Professional Documents

Culture Documents

2015-Assefa & Kaushal-A Comparative Study of Friction Factor Correlations For High Concentrate Slurry

Uploaded by

Andres PalacioOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2015-Assefa & Kaushal-A Comparative Study of Friction Factor Correlations For High Concentrate Slurry

Uploaded by

Andres PalacioCopyright:

Available Formats

J. Hydrol. Hydromech.

,63, 2015, 1, 13–20

DOI: 10.1515/johh-2015-0008

A comparative study of friction factor correlations for high concentrate slurry

flow in smooth pipes

K. M. Assefa, D. R. Kaushal*

Department of Civil Engineering, Indian Institute of Technology Delhi, Hauz Khas, New Delhi 110016, India.

*

Corresponding author. E-mail: kaushal@civil.iitd.ac.in

Abstract: A number of correlations for friction factor determinations in smooth pipes have been proposed in the past

decades. The accuracy and applicability of these friction factor formulas should be examined. Based on this notion the

paper is designed to provide a comparative study of friction factor correlations in smooth pipes for all flow regimes of

Bingham fluids. Nine models were chosen. The comparisons of the selected equations with the existing experimental

results, which are available in the literature, were expressed through MARE, MRE+, MRE-, RMSE, Ѳ, and S. The

statistical comparisons were also carried out using MSC and AIC. The analyses show that the Wilson-Thomas (1985)

and Morrison (2013) models are best fit models to the experimental data for the Reynolds number up to 40000. Within

this range, both models can be used alternately. But beyond this Re value the discrepancy of the Wilson-Thomas model

is higher than the Morrison model. In view of the fact that the Morrison model requires fewer calculations and

parameters as well as a single equation is used to compute the friction factor for all flow regimes, it is the authors’ advice

to use this model for friction factor estimation for the flow of Bingham fluids in smooth pipes as an alternative to the

Moody chart and other implicit formulae.

Keywords: Bingham fluid; Smooth pipe; Laminar flow; Turbulent flow; Friction factor; Reynolds number; Correlations;

Statistical parameters.

INTRODUCTION based on these equations. The implicit form of the Colebrook-

White equation for turbulent flow disables the quick estimation

Slurry pipelines are emerging technologies for long distance of friction factor in hand calculations. For these reasons, many

transportation of bulk materials such as coal, iron ore, dredging attempts were made in the recent past to calculate the value of

and tailings disposal. This slurry transportation system is friction factor with explicit relations.

considered to be significant, for its special characteristics such The basic intention of the present study is to compute the

as safety, reliability and friendliness to the environment plus its friction factor for flow of Bingham fluids in smooth pipes by

relatively low operational and maintenance costs. In design of various equations for the experimental data available in litera-

these pipelines for Newtonian and non-Newtonian fluids one of ture. The best representative model in order to obtain good

the most important technical parameters is the pressure drop as results for the experimental data is then decided.

it influences the requirement of pumping energy. The pressure

drop is produced by the internal friction of the slurry and THE EXISTING FRICTION FACTORS RELATIONS

friction between the pipe and the slurry. This interaction is

commonly expressed as a dimensionless factor called friction The following equations were selected for computing friction

factor. For flow in smooth pipes this friction factor is found to factor in laminar, and/or turbulent flow regimes and presented

be a function the Reynolds number which in turn primarily in chronological order.

depends on the slurry properties (velocity, density, and

viscosity) and pipe diameter. Several studies for friction factor Hagen and Poiseuille (1840) equation

prediction in slurry flow for smooth pipes are available in the

literature (Danish et al., 2011; Darby and Melson, 1981; It is a simple and the most common formula to estimate the

Moody, 1944; Morrison, 2013; Swamee and Aggarwal, 2011; friction factor in laminar flow. It is used to construct a Moody

Swamee and Jain, 1976; etc.). Some of the empirical chart for the laminar flow regime. It is given by:

correlations claim to apply to all flow regimes (Morrison, 2013)

and others are restricted to one or two flow regimes only 64

(Danish et al., 2011; Darby and Melson, 1981; etc.). f = Re ≤ 2100 (1)

Re

For laminar flow, the correlation between friction factor and

Reynolds number is well established (Moody, 1944; Swamee U ρm D

and Aggarwal, 2011). However, the prediction of the friction where Re =

factor in the turbulent regime is still one of the difficult theoret- ηp

ical and practical problems. The well-known friction factor in

the Darcy–Weisbach equation for pressure drop estimation for Blasius correlations (1913)

laminar and turbulent flow is given by Hagen-Poiseuille equa-

tion and the implicit Colebrook – White equation, respectively. It is the simplest numerical equation for solving the friction

Due to their demonstrated applicability, these equations have factor in turbulent flow. It is valid only for smooth pipes and up

become the accepted standard for calculation of the friction to the Reynolds number 105. As cited by Fang et al., (2011) the

factor. The Moody chart (1944) for friction factor is plotted friction factor is given as:

Brought to you by | Pontificia Universidade Católica do Rio Grande do Sul PUC/RS 13

Authenticated

Download Date | 2/22/18 1:26 PM

K. M. Assefa, D. R. Kaushal

−1

f = 0.316 ( Re ) 4 for 2100 < Re ≤ 2×104 (2) 6ReB 2

where Remod =

6ReB + He

−1

f = 0.184( Re) 5 for Re ≥ 2×104 They also developed an empirical expression for turbulent

flow as:

The Buckingham-Reiner equation

fT = 10a Re−0.193 (8)

A precise description of friction loss for Bingham plastics in

fully developed laminar pipe flow was first published by

a = −1.47 1 + 0.146e −2.9×10 He

−5

Buckingham (1921). His expression can be written as:

64 He 64 He4 To get a single explicit friction factor equation valid for all

fL = 1 + − (3) flow regimes, they developed the following relations:

Re 6 Re 3 f L3Re7

1

τ y ρm D2 f = f L m + fT m m (9)

where He =

ηp

40000

where m = 1.7 +

Although an exact analytical solution of the Buckingham- Re

Reiner equation can be obtained because it is a fourth order

polynomial equation in f, due to complexity of the solution it is Wilson and Thomas (1985)

rarely employed. Therefore, researchers have tried to develop

explicit approximations for the Buckingham-Reiner equation. They developed a new analytical equation for turbulent flow

of non-Newtonian fluids based on velocity profile alteration

Colebrook–White equation (1933) (drag reduction) associated with thickening of the viscous sub-

layer and the required flow parameters can be determined di-

If the relative roughness is taken as negligible, he suggested rectly from a rheogram without employing correlations based

the following implicit formula for smooth pipes: on pipe-flow data.

For the Bingham plastic fluids in turbulent flow they devel-

2.51 oped the following relationships:

1

= 2log10 (4)

f Re f V

= 2.5ln Re*' + 2.5ln (1 − ξ ) / (1 + ξ ) + ξ (14.1 + 1.25ξ ) (10)

2

U*

He also developed an explicit equation for smooth pipes to

estimate the friction factor as: τ yB

where Re'* = ρ DU * / η p ; ξ =

τ w U* = τ w / ρ

1 Re

= 1.8log10 (5)

f 6.9 V

and = 8/ f

U*

The validity of this equation was reported for Reynolds

number of 4000 ≤ Re ≤ 108 f is the Stanton-Moody friction factor.

