Professional Documents

Culture Documents

Instruction Manual For The Top Repairable Accumulator: Spare Parts

Uploaded by

Wilson Muñoz ArayaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Instruction Manual For The Top Repairable Accumulator: Spare Parts

Uploaded by

Wilson Muñoz ArayaCopyright:

Available Formats

Instruction Manual

for the Top Repairable

Accumulator

INSPECTING THE CONDITION AFTER DELIVERY

After unpacking the accumulator, inspect it for possible

damage caused during transit.

1. Inspect the Locknut, Jamnut and Beeder Plug for

3 1

tightness. 2

2. Check the precharge tag. The accumulator is either

precharged to 25 psig (1.7 bar) for shipping purposes

(indicated by a red tag) or it is charged to the pressure

specified on the purchase order (indicated by a green tag).

11 12 3. Check that the working pressure stamped on the

Reinstall the OilAir Charging & Gauging Assembly Remove the Charging & Gauging Assembly and accumulator shell is greater than or equal to the maximum 12

system pressure of the system.

* (OAH Part Number - T-CG-3000) and precharge the firmly install the yellow valve cap and the protective

accumulator with DRY NITROGEN ONLY, to its cap. Retighten the jamnut and the locknut on the fluid 4

required level, at a moderate rate of speed. It is a and the gas ends. PROTECTION & PRECAUTIONS

good idea to check for leaks around the valve Hand Protection 8

Always use chemical resistant gloves, when needed, to

stem using “snoop” or some other water based 6

solution which does not promote rusting. avoid prolonged or repeated exposure to cleaning 9

solutions or solvents.

Eye Protection 13 10 11 5 7

* CG-5000 for 5000 PSI Accumulators Always use safety glasses while performing any

maintenance on the accumulator!

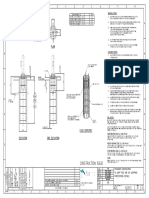

SPARE PARTS

OTHER PRECAUTIONS: 1. Shell 8. Spacer

DO NOT operate the accumulator beyond the allowable working 2. Bladder 9. Lock Nut

pressure and temperature limitations stamped or attached to the 3. Plug 10. Valve Cap

product. 4. Anti Extrusion Ring 11. Hex Jam Nut

Use only the tools recommended in this manual to perform 5. Metal Back Up Ring 12. Protective Cap

maintenance procedures. 6. "O" Ring 13. Bleeder Plug

Use only DRY NITROGEN when charging the accumulator. 7. Rubber Back Up (Not available for 1 quart

NEVER USE OXYGEN OR AIR, as this may result in an and 1 gallon sizes)

STORAGE: explosion. Use only valve cores approved for accumulator

service. NEVER USE AN AUTOMOTIVE TYPE VALVE CORE.

Accumulator storage instructions OILAIR ORIGINAL EQUIPMENT LIMITED

If after reassembly, the accumulators are stored, they must be charged with a low nitrogen pressure of 25 PRECHARGING:

WARRANTY 1. Use DRY NITROGEN ONLY to precharge the

psi (1.5 bar) and store in a cool and dry area. The fluid port must be sealed. The accumulator can be

accumulator.

stored in any position. The protective cap on the gas charging valve must be securely tightened to protect OILAIR warrants each of its products against 2. Use the OilAir Hydraulics’ charging assembly [T-CG-3000 for 1 5

it from any shock. original defects in materials and/or workmanship 3 KPSI or CG-5000 for 5 KPSI] to charge the accumulator to

and will repair or replace any product which is the required precharge if it does not already been precharge

Attach a label to the accumulator stating that they must be precharged before installing in the system. determined by OILAIR, within one (1) year of its by the factory.

installation, to be defective or below the manu- 3. Check the charging valve for leaks using snoop or a soapy

facturing standards of OILAIR, including warranty solution.

of merchantability, fitness for the purpose 4. Tighten the Jamnut at the gas valve stem and also the

If the accumulator is stored for longer than 6 years, all the elastomeric components (bladder, seals etc.)

intended, consequential and incidental damage Locknut on the fluid port with a wrench.

must be replaced. of liability. This Original Equipment Warranty 5. Tighten the valve cap on the gas valve stem and the

which anticipates installation by third parties, protective cap on the bladder stem to the hand-tight position.

expressly excludes warranty of merchantability, 5. Check the gas precharge pressure periodically. This must

BLADDER STORAGE INSTRUCTIONS: fitness for the purpose and consequential or be done after all the hydraulic system pressure is released.

incidental damage liability. The precharge must be checked once in the first week of opera-

tion, and then every six months during normal working condi-

DO NOT OPEN PLASTIC BAG UNTIL READY FOR INSTALLATION.

