Professional Documents

Culture Documents

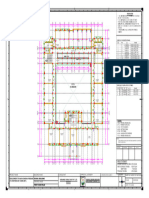

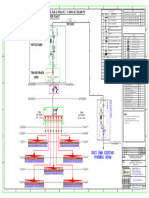

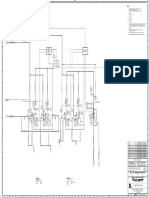

R6 (TYP) : Stub Axle-Rh (For RHD Vehicle)

Uploaded by

Sujay AvatiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

R6 (TYP) : Stub Axle-Rh (For RHD Vehicle)

Uploaded by

Sujay AvatiCopyright:

Available Formats

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 Nominal Tolerance

Dim in m

Do not scale the drg.

Unless otherwise stated, 1 All dim in mm.

2 Drg. drawn to first angle projection 57p6

+51

0.1 P If in doubt, Ask +32

0.05 P -10

55g5 -23

a 0.05

-9

40g6 -25

A 0.05 Q

a 165 b 42.5H12

+250

a 0

67

0 92 #0.04 +93

133 -0.5 a b 12D9 +50

63 #0.3 a +42

RAISED LETTER T EMBLEM , TS:11234 6p9 +12

83 a PART NO (12 DIGIT ONLY) SUPPLIER'S MARK = =

H +31

IN MEDIUM LETTER 4,DIN1451 (TS:11231) 37JS9

82 a 4 a -31

R5

43

2 HOLES 14 D9 +39

35H8

48 a R35 ON 145 #0.2 P.C.D. 00

+110

0.1 Y 15H11

47 a MACHINE IF REQUIRED 00

5 $ +93

I 8 a 14D9

B 46.5 a +50

24 H7 HOLE AT 54 #0.3R 63 MIN. R2

R1

FOR ABS SENSOR 63 0 16 D9 +93

8

B

8

0 +50

R1

R2

A A +34

a 12 #0.1 18F7

+16

I

48

12 #0.1 +21

24H7

61.5

22.3 00

a 2.5

9

48

a

b R8

R 10

a 6 $

M 10X1.5 a (T 5

YP

R1

P )

56 #0.1

R5

2

98

58.4

50 #0.2

82

a

R6

a

39.5

(TYP)

9 $#10'

56

K

K

8

C C b 1x45 $ a a

44

22 $ R1

55g5

C (TY 6

17.5

57p6

35g6

CUTTER 315 P)

23

18 $

20

R54

a 32 +0.5

0

5 R27.5 a

94+0.3

M24X1.5

2

54 #0.

50 $ 2 HOLES 14 D9

(217)

0

45+0.2( ON 145 #0.2 P.C.D.

2 TYP)

66.5 #0.1

B 0 a

D D

90

2 HOLES 8.5 0.05Q

60.5

27 a 0.05P

ON 73 #0.3 PCD. R3 37JS9 a a

b b 0.02P

R8

R75

E E 0.02P

D b

Q

POLISH TO CLEAR 0

ALL TOOL MARKS R2

R2

0

Y

48

a

R2

20 0 a

a R

61.5

5 $

R6 P) R6 (TYP)

Y

(T a

2 HOLES 14 D9

H = =

E

55 a 16 #1

= =

MACHINE IF REQUIRED

SCALE 1:1 86 #0.04

1X45 $

0

14 -1

7 $

R2

F

12 NOTES:

7 $

MAXIMUM ALLOWABLE 1)FORGING TOLERANCES AS PER IS:3469

AXIS SHIFT 0.2MM

2)UNMENTIONED DRAFT ANGLES 6 $

28 a

3)UNMENTIONED CORNER RADII 2.5 AND FILLET RADII 3

R1

(SPOT FACE)

R1

.6

4)FORGING TO BE SUPPLIED AS PER SS: 10000

G

5)FORGING TO BE CLEANED& PAINTED WITH PRIMER

SPOT FACE

24H7

RED OXIDE ZINC CHROMATE TO SS:7222,TS:25140

31

J F

18 SECTION K-K

& FINISHED PAINTED WITH PAINT ALKD

G STEEL GREY GUN AD/FD TO SS:7223A EXCEPT

114-0.1

MACHINED SURFACES

=

0

77

SECTION B-B

6) FORGING IS TO BE MADE

55 #3

SCALE 1:1

CENTER HOLE

AS PER KING PIN BOSS INCLINATION$ =8.5

a B-3.15,TS:12321

=

(2 NO.S 14D9)

SEE DETAIL Y

0.1 Y

R10

R5

1X45 $

J F

H .5

R0

0.013

0.011

12

G

NOTE:

9.5T STUB AXLE MACHINED TO GET 7.5T STUB AXLE

0.1

61 #0.1

+0.1

a 8.2 0 +0.1

8.2 0 5-C 1) DIMN. 39.5 WAS 40

07/05/2010

TENSILE TEST SPECIMEN 6-B 2) DIMN. 22.3 WAS 28

a DEBURR TO BE TAKEN FROM THE DML NO.

