Professional Documents

Culture Documents

Serial LED Driver With Current-Regulated, Step-Up DC/DC Converter

Uploaded by

Mubarak AliOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Serial LED Driver With Current-Regulated, Step-Up DC/DC Converter

Uploaded by

Mubarak AliCopyright:

Available Formats

www.fairchildsemi.

com

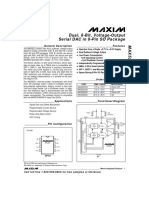

FAN5606

Serial LED Driver with Current-Regulated, Step-Up

DC/DC Converter

Features Description

• Drives Up to Six LEDs in Series The FAN5606 LED driver generates regulated output cur-

• Pulse Skip PWM Mode of Operation of the Boost Circuit rents from a battery with input voltage varying between 2.7V

• Up to 90% Peak Efficiency to 5V. An internal NMOS switch drives an external inductor,

• No External Schottky Diode Required and a Schottky diode delivers the inductor’s stored energy to

• Up to 25mA Output the load. Soft start circuitry prevents excessive current drawn

• Built-in DAC for Digital Brightness Control from the supply during power on. Any number of LEDs can

• LED’s Current Can be Duty-Cycle-Modulated be connected in series as long as the summed forward volt-

• Digital, Analog, and PWM Brightness Control ages do not lead to exceeding the specified operating output

• 2.7V to 5.5V Input Voltage Range voltage range.

• 0.5MHz Operating Frequency (8MHz internal clock)

• Soft Start In the FAN5606 device, the internal two-bit D/A converters

• Low Shutdown Current: ICC < 1µA provide programmability of the output channel current.

• LED Short Circuit Protection Analog programming of the output current is also possible

• Minimal External Components Needed in the FAN5606. To do this, ground the “B” pin and connect

• Available in an 8-lead MLP Package a resistor between the “A” pin and a fixed supply voltage.

The output current can then be programmed to any desired

Applications value within its specified range. The analog version uses a

single external resistor to set the current, and to turn the

• Cell Phones device ON and OFF. The device is available in an 8-lead

• Handheld Computers MLP package.

• PDAs, DSCs, MP3 Players

• Keyboard Backlights

• LED Display

Typical Applications

Analog Brightness Control Digital Brightness Control

VOUT VOUT

2.7V to 5.5V L = 6.8µH 2.7V to 5.5V L = 6.8µH 4.7µF

4.7µF IND IN

GND

IND IN

VOUT GND

CIN

FAN5606

CIN

FAN5606

VIN CAT

VIN CAT

VExternal R A B

A B DAC Inputs

REV. 1.0.3 1/7/05

FAN5606 PRODUCT SPECIFICATION

Pin Assignment

A 1 8 VIN

B 2 7 NC

CAT 3 6 GND

IND 4 5 VOUT

FAN5606

8-Lead 3x3mm MLP

Pin Descriptions

Pin No. Pin Name Pin Function Description

1 A DAC A Input

2 B DAC B Input

3 CAT LED Cathode

4 IND Inductor

5 VOUT Output LED’s Anode

6 GND Ground

7 NC No Connection

8 VIN Input Voltage

Definition of Terms

Output Current Accuracy: reflects the difference between the measured value of the output current (LED) and

programmed value of this current.

( I OUT measured – I OUT programmed ) × 100

Output Current Accuracy (%) = -------------------------------------------------------------------------------------------------------------

I OUT programmed

Efficiency: is expressed as a ratio between the electrical power into the LEDs and the total power consumed from the input

power supply.

( V LED × I LED ) × 100

Efficiency (%) = ---------------------------------------------------------

V IN × I IN

Although this definition leads to a lower value than the boost converter efficiency, it more accurately reflects better system

performance, from the user’s point-of-view.

2 REV. 1.0.3 1/7/05

PRODUCT SPECIFICATION FAN5606

Absolute Maximum Ratings

Parameter Min Typ Max Unit

VIN, A, B Voltage to GND -0.3 6.5 V

VOUT, CAT Voltage to GND -0.3 24 V

Any LED Short Circuit Duration (Anode to Cathode) Indefinite

Lead Soldering Temperature (10 seconds) 300 °C

Thermal Resistance θjc 8 °C/W

Operating Junction Temperature Range 150 °C

Storage Temperature Range -55 150 °C

Electrostatic Discharge (ESD) Protection (Note 1, 2) HBM 4

kV

CDM 1

Electrical Characteristics

VIN =2.7V to 5.5V, TA = 25°C, unless otherwise noted.