OPERATION OF ANY OILAIR ACCUMULATOR tions (or every month during high cycling or high temperature 4 2 3

DO NOT USE RAZOR OR SHARP OBJECTS TO OPEN THE PLASTIC BAG. OR COMPONENT BEYOND THE conditions).

MANUFACTURER'S WORKING PRESSURE

Bladder plastic bag must be stored in a cool (preferably 720 F), dry and dark place out of direct sunlight, LIMITATIONS, OR IN VIOLATION OF ANY INSTALLATION: TOOLS

fluorescent light, ultraviolet light and away from electrical equipment. OPERATING OR SERVICE INSTRUCTION The accumulator should be mounted vertically with fluid port on

STAMPED OR ATTACHED TO THE PRODUCT, bottom and gas valve on top using supporting brackets and 1. Charging & Gauging Assy - P.N. T-CG-3000

Direct sunlight or fluorescent light may cause the bladder to weather check and/or dry rot, which appears EXPRESSLY VOIDS THIS WARRANTY saddles specifically designed for accumulator mounting. For other 2. Spanner Wrench - P.N. 11-502

on the bladder surface as cracks. AND MAY BE DANGEROUS TO LIFE AND mounting configurations, consult the factory. Do not weld any 3. Ratchet Wrench (Corresponds to elastic

PROPERTY. supports to the accumulator. Doing so will void its pressure ves- stop nut and bleeder plug size)

sel certification! To facilitate periodic maintenance and precharge 4. Rubber Mallet

checking, an accumulator dump valve (ADV) should be installed 5. Tool Box

between the accumulator and system pressure line.

11505 West Little York Houston, Texas 77041 Tel: (713) 937-8900 Fax: (713) 937-0438

© copyright 1995 OilAir Hydraulics, Inc. Printed in USA Bulletin #MMM95

OLAER GROUP COMPANY OLAER GROUP COMPANY

DISASSEMBLY ASSEMBLY

Cleaning & Inspection

Clean all the metallic parts of the accumulator with

an organic solvent. Avoid exposing rubber compo-

nents to the solvent. Doing so may cause them to

decompose! Inspect the condition of the port

adapter and replace it if damaged. Clean the blad-

der with isopropyl alcohol or equivalent. Inspect the

bladder for any signs of visual damage. Replace if

necessary. Check that there is no corrosion inside

or outside of the shell. Replace any part which you

1 2 3 1 2

may suspect of being defective. The "O" ring and

Removal from the system After removing all hydrau- Remove the yellow cap from the valve stem. Discharge any pressure in the accumulator using back up rings must be replaced. Squeeze the bladder to discharge gas from it by Install the valve adapter; tighten to 90 inch-pounds

lic pressure from the system, remove the protective the OilAir Hydraulics charging and gauging assem- rolling it up from the bottom. of torque.

cap from the valve stem. bly, OAH Part number TCG-3000 (or CG-5000 for 5

kpsi models).

4 5 6 3 4 5

Once the remaining nitrogen has been discharged, Disassembly Remove the jamnut (attached to the Remove the locknut (the larger nut) using a span- Lubricate the accumulator shell and the bladder with Insert the port adapter carefully into the shell. Squeeze the anti-extrusion ring and insert it into the

remove the valve adapter using a socket wrench. valve stem), using a socket wrench, to free the blad- ner wrench (OAH Part Number 11-502). system fluid or similar product, then insert the blad- Be careful not to drop the port adapter into the shell.

(*If accumulator is mounted vertically, perform steps der from the accumulator. der into the shell. Rotate the shell around its axis shell! Slide the valve stem of the bladder through

5 through 12 before performing this step). several times to lubricate the bladder uniformly. the port adapter.

