkam Village

ACTION REPORT Page : 1 of 1

Chennai – 600 097

To:

Name : Mr. Mangesh Mohite Department : Quality

Process : QA Location : GBIPL, Maharashtra

Details of rejection / Non conformance / Customer Complaint

Part number 2H-160321 Customer NCR / Email ref. 2021/05/31 Dt:10.05.21

Part description Plan 52 Production / Purchase order 6100079644-1

No. of defectives 2 Audit NCR No. -

Interim Corrective action

Action taken on Stocks / WIP

Details Qty available Action taken / planned Resp Date

WIP

Child part

Sub assembly

Assembly

Similar part code(s)

Root cause

NC Magnetic Level Gauge bend observed

Why? Magnetic Level Gauge bend observed due to transit damage.

Why? Mishandling by the transporter.

Why? Due to heavy weight of the level gauge.

Why? Transport labour not aware of the weight of the package.

Why? Trasnport Labour not verified the packing list.

Corrective Action to eliminate recurrence Resp Date

Rectification done by end user.

Preventive Action / Risk Mitigation in other Process / Part Resp Date

Handling instructions intimated to transporter.

Also, decided to use handling instruction symbol of heavy weight on packages.

Details Prepared by Reviewed by Approved by

Name

Sign

Date

You might also like

- Well Testing Project Management: Onshore and Offshore OperationsFrom EverandWell Testing Project Management: Onshore and Offshore OperationsNo ratings yet

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- SMChap 011Document59 pagesSMChap 011testbank100% (2)

- Fir-001 - 10 03 18Document1 pageFir-001 - 10 03 18Kartik SolankiNo ratings yet

- Digital Circuit Testing: A Guide to DFT and Other TechniquesFrom EverandDigital Circuit Testing: A Guide to DFT and Other TechniquesNo ratings yet

- Enterprise computing systems and informationDocument53 pagesEnterprise computing systems and informationTrxtr GiananNo ratings yet

- Discussing customer survey results to improve serviceDocument3 pagesDiscussing customer survey results to improve serviceSyeda AmeenaNo ratings yet

- Track Software Financial AnalysisDocument8 pagesTrack Software Financial AnalysisMohamed Ahmed ZeinNo ratings yet

- Online Feedback System 2011Document2 pagesOnline Feedback System 2011santosh kumarNo ratings yet

- Online Feedback System for Faulty EquipmentDocument2 pagesOnline Feedback System for Faulty Equipmentsantosh kumarNo ratings yet

- Online Feedback System 1921Document2 pagesOnline Feedback System 1921santosh kumarNo ratings yet

- Online Feedback System 1563Document2 pagesOnline Feedback System 1563santosh kumarNo ratings yet

- Part Submission Warrant: Part Name: Stopper Bracket Part Number 1 L0081-13 Rev.:01Document4 pagesPart Submission Warrant: Part Name: Stopper Bracket Part Number 1 L0081-13 Rev.:01karan singhNo ratings yet

- Online Feedback System 1665Document2 pagesOnline Feedback System 1665santosh kumarNo ratings yet

- Nonconformance Report: Internal External SurveyDocument7 pagesNonconformance Report: Internal External Surveymuhammad imtiazNo ratings yet

- Online Feedback System 1529Document2 pagesOnline Feedback System 1529santosh kumarNo ratings yet

- Hydraulic Filter 1Document2 pagesHydraulic Filter 1OUC-SECBNo ratings yet

- Online Feedback System 1435Document2 pagesOnline Feedback System 1435santosh kumarNo ratings yet

- Online Feedback System 1723Document2 pagesOnline Feedback System 1723santosh kumarNo ratings yet

- Online Feedback System 1670Document2 pagesOnline Feedback System 1670santosh kumarNo ratings yet

- Ir - Mum-22-Yrb 076 DT 30.12Document5 pagesIr - Mum-22-Yrb 076 DT 30.12Sampa DeyNo ratings yet

- Online Feedback System Progress ReportDocument2 pagesOnline Feedback System Progress Reportsantosh kumarNo ratings yet

- Online Feedback System 1738Document2 pagesOnline Feedback System 1738santosh kumarNo ratings yet

- NDE NDT Procedures Piping ADM 35313M-01 Q 153 01-1-150Document150 pagesNDE NDT Procedures Piping ADM 35313M-01 Q 153 01-1-150QC ManagerNo ratings yet

- NDE NDT Procedures Piping ADM 35313M-01 Q 153 01Document392 pagesNDE NDT Procedures Piping ADM 35313M-01 Q 153 01Neil JavierNo ratings yet

- Online Feedback System for Faulty EquipmentDocument2 pagesOnline Feedback System for Faulty Equipmentsantosh kumarNo ratings yet

