Professional Documents

Culture Documents

17 Samss 511

Uploaded by

Santhosh AliasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

17 Samss 511

Uploaded by

Santhosh AliasCopyright:

Available Formats

Materials System Specification

17-SAMSS-511 22 June 2020

Stationary Storage Batteries

Document Responsibility: UPS, DC Systems, and Power Electronics Standards

Committee

Previous Issue: 07 June 2017 Next Planned Update: 22 June 2025

Page 1 of 26

Contact: Dubaikel, Faisal A. (DUBAIKFA)

©Saudi Aramco 2020. All rights reserved.

Saudi Aramco: Company General Use

Document Responsibility: UPS, DC Systems, and Power Electronics Standards Committee 17-SAMSS-511

Issue Date: 22 June 2020

Next Planned Update: 22 June 2025 Stationary Storage Batteries

Contents

Summary of Changes ........................................................................................... 3

1 Scope .............................................................................................................. 4

2 Conflicts and Deviations.................................................................................. 4

3 References ...................................................................................................... 4

4 Field Experience .............................................................................................. 6

5 Service Conditions .......................................................................................... 6

6 General Design and Performance Requirements ............................................ 8

7 Vented (Flooded) Lead-Acid Batteries........................................................... 12

8 Valve Regulated Lead-Acid (Vrla) Batteries ................................................... 13

9 Nickel-Cadmium Batteries ............................................................................ 15

10 Lithium Iron Phosphate Batteries.................................................................. 16

11 Battery Racks (Indoors Mounting) ................................................................ 17

12 Battery Enclosures for Indoors Mounting ..................................................... 18

13 Battery Enclosures for Outdoors Mounting .................................................. 19

14 Battery Enclosures for Offshore Applications................................................ 19

15 Accessories ................................................................................................... 19

16 Markings (Follow Iec or Equivalent Standard) ............................................... 20

17 Tests ............................................................................................................. 21

18 Export Packing, Marking and Shipping .......................................................... 22

19 Drawings and Data Submittal in English Language ........................................ 22

Revision Summary ............................................................................................. 24

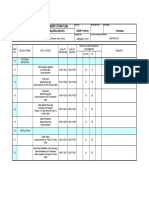

Data Schedule-1 ................................................................................................. 25

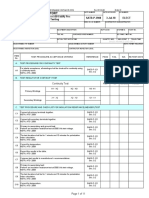

Data Schedule-2 ................................................................................................. 26

Page 2 of 26

Saudi Aramco: Company General Use

Document Responsibility: UPS, DC Systems, and Power Electronics Standards Committee 17-SAMSS-511

Issue Date: 22 June 2020

Next Planned Update: 22 June 2025 Stationary Storage Batteries

Summary of Changes

Paragraph Number Change Type

(Addition, Modification, Technical Change(s)

Previous Revision Current Revision Deletion)

(07 June 2017) (22 June 2020)

Added Lithium Iron Phosphate

1 1 Addition batteries (LiFEPO4).

3.2 3.2 Modification Updated the reference list

5 - Deletion Deleted deviation due to repetition

6.3.2 5.3.2 Modification Updated temperature requirement

Recharge to 10 hours instead of 8

7.2.1 6.2.1 Modification

hours

7.3 6.3 Modification Clarify warranty conditions

13 13 Modification Change the outdoor enclosure from

IP65 to IP55

Change the offshroe outdoor

14 14 Modification enclosure from IP65 to IP55 with

corrosion protection

Adding Lithium Iron Phosphate

Many Many batteries (LiFEPO4).batteries to the

Addition

Paragraphs Paragraphs specification

Page 3 of 26

Saudi Aramco: Company General Use

Document Responsibility: UPS, DC Systems, and Power Electronics Standards Committee 17-SAMSS-511

Issue Date: 22 June 2020

Next Planned Update: 22 June 2025 Stationary Storage Batteries

1 Scope

1.1 This specification defines the mandatory requirements for the purchase of the

following types of energy storage batteries for use in indoor or outdoor

industrial applications such as Substations, Uninterruptible Power Supply (UPS)

Systems, DC Systems, Communication Systems, Photovoltaic Systems, Wind

Generator Systems; Back-up and Standby power supplies:

Vented (Flooded) Lead-Acid Batteries: Tubular, Plante, Rod, and Pasted

Positive Plate; lead-calcium, lead-antimony, lead-selenium, and lead tin

alloys; or as specified on Data Schedule-1.

Nickel-Cadmium Batteries.

Valve Regulated Lead-Acid Batteries: Absorptive Glass Mat (AGM) and

Gelled Electrolyte (GEL).