ALWAYS WEAR GLOVES! *

7 8 9 6 7 8

Remove the spacer washer located directly under- Push the plug assembly (bladder and top- Remove the O-ring, O-ring back-up and metal back- Carefully pull the port adapter through the anti ex- Install the OilAir Charging & Gauging assembly on Slide the metal back-up ring, “O”ring and rubber

neath the lock-nut. repairable adapter) into the accumulator shell. up rings (avoid letting these items fall into the trusion ring and on through the port opening of the to the valve adapter and fill the accumulator with back-up ring, in this order, on at a time, over the port

shell; it will be difficult to retrieve these items, shell. Nitrogen up to 30 psig (2 bar). This helps to seat adapter and all the way into the port opening, firmly

especially if your accumulators are vertically the port adapter and anti-extrusion ring into the against the anti-extrusion ring. (The “O”ring may

mounted). shell opening. Remove the C & G assembly. require some force to get it into position.)

10 11 12 9 10

Slide the anti-extrusion ring off of the adapter. Fold Remove the port adapter from the shell. Squeeze out any residual Nitrogen and gently re- Slide the spacer over the port adapter until it touches Using a socket wrench, install the Jamnut onto the Continued ❘ ❘ ❙ ❙ ❚ ❚ ◗

the ring and carefully pull it out of the shell. Be very move the bladder from the shell. the shell. Screw the locknut onto the port adapter valve stem of the bladder.

careful not to pinch your fingers as you are performing and tighten it using a spanner wrench

this operation. [Be sure to keep a firm grasp on the (OAH Part Number - 11-502).

port adapter to prevent it from falling inside the shell.]

* IfIf the

the fluid port body does not go inside, then there is some hydraulic pressure left inside the accumulator. If this happens, do not attempt to do any maintenance. Consult the factory.

accumulator is mounted vertically, step 4 should be delayed until steps 5 through 12 are completed. Additionally, a bladder pull rod (not shown, OAH Part Number 11-503-4) should be attached to the

For accumulators mounted vertically, pull rods (OAH Part Number 11-503-4) should be attached to the valve stem following step 2, to prevent from falling into the accumulator. Some hydraulic

*oils are known to contain carcinogenic or cancer causing additives! After step 6 install the jamnut and outer locknut to hold the bladder and adapter in place, then the pull rod can be repaired.

*valve adaptor after step 3 is complete, to prevent parts from falling into the shell. Then proceed with step 7.

You might also like

- Tape Area: SpliceDocument2 pagesTape Area: SpliceMiguel RamirezNo ratings yet

- Disassembly RoHSWEEE FPS 48V Basic 1U2R (E - 2129976 - 1 - 3) - 1Document2 pagesDisassembly RoHSWEEE FPS 48V Basic 1U2R (E - 2129976 - 1 - 3) - 1v9rbqae9d7fg0wNo ratings yet

- At-Dom24-58-At-Dom24 ManualDocument5 pagesAt-Dom24-58-At-Dom24 ManualJuanNo ratings yet

- GT S7390 2 Service ManualDocument51 pagesGT S7390 2 Service ManualgonzaloNo ratings yet

- Evap P.T. Cap MechanismDocument3 pagesEvap P.T. Cap MechanismKuldeep SinghNo ratings yet

- Pages From SAT-4208-AL-T-MAR-ME-003-00 (1) - 6Document42 pagesPages From SAT-4208-AL-T-MAR-ME-003-00 (1) - 6Navid Akhtar Abdul SattarNo ratings yet

- WEG WMO Brake Motor Instruction Manual For Installation Operation Maintenance of Brake Motors 50021973 Brochure English WebDocument2 pagesWEG WMO Brake Motor Instruction Manual For Installation Operation Maintenance of Brake Motors 50021973 Brochure English WebMiguel LunaNo ratings yet

- KRMF706ESS00 Tech Sheet - W10738568 - Kitchen AidDocument2 pagesKRMF706ESS00 Tech Sheet - W10738568 - Kitchen AidEdison EspinalNo ratings yet

- Chemical Spill KitDocument1 pageChemical Spill KitVirna Estela BunanNo ratings yet

- Section I - Switchgear & Substation ApparatusDocument1 pageSection I - Switchgear & Substation ApparatusYasir MehmoodNo ratings yet

- 2013.08 RCT100 +TR430 ManualDocument2 pages2013.08 RCT100 +TR430 ManualhungryscribeNo ratings yet

- Preventive Maintenance PM-Freq (Q/H/Y) : - Check Points Checked Remarks Action Taken Status YES NODocument1 pagePreventive Maintenance PM-Freq (Q/H/Y) : - Check Points Checked Remarks Action Taken Status YES NOGnanavel GNo ratings yet