Parameter Conditions Min. Typ. Max. Units

Output Current Accuracy A = HIGH, 0.9 × I NOM INOM = 20 1.1 × I NOM mA

B = HIGH

Efficiency (AVG) VIN > 3.0V 80 %

Switching Frequency 0.5 MHz

Multiplication Ratio (Note 3) 850 1000 1150

Supply Current in OFF mode VA = VB = 0V 0.1 µA

Input A Threshold Digital High VIN-0.7 VIN

Mode

Low 0 0.6 V

Analog Mode 1.2

Input B Threshold Digital Mode High 0.6 × V IN VIN

V

Low 0 0.3 × V IN

Recommended Operating Conditions

Parameter Min Typ Max Unit

Input Voltage Range 2.7 5.5 V

Operating Ambient Temperature Range -40 25 85 °C

Output Voltage Range VIN 18 V

Notes:

1. Using Mil Std. 883E, method 3015.7 (Human Body Model) and EIA/JESD22C101-A (Charge Device Model).

2. Avoid positive polarity ESD stress at the cathode of the internal Schottky diode.

3. Multiplication Ratio is ILED /I INPUT A .

REV. 1.0.3 1/7/05 3

FAN5606 PRODUCT SPECIFICATION

Block Diagram

V

OUT

V

IN

OSC DBB COIL DRIVER IND

START-UP LINEAR REGULA TOR CAT

AMPLIFIER

B

DAC

A

BG REF

POWER GOOD

GND

Circuit Description Digital Control

The FAN5606’s digital decoder allows selection of the fol-

When the input voltage is connected to VIN pin, the system is

lowing modes of operation: OFF, 5mA, 10mA, 20mA per

turned on, the bandgap reference acquires its nominal volt-

branch.

age and the soft-start cycle begins. Once "power good" is

achieved (0.5mA in the diodes), the soft-start cycle stops and

the boost voltage increases to generate the desired current A 0 1 0 1

selected by the input control pins. B 0 0 1 1

ILED OFF 5mA 10mA 20mA

The FAN5606 DC/DC converter automatically adjusts its

internal duty cycle to achieve high efficiency. If the output

Analog Control with PWM

external capacitor is shorted, the Schottky diode can be dam-

aged, therefore such a condition should be avoided. In analog control mode, the LED current can go up to 25mA.

Input A is used to control the LED currents. Input B should

LED Brightness Control be connected to GND (logic level "0"). An external resistor

(R) is connected from A to a stable voltage source (VEXTER-

The inputs A and B can be digitally controlled LOW (GND)

NAL) to control the LED current, ILED. The ILED is given by

and HIGH (VCC) signals. In analog mode, A input is con- the formula or the graph below:

nected to an external stable voltage source via an external

V External – V Ref

resistor and B input is connected to ground. The current I LED = ----------------------------------------- × Multiplication Ratio

flowing through the resistor is scaled by a factor of approxi- R

mately 1000.

4 REV. 1.0.3 1/7/05

PRODUCT SPECIFICATION FAN5606

Where V Ref = 1.22V Pulse-Width-Modulation (PWM) Control

A variable duty cycle (δ) can modulate any DAC input. Care

25

should be taken not to use a too low frequency, otherwise a

R=10Kohm

20 flickering effect may occur. The minimum range is 100Hz to

1KHz. For a maximum range of LED current, both A and B

I LED (mA)

15 inputs can be modulated at the same time.

10 R=100kohm Open Circuit Protection

5 A built-in over voltage protection circuit prevents the device

from being damaged when it is powered up with no load.