- INSPECTION REPORTDocument3 pagesINSPECTION REPORTsheikmoinNo ratings yet

- NCR 002 - Bengkokan Besi Slab Control RoomDocument2 pagesNCR 002 - Bengkokan Besi Slab Control RoomAl Farisi FirdausNo ratings yet

- Online Feedback System 1782Document2 pagesOnline Feedback System 1782santosh kumarNo ratings yet

- Online Feedback System 1650Document2 pagesOnline Feedback System 1650santosh kumarNo ratings yet

- LAB121-2020-031 RFI Inspection For Rebound Test of Precast Segment V1-P53-P52-8#Document1 pageLAB121-2020-031 RFI Inspection For Rebound Test of Precast Segment V1-P53-P52-8#bojun liNo ratings yet

- Online Feedback System 1656Document2 pagesOnline Feedback System 1656santosh kumarNo ratings yet

- Procurement Services: Industry & Facilities DivisionDocument6 pagesProcurement Services: Industry & Facilities DivisionVikas Mani TripathiNo ratings yet

- BPCL Paver Block InspectionDocument4 pagesBPCL Paver Block Inspectionmithalesh kumarNo ratings yet

- RPT 001Document6 pagesRPT 001Juan Montes de ocaNo ratings yet

- Nonconformance Report: Internal External SurveyDocument6 pagesNonconformance Report: Internal External Surveymuhammad imtiazNo ratings yet

- NDE Procedure - Flare KOD - Structure Rev ADocument90 pagesNDE Procedure - Flare KOD - Structure Rev ARajesh K PillaiNo ratings yet

- Format. No: TSSA - IS - IN - FR - 05 Rev 4 Dated. 15.01.2021Document3 pagesFormat. No: TSSA - IS - IN - FR - 05 Rev 4 Dated. 15.01.2021Raja KrsNo ratings yet

- Inspection Report: 150 MW Dhamangaon Solar Project, MaharashtraDocument6 pagesInspection Report: 150 MW Dhamangaon Solar Project, Maharashtrakaushik21185No ratings yet

- Online Feedback System 1769Document2 pagesOnline Feedback System 1769santosh kumarNo ratings yet

- Ir - Mum-23-Yrb 023 DT 27.01.2023Document6 pagesIr - Mum-23-Yrb 023 DT 27.01.2023Sampa DeyNo ratings yet

- Nfe1 Ing Me Rfi 00036Document11 pagesNfe1 Ing Me Rfi 00036Deepu CNo ratings yet

- Online Feedback System2016Document2 pagesOnline Feedback System2016santosh kumarNo ratings yet

- DRP001-OUF-GAL-PRO-Q-000-067 Rev-S1Document61 pagesDRP001-OUF-GAL-PRO-Q-000-067 Rev-S1Rafat KhanNo ratings yet

- Chem Process-Skoda 03.06.2019Document9 pagesChem Process-Skoda 03.06.2019Mayank GandhiNo ratings yet

- Industry & Facilities Inspection ReportDocument10 pagesIndustry & Facilities Inspection Reportkbpatel123No ratings yet

- Online Feedback System Case DetailsDocument2 pagesOnline Feedback System Case Detailssantosh kumarNo ratings yet

- 05-11-2018 Ppap Documents Format Threaded Washer - 5 LtsDocument75 pages05-11-2018 Ppap Documents Format Threaded Washer - 5 LtsManoharar RNo ratings yet

- A-Star Testing & Inspection (S) Pte LTD: Magnetic Particle Testing ReportDocument4 pagesA-Star Testing & Inspection (S) Pte LTD: Magnetic Particle Testing ReportHari KarthickNo ratings yet

- 7 PDF - 1 - 2781 NCR TEP JHS 001 - 05sep18Document1 page7 PDF - 1 - 2781 NCR TEP JHS 001 - 05sep18Victor ManaoNo ratings yet

- MIghty Machine RejectDocument1 pageMIghty Machine RejectMohammad Shanawaz MNo ratings yet

- SFR Ofdb 3.0 Lock Screw LooseDocument2 pagesSFR Ofdb 3.0 Lock Screw LoosePuneet SharmaNo ratings yet

- Incoming Material Inspection Report: Date of ReceiptDocument1 pageIncoming Material Inspection Report: Date of ReceiptRaj MNo ratings yet

- NCR 4e38785b PDFDocument9 pagesNCR 4e38785b PDFDeepak DasNo ratings yet

- URM-0819-098-MA - Cover - Warping - Condition - KDC-X7200DABEN MA12Document7 pagesURM-0819-098-MA - Cover - Warping - Condition - KDC-X7200DABEN MA12Sahid Nugroho WNo ratings yet

