Professional Documents

Culture Documents

Designing Product Layouts

Designing Product Layouts

Uploaded by

PrajaktaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Designing Product Layouts

Designing Product Layouts

Uploaded by

PrajaktaCopyright:

Available Formats

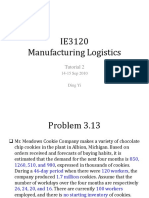

Q1.

Real Fruit Snack Strips are made from a mixture of dried fruits, food colouring ,

preservatives and glucose. The mixture is pressed out into a thin sheet, imprinted with various

shapes ,rolled and packaged. The precedence and time requirements for each step in the

assembly process are given below. To meet the demand, Real Fruit needs to produce 6000

fruit strips every 40-hour week. Design an assembly line with the fewest number of

workstations that will achieve the production quota without violating precedence constraints.

Work Element Precedence Time(min)

A Press out sheet of fruit _ 0.1

B Cut into strips A 0.2

C Outline fun shapes A 0.4

D Roll up and package B,C 0.3

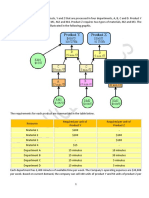

Q.2 The Basic Block company needs to produce 4000 boxes of blocks per 40-hour week to

meet upcoming holiday demand. The process of making blocks can be broken down into six

work elements. The precedence and time requirements for each element are as follows. Draw

and label a precedence diagram for the production process. Set up a balanced assembly line

and calculate the efficiency of the line.

Work Element Precedence Performance

Time(Min)

A - 0.10

B A 0.40

C A 0.50

D - 0.20

E C,D 0.60

F B,E 0.40

You might also like

- Sample Problems in Capacity PlanningDocument19 pagesSample Problems in Capacity PlanningJeanelle Abadilla0% (1)

- Imt 15Document8 pagesImt 15remembersameerNo ratings yet

- True FalseDocument5 pagesTrue FalseCarlo ParasNo ratings yet

- Line Balancing: Output (Production) RateDocument14 pagesLine Balancing: Output (Production) RateAzmii BelimNo ratings yet

- Team PRTC 1stPB May 2023 - Key AnswersDocument51 pagesTeam PRTC 1stPB May 2023 - Key Answerskathryn b. fordNo ratings yet

- 06 Task Performance 1Document2 pages06 Task Performance 1Goose ChanNo ratings yet

- IE3120 Manufacturing Logistics: Tutorial 2Document27 pagesIE3120 Manufacturing Logistics: Tutorial 2Joli SmithNo ratings yet

- Designing Product LayoutDocument7 pagesDesigning Product LayoutPrajaktaNo ratings yet

- Assembly Line - NumericalDocument22 pagesAssembly Line - NumericalRahul ShawNo ratings yet

- Exercises On Process Layout & Product LayoutDocument4 pagesExercises On Process Layout & Product Layoutjanhabi.s25No ratings yet

- OM - Group AssignmentDocument20 pagesOM - Group Assignmentmesfinnigussie28No ratings yet

- Operation Management AssignmentDocument8 pagesOperation Management AssignmentSineshaw AlemuNo ratings yet

- QB 601Document6 pagesQB 601Saksham MaheshwariNo ratings yet

- Module 1 - Productivity, Competitiveness, and Strategy (Illustrations)Document5 pagesModule 1 - Productivity, Competitiveness, and Strategy (Illustrations)Eliza Jayne Princess VizcondeNo ratings yet

- PGDM (2017-19) Term-II: End Term Examination - Operations Management - IDocument6 pagesPGDM (2017-19) Term-II: End Term Examination - Operations Management - IAanchal MahajanNo ratings yet

- Facility LayoutDocument19 pagesFacility LayoutSyeda Samia SultanaNo ratings yet

- Facility LayoutDocument2 pagesFacility LayoutOsama0% (1)