0 This circuit reduces the boost converter duty cycle, to a min-

1.25 1.5 1.75 2 2.25 2.5 2.75 3 3.25 3.5 imum thus limiting the output voltage to a safe value when

VExternal (V) no load condition is detected. However, the FAN5606 can be

damaged when a full load (Six LEDs driven by 20mA) is

If the analog input A is driven in digital mode by an open suddenly disconnected from VOUT. To protect the FAN5606

drain output, it is important to choose the appropriate value against this unlikely event, an external 24 V Zener diode can

of the pull-up resistor. Its resistance should be low enough to be connected between VOUT and GND.

ensure less than 0.7V dropout, hence VA > (VIN–0.7V), as

required for HIGH logic level: Shutdown Mode

The device can be disabled by applying LOW logic level

700mV voltage to the A and B inputs. In Shutdown mode the supply

Rpull-up < ------------------ = 11kΩ

60µA current is reduced to less than 1µA.

PWM Control

1. A is PWM Controlled, B is Low. ILED (Average) = δ x 5mA, where δ is Duty Cycle. (Note 4)

A Input (PWM)

ss ss ss

30%

Duty Cycle 70%

Duty Cycle

1KHz 1KHz

B Input (0)

ILED (Average) = 0.7 x 5mA = 3.5mA

ILED (Average) = 0.3 x 5mA = 1.5mA

ILED 0mA

ss

OFF

2. A is High and B is PWM. ILED (Average) = 5mA + δ x 15mA, where δ is Duty Cycle.(Note 5, 6)

A Input

ss

B Input (PWM)

ss ss ss

30%

Duty Cycle 70%

Duty Cycle

1KHz 1KHz

ILED (Average) = 0.7 x 20mA + 0.3 x 5mA = 15.5mA

ILED (Average) = 0.3 x 20mA + 0.7 x 5mA = 9.5mA

ss

ILED 0mA OFF

REV. 1.0.3 1/7/05 5

FAN5606 PRODUCT SPECIFICATION

PWM Control (Continued)

3. A and B are PWM. ILED (Average) = δ x 20mA, where δ is Duty Cycle.

A Input (PWM)

ss ss ss

30%

Duty Cycle 70%

Duty Cycle

1KHz 1KHz

B Input (PWM)

ss ss ss

30%

Duty Cycle 70%

Duty Cycle

1KHz 1KHz

ILED (Average) = 0.7 x 20mA = 14mA

ILED (Average) = 0.3 x 20mA = 6mA

LED CURRENT 0mA

ss

OFF

Notes:

4. Proportionally select the duty cycle to achieve a typical LED current between 1mA to 4mA.

5. Maximum PWM frequency can be up to 30KHz.

6. Proportionally select the duty cycle to achieve a typical LED current between 1mA and 19mA.

Applications Information The above relation is applicable up to POUT = 0.6W and

L = 4.3µΗ , or greater. The peak current in the inductor is:

Inductor Selection

T ON_Max × V IN_Max

The inductor is one of the main components required by the I = --------------------------------------------------

L

boost converter to store energy. The amount of energy stored

in the inductor and transferred to the load is controlled by the

where TON_Max = 1.25µS. The recommended inductor for

regulator using PWM and pulse skipping techniques. In most

driving upto 6 LEDs, type QTLP670CiW is L = 6.8µH rated

cases, the FAN5606 operates the inductor in discontinuous

at minimum 0.5A.

conduction mode.

Low ESR capacitors should be used to minimize the input

To ensure proper operation of the current regulator over the

and output ripple voltage. Use of CIN = 4.7µF/6.3V and

entire range of conditions, the inductor should be selected

COUT = 4.7µF/25V type X5R/X7R multi layer ceramic

based on the maximum required power (POUT) and the mini-

capacitor are recommended.

mum input voltage (VIN).

2

( V IN ) × F A larger value input capacitor placed as close as possible to

L < --------------------------- FAN5606 may be needed to reduce the input voltage ripple

P OUT

in noise sensitive applications. An additional LC filter

between the battery and the FAN5606 input can help to fur-

where units of L, VIN, and POUT are in µH, Volt, and Watt, ther reduces the battery ripple to the level required by a par-

respectively and F = 0.4 is a factor depending upon the ticular application.

FAN5606 architecture.