Prandtl correlation (1935) Corresponding to Re *' > 830 and ρ DV / ηt > 1.7 × 104 the fol-

lowing formula would be implemented:

It is not explicit in friction factor and must be solved itera-

tively. This is good only for Re in the range of 4000 to 106. The V

= 2.5ln( Re*' ) + 32

formula has the following forms: U*

1 For smaller values of Hedstrom number (He< 450000) the

= 2log( Re f ) − 0.8 (6)

f turbulent expression can be based on equation (10) and for

laminar regime expression the following is well known:

Darby and Melson (1981) model

V

=

(

3 − ξ 4 − ξ 3 Re'

* ) (11)

Darby and Melson (1981) modified the Buckingham-

U* 24

Reiner equation (3) for Fanning friction factor (Cf) in terms of

modified Reynolds number (Remod) as:

Slatter (1995) correlation

16

Cf = (7) He modified the Reynolds number for determining the transi-

Remod

tion from laminar to turbulent flow for Herschel-Bulkley (and

Bingham plastic) slurries as:

14 Brought to you by | Pontificia Universidade Católica do Rio Grande do Sul PUC/RS

Authenticated

Download Date | 2/22/18 1:26 PM

A comparative study of friction factor correlations for high concentrate slurry flow in smooth pipes

8ρVann 2 where R is the inside radius of the pipe.

Remod = n

and laminar ceases at Remod ≤ 2100

8Vann Danish-Kumar solution

τ YH + K

Dshear

(12) Danish et al. (2011) have provided an explicit procedure to

calculate the friction factor by using the Adomian decomposi-

Q − Q plug

where Vann = tion method. The friction factor containing two terms through

(

π R 2 − R plug 2 ) this method for laminar flow is given as:

4K2

D shear = D − D plug = 2 R − R plug ( ) K1 +

KK

3

K1 + 4 1 2

1 K1 + 3K 2

nR τ w n ( n +1) fL = (17)

V plug = (1 − φ ) n 3K 2

( n + 1) K 1+

4

KK

K1 + 4 1 2

D plug τ YH K1 + 3K 2

where φ = =

D τw

16 16 He 16He4

where K1 = + and K 2 = −

1

( n +1) (1 − φ )2 2φ (1 − φ ) φ 2 Re 6 Re2 3Re8

τ n

3

Q = πR n w (1 − φ ) n + +

K 3n + 1 2n + 1 n + 1

and for turbulent flow:

2

Qplug = π Dplug 2 Vplug 1 1.73718Co ( lnCo ) 2.62122Co ( lnCo )

= Co − + +

2 f 1.73718 + Co (1.73718 + Co )3

where Remod = Slatter modified Reynolds number, Vann = veloci- 3

ty in the sheared annulus (m/s), Dshear = equivalent diameter of 3.03568Co ( lnCo )

+ (18)

sheared region (m), Q = transitional volumetric flow rate (m3/s) (1.73718 + Co )4

n

ρV n −1D n 4n 16 where Co = 4log10 Re − 0.4

RHB = n −1 and f f = (13)

8 K 1 + 3n ΨRHB For the flow of Bingham fluids to be in the laminar regime,

the Reynolds number for a given Hedstrom number should be

(1 − φ )2 2φ (1 − φ ) φ 2 less than the corresponding critical Reynolds number.

n 1+ n

where Ψ = (1 + 3n ) (1 + φ ) + +

1 + 3n 1 + 2n 1+ n

Swamee-Aggarwal equation (2011)

For Bingham Plastic slurries, set n = 1, τHB = τYB and K = ηP. This equation is used to solve directly for the Darcy–

This approach was specifically developed to place emphasis on Weisbach friction factor fL for laminar flow of Bingham plastic

the visco-plastic nature of the material (Slatter, 1995). He also fluids. It is an approximation of the implicit Buckingham

developed a turbulent flow model appropriate for non- Reiner equation, but the discrepancy from experimental data is

Newtonian sludges. A roughness Reynolds number for non- well within the accuracy of the data. It is given by:

Newtonian sludges was formulated to accommodate the particle

1.143

roughness effect based on a representative particle size, d85, and He

the Herschel-Bulkley rheological parameters: 10.67 + 0.1414

64 Re He

fL = + (19)

Re He

1.16 Re

8ρU*2 1 + 0.0149 Re

Rer = n

(14) Re

8U

τ YB + K *

d85 Morrison correlation (2013)

If Rer< 3.32 then smooth wall turbulent flow exists and the It is occasionally desirable to have a data correlation that

mean velocity is given by: spans the entire range of Reynolds number, from laminar flow,

through transitional flow, and reaching the highest values of

V R Reynolds number. For this Morrison (2013) developed a new

= 2.5ln + 2.5ln ( Rer ) + 1.75 (15) data correlation for smooth pipes which is more explicit and

U* d85

relatively simple in form.

If Rer > 3.32 then fully developed rough wall turbulent flow

exists and the mean velocity is given by: 3170

0.165

0.0076

Cf = Re + 16 (20)

V R 7.0 Re

1 +

= 2.5 ln 3170

+ 4.75 (16)

U* d 85 Re

Brought to you by | Pontificia Universidade Católica do Rio Grande do Sul PUC/RS 15

Authenticated

Download Date | 2/22/18 1:26 PM

K. M. Assefa, D. R. Kaushal

At lower Reynolds number this equation become (16/Re) and digitizer 2.6.6 and used to get the experimental friction factors.

at high Reynolds numbers (4000≤ Re ≤ 106) this equation fol- The friction factor is computed as:

lows the Prandtl correlation, the smooth-pipe equivalent and

original source of the Colebrook equation.

ΔP 2 D

f = (21)

Transitional flow L ρU 2

The value of the Darcy friction factor may be subject to large Details of the experimental data for rheological properties

uncertainties in this flow regime. For uniformity the range of are reported in Table S1 of the Appendix. The friction factors of

Reynolds number for laminar-turbulent flow proposed by Hanks observed data were computed by equation (21) and the compar-

and Pratt (1967) were remained in between 2100 to 4000, valid ison between these values and friction factors estimated by the

for all correlations in this review except for some equations correlation models (Table S3 in Supplementary material) are

which do have their own critical Reynolds number formula or shown in Figure 1. In this Figure Re is the Reynolds number.

values.