- Air Vent Valve SamyangDocument1 pageAir Vent Valve SamyangAnonymous MYUWvUrhdbNo ratings yet

- Read This First: Required ToolsDocument2 pagesRead This First: Required ToolsEmmanuel AladroNo ratings yet

- Sop of k3 A B Off Gas Compressor Start Up After Maintenance.Document4 pagesSop of k3 A B Off Gas Compressor Start Up After Maintenance.00083583rfNo ratings yet

- Air Over Oil Packing Lube System OM - 6288330 - 01Document14 pagesAir Over Oil Packing Lube System OM - 6288330 - 01harshal patilNo ratings yet

- 102.SOP - Lifting, Rigging & Slinging - Rev01Document4 pages102.SOP - Lifting, Rigging & Slinging - Rev01Arjuna PetroNo ratings yet

- Theory and Practice of The Closed-Chamber Drillstelll Test MethodDocument6 pagesTheory and Practice of The Closed-Chamber Drillstelll Test MethodvastaguenNo ratings yet

- Scmbac-2023 Quarterly ReportDocument1 pageScmbac-2023 Quarterly ReportAlbert TayabasNo ratings yet

- 106M5801K Diagramas de Conexionado 2300Document11 pages106M5801K Diagramas de Conexionado 2300Leinner RamirezNo ratings yet

- ToolsCat 74Document58 pagesToolsCat 742791957No ratings yet

- 25 M07194TXgardPlusUserManualIss4Sep11GB PDFDocument2 pages25 M07194TXgardPlusUserManualIss4Sep11GB PDFZalfa MaulanaNo ratings yet

- Consep Condenser / Separator Installation, Maintenance and InspectionDocument4 pagesConsep Condenser / Separator Installation, Maintenance and InspectioncarlosegomezfNo ratings yet

- GFK - Operating Instructions - 06.2014Document4 pagesGFK - Operating Instructions - 06.2014brotaccristianNo ratings yet

- 2019 A320 RefuelProcedureGuidelines - V2Document2 pages2019 A320 RefuelProcedureGuidelines - V2br213No ratings yet

- Nissan Skyline R32 Engine ManualDocument580 pagesNissan Skyline R32 Engine ManualEminence Imports100% (6)

- QRG (Us)Document2 pagesQRG (Us)sepehr1373shgNo ratings yet

- Bl-Nepl-Ip-Proj-0015 - Manifold Replacement Work Method StatementDocument4 pagesBl-Nepl-Ip-Proj-0015 - Manifold Replacement Work Method Statementsamuel madisonNo ratings yet

- Preventive Maintenance PM-Freq (Q/H/Y) : - Check Points Checked Remarks Action Taken Status YES NODocument1 pagePreventive Maintenance PM-Freq (Q/H/Y) : - Check Points Checked Remarks Action Taken Status YES NOGnanavel GNo ratings yet

- A5E34928958-01en PS2HART FBDocument2 pagesA5E34928958-01en PS2HART FBesutjiadiNo ratings yet

- Operating Instructions Gas Pressure Regulators VGBF: DK S N P GR D GB F NL I E TR CZ PL RUS HDocument8 pagesOperating Instructions Gas Pressure Regulators VGBF: DK S N P GR D GB F NL I E TR CZ PL RUS HLuis Enrique Vidal GachaNo ratings yet

- Construction Issue: General NotesDocument1 pageConstruction Issue: General NotesShokry AlkissyNo ratings yet

- Lampiran RKS ElectricalDocument10 pagesLampiran RKS ElectricalFuji HidayatNo ratings yet

- Safety SectionDocument10 pagesSafety SectionHussain Al NajjarNo ratings yet

- Checlist Maintenance Preventif (OK)Document2 pagesCheclist Maintenance Preventif (OK)Muhammad Jamaludin ridhoNo ratings yet

- Sce - Life Saving Equipment, Life Jackets: Tick The Appropriate Box To Indicate Which Areas Require To Be Complied WithDocument4 pagesSce - Life Saving Equipment, Life Jackets: Tick The Appropriate Box To Indicate Which Areas Require To Be Complied Withsafar matakNo ratings yet

- 46-89 Sears LGS 66812 Coldspot Refrigerator PDFDocument21 pages46-89 Sears LGS 66812 Coldspot Refrigerator PDFdrt1200No ratings yet

- Safety Tests DetailedDocument3 pagesSafety Tests Detailedtripathi prashantNo ratings yet