6 REV. 1.0.3 1/7/05

PRODUCT SPECIFICATION FAN5606

Typical Performance Characteristics

TA = 25 °C, CIN = 47µF, COUT = 4.7µF, L = 6.8µH, unless otherwise noted.

Regulated LED Current vs Input Voltage Efficiency vs Input Voltage

10.5 0.95

20 2 x 20mA Load, L = 22µH

5.4

0.90

10.0 19

5.2 0.85

Efficiency (%)

LED Current (mA)

LED Current (mA)

LED Current (mA)

0.80

Scale1

18

Scale2

5.0 9.5

Scale3

0.75

17

4.8 A=1, B=0 Scale1 0.70

A=0, B=1 Scale2 9.0

A=1, B=1 Scale3 16 4 x 20mA Load, L = 6.8µH

0.65

4.6

8.5 15 0.60

2.5 3.0 3.5 4.0 4.5 5.0 5.5 2.5 3.0 3.5 4.0 4.5 5.0 5.5

Input Voltage (V) Input Voltage (V)

Shutdown Current vs Input Voltage

0.065

0.060

Shutdown Current (µA)

0.055

0.050

0.045

0.040

0.035

2.5 3.0 3.5 4.0 4.5 5.0 5.5

Input Voltage (V)

REV. 1.0.3 1/7/05 7

FAN5606 PRODUCT SPECIFICATION

Mechanical Dimensions

3x3mm 8-Lead MLP (Internal Schottky Diode)

2.54

GND 1.37 VOUT

0.76

3.0 A 1.27

0.15 C 8 5

2X B

1.99 3.30

1.18

1.40

3.0

(0.65)

1 4

0.15 C

0.65 TYP 0.42 MAX

2X

TOP VIEW

0.8 MAX RECOMMENDED LAND PATTERN

0.10 C

(0.20)

0.08 C

0.05

0.00 C

SEATING SIDE VIEW

PLANE

2.54 MAX

1.37 0.76

PIN #1 IDENT

1.26

1 4

0.45

0.43

1.40 MAX

1.18

8 5

0.25~0.35

0.65 0.10 M C A B

1.95 0.05 M

BOTTOM VIEW

NOTES:

A. CONFORMS TO JEDEC REGISTRATION MO-229,

VARIATION VEEC, DATED 11/2001

B. DIMENSIONS ARE IN MILLIMETERS.

C. DIMENSIONS AND TOLERANCES PER

ASME Y14.5M, 1994

8 REV. 1.0.3 1/7/05

PRODUCT SPECIFICATION FAN5606

Ordering Information

Product Number Package Type Order Code

FAN5606 8-Lead 3x3mm MLP FAN5606DMPX

DISCLAIMER

FAIRCHILD SEMICONDUCTOR RESERVES THE RIGHT TO MAKE CHANGES WITHOUT FURTHER NOTICE TO

ANY PRODUCTS HEREIN TO IMPROVE RELIABILITY, FUNCTION OR DESIGN. FAIRCHILD DOES NOT ASSUME

ANY LIABILITY ARISING OUT OF THE APPLICATION OR USE OF ANY PRODUCT OR CIRCUIT DESCRIBED HEREIN;

NEITHER DOES IT CONVEY ANY LICENSE UNDER ITS PATENT RIGHTS, NOR THE RIGHTS OF OTHERS.

LIFE SUPPORT POLICY

FAIRCHILD’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES

OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF FAIRCHILD SEMICONDUCTOR

CORPORATION. As used herein:

1. Life support devices or systems are devices or systems 2. A critical component in any component of a life support

which, (a) are intended for surgical implant into the body, device or system whose failure to perform can be

or (b) support or sustain life, and (c) whose failure to reasonably expected to cause the failure of the life support

perform when properly used in accordance with device or system, or to affect its safety or effectiveness.

instructions for use provided in the labeling, can be

reasonably expected to result in a significant injury of the

user.

www.fairchildsemi.com

REV. 1.0.3 5/12/04

2005 Fairchild Semiconductor Corporation

You might also like

- Last Time Buy: 16-Bit Serial Input, Constant-Current Latched LED DriverDocument13 pagesLast Time Buy: 16-Bit Serial Input, Constant-Current Latched LED DriverDario Ochoa CoronelNo ratings yet