EVALUATION OF THE SELECTED FRICTION

STATISTICAL ANALYSIS AND MODELS FACTOR CORRELATIONS

COMPUTATIONS

Based on the statistical parameters analysis, the majority of

In order to compare predicted friction factor (fM,pred) with the model predictions have RMSE and S values less than 20%

experimental data (fM,exp), eight commonly used statistical (Table 1). Equation (20) showed best results according to all the

parameters were implemented based on the literature listed criteria in laminar flow. It is interesting that equations (7),

recommendations (García et al., 2003, 2005, 2007; Genić et al., (17), and (19) for laminar flow have the same values in all

2011; Gregory and Fogarasi, 1985; Ouyang, 1998; Xiao et al., statistical parameters. But equation (19) should be given the

1990). The parameters involved in the models comparison with advantage because of its simplicity in calculation. The analysis

their details interpretations are listed in Table S2 in for laminar flow showed that both equations (1) and (12) have

Supplementary material. the same values in terms of relative errors and degree of

From research works of Sunil et al. (2009, 2010), the correlation with the experimental data but equation (1) showed

experimental data for pressure drops for the flow of fly ash less data variability with in the estimated values. Even though

having specific gravity of 1.992 through a smooth pipe of 40 equations (10) and (20) have the same minimum error and

mm diameter in the range of velocity from 1 to 3 m/s and better regression estimations in all flow regimes, equation (20)

concentration by weight from 60 to 70% were reproduced by plot is superior in terms of less number of input parameters and ease

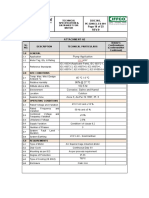

Table 1. Calculated values of statistical parameters for the selected models.

Flow Eqn* MARE MRE+ MRE– RMSE S Ѳ AIC MSC

1 10.63 2.93 –27.5 12.4 6.897 0.954 –95.25 –35.75

4 7.68 9.37 –23.3 9.09 6.91 0.969 –109.94 –35.27

5 6.72 15.18 –24.87 8.3 11.06 0.971 –111.66 –34.54

Laminar

6 10.43 7.01 –31.44 13.57 10.24 0.95 –92.51 –35.63

7 7.68 9.37 –24.8 9.09 6.91 0.969 –109.94 –35.27

8 7.68 9.37 –24.8 9.09 6.91 0.969 –109.94 –35.27

9 2.994 5.18 –12.2 4.14 4.11 0.994 –169.56 –33.27

2 17.75 25.91 –27.5 20.07 20.02 0.662 –113.41 –36.3

3 16.25 24.97 –28.8 18.48 18.23 0.702 –116.76 –42.09

4 16.42 4.23 –23.3 18.41 18.52 ** –90.12 –38.10

Turbulent

5 10.12 28.52 –30.88 12.83 14.62 0.732 –119.74 –35.68

6 47.39 68.9 –56.12 50.15 41.9 ** –91.68 –37.98

8 16.24 23.51 –24.8 18.53 18.51 0.691 –115.79 –42.21

9 14.07 13.75 –13.2 12.62 12.64 0.923 –130.55 –32.42

1&3 13.28 24.97 –27.5 15.45 15.45 0.963 –155.68 –34.32

7&2 12.43 25.91 –28.8 15.16 15.17 0.971 –171.92 –33.73

All regimes

4 16.38 9.37 –23.3 21.73 21.78 0.959 –148.51 –34.88

5 8.32 28.52 –30.88 11.86 11.86 0.973 –178.94 –33.50

6 28.14 68.9 –56.15 35.87 35.91 0.945 –133.73 –32.28

8 11.71 23.51 –24.8 14.23 14.23 0.971 –173.84 –33.76

9 6.57 13.75 –13.2 12.36 12.34 0.984 –214.45 –32.03

*

The models corresponding to the equations number are listed in Table S2 in Supplementary material.

**

The correlation ratio is undefined.

16 Brought to you by | Pontificia Universidade Católica do Rio Grande do Sul PUC/RS

Authenticated

Download Date | 2/22/18 1:26 PM

A comparative study of friction factor correlations for high concentrate slurry flow in smooth pipes

Fig. 1. Comparison of experimental data with predicted friction factors in smooth pipe.

of calculation requirements. Another important feature observed deviation from the experimental data. Similar observations were

is that for a transitional and turbulent regime (Re ≅ 3000– made by El-Nahhas and Mostafa (2006).

400000), equation (10) has minimum error followed by Estimations have also been done by combining different cor-

equation (20) but showed high variability in terms of data relations for laminar and turbulent flow developed separately by

representation (Fig. 2e and Table 1) and show high rate of various researchers, for instance combining equation (1) with

increment of relative error beyond 40000 Re which likewise is (5), and equation (19) with (2). In this aspect, results obtained

also explained by Wilson and Thomas (1985). Equation (15) by combining equation (19) with (2) showed better results in

failed to predict and shows highest variability and greatest terms of mean absolute relative % error (MARE), root mean square

Brought to you by | Pontificia Universidade Católica do Rio Grande do Sul PUC/RS 17

Authenticated

Download Date | 2/22/18 1:26 PM

K. M. Assefa, D. R. Kaushal

Fig. 2. Comparison of the relative error of Morrison equation (20) with the remaining models as a function of the Reynolds number Re.

error (RMSE), standard deviation of MARE (S), and correlation models under-predict the friction factors in laminar flow and

ratio (Ѳ) than equation (9) in overall estimation. This notion over predict for turbulent flows for the given maximum ranges

will motivate for further investigations and improving the of Reynolds number. The extent of under-prediction by the

accuracy of the data. In general the performance of equation Darby- Melson model for turbulent flow is much higher than

(20) for the estimation of friction factors in smooth pipes is the over-prediction by the other models except Blasius (1939)

excellent with relative deviation of ±15% followed by equation and Slatter (1995) model. For turbulent flow in smooth pipes,

(10–11). The relative errors of the other models were compared the Slatter (1995) equation is the least accurate, whereas the

with equation (20) as displayed in Fig. 2. Wilson-Thomas (1985) model has the highest accuracy

As shown in Fig. 1, Darby-Melson (1981) model under- followed by Morrison (2013) and Danish-Kumar (2011)

predicts the friction factors for all flow regimes. But the other equation.

18 Brought to you by | Pontificia Universidade Católica do Rio Grande do Sul PUC/RS

Authenticated

Download Date | 2/22/18 1:26 PM

A comparative study of friction factor correlations for high concentrate slurry flow in smooth pipes

Processes in Liquids]. VDI Mitt. Forschungsarb., 131, 1–39.

(In German.)

Buckingham, E., 1921. On plastic flow through capillary tubes.

ASTM Proceeding, 21, 1154–1161.

Colebrook, C.F., 1938–1939. Turbulent flow in pipes with

particular reference to the transition region between the

smooth and rough pipe laws. Journal of the Institution of

Civil Engineering, 11, 133–156.

Danish, M., Kumar, S., Kumar, S., 2011. Approximate explicit

analytical expressions of friction factor for flow of Bingham

fluids in smooth pipes using Adomian Decomposition

Method. Commun. Nonlinear Sci. Numer. Simulat., 16, 1,

239–251.

Darby, R., Melson, J., 1981. How to predict the friction factor

for flow of Bingham Plastics. Chemical Engineering, 28,

59–61.