6-D 3) DIMN 27 WAS 30

6-A 4) DIMN 133 WAS 135 MD ACC

12.5 #0.2

CORE AT THE PLACED MARKED 06PP374030

b 7-A 5) DIMN 165 WAS 170

5

I 9-I 6) DIMN 8 WAS 8.6

8(MIN)

= = 7-D 7) REF CHANGED FOR TOL AT TWO PLACES

30 $ a = =

8 #0.2

8-E 1) DIMN. 55 ADDED

30 $ a DEBURR 8-C 2) DIMN. R27.5 ADDED

9-B 3)DIMN. 8 MIN ADDED

R1.5

1 b 8-A 4) DIMN. 67 WAS 66

7-D 5) DIMN. 12#0.1 WAS 6#0.1

7-I 6) DIMN. 8.2 WAS 8

DETAIL Y 8-I 7) SEC I-I ADDED

9-D 8) DIMN. 37JS9& 45 ADDED

SCALE 2:1 9-B,E

9) DIMN. 48 ADDED AT 2 PLACES

13-A10) DIMN. 43 ADDED

15-B11) DIMN. 58.4 ADDED

a

SECTION A-A 9-C 12) DIMN 9$#10' WAS 8.5$#10'

2-B 13) POSITION OF SENSOR MOUNTING

HOLE CHANGED

3-C 14) POSITION OF OIL SEAL REMOVAL HOLE

SECTION F-F SECTION J-J CHANGED

J CENTRE HOLE-BX5 SCALE 1:1 1-I 15) SECTION J-J ADDED

OR BX6.3, TS:12321 SECTION G-G ISOMETRIC VIEW 2-L 16) DIMN. 34 WAS 26

SCALE 1:1 4-F 17) DIMN. 28WAS 20

SCALE 4:5 18) DIMN. 31, 24,10,17.5 REMOVED

02/12/09

FROM SECB-B

30 $

DML NO.

06PP374019

a 6-B 19) DIMN.28 WAS18,9 WAS 10 APS ACC

20) SOME SEC RENAMED&SOME SEC.ADDED

1-C 21) DIMN. 56 ADDED

(2 NOS. 14 D9) 2-E 22) DIMN. R20 WAS R16

4-I 23) DIMN. 5 REF. CHANGED

0.1 Y 2-K 24) DIMN.22.5 ADDED

42.5 H1

1X45 $

2 2-K 25) DIMN.10 WAS 12

1

22.5 a 4-K 26) DIMN.21 WAS 22

1X45 $

(MIN.)

a 10-K27) DIMN.3.5 REMOVED & 2.5 ADDED

3

1X45 $

SECTION I-I

2.5

13-D28) DIMN.5$WAS 15 $

(22)

10

15-D29) DIMN 90 WAS 98

a 1.85+0.2 8-A 30) DIMN.63#0.3 REF. CHANGED

0

a 31) DIMN.51.5,66,96.5 137 REMOVED

K FROM SIDE VIEW

DEBURR 32) DIMN.46.5,47,48,82,83,135 ADDED

41.5 #0.3

0.1

30 $ TO SIDE VIEW

6-A 33) DIMN.170 REF. CHANGED

1X45 $

6-D 34) DIMN. 30 ADDED

10 #0.2

, , , 35) DETAILED VIEW Z REMOVED

Material Description,Size,Spec,Std No.

R3

36) REF. FOR 2 DIMN. CHANGED IN

a 40CR4, TYPE-C SS:4027 SEC.

& SECF J

7 $ T14,90-105(POLYMER QUENCHING)

DATUM REF. 3 P,Q & Y MIN. YIELD STRENGTH 70Kg/mm2

Classification of characteristics:

Critical, Key Instruction

Major, (None) Minor DML NO.