- AL8860EV2 User GuideDocument8 pagesAL8860EV2 User GuideHans ClarinNo ratings yet

- Switched Capacitor Voltage Converter With Regulated Output ADP3604Document8 pagesSwitched Capacitor Voltage Converter With Regulated Output ADP3604Luís GuerreiroNo ratings yet

- Shenzhen Sunmoon Micro SM2255E - C881537Document12 pagesShenzhen Sunmoon Micro SM2255E - C881537Technical sidhuNo ratings yet

- TB67H451FNG: PWM Chopper Type DC Brushed Motor DriverDocument21 pagesTB67H451FNG: PWM Chopper Type DC Brushed Motor Drivermalak na3eemNo ratings yet

- Data Sheet: TDA6111QDocument16 pagesData Sheet: TDA6111QNestor TorresNo ratings yet

- MIC5209 500ma Low Noise LDO Regulator DS20005720B-2905047Document31 pagesMIC5209 500ma Low Noise LDO Regulator DS20005720B-2905047jaime elias gil rocaNo ratings yet

- AP8012 ChipownDocument8 pagesAP8012 ChipownRavi ChavhanNo ratings yet

- Hx712 English Datasheet PDFDocument9 pagesHx712 English Datasheet PDFkibriaNo ratings yet

- Data Sheet Se5004L: 5 GHZ, 26Dbm Power Amplifier With Power Detector Applications Product DescriptionDocument9 pagesData Sheet Se5004L: 5 GHZ, 26Dbm Power Amplifier With Power Detector Applications Product DescriptionashfaqNo ratings yet

- Datasheet AP72200Document30 pagesDatasheet AP72200ecoplazabrNo ratings yet

- HX711 Avia SemiconductorDocument9 pagesHX711 Avia SemiconductorAnjar Bangsa MimpiNo ratings yet

- 2A, 380 KHZ Step-Down Converter: The Future of Analog Ic TechnologyDocument10 pages2A, 380 KHZ Step-Down Converter: The Future of Analog Ic TechnologyAnonymous aP1FSUPoNo ratings yet

- gm07652r PDFDocument21 pagesgm07652r PDFjose luisNo ratings yet

- ZH-CN enDocument12 pagesZH-CN enTanmay MalhotraNo ratings yet

- 10A45 SimerahDocument8 pages10A45 Simerahega nur aziesNo ratings yet

- Off-Line Quasi-Resonant Switching Regulators: STR-Y6763, STR-Y6765, and STR-Y6766Document13 pagesOff-Line Quasi-Resonant Switching Regulators: STR-Y6763, STR-Y6765, and STR-Y6766Renato Luther escalanteNo ratings yet

- AOZ2023PIDocument11 pagesAOZ2023PIjuliocunachiNo ratings yet

- Embedded ASIC Macrocell: Power Management RE028 Fixed 4.5V 30 Ma LDO Voltage RegulatorDocument9 pagesEmbedded ASIC Macrocell: Power Management RE028 Fixed 4.5V 30 Ma LDO Voltage RegulatorHILLNo ratings yet

- X60008B-25, X60008C-25, X60008D-25: Precision 2.5V FGA™ Voltage ReferenceDocument10 pagesX60008B-25, X60008C-25, X60008D-25: Precision 2.5V FGA™ Voltage ReferenceDiego Felipe Silva VarelaNo ratings yet

- AL8862QDocument17 pagesAL8862QIvo MatosNo ratings yet

- AL8861EV1 User GuideDocument8 pagesAL8861EV1 User GuideHans ClarinNo ratings yet

- DM0565RDocument20 pagesDM0565RSURESH CHANDRA ROUTNo ratings yet

- R1162x SERIES: 3-Mode 150ma Ldo Regulator OutlineDocument32 pagesR1162x SERIES: 3-Mode 150ma Ldo Regulator OutlineZak zsNo ratings yet

- 24-Bit Analog-to-Digital Converter (ADC) With Built-In Temperature SensorDocument8 pages24-Bit Analog-to-Digital Converter (ADC) With Built-In Temperature SensorFabricio AmaguañaNo ratings yet