Darcy friction factor formulae. Wikipedia: The free encyclo-

paedia. Retrieved on September 21, 2014 from

http://en.wikipedia.org/wiki/Darcy_friction_factor_formulae

Fig. 3. Comparison of the Morrison’s model data with the experi- El-Nahhas, K., Mostafa, N.H., 2006. Prediction of non-

mental data for ±15% deviation. Newtonian turbulent flow behavior by a Newtonian ap-

proach. In: Proc. 10th International Water Technology Con-

CONCLUSIONS AND RECOMMENDATION ference, IWTC10, Alexandria, Egypt, pp. 479–490.

Fang, X.D., Xu, Y., Zhou, Z.R., 2011. New correlations of

• Experimental data of rheology and pressure drops were col- single-phase friction factor for turbulent pipe flow and eval-

lected from literature for flow of Bingham-plastic fluids through uation of existing single-phase friction factor correlations.

smooth pipes at different solid concentrations and flow veloci- Nuclear Engineering and Design, 241, 897–902.

ties. García, F., García, R., Padrino, J.C., Mata, C., Trallero, J.,

• Nine explicit equations have been chosen to estimate Joseph, D., 2003. Power law and composite power law

the friction factor in laminar, and/or turbulent flows in smooth friction factor correlations for laminar and turbulent gas–

pipes. All the equations were compared with experimental data liquid flow in horizontal pipelines. Int. J. Multiphase Flow,

statistically. 29, 10, 1605–1624.

• The Morrison (2013) is the only equation representing a García, F., García, R., Joseph, D., 2005. Composite power law

friction factor for all flow regimes with single equation (Fig. 3). hold up correlations in horizontal pipes. Int. J. Multiphase

The Darby-Melson (1981), Wilson-Thomas (1985), Slatter Flow, 31, 12, 1276–1303.

(1995) and Danish-Kumar (2011) developed separate equations García, F., García, J.M., García, R., Joseph, D., 2007. Friction

for each flow regimes. By combining different formulas (such factor improved correlations for laminar and turbulent gas–

as Hagen-Poiseuille (1840) with Colebrook equation, and liquid flow in horizontal pipelines. Int. J. Multiphase Flow,

Swamee-Aggarwal (2011) with Blasius (1913)), the statistical 33, 1320–1336.

analysis and comparisons with experimental data were made for Genić, S., Arandjelović, I., Kolendić, P., Jarić, M., Budimir, N.,

all flow regimes. Genić, V., 2011. A review of explicit approximations of

• The Wilson-Thomas (1985) and Morrison (2013) models are Colebrook’s equation. FME Transactions, 39, 67–71.

found to be the best fit models to the experimental data in the Gregory G. A., Fogarasi, M., 1985. Alternate to standard fric-

range up to 40000 Re. Within this range both the models can be tion factor equation. Oil Gas Journal, 83, 13, 120–127.

used alternately. But beyond this Re, the discrepancy of Wilson- Hanks, R.W., Pratt, D.R., 1967. On the flow of Bingham Plastic

Thomas model is higher than the Morrison model. slurries in pipes and between parallel plates. Journal of Soci-

• In view of the fact that the Morrison model requires fewer ety of Petroleum Engineers, 1682, 342–346.

calculations and parameters as well as all flow regimes being Moody, L., 1944. Friction factors for pipe flow. Trans. ASME,

computed by a single equation, it is the authors’ advice to use 66, 8, 671–684.

this model for friction factor estimation of Bingham fluids in Morrison, F.A., 2013. Data correlation for friction factor in

smooth pipes as an alternative to the Moody chart and to other smooth pipes. Department of Chemical Engineering, Michi-

implicit formulas. gan Technological University, Houghton, MI.

• The results obtained by Morrison (2013) correlation can be Ouyang, L., 1998. Single phase and multiphase fluid flow in

used as an initial guess for Adomian Decomposition Method horizontal wells. Ph.D. Dissertation Thesis. Dept. of Petro.

(ADM) and Restarted Adomian Decomposition Method Eng., School of Earth Sciences. Stanford Univ., 248 p.

(RADM) used in Danish et al. (2011) correlation equation to get Prandtl, L., 1935. The mechanics of viscous fluids. In: Durand,

better results. W.F. (Ed.): Aerodynamic Theory, 3, 34–208.

Slatter, P.T., 1995. The turbulent flow of non-Newtonian slur-

REFERENCES ries in pipe. In: Proc. 8th Conference on Transport and sedi-

mentation of solid particles. Prague, A3.

Bingham Plastic. Wikipedia: the free encyclopaedia. Retrieved on Sunil, C., Seshadri, V., Singh, S.N., 2009. Effect of additive on

May10, 2014 from http://en.wikipedia.org/wiki/Bingham_plastic pressure drop and rheological characteristics of fly ash slurry

Blasius, H., 1913. Das Aehnlichkeitsgesetz bei Reibungsvor- at high concentration. Particulate Science and Technology,

gangen in Flussigkeiten. [The Law of Similarity in Friction 27, 3, 271–284.

Brought to you by | Pontificia Universidade Católica do Rio Grande do Sul PUC/RS 19

Authenticated

Download Date | 2/22/18 1:26 PM

K. M. Assefa, D. R. Kaushal

Sunil, C., Seshadri, V., Singh, S.N., 2010. Transportation of Notation

high concentration coal ash slurries through pipelines. Inter- Cf Fanning friction fav, exp Average friction factor of

national Archive of Applied Science and Technology, 1, 1. factor the experimental data

Swamee, P.K., Aggarwal, N., 2011. Explicit equations for lami- f Darcy-Weisbach fexp Experiment friction

nar flow of Bingham Plastic fluids. Journal of Petroleum friction factor factor

Re Reynolds number fpred Predicted friction factor

Science and Engineering, 76, 178–184.

U Mean velocity of n Number of experimental

Swamee, P., Jain, A., 1976. Explicit equations for pipe flow the mixture (m/s) data

problems. Journal of the Hydraulics Division (ASCE), 102, ρm Density of mixture Remod Modified Reynolds

5, 657–664. (kg/m3) number

Xiao, J.J., Shonham, O., Brill, J.P., 1990. A comprehensive ηp Dynamic viscosity He Hedstrom number

mechanistic model for two-phase flow in pipelines. In: Proc. (Pa.S)

65th SPE Annual Technical Conference and Exhibition, New τy Yield shear stress fL Friction factor for lami-

Orleans, LA, Paper SPE 20631, pp. 167–180. (Pa) nar flow

Wilson K.C., Thomas, A.D., 1985. New analysis of the turbu- D Pipe diameter (m) fT Friction factor for turbu-

lent flow of non-Newtonian fluids. Canadian Journal of lent flow

Chemical Engineering, 63, 539–546. NP Number of parame-

ters in the equation

Received 17 July 2014

Accepted 3 November 2014

Note: Supplementary Tables (S1–S3) can be found in the web version of this article.