Lithium Iron Phosphate batteries (LiFEPO4).

1.2 Excluded from this specification are batteries for self-contained emergency

lighting fixtures, automotive applications, engine-cranking and consumer-type

devices.

2 Conflicts and Deviations

2.1 Any conflict between this document and other Applicable Mandatory Saudi

Aramco Engineering Requirements (MSAERs) shall be addressed in writing to

the EK&RD Coordinator.

2.2 Any deviation from the requirements herein shall follow internal company

procedure SAEP-302.

2.3 The designation “Commentary” is used to label a sub-paragraph that contains

comments that are explanatory or advisory. These comments are not mandatory,

except to the extent that they explain mandatory requirements contained in this

SAMSS.

3 References

The following is a summary of all the documents which have been mentioned within

this specification. The specific part(s) of these documents which are applicable have

been identified throughout this specification.

3.1 Saudi Aramco References

Saudi Aramco Engineering Procedures

Page 4 of 26

Saudi Aramco: Company General Use

Document Responsibility: UPS, DC Systems, and Power Electronics Standards Committee 17-SAMSS-511

Issue Date: 22 June 2020

Next Planned Update: 22 June 2025 Stationary Storage Batteries

SAEP-302 Waiver of a Mandatory Saudi Aramco Engineering

Requirement

Saudi Aramco Inspection Requirements – Form 175

Form 175-173800 Inspection Requirements for Stationary Batteries

Saudi Aramco Forms and Data Sheets

Data Schedule-1 & Data Schedule-2

3.2 Industry Codes and Standards

International Electrotechnical Commission

IEC 60623 Vented Nickel-Cadmium Prismatic Rechargeable

Single cells

IEC 60707 Methods of Test for the Determination of the

Flammability of Solid Electrical Insulating

Materials When Exposed to an Igniting Source

IEC 60896-11 Stationary Lead-Acid Batteries – General

Requirements and Methods of Test, Part 1:

Vented Types

IEC 60896-21 Stationary Lead-Acid Batteries – General

Requirements and Methods of Test, Part 2: Valve

IEC 61960-3 Secondary cells and batteries containing alkaline or

other non-acid electrolytes- Lithium batteries

made of prismatic or cylindrical cells

IEC 61959 Secondary cells and batteries containing alkaline or

other non-acid electrolytes –Mechanical tests for

sealed portable secondary cells and batteries

Institute of Electrical & Electronic Engineers

IEEE 450 Recommended Practice for Maintenance, Testing,

and Replacement of Vented Lead-Acid Batteries

for Stationary Applications

IEEE 485 Recommended Practice for Sizing Lead-Acid

Batteries for Stationary Applications

IEEE 1013 Recommended Practice for Sizing Lead-Acid

Batteries for Photovoltaic (PV) Systems

Page 5 of 26

Saudi Aramco: Company General Use

Document Responsibility: UPS, DC Systems, and Power Electronics Standards Committee 17-SAMSS-511

Issue Date: 22 June 2020

Next Planned Update: 22 June 2025 Stationary Storage Batteries

IEEE 1106 Recommended Practice for Maintenance, Testing,

and Replacement of Nickel-Cadmium Batteries

for Generating Stations and Substations

IEEE 1115 Recommended Practice for Sizing Nickel-Cadmium

Batteries for Stationary Applications

IEEE 1184 Guide for Selection and Sizing of Batteries for

Uninterruptible Power Systems

IEEE 1188 Recommended Practice for Maintenance, Testing,

and Replacement of Valve Regulated Lead-Acid

(VRLA) Batteries for Stationary Applications

National Electrical Manufacturers Association

NEMA 250 Enclosures for Electrical Equipment

(1000 Volts Maximum)

Underwriters Laboratories, Inc.

UL 94 Tests for Flammability of Plastic Materials for Parts

in Devices and Appliances: Vertical Burning

Tests for Classifying Materials 94V-0, 94V-1, or

94V-2

UL1642 Lithium Batteries Safety Standard

4 Field Experience

Designs and materials used in stationary storage batteries shall have at least five

(5) years of verifiable, proven field experience in the Kingdom of Saudi Arabia.

The Bidder shall supply a user list indicating the company name, installation site,

date of installation and equipment rating.

5 Service Conditions

5.1 Battery in Standby Float Service: The battery will be connected to a constant

voltage battery charger and to a load bus. In normal operation, the battery will

be in “float charge” at the manufacturer’s recommended float charge voltage.

The battery charger will supply the required load current and the battery

charging current.

5.2 Batteries Subjected to Frequent or Daily Charge/Discharge Cycles: The battery

will be connected to non-continuous and unstable charging source, and load bus.