- Datasheet DMO565RDocument21 pagesDatasheet DMO565RSteve Bravo83% (6)

- MP2212 r1.01Document14 pagesMP2212 r1.01Joseni FigueiredoNo ratings yet

- 200mW Stereo Power Amplifier With Shutdown: Features DescriptionDocument17 pages200mW Stereo Power Amplifier With Shutdown: Features DescriptionRavi kumarNo ratings yet

- APL5932A/B/C/D: Features General DescriptionDocument21 pagesAPL5932A/B/C/D: Features General DescriptionAku KudupiknikNo ratings yet

- Data SheetDocument2 pagesData SheetEdmir Jose QuirinoNo ratings yet

- UC3840Document4 pagesUC3840raveendraNo ratings yet

- Driver MC34152Document4 pagesDriver MC34152William RamírezNo ratings yet

- Dual, 8-Bit, Voltage-Output Serial DAC in 8-Pin SO PackageDocument12 pagesDual, 8-Bit, Voltage-Output Serial DAC in 8-Pin SO PackagemvpgmNo ratings yet

- MC33879Document26 pagesMC33879AENo ratings yet

- Ultra High Frequency PrescalerDocument4 pagesUltra High Frequency PrescalerPadmajan YesodharanNo ratings yet

- Precision 2.5V FGA™ Voltage Reference: X60008B-25 X60008C-25 X60008D-25Document10 pagesPrecision 2.5V FGA™ Voltage Reference: X60008B-25 X60008C-25 X60008D-25Alejandro HerediaNo ratings yet

- AL5815EV1 User GuideDocument8 pagesAL5815EV1 User GuideJuan Vicente Hernandez LogytelNo ratings yet

- Shouding: Features General DescriptionDocument7 pagesShouding: Features General DescriptionJuan SenatoriNo ratings yet

- Features Applications: Slis124D - June 2006 - Revised February 2008Document21 pagesFeatures Applications: Slis124D - June 2006 - Revised February 2008Ahmad FarisNo ratings yet

- Al8860 1019719Document18 pagesAl8860 1019719hansNo ratings yet

- FOD3184 Opto Mosfet, IgbtDocument23 pagesFOD3184 Opto Mosfet, IgbtManuel SierraNo ratings yet

- AP62200/AP62201/AP62200T: 4.2V To 18V Input, 2A Low Iq Synchronous Buck ConverterDocument24 pagesAP62200/AP62201/AP62200T: 4.2V To 18V Input, 2A Low Iq Synchronous Buck ConverterAarsol AdvanceNo ratings yet

- SYFgtj MZ2 Ds X6 TRXC ZSog 91 Yk JZW 30 IUBtl 8 JAb JDocument34 pagesSYFgtj MZ2 Ds X6 TRXC ZSog 91 Yk JZW 30 IUBtl 8 JAb Jccpsf4fkhtNo ratings yet

- Digital Electronics Course MaterialDocument54 pagesDigital Electronics Course MaterialMuhammad SalisNo ratings yet

- Fairchild - Semiconductor FAN73611MX DatasheetDocument14 pagesFairchild - Semiconductor FAN73611MX DatasheetDeddy WilopoNo ratings yet

- 6A High-Speed Power MOSFET Drivers: Features General DescriptionDocument30 pages6A High-Speed Power MOSFET Drivers: Features General DescriptionDonchon chungNo ratings yet

- SEIPRA Girouette AV Minibus - MBI5168Document15 pagesSEIPRA Girouette AV Minibus - MBI5168Smec KEOLISNo ratings yet

- Mcp1407driver BufferDocument28 pagesMcp1407driver BufferAntonio NappaNo ratings yet

- MCP1640/B/C/D: 0.65V Start-Up Synchronous Boost Regulator With True Output Disconnect or Input/Output Bypass OptionDocument32 pagesMCP1640/B/C/D: 0.65V Start-Up Synchronous Boost Regulator With True Output Disconnect or Input/Output Bypass OptionseseNo ratings yet

- Charge Pump DC-to-DC Voltage Converter: Features Package TypesDocument20 pagesCharge Pump DC-to-DC Voltage Converter: Features Package TypesTomás CuetoNo ratings yet