20 Brought to you by | Pontificia Universidade Católica do Rio Grande do Sul PUC/RS

Authenticated

Download Date | 2/22/18 1:26 PM

A comparative study of friction factor correlations for high concentrate slurry flow in smooth pipes

SUPPLEMENTARY MATERIAL

Table S1. Details of rheological data considered in the present study (Sunil et al., 2009 and 2010).

Weight conc (%) Yield stress Slurry viscosity

(τy) [Pa] (ηp) (*10–3) [Pa s]

60 0.36 14.5

65 1.36 53.4

68 1.712 172.1

70 1.945 245.3

Table S2. Governing equation of the statistical parameters and their interpretations.

No. Statistical parameter Governing equations Interpretation

1 Mean Absolute Relative 1 n The smaller the value the better the

Error [%] MARE,% = ri

n i =1

model

ei

where ri = × 100 and

f M ,exp

ei = f M , pred − f M ,exp

2 Root Mean Square Error The better the regression estimate, the

1 n 2

[%] RMSE ,% = ( ri )

n i =1

smaller the size of the errors

3 Standard deviation of Lower percentage indicates a lower

1 n 2

MARE S= ( ri − E1 )

n i =1

variability in the data

1 n

where E1 = ri

n i =1

4 Correlation ratio Higher value indicate close correlations

( f M ,exp − f M , pred )

n 2

between samples

θ= 1 − i =1

i =1( f M ,exp − f av,exp )

n 2

n

where fav,exp

fM ,exp

= i =1

n

5 Akaike Information The most appropriate model is the one

2

n

Criterion AIC = n ln ( ei ) + 2 NP with the smallest values

i =1

6 Model selection criterion The most appropriate model is the one

i =1( fM ,exp − fav,exp ) − 2NP

n

MSC = ln with the largest MSC

i=1( fM , pred − fM ,exp ) n

n

NP = the number of parameters in the model or equivalently the number of degrees of freedom and n = the number of sample data size

Brought to you by | Pontificia Universidade Católica do Rio Grande do Sul PUC/RS

Authenticated

Download Date | 2/22/18 1:26 PM

K. M. Assefa, D. R. Kaushal

Table S3. Selected explicit equations for the calculation of the friction factor of Bingham plastic fluids in smooth pipes.

No. Equation Flow type Range of Re References

1 64 Laminar ≤ 2100 Hagen and Poiseuille

f = (1840)

Re

2 −1 Turbulent 2100–2×104 Blasius

f = 0.316 ( Re ) 4

(1913)

−1

f = 0.184( Re ) 5 ≥ 2×104

3 1 Re Turbulent 4000–108 Colebrook

= 1.8log10 (1939)

f 6.9

4 16 6ReB2 Laminar

Cf = ; Remod = NM Darby and Melson

Remod 6ReB + He (1981)

fT = 10a Re −0.193a = −1.47 1 + 0.146e −2.9×10 He

−5

Turbulent

1 All flow

f = f L m + fT m m regimes

5 V Re *' > 830

= 2.5ln Re '* + 2.5ln (1 − ξ ) / (1 + ξ ) + ξ (14.1 + 1.25ξ )

2

All regimes Wilson and Thomas

U* and (1985)

V

= 2.5ln( Re*' ) + 32

U* Re > 17000

V =

(

3 − ξ 4 − ξ 3

) Re'

* Re < 2100

U* 24

τ yB

ξ= τw

V

where, Re'* = ρ DU* / η p ; U* = τ w / ρ and = 8/ f

U*

6 8 ρVann 2 Laminar Remod ≤ 2100

Remod = n

Slatter

8V (1995)

τ YH + K ann

D

shear

ρVDn 16

RYB = and f f =

ηp Ψτ YB

2 (1 − φ )

2

2φ (1 − φ ) φ 2

where Ψ = 4 (1 + φ ) + + and

4 3 2

τ YB

φ=

τw

8ρU*2

Rer = n

8U*

τ YB + K Turbulent Remod≥ 2100

d85

V R

If Rer< 3.32; = 2.5ln + 2.5ln ( Rer ) + 1.75

U* d85

V R

If Rer> 3.32; = 2.5ln + 4.75

U* d85

7 1.143 Laminar ≤ 2100

He

10.67 + 0.1414 Swamee-Aggarwal

64 Re He (2011)

fL = +

Re He

1.16 Re

1 + 0.0149 Re

Re

Brought to you by | Pontificia Universidade Católica do Rio Grande do Sul PUC/RS

Authenticated

Download Date | 2/22/18 1:26 PM

A comparative study of friction factor correlations for high concentrate slurry flow in smooth pipes

8 4K2

K1 + 3 NM Danish-Kumar

KK (2011)

K1 + 4 1 2

K1 + 3K 2

fL = ; Laminar

3K 2

1+ 4

KK

K1 + 4 1 2

K1 + 3K 2

16 16 He 16He4

K1 = + ; K 2 = −

Re 6 Re 2 3Re8

1 1.73718Co ( lnCo )

= Co − + Turbulent

2 f 1.73718 + Co

2 3

2.62122Co ( lnCo ) 3.03568Co ( lnCo )

+ +

(1.73718 + Co )3 (1.73718 + Co )4

where Co = 4log10 Re − 0.4

9 0.165 All flow ≤ 2100 Morrison

3170 regimes (2013)

0.0076

Cf = Re + 16 4000–108

7.0 Re

1 +

3170

Re

NM: Not mentioned

Brought to you by | Pontificia Universidade Católica do Rio Grande do Sul PUC/RS

Authenticated

Download Date | 2/22/18 1:26 PM

You might also like

- A Comparative Study of Friction Factor Correlations For High Concentrate Slurry PDFDocument11 pagesA Comparative Study of Friction Factor Correlations For High Concentrate Slurry PDFVighnesh PrasadNo ratings yet

- 147.213.145.2 VC Articles 2015 63 InProgress Assefa 1Document11 pages147.213.145.2 VC Articles 2015 63 InProgress Assefa 1abdullaalakourNo ratings yet

- A Review of Non Iterative Friction Factor Correlations For The Calculation of Pressure Drop in PipesDocument8 pagesA Review of Non Iterative Friction Factor Correlations For The Calculation of Pressure Drop in PipesCynthia MortemNo ratings yet

- A Review of Non Iterative Friction Factor Correlations For The Calculation of Pressure Drop in PipesDocument8 pagesA Review of Non Iterative Friction Factor Correlations For The Calculation of Pressure Drop in PipesJoão Rubens MartinsNo ratings yet

- Una Nueva Fórmula Explícita de Factor de Fricción para Flujos Laminares, de Transición y Turbulentos en Tuberías Lisas y RugosasDocument6 pagesUna Nueva Fórmula Explícita de Factor de Fricción para Flujos Laminares, de Transición y Turbulentos en Tuberías Lisas y Rugosasdaniel quispe mezaNo ratings yet

- Fourier Restriction for Hypersurfaces in Three Dimensions and Newton Polyhedra (AM-194)From EverandFourier Restriction for Hypersurfaces in Three Dimensions and Newton Polyhedra (AM-194)No ratings yet