- Chapter9 10Document5 pagesChapter9 10Nyan Lynn HtunNo ratings yet

- Quantitative Analysis For Management DecisionsDocument4 pagesQuantitative Analysis For Management DecisionsWondim BelayNo ratings yet

- Quiz 2 With AnsDocument4 pagesQuiz 2 With AnsAbhishree JainNo ratings yet

- Exercises On Line BalancingDocument3 pagesExercises On Line BalancingHimanshu SharmaNo ratings yet

- Assignment Chapter 5 Post For StudentsDocument7 pagesAssignment Chapter 5 Post For StudentsHoàng Ánh LýNo ratings yet

- Blue Furniture: Property of STIDocument2 pagesBlue Furniture: Property of STIGoose ChanNo ratings yet

- C2 Linear Programing orDocument89 pagesC2 Linear Programing orvznp2vpp9qNo ratings yet

- Assignment I - OMDocument2 pagesAssignment I - OMnirajrampuriaNo ratings yet

- Model FormulationDocument11 pagesModel FormulationDileep KumarNo ratings yet

- C2 - Linear Programing Jan 2021Document76 pagesC2 - Linear Programing Jan 2021mytiensakuraNo ratings yet

- Assignment 1 by Ahammed Akib 6220101009 (6220101009Document11 pagesAssignment 1 by Ahammed Akib 6220101009 (6220101009ahammed akibNo ratings yet

- MGT 3110: Exam 3 Study Guide Discussion QuestionsDocument13 pagesMGT 3110: Exam 3 Study Guide Discussion QuestionsSihle GwazelaNo ratings yet

- Tutorial 1Document4 pagesTutorial 1Puvithera A/P GunasegaranNo ratings yet

- Capacity Planning: Problems 1, 3, 7, 11, 15Document13 pagesCapacity Planning: Problems 1, 3, 7, 11, 15Queenie Marie CastilloNo ratings yet

- Questions For PracticeDocument5 pagesQuestions For PracticeKeshav GuptaNo ratings yet

- Assignment 4 - MS - 2020Document3 pagesAssignment 4 - MS - 2020HOÀNG Võ NhậtNo ratings yet

- Assignment 4Document2 pagesAssignment 4chitraliNo ratings yet

- MGT 3110: Exam 2 Study GuideDocument16 pagesMGT 3110: Exam 2 Study GuideJazehl Joy ValdezNo ratings yet

- Solved Practice QuestionsDocument5 pagesSolved Practice QuestionsKwaku Frimpong GyauNo ratings yet

- Akhil Rathore - PGFB2210 - OmDocument10 pagesAkhil Rathore - PGFB2210 - OmSakshi 2No ratings yet

- Standard Costing Ex QuestionsDocument20 pagesStandard Costing Ex QuestionsKaruna ChakinalaNo ratings yet

- Activity B2. Yamilex RobledoDocument2 pagesActivity B2. Yamilex RobledoYamilex CampoyNo ratings yet

- Asignación 1-TOCDocument5 pagesAsignación 1-TOCKelly ArredondoNo ratings yet

- Commerce (Regular) (Cost Accounting Group) Production and Operations Management Paper - 3.3 (B)Document4 pagesCommerce (Regular) (Cost Accounting Group) Production and Operations Management Paper - 3.3 (B)Sanaullah M SultanpurNo ratings yet

- Question Paper MBA OM I 2021Document3 pagesQuestion Paper MBA OM I 2021Neelam SunilManeNo ratings yet

- Operataions MGMT - Final Exam Paper-PGDM TERM-IIDocument3 pagesOperataions MGMT - Final Exam Paper-PGDM TERM-IIkishan kanojiaNo ratings yet

- p1 Question Dec 2018Document6 pagesp1 Question Dec 2018S.M.A AwalNo ratings yet

- C2 - Linear ProgramingDocument76 pagesC2 - Linear ProgramingLy LêNo ratings yet

- Operations HW & SolDocument4 pagesOperations HW & Solfoon.dionne47No ratings yet