- SDC606 SDCDocument11 pagesSDC606 SDCGopalNo ratings yet

- SDC606 SDC PDFDocument11 pagesSDC606 SDC PDFGopalNo ratings yet

- Features Description: Ltc3565 1.25A, 4Mhz, Synchronous Step-Down DC/DC ConverterDocument22 pagesFeatures Description: Ltc3565 1.25A, 4Mhz, Synchronous Step-Down DC/DC Converterferney_09No ratings yet

- AD584KNZ Precision Voltage ReferenceDocument13 pagesAD584KNZ Precision Voltage ReferenceRoger O. ThornhillNo ratings yet

- 2576 LDocument9 pages2576 LclanonNo ratings yet

- Vishay Telefunken: D D D D D D DDocument9 pagesVishay Telefunken: D D D D D D DMubarak AliNo ratings yet

- Features: Lt1930/Lt1930A 1A, 1.2Mhz/2.2Mhz, Step-Up DC/DC Converters in ThinsotDocument12 pagesFeatures: Lt1930/Lt1930A 1A, 1.2Mhz/2.2Mhz, Step-Up DC/DC Converters in ThinsotMubarak AliNo ratings yet

- Types R1275NS14# To R1275NS21#: Distributed Gate ThyristorDocument12 pagesTypes R1275NS14# To R1275NS21#: Distributed Gate ThyristorMubarak AliNo ratings yet

- Vishay Telefunken: D D D D D D DDocument9 pagesVishay Telefunken: D D D D D D DMubarak AliNo ratings yet

- Vishay Telefunken: D D D D D D DDocument9 pagesVishay Telefunken: D D D D D D DMubarak AliNo ratings yet

- The Physical Arrangement Based On The SLP Method, An Analysis On The LCM Fabrication ProcessDocument6 pagesThe Physical Arrangement Based On The SLP Method, An Analysis On The LCM Fabrication ProcessIJAERS JOURNALNo ratings yet

- Hitachi Plasma 32pd5200Document101 pagesHitachi Plasma 32pd5200philiphendersonNo ratings yet

- Vestel 17pw26-4 PDFDocument1 pageVestel 17pw26-4 PDFjoseNo ratings yet

- Vestel 17pw26-4 PDFDocument1 pageVestel 17pw26-4 PDFjoseNo ratings yet

- HP Prodisplay P17A 17-Inch 5:4 Led Backlit Monitor: Your Legacy-Friendly Everyday Business MonitorDocument3 pagesHP Prodisplay P17A 17-Inch 5:4 Led Backlit Monitor: Your Legacy-Friendly Everyday Business MonitorMubarak AliNo ratings yet

- 32 PD 5000Document101 pages32 PD 5000Mubarak AliNo ratings yet

- Product Specification: Au Optronics CorporationDocument20 pagesProduct Specification: Au Optronics CorporationMubarak AliNo ratings yet

- Soft 4 LedDocument1 pageSoft 4 LedMubarak AliNo ratings yet

- HP Prodisplay P17A 17-Inch 5:4 Led Backlit Monitor: Your Legacy-Friendly Everyday Business MonitorDocument3 pagesHP Prodisplay P17A 17-Inch 5:4 Led Backlit Monitor: Your Legacy-Friendly Everyday Business MonitorMubarak AliNo ratings yet

- HP Prodisplay P17A 17-Inch 5:4 Led Backlit Monitor: Your Legacy-Friendly Everyday Business MonitorDocument3 pagesHP Prodisplay P17A 17-Inch 5:4 Led Backlit Monitor: Your Legacy-Friendly Everyday Business MonitorMubarak AliNo ratings yet

- A Project Report On: Design of AC 220V To Variable DC Converter"Document17 pagesA Project Report On: Design of AC 220V To Variable DC Converter"Akram HossenNo ratings yet

- Vlsi Device Modelling ENP 302Document9 pagesVlsi Device Modelling ENP 302BT19ECE067 MiteshNo ratings yet

- LTNB (lt1616fs)Document16 pagesLTNB (lt1616fs)CeasarNo ratings yet

- Experimental Investigation of Harmonics in A Grid-Tied Solar Photovoltaic SystemDocument7 pagesExperimental Investigation of Harmonics in A Grid-Tied Solar Photovoltaic SystemEarl IneNo ratings yet