- Predict Friction Lossin Slurry Pipes Darbyetal 1992Document5 pagesPredict Friction Lossin Slurry Pipes Darbyetal 1992Baris YeltekinNo ratings yet

- Predict Friction Lossin Slurry Pipes Darbyetal 1992Document5 pagesPredict Friction Lossin Slurry Pipes Darbyetal 1992Viajante_santosNo ratings yet

- Comparison of Friction Factor Equations For Non-Newtonian Fluids in A Pipe FlowDocument28 pagesComparison of Friction Factor Equations For Non-Newtonian Fluids in A Pipe FlowManu K MohanNo ratings yet

- Darcy Friction Factor FormulaeDocument10 pagesDarcy Friction Factor Formulaesiva242245No ratings yet

- Reconsideration of The Friction Factor Data and Eq PDFDocument20 pagesReconsideration of The Friction Factor Data and Eq PDFRajeev PandeyNo ratings yet

- Fanning Friction Factor EquationDocument6 pagesFanning Friction Factor EquationaliyahfitNo ratings yet

- Friction Factor For Turbulent Pipe FlowDocument16 pagesFriction Factor For Turbulent Pipe Flowyu won hoNo ratings yet

- Process-Based Friction Factor For Pipe Flow: James M. Gregory, John A. MceneryDocument2 pagesProcess-Based Friction Factor For Pipe Flow: James M. Gregory, John A. MceneryNur Rokhma SNo ratings yet

- WONG 2005 TC Varios Overland Flow YEN CHOW 1983Document6 pagesWONG 2005 TC Varios Overland Flow YEN CHOW 1983Valter AlbinoNo ratings yet

- Numerical Investigation of Flow Through Convergent or Divergent Channel With Finite Difference MethodDocument5 pagesNumerical Investigation of Flow Through Convergent or Divergent Channel With Finite Difference MethodAli Embarak 201-900-040No ratings yet

- New Correlations of Single-Phase Friction Factor For Turbulent Pipe Flow and Evaluation of Existing Single-Phase Friction Factor CorrelationsDocument7 pagesNew Correlations of Single-Phase Friction Factor For Turbulent Pipe Flow and Evaluation of Existing Single-Phase Friction Factor CorrelationsHernán GonzálezNo ratings yet

- Friction FactorDocument79 pagesFriction FactorahmedNo ratings yet

- CHAPTER 9 Gas Gathering & TransportationDocument64 pagesCHAPTER 9 Gas Gathering & Transportationfaitholiks841No ratings yet

- Drag LawsDocument10 pagesDrag LawsRelining MineralsNo ratings yet

- HERSCHEL-BULKLEY FLUID Parameters EstimationDocument10 pagesHERSCHEL-BULKLEY FLUID Parameters EstimationgombossandorNo ratings yet

- Van Genuchten 1980 Predicting Hydraulic Conductivity of Unsaturated SoilsDocument7 pagesVan Genuchten 1980 Predicting Hydraulic Conductivity of Unsaturated SoilsMarta GarciaNo ratings yet

- A Novel Explicit EquationDocument4 pagesA Novel Explicit EquationMehmet SorgunNo ratings yet

- Comparison of Low Reynolds Number K-E Turbulence Models in Predicting Fully Developed Pipe FlowDocument19 pagesComparison of Low Reynolds Number K-E Turbulence Models in Predicting Fully Developed Pipe Flowsaleamlak muluNo ratings yet

- Energy Losses in Pipe PDFDocument7 pagesEnergy Losses in Pipe PDFnadiselNo ratings yet

- Karabelas - Liquid - Liquid Droplet Size Distribution PDFDocument11 pagesKarabelas - Liquid - Liquid Droplet Size Distribution PDFSwiftTGSolutionsNo ratings yet

- 48 Modeling Consolidation of Tailings Impoundments in One and Two DimensionsDocument12 pages48 Modeling Consolidation of Tailings Impoundments in One and Two Dimensionsgavisita123No ratings yet

- Toufik-Mahmoud2021 Article FrictionCoefficientEquationInADocument9 pagesToufik-Mahmoud2021 Article FrictionCoefficientEquationInAFrancesco ColosimoNo ratings yet

- Fluid Flow in Pipes: Analyzing Fanning Friction Factors Turbulent Velocity ProfilesDocument14 pagesFluid Flow in Pipes: Analyzing Fanning Friction Factors Turbulent Velocity Profilestheeta88No ratings yet

- Colebrook White EcuatiDocument7 pagesColebrook White Ecuatimoraru coriolanNo ratings yet

- Friction Factor For Turbulent Pipe Flow: January 2006Document17 pagesFriction Factor For Turbulent Pipe Flow: January 2006John AnthoniNo ratings yet

- Evaluation of Friction and Pressure Loss and Its Impact in Petroleum Pipeline TransportationDocument13 pagesEvaluation of Friction and Pressure Loss and Its Impact in Petroleum Pipeline TransportationGideon KipronoNo ratings yet

- Replace Implicit Equations With Signomial FunctionsDocument8 pagesReplace Implicit Equations With Signomial FunctionsnurudinsatharNo ratings yet

- Cmes 2006 012 121Document16 pagesCmes 2006 012 121tijsnoyonNo ratings yet

- Choosing A Formula: Laminar FlowDocument7 pagesChoosing A Formula: Laminar FlowMrmoa MohammedNo ratings yet

- A Dual-Time Central Difference Finite Volume Scheme For Interface Capturing On Unstructured MeshesDocument27 pagesA Dual-Time Central Difference Finite Volume Scheme For Interface Capturing On Unstructured MeshesMaricruz HernándezNo ratings yet

- FrictionalPipeFlowSimulationv 02 PDFDocument25 pagesFrictionalPipeFlowSimulationv 02 PDFFederico FainiNo ratings yet

- Can Pipes Be Actually Really SmoothDocument7 pagesCan Pipes Be Actually Really Smoothpedro javier saavedra martinezNo ratings yet

- Week 3Document6 pagesWeek 3Tanvir Ahmad HashmiNo ratings yet

- T-duality and α -correctionsDocument36 pagesT-duality and α -correctionsMatias VolijNo ratings yet

- Pressure Losses in Pipeline FlowDocument11 pagesPressure Losses in Pipeline FlowParameshNo ratings yet

- Effect of Rans Turbulence Model in Hydraulic Jump CFD SimulationsDocument9 pagesEffect of Rans Turbulence Model in Hydraulic Jump CFD Simulationsdurgam kkNo ratings yet

- SdarticleDocument11 pagesSdarticlemickeytron2010No ratings yet

- Friction FormulaDocument19 pagesFriction FormularenatoNo ratings yet

- AAAA Terra-Et-Aqua Nr81 02Document9 pagesAAAA Terra-Et-Aqua Nr81 02Cristian Guillermo Araneda PeñaililloNo ratings yet