- DRP001 Ouf Gal Spe B 000 001 S1Document25 pagesDRP001 Ouf Gal Spe B 000 001 S1Rafat KhanNo ratings yet

- DRP001-OUF-GAL-RAM-E-000-191 Rev-S! PDFDocument10 pagesDRP001-OUF-GAL-RAM-E-000-191 Rev-S! PDFMohammad AftabNo ratings yet

- Inspection of 15MVA Power Transformer for Solar ProjectDocument1 pageInspection of 15MVA Power Transformer for Solar ProjectAbhishek SenguptaNo ratings yet

- F-02 (Magnetic Particle Test) - (NEW) ..Latest 006Document42 pagesF-02 (Magnetic Particle Test) - (NEW) ..Latest 006Himanshu SinghNo ratings yet

- 2-D Drawing For VJTI LabDocument1 page2-D Drawing For VJTI LabMangesh MohiteNo ratings yet

- Final Paper Saving Tips 1Document8 pagesFinal Paper Saving Tips 1Sneha MishraNo ratings yet

- myeNovation-Kaizen DeckDocument11 pagesmyeNovation-Kaizen DeckMangesh MohiteNo ratings yet

- Energy ConservationDocument16 pagesEnergy ConservationChanpreet SinghNo ratings yet

- Success Stories-KAIZENDocument6 pagesSuccess Stories-KAIZENMangesh MohiteNo ratings yet

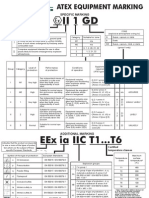

- Atex MarkingDocument1 pageAtex Markinggangotri05No ratings yet

- Sensors and ActuatorsDocument33 pagesSensors and ActuatorsMangesh MohiteNo ratings yet

- National Acereditation Board Grants Accreditation to Aimtech Solutions LaboratoryDocument1 pageNational Acereditation Board Grants Accreditation to Aimtech Solutions LaboratoryMangesh MohiteNo ratings yet

- Https Incometaxindiaefiling - Gov.in E-Filing MyAccount printITRVAckDocument1 pageHttps Incometaxindiaefiling - Gov.in E-Filing MyAccount printITRVAckMangesh MohiteNo ratings yet

- Material Safety Data Sheet: Section I Product IdentificationDocument4 pagesMaterial Safety Data Sheet: Section I Product IdentificationMangesh MohiteNo ratings yet

- Wika-Rtd-Tc Operating ManualsDocument60 pagesWika-Rtd-Tc Operating ManualsMangesh MohiteNo ratings yet

- Wet and Dry Bulb (JavaScript) .HTMLDocument1 pageWet and Dry Bulb (JavaScript) .HTMLMangesh MohiteNo ratings yet

- KPC-01 Temperature Control Trainer LabDocument1 pageKPC-01 Temperature Control Trainer LabMangesh MohiteNo ratings yet

- Tool Maker Microscope: Since 1954Document2 pagesTool Maker Microscope: Since 1954Mangesh MohiteNo ratings yet

- Does Immersion Depth Really Matter?: Application NoteDocument2 pagesDoes Immersion Depth Really Matter?: Application NoteMangesh MohiteNo ratings yet

- Differential Pressure Switches DPS Series: For Air Conditioning / Ventilation, User-AdjustableDocument4 pagesDifferential Pressure Switches DPS Series: For Air Conditioning / Ventilation, User-AdjustableMangesh MohiteNo ratings yet

- Honeywell: Artee Flow Controls Pvt. LTDDocument2 pagesHoneywell: Artee Flow Controls Pvt. LTDMangesh MohiteNo ratings yet

- New Doc 2020-08-13 16.51.48 - 1Document1 pageNew Doc 2020-08-13 16.51.48 - 1Mangesh MohiteNo ratings yet

- Pressure Gauge GuideDocument3 pagesPressure Gauge GuideMangesh MohiteNo ratings yet

- RT Asmeb31.3 Withoutsecure PDFDocument4 pagesRT Asmeb31.3 Withoutsecure PDFkishorekumar.animuNo ratings yet

- RT Asmeb31.3 Withoutsecure PDFDocument4 pagesRT Asmeb31.3 Withoutsecure PDFkishorekumar.animuNo ratings yet

- Asme Sec V B Se 165 Examen Con Liquidos Penetrantes PDFDocument25 pagesAsme Sec V B Se 165 Examen Con Liquidos Penetrantes PDFA.A100% (1)

- TW BF 01 - Barstock Flanged Type Thermowell (Straight) : TWBF - 01Document17 pagesTW BF 01 - Barstock Flanged Type Thermowell (Straight) : TWBF - 01Mangesh MohiteNo ratings yet