- Yamaha RX V365 Owners ManualDocument1 pageYamaha RX V365 Owners ManualandreiNo ratings yet

- Formato Removal & Installation Transmisión 994HDocument3 pagesFormato Removal & Installation Transmisión 994HJuanNo ratings yet

- Xiaomi Smart Humidifier 2-User ManualDocument1 pageXiaomi Smart Humidifier 2-User ManualSalvador AvelinoNo ratings yet

- GP4000 User ManualDocument1 pageGP4000 User Manualmateor_89No ratings yet

- JGC & JGD Compressor InstalationDocument6 pagesJGC & JGD Compressor InstalationAhmad Imam TohariNo ratings yet

- Pekerjaan Upgrade Turbine Protection and Tripping System Pltu Nii TanasaDocument5 pagesPekerjaan Upgrade Turbine Protection and Tripping System Pltu Nii TanasapaulNo ratings yet

- WC Daily Checklist Procedure - v1.1 - MH-1Document13 pagesWC Daily Checklist Procedure - v1.1 - MH-1Hatem RmNo ratings yet

- Pressure Switch Assembly For Portable Air Compressors: DescriptionDocument8 pagesPressure Switch Assembly For Portable Air Compressors: DescriptionA delca-No ratings yet

- Heating and Ventilating Contractors' AssociationDocument18 pagesHeating and Ventilating Contractors' AssociationHENo ratings yet

- FP-ERL4. Oil Level Regulator.: Cooling TechnologiesDocument2 pagesFP-ERL4. Oil Level Regulator.: Cooling TechnologiesChí Khang NguyễnNo ratings yet

- Flamgard PDFDocument2 pagesFlamgard PDFStalin JoseNo ratings yet

- Transducer Installation Guide: MaintenanceDocument2 pagesTransducer Installation Guide: MaintenanceJohn HedgepethNo ratings yet

- Turbocharger Trouble Shooting ChartDocument1 pageTurbocharger Trouble Shooting Chartvikrant GarudNo ratings yet

- P&id-Pressure Reducing Skic For HRSGDocument1 pageP&id-Pressure Reducing Skic For HRSGHsein WangNo ratings yet

- Busch Instruction Manual Mink MM 1104-1142 BV ATEX Gastight en 0870141675Document56 pagesBusch Instruction Manual Mink MM 1104-1142 BV ATEX Gastight en 0870141675Vinícius BardellaNo ratings yet

- Gate Valve Troubleshoot-3Document7 pagesGate Valve Troubleshoot-3Trushar GhosalkarNo ratings yet

- Check List Preventive MaintenanceDocument2 pagesCheck List Preventive MaintenancemainiNo ratings yet

- Bladder AccumulatorsDocument7 pagesBladder AccumulatorsMaciej KostenckiNo ratings yet

- AKT Operating Instructions - 2016Document6 pagesAKT Operating Instructions - 2016brotaccristianNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Plano Intercambiador de CalorDocument1 pagePlano Intercambiador de CalorWilson Muñoz ArayaNo ratings yet

- Plano Intercambiador de CalorDocument1 pagePlano Intercambiador de CalorWilson Muñoz ArayaNo ratings yet

- Installation Maintenance Guide GOODYEARDocument44 pagesInstallation Maintenance Guide GOODYEARWilson Muñoz ArayaNo ratings yet

- TensionRite® Belt Frequency MeterDocument31 pagesTensionRite® Belt Frequency MeterWilson Muñoz ArayaNo ratings yet

- TensionRite® Belt Frequency MeterDocument31 pagesTensionRite® Belt Frequency MeterWilson Muñoz ArayaNo ratings yet

- Installation Maintenance Guide GOODYEARDocument44 pagesInstallation Maintenance Guide GOODYEARWilson Muñoz ArayaNo ratings yet

- Soldadura de Seat LinerDocument3 pagesSoldadura de Seat LinerWilson Muñoz Araya100% (1)

- European Catalog Series 263 264 Air Operated Poppet Valves en 5143066Document2 pagesEuropean Catalog Series 263 264 Air Operated Poppet Valves en 5143066BalotileNo ratings yet

- Company Profile VH DamsDocument29 pagesCompany Profile VH DamsanbilselvamNo ratings yet

- Fopx 605Document62 pagesFopx 605Aleksanrd Mihailov0% (1)