34 a Applies to upper limit

02/0906PP374015 NEW RELEASE KDD ACC

SECTION 12 A TO K Applies to lower limit

(SPOT FACE) Date Mod. No. Sl.No.

Zone Modification Chkd Appd

2008 SIGN DATE Fin.massSurface protection as per Std.

DRN PSW 02/09 in kg

L DETAIL 1 Y 8.11 Tol. as per Std.

CHKD KDD 02/09

40+0.3

-0.3 APPD ACC Product/Group No. Replaces Drg.

Y1-7.5T (BUS)

SECTION C-C Scale: 1:1 Reference Drg. No.

Machining Deviation as per . . . . . . . . . . . . . . . class to ISO 2768

SECTION D-D (2:1),(3:2) Opp. Hand Drg./ Pt. No.

SECTION H-H Machining Deviations as per ISO 2768 mSURFACE ROUGHNESS SYMBOLS / VALUES IN m Ra

SCALE 2:1 Drg./Part Designation Drg./Part No.

SECTION E-E Over - 6 30 120 400 1000 2000 Symbol

Upto& incl.6

Dim 30 120 400 1000 2000 4000

Value 50 25 6.3 1.6 0.8 0.1 0.8 0.8

STUB AXLE-RH 5506 3320 51 09

Tolerance #0.1 #0.2 #0.3 #0.5 #0.8 #1.2 #2 FOR OTHER ROUGHNESS SYMBOLS

& VALUES, SEE IS 10719 ERC (FOR RHD VEHICLE) Sheet No....

1.... of

1....

....Sheets

PRINTED BY: PRINTED

11-Feb-07

ON: STATUS:

*** 8845 41 510 079 PCF- 075(R3)6/99

You might also like

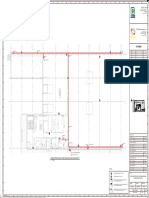

- CMN.18.477 Smart Plant Documentation Ruwais NGL Train 3: From El.93 800 To Above LP Flare Piping Ga Plan Area TD Zone 736Document1 pageCMN.18.477 Smart Plant Documentation Ruwais NGL Train 3: From El.93 800 To Above LP Flare Piping Ga Plan Area TD Zone 736steepa22No ratings yet

- 30lbf11br001-Rev 2Document1 page30lbf11br001-Rev 2Mohd Effiezool YaserNo ratings yet

- 26071-203-M6-315-00005 - Piping and Instrumentation Diagram Fuel Oil and Fuel Gas System (Unit 315) Fuel Gas KO DrumDocument1 page26071-203-M6-315-00005 - Piping and Instrumentation Diagram Fuel Oil and Fuel Gas System (Unit 315) Fuel Gas KO DrumJeroan AyamNo ratings yet

- Va 1302 070822Document1 pageVa 1302 070822api-3698996No ratings yet

- Unit 6900 Area 01Document1 pageUnit 6900 Area 01Khairul IdhamNo ratings yet

- 10lab12br001-Rev 1 - 1Document1 page10lab12br001-Rev 1 - 1Mohd Effiezool YaserNo ratings yet

- Scale: 1:5 (1:2) : R TYP 5Document1 pageScale: 1:5 (1:2) : R TYP 5Prateek AnandNo ratings yet

- Second TELEDocument1 pageSecond TELESama FayizNo ratings yet

- Lant P2C3 Ugs DR Sty 30004 01 DDocument1 pageLant P2C3 Ugs DR Sty 30004 01 DsubhashkumarmandalamcivilNo ratings yet

- Part-1A Part-1B: Dead Loads On Mid Roof & 1St Floor SlabsDocument5 pagesPart-1A Part-1B: Dead Loads On Mid Roof & 1St Floor SlabskuraimundNo ratings yet

- 3387 04 PL CC 01Document11 pages3387 04 PL CC 01Ha Kim BJNo ratings yet

- Terminal 2: E48 E50 E53 E55 E49 E52 E51 E54Document1 pageTerminal 2: E48 E50 E53 E55 E49 E52 E51 E54waz ahmedNo ratings yet

- Demin Water SystemDocument1 pageDemin Water Systemmohamed abourayaNo ratings yet

- Bp2021-C026s-Jwn07-A01-Drainage System-Fp-1001-Office-05 PlansDocument1 pageBp2021-C026s-Jwn07-A01-Drainage System-Fp-1001-Office-05 PlansMohammad IsmailNo ratings yet