- VG-2W Series: MotienDocument4 pagesVG-2W Series: MotienYonatan RivadeneyraNo ratings yet

- DatasheetDocument13 pagesDatasheetkishore kumarNo ratings yet

- Edc Viva QuestionsDocument12 pagesEdc Viva Questionsitchai uchia100% (1)

- Chapter 2 FinalDocument83 pagesChapter 2 FinalSana SaleemNo ratings yet

- Daikin PSL Controller GK247A - J-088Document2 pagesDaikin PSL Controller GK247A - J-088sunhuynhNo ratings yet

- Instruktsiya Po Ekspluatatsii - YCIV (En) .1218012617Document128 pagesInstruktsiya Po Ekspluatatsii - YCIV (En) .1218012617lilli786No ratings yet

- Control of 3-Leg 4-Wire Inverter With Passive LC Output Filter Operating With Nonlinear Unbalanced LoadDocument6 pagesControl of 3-Leg 4-Wire Inverter With Passive LC Output Filter Operating With Nonlinear Unbalanced Loadsanafayaz12No ratings yet

- Maritime University of Szczecin: InstructionDocument10 pagesMaritime University of Szczecin: InstructionFred GrosfilerNo ratings yet

- STI3470 600KHz - 18V 2.0A Synchronous Step - Down ConverterDocument10 pagesSTI3470 600KHz - 18V 2.0A Synchronous Step - Down ConverterHoson AkNo ratings yet

- Electronic ProjectDocument48 pagesElectronic Projectshehryar khanNo ratings yet

- Harmonics Cancellation and Alleviation of Ripple Content From AC-DC Uncontrolled Rectifier by Pulse-Multiplication Technique Using Phase-Shifting TransformerDocument7 pagesHarmonics Cancellation and Alleviation of Ripple Content From AC-DC Uncontrolled Rectifier by Pulse-Multiplication Technique Using Phase-Shifting TransformerBhanu ThestarNo ratings yet

- Datasheet IC LM304Document6 pagesDatasheet IC LM304Tờ RungNo ratings yet

- TSD 1395Document2 pagesTSD 1395vincent02hk_57881301No ratings yet

- Ieee76b8073a Ed83 20160227121547 PDFDocument13 pagesIeee76b8073a Ed83 20160227121547 PDFSani1248No ratings yet

- TPC PS-35-XSDocument4 pagesTPC PS-35-XStoppowerNo ratings yet

- Simple Circuit Design Tutorial For PoE ApplicationsDocument10 pagesSimple Circuit Design Tutorial For PoE ApplicationsTayyeb AliNo ratings yet

- MT7636 DS-EN - Rev1.30Document9 pagesMT7636 DS-EN - Rev1.30Vishal dtuNo ratings yet

- Telephone Exchange SystemDocument7 pagesTelephone Exchange SystemkellechaiNo ratings yet

- LM 2676Document37 pagesLM 2676api-432313169No ratings yet

- Power Distribution BoardDocument10 pagesPower Distribution BoardMouayed ZeadanNo ratings yet

- Design and Construction of Load Sharing Control System Using PIC MicrocontrollerDocument10 pagesDesign and Construction of Load Sharing Control System Using PIC MicrocontrollerFuture Technovation75% (4)

- DC Electrification Supply System DesignDocument29 pagesDC Electrification Supply System Design曾乙申100% (4)

- SMS Based Automatic Two Wheeler Locking SystemDocument42 pagesSMS Based Automatic Two Wheeler Locking SystemmboomiNo ratings yet

- Explain The Importance of Electronics in Everyday LifeDocument10 pagesExplain The Importance of Electronics in Everyday Lifekelvin msossyNo ratings yet

- Report of IoT Based Power Theft Detection System (01 Suit)Document49 pagesReport of IoT Based Power Theft Detection System (01 Suit)sumit.copy12No ratings yet

- Analytical Method DC Link CapacitorDocument8 pagesAnalytical Method DC Link CapacitorAnonymous 3qfK4rrYuNo ratings yet