- Standard 3057 PDFDocument1 pageStandard 3057 PDFMangesh MohiteNo ratings yet

- PROFORMA INVOICE STANDARDSDocument1 pagePROFORMA INVOICE STANDARDSMangesh MohiteNo ratings yet

- Calibrating taper thread ring gaugesDocument1 pageCalibrating taper thread ring gaugesMangesh MohiteNo ratings yet

- TDS Hardtop XP GB English ProtectiveDocument5 pagesTDS Hardtop XP GB English Protective폴로 쥰 차No ratings yet

- DPS Qatar Revision Questions History Civics Class 7Document19 pagesDPS Qatar Revision Questions History Civics Class 7BNo ratings yet

- PowerPoint presentation history and featuresDocument7 pagesPowerPoint presentation history and featuresJL SabioNo ratings yet

- Republic Act NoDocument2 pagesRepublic Act NoLEAHNAH NAHNo ratings yet

- Managerial Theories, Approaches, Functions and ReferencesDocument4 pagesManagerial Theories, Approaches, Functions and Referencesdheeksha puvvadaNo ratings yet

- PACS How To Clear The UNCACCOUNT BalancesDocument9 pagesPACS How To Clear The UNCACCOUNT BalancesEmmanuel Uchenna ChukwuNo ratings yet

- Project Fixed Assets Management by CH - Shravan KumarDocument74 pagesProject Fixed Assets Management by CH - Shravan KumarSandy SanNo ratings yet

- Reddy - Prathap - Web TranscriptDocument26 pagesReddy - Prathap - Web TranscriptSridhar KrishnamurthiNo ratings yet

- Characteristics of The TourismDocument4 pagesCharacteristics of The TourismRay KNo ratings yet

- Expenditures: V-Audit of Property, Plant and EquipmentDocument24 pagesExpenditures: V-Audit of Property, Plant and EquipmentKirstine DelegenciaNo ratings yet

- Marketing Management Rubric PDFDocument6 pagesMarketing Management Rubric PDFNguyen AnhNo ratings yet

- Grace Strux Beton PDFDocument33 pagesGrace Strux Beton PDFmpilgirNo ratings yet

- Time Is Money: Presented By:Hammad Ur Rehman Submitted To: Ms Naila ShahzadDocument10 pagesTime Is Money: Presented By:Hammad Ur Rehman Submitted To: Ms Naila ShahzadHAMMAD UR REHMANNo ratings yet

- Pricing Strategy - Kotler KellerDocument57 pagesPricing Strategy - Kotler Kellerbj332650% (2)

- Process CostingDocument20 pagesProcess CostingJanak DandNo ratings yet

- Agile Use CasesDocument80 pagesAgile Use CasesJessica PetersonNo ratings yet

- Chapter 1Document21 pagesChapter 1SABBIR AHMEDNo ratings yet

- leapfilesvsJUoMTVBxWim04bhb92eEHYlC7CF5TGGeV5zeTL Attachment - PDDocument2 pagesleapfilesvsJUoMTVBxWim04bhb92eEHYlC7CF5TGGeV5zeTL Attachment - PDJuan GonzalezNo ratings yet

- Demand Forecasting of Cement IndustryDocument20 pagesDemand Forecasting of Cement IndustryShraddhaNaikNo ratings yet

- Internet of Things Iot Advantages On E-LDocument7 pagesInternet of Things Iot Advantages On E-LselmiNo ratings yet

- GPB 321 (1+0) - NotesDocument96 pagesGPB 321 (1+0) - Noteskapil agrawalNo ratings yet

- Rise Tax Mock QP With SolutionDocument18 pagesRise Tax Mock QP With SolutionEmperor YasuoNo ratings yet

- How The CIA Made Google (Google Did Not Start in Susan Wojcicki's Garage)Document9 pagesHow The CIA Made Google (Google Did Not Start in Susan Wojcicki's Garage)karen hudesNo ratings yet

- Corporation and Estate Taxation - Sample ProblemDocument5 pagesCorporation and Estate Taxation - Sample Problemwind snip3r reojaNo ratings yet

- LXP RFP For L&D TransformationDocument24 pagesLXP RFP For L&D Transformationnana hariNo ratings yet

- Tcs Employment Application FormDocument6 pagesTcs Employment Application FormRaveenaNo ratings yet

- Inventory Management Just in Time and Costing Methods Multiple Choice Questions - Accounting Quiz Answers 5 PDFDocument4 pagesInventory Management Just in Time and Costing Methods Multiple Choice Questions - Accounting Quiz Answers 5 PDFSumedha SawniNo ratings yet