- 1 Skin FrictionDocument9 pages1 Skin FrictionBianca BelmonteNo ratings yet

- P129130 Study of Different Approaches For Modeling Cyclones Using CFDDocument10 pagesP129130 Study of Different Approaches For Modeling Cyclones Using CFDPhilippe LAVOISIERNo ratings yet

- Process-Based Friction Factor For Pipe Flow: James M. Gregory, John A. MceneryDocument12 pagesProcess-Based Friction Factor For Pipe Flow: James M. Gregory, John A. MceneryNur RokhmaNo ratings yet

- Papers Fall VelocityDocument7 pagesPapers Fall VelocityAnonymous K02EhzNo ratings yet

- Paper F April 2020Document9 pagesPaper F April 2020Suresh CNo ratings yet

- Determination of Kozeny Constant Based On Porosity and Pore To Throat Size Ratio in Porous Medium With Rectangular RodsDocument12 pagesDetermination of Kozeny Constant Based On Porosity and Pore To Throat Size Ratio in Porous Medium With Rectangular RodsAGT 6BNo ratings yet

- Distribution Eddy Viscosity Length: Mixing inDocument6 pagesDistribution Eddy Viscosity Length: Mixing inGustavo Gabriel JimenezNo ratings yet

- J Jngse 2014 06 002 PDFDocument11 pagesJ Jngse 2014 06 002 PDFvastaguenNo ratings yet

- Churchill 1977Document7 pagesChurchill 1977weonNo ratings yet

- (Moreira, 2012) - Numerical Study of The Neutral Atmospheric Boundary Layer Over Complex TerrainDocument15 pages(Moreira, 2012) - Numerical Study of The Neutral Atmospheric Boundary Layer Over Complex TerrainDalmedson Freitas FilhoNo ratings yet

- Cathodic Disbonding of Pipeline Coatings: Standard Test Methods ForDocument9 pagesCathodic Disbonding of Pipeline Coatings: Standard Test Methods ForAndres PalacioNo ratings yet

- Conducting Corrosion Coupon Tests in Field Applications: Standard Guide ForDocument10 pagesConducting Corrosion Coupon Tests in Field Applications: Standard Guide ForCris GauchoNo ratings yet

- GearologyDocument132 pagesGearologyRyley McCarthyNo ratings yet

- Preparing, Cleaning, and Evaluating Corrosion Test SpecimensDocument9 pagesPreparing, Cleaning, and Evaluating Corrosion Test SpecimensRichard De Medeiros CastroNo ratings yet

- G 7 - 97 - RZC - PDFDocument7 pagesG 7 - 97 - RZC - PDFjayakumarNo ratings yet

- Astm G-6Document4 pagesAstm G-6Alper Bas100% (1)

- G 10 - 83 R02 - RzewDocument3 pagesG 10 - 83 R02 - RzewAndres PalacioNo ratings yet

- Water Penetration Into Pipeline Coatings: Standard Test Method ForDocument4 pagesWater Penetration Into Pipeline Coatings: Standard Test Method ForAndres PalacioNo ratings yet

- G4Document9 pagesG4Sameer SaNo ratings yet

- DOE-HDBK-1016-1-93-Engineering Symbology - Prints and Drawings-Vol 1Document120 pagesDOE-HDBK-1016-1-93-Engineering Symbology - Prints and Drawings-Vol 1Andres PalacioNo ratings yet

- Stress Concentrations in Keyways and Optimization of Keyway DesignDocument13 pagesStress Concentrations in Keyways and Optimization of Keyway Designluisgonzalezf95No ratings yet

- Diccionario de Mineria Ingles-EspañolDocument307 pagesDiccionario de Mineria Ingles-EspañolOmarhersan94% (16)

- Asee 2013 6775 PDFDocument16 pagesAsee 2013 6775 PDFNermin RedzovićNo ratings yet

- Mechanical Springs WahlDocument463 pagesMechanical Springs WahlVicente Scott67% (3)

- 2012-Bhatia-Engineering Symbology, Prints and DrawingsDocument70 pages2012-Bhatia-Engineering Symbology, Prints and DrawingsAndres PalacioNo ratings yet

- DOE Engineering Symbols-HandbookDocument96 pagesDOE Engineering Symbols-Handbookapi-3717958No ratings yet

- Hydroelectric Power Plants Mechanical DesignDocument124 pagesHydroelectric Power Plants Mechanical DesignnoxleekNo ratings yet

- 2013-Zhang-Image-based Geometric Modeling and Mesh GenerationDocument302 pages2013-Zhang-Image-based Geometric Modeling and Mesh GenerationAndres PalacioNo ratings yet

- Wire Rope Catalog of Sizes Grades Constructions Price Lists Data Tables and Information On The Proper Use of Wire Rope 1940Document151 pagesWire Rope Catalog of Sizes Grades Constructions Price Lists Data Tables and Information On The Proper Use of Wire Rope 1940jaynard_alejandrinoNo ratings yet

- Engineering DrawingDocument240 pagesEngineering DrawingKhelly Shan C. Sta. RitaNo ratings yet

- Diccionario de Ingenieria - MC Graw Hill PDFDocument1,830 pagesDiccionario de Ingenieria - MC Graw Hill PDFkike18mxNo ratings yet

- AHEC Hydaulic Design of Small Hydro 2011Document116 pagesAHEC Hydaulic Design of Small Hydro 2011dunlcaaNo ratings yet

- Chapter 07Document78 pagesChapter 07Andreita PilcoNo ratings yet

- 2003 HFDS Anthropometry and Biomechanics Chapter 14Document61 pages2003 HFDS Anthropometry and Biomechanics Chapter 14Andres PalacioNo ratings yet

- Inspection and Retirement of Wire RopeDocument13 pagesInspection and Retirement of Wire RopeajivakkomNo ratings yet

- Ergonomics Centre StrengthDocument13 pagesErgonomics Centre StrengthMark WoodNo ratings yet

- Turbines 101Document184 pagesTurbines 101Juan ElektroNo ratings yet

- Wire Rope Catalog of Sizes Grades Constructions Price Lists Data Tables and Information On The Proper Use of Wire Rope 1940Document151 pagesWire Rope Catalog of Sizes Grades Constructions Price Lists Data Tables and Information On The Proper Use of Wire Rope 1940jaynard_alejandrinoNo ratings yet

- Usha Martin Wirerope HandbookDocument72 pagesUsha Martin Wirerope Handbookhaydarburedah100% (2)

- Indian Wind Grid Code: Draft Report OnDocument54 pagesIndian Wind Grid Code: Draft Report OnRamesh NaiduNo ratings yet

- NKVE 15-6 Datasheet-9Document1 pageNKVE 15-6 Datasheet-9InácioMendalaNo ratings yet

- Ee3271 - Ec LabDocument87 pagesEe3271 - Ec LabPALANIAPPAN C100% (3)

- Mean Free PathDocument19 pagesMean Free PathShamim khanNo ratings yet

- UEEA 1243 - Circuit TheoryDocument28 pagesUEEA 1243 - Circuit TheoryDaniel LohNo ratings yet