- Final Exam QANT630 Fall 2019 (Part-2)Document14 pagesFinal Exam QANT630 Fall 2019 (Part-2)Simran SachdevaNo ratings yet

- POM 1 Exam 2014 FinalDocument17 pagesPOM 1 Exam 2014 FinalBi11y 1eeNo ratings yet

- JUSKOLORDDocument2 pagesJUSKOLORDJaceNo ratings yet

- Intro To Production & Operation Mgt.Document2 pagesIntro To Production & Operation Mgt.Kritu GuptaNo ratings yet

- Production Planning 2. Production PlanningDocument12 pagesProduction Planning 2. Production Planningkarthik sNo ratings yet

- Session 5 Facility Layout PlanningDocument35 pagesSession 5 Facility Layout PlanningArka BandyopadhyayNo ratings yet

- Linear ProgrammingDocument19 pagesLinear Programmingnikko.emping.20No ratings yet

- Af 211-Assignment 1Document6 pagesAf 211-Assignment 1latifa.haroun100% (1)

- Instructions: Compulsory.: Questions WorkingsDocument5 pagesInstructions: Compulsory.: Questions WorkingsWilliam OkothNo ratings yet

- file TA send (file chị dùng giảng bài)Document24 pagesfile TA send (file chị dùng giảng bài)Sang PhanNo ratings yet

- Tutorials BAMS1424 BASIC STATISTICAL METHODS FOR SCIENTIFIC ANALYSISDocument25 pagesTutorials BAMS1424 BASIC STATISTICAL METHODS FOR SCIENTIFIC ANALYSISsithaarthun-wp21No ratings yet

- AsynchronousWeek17OM PITARGUEDocument5 pagesAsynchronousWeek17OM PITARGUEAdoree RamosNo ratings yet

- Practice QuestionsDocument5 pagesPractice QuestionsAlthea Griffiths-BrownNo ratings yet

- Project Monitoring - Darshan - EMVDocument17 pagesProject Monitoring - Darshan - EMVPrajaktaNo ratings yet

- PERTDocument7 pagesPERTPrajaktaNo ratings yet

- AHP Case StudyDocument10 pagesAHP Case StudyPrajaktaNo ratings yet

- Earned Value Analysis-ContinuedDocument2 pagesEarned Value Analysis-ContinuedPrajakta0% (1)

- Activity Descript Ion Duratio N (Weeks) Predeces SorsDocument7 pagesActivity Descript Ion Duratio N (Weeks) Predeces SorsPrajaktaNo ratings yet

- Pessimistic Average Optimistic Revenue Variable Cost Fixed Cost Depriciation Ebit Tax EAT CF Pvifa PV NPVDocument6 pagesPessimistic Average Optimistic Revenue Variable Cost Fixed Cost Depriciation Ebit Tax EAT CF Pvifa PV NPVPrajaktaNo ratings yet

- Objective: Purchase The Mobile Phone: Color Memory Delivery Color Memory DeliveryDocument22 pagesObjective: Purchase The Mobile Phone: Color Memory Delivery Color Memory DeliveryPrajaktaNo ratings yet

- AHP CaseDocument8 pagesAHP CasePrajaktaNo ratings yet

- Process Analysis, Productivity ConceptsDocument9 pagesProcess Analysis, Productivity ConceptsPrajaktaNo ratings yet

- Facility Location SolvedDocument23 pagesFacility Location SolvedPrajaktaNo ratings yet

- EOQDocument15 pagesEOQPrajaktaNo ratings yet

- Apply Simple Moving Average To Forecast The Sales For The Month of SeptemberDocument15 pagesApply Simple Moving Average To Forecast The Sales For The Month of SeptemberPrajaktaNo ratings yet

- Observations in Each Sub-Group (In CM) Subgrou PS: X - Bar Average RangeDocument29 pagesObservations in Each Sub-Group (In CM) Subgrou PS: X - Bar Average RangePrajaktaNo ratings yet