- b1 FIRE ALARM-AE1012Document1 pageb1 FIRE ALARM-AE1012Sama FayizNo ratings yet

- Two-Way Mobility Adams & Forsyth Streets: City of Jacksonville NotesDocument133 pagesTwo-Way Mobility Adams & Forsyth Streets: City of Jacksonville NotesJJNo ratings yet

- Amazing Grace - Marimba Chorale (Arr. Jilly Cooke)Document1 pageAmazing Grace - Marimba Chorale (Arr. Jilly Cooke)Jilly CookeNo ratings yet

- Terminal 2: E50 E53 E55 E49 E52 E51 E54Document1 pageTerminal 2: E50 E53 E55 E49 E52 E51 E54waz ahmedNo ratings yet

- VG 1002 070820Document1 pageVG 1002 070820api-3698996No ratings yet

- Hpcl-Mittal Energy LTD., P Ih LKH, Y & Ferry, Uzth FyfevsmDocument1 pageHpcl-Mittal Energy LTD., P Ih LKH, Y & Ferry, Uzth Fyfevsmiqbal6982No ratings yet

- Cable Trenc Layout Jmaui R0-ModelDocument1 pageCable Trenc Layout Jmaui R0-ModelManas MondalNo ratings yet

- Site LayoutDocument1 pageSite Layoutvenkat rajuNo ratings yet

- 918 - AR - (13) Clinic Level Reflected CeilingDocument1 page918 - AR - (13) Clinic Level Reflected CeilingJelson RumuarNo ratings yet

- Reference Drawing Bill of Material For This Drawing General Notes Topographic Symbols Pipeline Symbols Soil SymbolsDocument26 pagesReference Drawing Bill of Material For This Drawing General Notes Topographic Symbols Pipeline Symbols Soil SymbolssubudhiprasannaNo ratings yet

- SCHOOL BUILDING FIRST FLOOR PLAN - ModelDocument1 pageSCHOOL BUILDING FIRST FLOOR PLAN - ModelAATVIK SHRIVASTAVANo ratings yet

- Keep On Rocking in The Free World: Neil YoungDocument4 pagesKeep On Rocking in The Free World: Neil YoungthierryNo ratings yet

- Piping Isometric Building:: Pengerang Cogeneration PlantDocument1 pagePiping Isometric Building:: Pengerang Cogeneration PlantMohd Effiezool YaserNo ratings yet

- No.20 - TBN Oil Piping 2of2Document1 pageNo.20 - TBN Oil Piping 2of2Adetunji Babatunde TaiwoNo ratings yet

- Exw P007 0104 Al Uiy DG 99012 001 A7Document1 pageExw P007 0104 Al Uiy DG 99012 001 A7Dilshan PamudithaNo ratings yet

- Bp2021-C026s-Jwn06-A01-Drainage System-Fp-1001-Office-03 PlansDocument1 pageBp2021-C026s-Jwn06-A01-Drainage System-Fp-1001-Office-03 PlansMohammad IsmailNo ratings yet

- A6.01 - Wall Sections Rev.2 MarkupDocument1 pageA6.01 - Wall Sections Rev.2 MarkupIMPRESIONESNo ratings yet

- Bhatinda R 2 SLDDocument1 pageBhatinda R 2 SLDvineets058No ratings yet

- Esquema Hidráulico Do 6407Document4 pagesEsquema Hidráulico Do 6407Anderson EricklisNo ratings yet

- 30lbe51br001-Rev 2 - 2Document1 page30lbe51br001-Rev 2 - 2Mohd Effiezool YaserNo ratings yet

- 08 SwitchgearDocument12 pages08 SwitchgearMuhammad AsifNo ratings yet

- 7-13. Printed Wiring Boards - Main SectionDocument1 page7-13. Printed Wiring Boards - Main SectionJeison GarciaNo ratings yet

- 1-ModelDocument1 page1-Modeljoselito navarroNo ratings yet

- Notes: Piping & Instrument Diagram Osbl Fire Water System Main Fire Water PumpDocument1 pageNotes: Piping & Instrument Diagram Osbl Fire Water System Main Fire Water PumpHadi SuagungNo ratings yet

- Gorillaz - FaustDocument2 pagesGorillaz - FaustÁllan WesleyNo ratings yet

- B011 000 16 50 01205 - Rev 2Document1 pageB011 000 16 50 01205 - Rev 2GLOBUS ENGINEERSNo ratings yet

- Bepl BMR DWG El 410 SLD Rev00Document1 pageBepl BMR DWG El 410 SLD Rev00pavantirumala03No ratings yet