- ExcitationDocument12 pagesExcitationDdumbaNo ratings yet

- D0685-Phy-Paper 2Document20 pagesD0685-Phy-Paper 2AshmitNo ratings yet

- Physics: Question Bank-6Document34 pagesPhysics: Question Bank-6MUSIC WORLDNo ratings yet

- Reviewer in Mathematics 112 Part 1Document7 pagesReviewer in Mathematics 112 Part 1Master JaguarNo ratings yet

- Electrical Data Part-Turn Actuators For Open-Close Duty With 3-Phase AC Motors Short-Time Duty S2 - 15 Min, 200 V/60 HZ SG 05.1 - SG 12.1Document1 pageElectrical Data Part-Turn Actuators For Open-Close Duty With 3-Phase AC Motors Short-Time Duty S2 - 15 Min, 200 V/60 HZ SG 05.1 - SG 12.1lopez sanderNo ratings yet

- Technical Specification & Datasheet For Motor PE-3208-EL-ES-001Document7 pagesTechnical Specification & Datasheet For Motor PE-3208-EL-ES-001Akhil JainNo ratings yet

- L7 - Hydraulic Motors and AccumulatorsDocument33 pagesL7 - Hydraulic Motors and Accumulatorsu1909030No ratings yet

- Busbar Size and CalculationDocument8 pagesBusbar Size and Calculationandro max100% (1)

- Consolidated Grade 8 Science Worksheets Excluding STE 2Document26 pagesConsolidated Grade 8 Science Worksheets Excluding STE 2Sofia Abella100% (1)

- Steam Turbine MaintenanceDocument3 pagesSteam Turbine Maintenancedreamboy87No ratings yet

- Assessment and Redesign of The Electrical SystemDocument21 pagesAssessment and Redesign of The Electrical SystemCyriel HalasanNo ratings yet

- (6sl3210-1ne31-1al0) Power Module PM230Document2 pages(6sl3210-1ne31-1al0) Power Module PM230Ryan TorresNo ratings yet

- Operator (Steel Plant) : CurriculumDocument47 pagesOperator (Steel Plant) : CurriculumJunaid AliNo ratings yet

- Torsional Stress Calculator and Equations - Engineers EdgeDocument2 pagesTorsional Stress Calculator and Equations - Engineers EdgeJose RattiaNo ratings yet

- Presentation No.1Document33 pagesPresentation No.1Akif Zia KhanNo ratings yet

- Eee 2164Document4 pagesEee 2164Mani MalNo ratings yet

- Bernoulli's Equation PNDocument4 pagesBernoulli's Equation PNafifa100% (1)

- Solucionario Ondas y Fluidos FrenchDocument94 pagesSolucionario Ondas y Fluidos FrenchErick Prince100% (1)

- 3rd Sem SyllabusDocument2 pages3rd Sem SyllabusAnkur TamrakarNo ratings yet

- Prof. Ajay B. Balar: Darshan Institute of Engineering & Technology, Rajkot (Gujarat)Document34 pagesProf. Ajay B. Balar: Darshan Institute of Engineering & Technology, Rajkot (Gujarat)Rozitarmizi MohammadNo ratings yet

- GP50B60PD1 InternationalRectifierDocument11 pagesGP50B60PD1 InternationalRectifierStelvio QuizolaNo ratings yet

- Soorya Bala Sangramaya LECO Loan LECO ApplicationDocument2 pagesSoorya Bala Sangramaya LECO Loan LECO ApplicationnavindraNo ratings yet

- UNIT III - System Building Blocks, Models and Closed Loop ControllersDocument122 pagesUNIT III - System Building Blocks, Models and Closed Loop ControllersKuppan Chetty RamanathanNo ratings yet

- Chapter 8Document103 pagesChapter 8skywalker_handsomeNo ratings yet

- Alex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessFrom EverandAlex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessNo ratings yet

- The Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionFrom EverandThe Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionRating: 4 out of 5 stars4/5 (811)

- The Other End of the Leash: Why We Do What We Do Around DogsFrom EverandThe Other End of the Leash: Why We Do What We Do Around DogsRating: 5 out of 5 stars5/5 (64)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingFrom EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingRating: 3.5 out of 5 stars3.5/5 (33)

- Dark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseFrom EverandDark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseRating: 3.5 out of 5 stars3.5/5 (69)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingFrom EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingRating: 5 out of 5 stars5/5 (5)

- Fire Season: Field Notes from a Wilderness LookoutFrom EverandFire Season: Field Notes from a Wilderness LookoutRating: 4 out of 5 stars4/5 (142)

- Why Fish Don't Exist: A Story of Loss, Love, and the Hidden Order of LifeFrom EverandWhy Fish Don't Exist: A Story of Loss, Love, and the Hidden Order of LifeRating: 4.5 out of 5 stars4.5/5 (699)

- Wayfinding: The Science and Mystery of How Humans Navigate the WorldFrom EverandWayfinding: The Science and Mystery of How Humans Navigate the WorldRating: 4.5 out of 5 stars4.5/5 (18)

- World of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsFrom EverandWorld of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsRating: 4 out of 5 stars4/5 (223)

- The Lives of Bees: The Untold Story of the Honey Bee in the WildFrom EverandThe Lives of Bees: The Untold Story of the Honey Bee in the WildRating: 4.5 out of 5 stars4.5/5 (44)

- The Secret Life of Lobsters: How Fishermen and Scientists Are Unraveling the Mysteries of Our Favorite CrustaceanFrom EverandThe Secret Life of Lobsters: How Fishermen and Scientists Are Unraveling the Mysteries of Our Favorite CrustaceanNo ratings yet

- Spoiled Rotten America: Outrages of Everyday LifeFrom EverandSpoiled Rotten America: Outrages of Everyday LifeRating: 3 out of 5 stars3/5 (19)

- Come Back, Como: Winning the Heart of a Reluctant DogFrom EverandCome Back, Como: Winning the Heart of a Reluctant DogRating: 3.5 out of 5 stars3.5/5 (10)

- When You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsFrom EverandWhen You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsRating: 3.5 out of 5 stars3.5/5 (13)

- The Mind of Plants: Narratives of Vegetal IntelligenceFrom EverandThe Mind of Plants: Narratives of Vegetal IntelligenceRating: 4.5 out of 5 stars4.5/5 (11)

- The Big, Bad Book of Botany: The World's Most Fascinating FloraFrom EverandThe Big, Bad Book of Botany: The World's Most Fascinating FloraRating: 3 out of 5 stars3/5 (10)

- When the Sahara Was Green: How Our Greatest Desert Came to BeFrom EverandWhen the Sahara Was Green: How Our Greatest Desert Came to BeRating: 4.5 out of 5 stars4.5/5 (5)

- Braiding Sweetgrass: Indigenous Wisdom, Scientific Knowledge and the Teachings of PlantsFrom EverandBraiding Sweetgrass: Indigenous Wisdom, Scientific Knowledge and the Teachings of PlantsRating: 4.5 out of 5 stars4.5/5 (1423)