- Versa Solenoid Valve PDFDocument36 pagesVersa Solenoid Valve PDFAbhayy DevNo ratings yet

- Pump GP - Main Hydraulic Main Control Valve: 320E RR Excavator Hydraulic System - AttachmentDocument2 pagesPump GP - Main Hydraulic Main Control Valve: 320E RR Excavator Hydraulic System - AttachmentYvan Vidal Calapuja MachacaNo ratings yet

- Installation Instructions: Parts in Kit Qty. DescriptionDocument11 pagesInstallation Instructions: Parts in Kit Qty. Descriptionjaime bolivarNo ratings yet

- York Check and Foot Valves: Technical CatalogueDocument14 pagesYork Check and Foot Valves: Technical CatalogueWilliam OeyNo ratings yet

- 4E Iron Valves CatalogueDocument9 pages4E Iron Valves CatalogueGuillermo de la Fuente SantiagoNo ratings yet

- Operation Manual General-36R4XTDocument33 pagesOperation Manual General-36R4XTMiguelNo ratings yet

- Scanreco G2 Radio Remote Control System, 20-13Document55 pagesScanreco G2 Radio Remote Control System, 20-13mauricio arias100% (4)

- Kfseriesfballvalves KF Series P3 Ball Valves: Superior Fluid Control ProductsDocument20 pagesKfseriesfballvalves KF Series P3 Ball Valves: Superior Fluid Control Productsdiego aguilarNo ratings yet

- Dynamometer CardsDocument115 pagesDynamometer CardsjohnrofaNo ratings yet

- L 700Document51 pagesL 700heartofdixieNo ratings yet

- IQ Range Installation and Maintenance InstructionsDocument88 pagesIQ Range Installation and Maintenance Instructionsxinying liu100% (1)

- Evo Duo Manual Us Lit91127us 05.2018Document67 pagesEvo Duo Manual Us Lit91127us 05.2018Ronal SolisNo ratings yet

- DPWH Price QuotationDocument1 pageDPWH Price QuotationRonaldo B VillaromanNo ratings yet

- Aqua Fittings CatalogueDocument5 pagesAqua Fittings CatalogueAnkit Kanojia100% (1)

- He Thong Chua Chay FoamDocument27 pagesHe Thong Chua Chay FoamVũ Hằng PhươngNo ratings yet

- 3 SOP For Cleaning of Clinker Cooler DischargeDocument3 pages3 SOP For Cleaning of Clinker Cooler DischargekakaNo ratings yet

- 11-3842 PSV Jump StartDocument20 pages11-3842 PSV Jump StartchikukotwalNo ratings yet

- Condensing Units: Installation and Operations ManualDocument40 pagesCondensing Units: Installation and Operations ManualHoàngViệtAnhNo ratings yet

- Fluid Mechanics I Lab - MENG 370L: Experiment 3: Venturi MeterDocument20 pagesFluid Mechanics I Lab - MENG 370L: Experiment 3: Venturi MeterMahdi GharibNo ratings yet

- Surface Manifold Equipment High and Low PressureDocument202 pagesSurface Manifold Equipment High and Low PressureGuidoNo ratings yet

- GLV-Catalogue - Botil IndiaDocument18 pagesGLV-Catalogue - Botil IndiaHamza LamamraNo ratings yet

- Owner's ManualDocument14 pagesOwner's ManualMiguel Almora GarciaNo ratings yet

- Series6400&6600 111C R2Document20 pagesSeries6400&6600 111C R2Nitin AggarwalNo ratings yet

- Goodnature - Brochure X1 ColdpressDocument25 pagesGoodnature - Brochure X1 ColdpressColdpressFranceNo ratings yet

- Hitachi-Man B&W Diesel Engine Service Data: Exhaust Valve Condition and Recommendation On M/E Low-Load OperationDocument5 pagesHitachi-Man B&W Diesel Engine Service Data: Exhaust Valve Condition and Recommendation On M/E Low-Load Operationg arvNo ratings yet

- Technical Manual: Air-Water Chillers and Heat Pumps For Outdoor InstallationDocument56 pagesTechnical Manual: Air-Water Chillers and Heat Pumps For Outdoor InstallationDumitru MariusNo ratings yet

- Operation and Maintenance Manual: Effluent Treatment PlantDocument49 pagesOperation and Maintenance Manual: Effluent Treatment PlantOmkar BharankarNo ratings yet