- Mac - Tar-Ndl - Ac Layout-052923Document1 pageMac - Tar-Ndl - Ac Layout-052923Jay MarkNo ratings yet

- Attachement-1 RFC-29-18Document14 pagesAttachement-1 RFC-29-18Mohamed ArafaNo ratings yet

- 15-032!00!034 - Fire Protection System Ground Floor Plan Part-3Document1 page15-032!00!034 - Fire Protection System Ground Floor Plan Part-3Amit BiswasNo ratings yet

- Ed 0100 PRS Pid 000 01005uDocument1 pageEd 0100 PRS Pid 000 01005uMohamed ArafaNo ratings yet

- Terminal 2: E48 E50 E53 E55 E49 E52 E51 E54Document1 pageTerminal 2: E48 E50 E53 E55 E49 E52 E51 E54waz ahmedNo ratings yet

- M BD3 1F8000 Cutl Edr 000302Document1 pageM BD3 1F8000 Cutl Edr 000302ahmed.abdelmegeed78No ratings yet

- WD Centre Line PlanDocument1 pageWD Centre Line PlanRaj GuptaNo ratings yet

- 00UMF611 - LAYOUT A ARRANGEMENT POWER HOUSE - Equipment Location Plan - 002Document9 pages00UMF611 - LAYOUT A ARRANGEMENT POWER HOUSE - Equipment Location Plan - 002tiantaufikNo ratings yet

- Existing - Earthing - Layout For Bogra 230kV SubstationDocument1 pageExisting - Earthing - Layout For Bogra 230kV SubstationRashad SarwarNo ratings yet

- 15-032!00!033 - Fire Protection System Ground Floor Plan Part-2Document1 page15-032!00!033 - Fire Protection System Ground Floor Plan Part-2Amit BiswasNo ratings yet

- Legend: Project Name: LPIC EPC1 SCUDocument1 pageLegend: Project Name: LPIC EPC1 SCUjeswinNo ratings yet

- Petronas Carigali SDN BHD: Document Review StatusDocument1 pagePetronas Carigali SDN BHD: Document Review StatusMohd KhaidirNo ratings yet

- Pilares Que Nacen en NIVEL 0.0 y Mueren en NIVEL 3.0 Hormigón: H-21 Acero en Barras: AH-420 Acero en Estribos: AH-420Document1 pagePilares Que Nacen en NIVEL 0.0 y Mueren en NIVEL 3.0 Hormigón: H-21 Acero en Barras: AH-420 Acero en Estribos: AH-420Edwin Henrry Tarifa MercierNo ratings yet

- 30lbe51br002-Rev 1Document1 page30lbe51br002-Rev 1Mohd Effiezool YaserNo ratings yet

- Hps141c EeDocument1 pageHps141c Eeapi-3709639No ratings yet

- Johan Castberg: PT TTDocument9 pagesJohan Castberg: PT TTFarshid KhoshkarNo ratings yet

- CH BB SLD El 01 06Document1 pageCH BB SLD El 01 06Ahmed MarzokNo ratings yet

- Instant Assessments for Data Tracking, Grade 3: MathFrom EverandInstant Assessments for Data Tracking, Grade 3: MathRating: 5 out of 5 stars5/5 (2)

- Pototyaping ThesisDocument191 pagesPototyaping ThesisSujay AvatiNo ratings yet

- Elements of Press Tool: Base PlateDocument3 pagesElements of Press Tool: Base PlateSujay AvatiNo ratings yet

- Types of Press ToolsDocument5 pagesTypes of Press ToolsSujay AvatiNo ratings yet

- According To ISO965 All Dimensions in MM Unless Otherwise Stated Tolerances: Male Thread 6g Female Thread: 6hDocument4 pagesAccording To ISO965 All Dimensions in MM Unless Otherwise Stated Tolerances: Male Thread 6g Female Thread: 6hSujay AvatiNo ratings yet

- Vario Clamp V/V2 .1 BR2 A40 5° - 135°Document1 pageVario Clamp V/V2 .1 BR2 A40 5° - 135°Sujay AvatiNo ratings yet

- Biw Interview QusDocument3 pagesBiw Interview QusSujay AvatiNo ratings yet

- Introduction To ANSYS Mechanical: Workshop 4.2 Meshing ControlDocument16 pagesIntroduction To ANSYS Mechanical: Workshop 4.2 Meshing ControlSujay AvatiNo ratings yet

- Caribbean Examination Council: School Based AssessmentDocument17 pagesCaribbean Examination Council: School Based AssessmentDiana FrillsNo ratings yet

- Engineering Data: Wireway SelectionDocument3 pagesEngineering Data: Wireway SelectionFidel Castrzzo BaeNo ratings yet

- Test Report For Feeder Protection RelayDocument3 pagesTest Report For Feeder Protection RelayHari haranNo ratings yet

- Orchid Group of Companies Company ProfileDocument3 pagesOrchid Group of Companies Company ProfileAngelica Nicole TamayoNo ratings yet

- Serie10 ElecDocument75 pagesSerie10 Elecmealier severineNo ratings yet

- Acid Bases and Salts Previous Year Questiosn Class 10 ScienceDocument5 pagesAcid Bases and Salts Previous Year Questiosn Class 10 Scienceclashhunting123123No ratings yet

- Fatty AcidsDocument13 pagesFatty AcidsRaviraj MalaniNo ratings yet

- Downloaded From Manuals Search EngineDocument14 pagesDownloaded From Manuals Search EngineAl AlNo ratings yet

- Mitsubishi IC Pneumatic Forklift PDFDocument5 pagesMitsubishi IC Pneumatic Forklift PDFfdpc1987No ratings yet

- GlobalisationDocument8 pagesGlobalisationdummy12345No ratings yet

- Fulltext PDFDocument454 pagesFulltext PDFVirmantas JuoceviciusNo ratings yet

- Small Scale IndustriesDocument6 pagesSmall Scale IndustriesMangesh KadamNo ratings yet

- Imamsha Maharaj Na Parcha NewDocument16 pagesImamsha Maharaj Na Parcha NewNARESH R.PATELNo ratings yet

- Network Tools and Protocols Lab 2: Introduction To Iperf3Document17 pagesNetwork Tools and Protocols Lab 2: Introduction To Iperf3Fabio MenesesNo ratings yet

- Sample Minutes of MeetingDocument3 pagesSample Minutes of MeetingMohamad AzmeerNo ratings yet

- Fundamentals of Heat and Mass Transfer 7Th Edition Incropera Solutions Manual Full Chapter PDFDocument68 pagesFundamentals of Heat and Mass Transfer 7Th Edition Incropera Solutions Manual Full Chapter PDFbrainykabassoullw100% (10)

- Food Product Innovation PDFDocument35 pagesFood Product Innovation PDFDidik HariadiNo ratings yet

- Small Molecule Modulators of PCSK9 A Litera 2018 Bioorganic Medicinal CHDocument6 pagesSmall Molecule Modulators of PCSK9 A Litera 2018 Bioorganic Medicinal CHMikeNo ratings yet

- PURL Questions and AnswersDocument3 pagesPURL Questions and AnswersSHAHAN VS100% (5)

- LGDocument36 pagesLGNanchavisNo ratings yet

- APA 6th Edition - Citation Styles APA, MLA, Chicago, Turabian, IEEE - LibGuDocument2 pagesAPA 6th Edition - Citation Styles APA, MLA, Chicago, Turabian, IEEE - LibGuJan Louis SalazarNo ratings yet

- Social Skills Assessments For Children With Autism Spectrum Disorders 2165 7890.1000122Document9 pagesSocial Skills Assessments For Children With Autism Spectrum Disorders 2165 7890.1000122Shinta SeptiaNo ratings yet

- Hortee OromooDocument48 pagesHortee OromooAsnaafii BantiiNo ratings yet

- Subordination, Non - Disturbance and Attornment AgreementDocument7 pagesSubordination, Non - Disturbance and Attornment AgreementDavid CromwellNo ratings yet

- Capital BudgetingDocument24 pagesCapital BudgetingHassaan NasirNo ratings yet

- Proplanner Assembly Planner PFEPDocument5 pagesProplanner Assembly Planner PFEPAya MdimeghNo ratings yet

- Assignment 1 SolutionDocument11 pagesAssignment 1 SolutionKash TorabiNo ratings yet

- Cutting Conics AsDocument3 pagesCutting Conics Asbabe09No ratings yet

- Classical Mechanics MCQ GamecampuscoDocument3 pagesClassical Mechanics MCQ GamecampuscoFaryal TalibNo ratings yet

- History of Communication - Project - File - 455 PDFDocument20 pagesHistory of Communication - Project - File - 455 PDFlathaNo ratings yet