Page 6 of 26

Saudi Aramco: Company General Use

Document Responsibility: UPS, DC Systems, and Power Electronics Standards Committee 17-SAMSS-511

Issue Date: 22 June 2020

Next Planned Update: 22 June 2025 Stationary Storage Batteries

The charging source may be a photovoltaic array or a wind electricity generator.

The charging source will supply power to the load and to charge the batteries.

Battery power will supply the connected load when the AC charging source

fluctuates or lost.

5.3 Battery Location and Ambient Conditions

5.3.1 Indoors Location

Average room temperature 25°C

40°C (maximum 5 occurrences

Maximum operating temperature

per year; 48 hours per occurrence)

Minimum operating temperature 10°C

5.3.2 Outdoors Location

Average daily temperature 33°C

56°C (for up to 5 hours per day;

Maximum operating temperature 6 months per year) for NiCad and

flooded lead acid batteries

33°C (for up to 5 hours per day;

6 months per year) for VRLA Gel

Maximum Operating

type batteries. AGM type VRLA

Temperature

batteries shall have maximum

25°C operating temperature

45°C (for up to 5 hours per day; 6

Maximum operating temperature months per year for LiFePO4

batteries.

5°C (for up to 8 hours per day;

3 months per year) for NiCd and

Minimum operating temperature

Vented(Flooded) Lead Acid and

VRLA type batteries

10°C (for up to 8 hours per day;

Minimum operating temperature 3 months per year) for LiFePO4

batteries

5.3.3 Ambient temperature of 25°C shall be used for battery sizing.

5.4 LiFePO4 Battery shall comply with IEC61960-3, IEC61959 and UL1642 for

electrical, mechanical, and fire safety tests.

Page 7 of 26

Saudi Aramco: Company General Use

Document Responsibility: UPS, DC Systems, and Power Electronics Standards Committee 17-SAMSS-511

Issue Date: 22 June 2020

Next Planned Update: 22 June 2025 Stationary Storage Batteries

6 General Design and Performance Requirements

Vendor shall provide individual batteries or a complete battery system as required by

the purchase order. A complete battery system shall include batteries, racks,

connectors, covers for the battery terminals and intercell connectors or insulated copper

busbars, hardware, and accessories described in this specification.

The following requirements are applicable to all battery types:

6.1 Design Life

6.1.1 The design life of nickel cadmium and flooded (vented) lead acid

batteries shall be at least 20 years, valve regulated lead acid (VRLA)

batteries shall be at least 10 years, and Lithium Iron Phosphate

(LiFEPO4) shall be at least 15 years when they are operating in float

charging cycle at 25°C.

6.1.2 The cell shall be considered to have reached the end of its useful life

when the ampere-hour capacity drops to 80% of the rated capacity at the

5 hour discharge rate for nickel-cadmium batteries, 8/10 hour discharge

rate for lead-acid batteries, and 2/5 hours discharge rate for Lithium Iron

Phosphate (LiFEPO4) batteries

6.1.3 Battery type, Ah capacity, and date of manufacturing shall be fixed on

every battery.

6.2 Shelf Life

6.2.1 Flooded (Vented) Lead-Acid & Nickel-Cadmium Batteries

The shelf life of vented lead-acid and nickel-cadmium batteries shall be

minimum 2 years when stored at 35°C room temperature. The cell shall

recharge to at least 80% of the rated capacity within 10 hours.

6.2.2 Valve Regulated Lead Acid (VRLA) Batteries

The shelf life shall be a minimum of 6 months at 35°C. The available

capacity at the end of this time period shall not be less than 75% of the

rated capacity. The cell shall recharge to at least 80% of the rated

capacity within 10 hours.

6.2.3 Lithium Iron Phosphate Batteries (LiFEPO4)

The shelf life of lithium iron phosphate (LiFePO4) batteries shall be

minimum 1 year with self-discharge of 3% per month at 25°C room

temperature

Page 8 of 26

Saudi Aramco: Company General Use

Document Responsibility: UPS, DC Systems, and Power Electronics Standards Committee 17-SAMSS-511

Issue Date: 22 June 2020

Next Planned Update: 22 June 2025 Stationary Storage Batteries

6.2.4 The battery shall be stored according to manufacturer's

recommendations.

6.3 Warranty

6.3.1 Flooded (Vented) Lead Acid and Nickel Cadmium Batteries

The manufacturer shall provide full replacement warranty for 3 years

from the date of commissioning. However, the manufacturer shall accept

a pro-rata warrantee for 20 years in case it was proven that battery failure

happened due to manufacturer defect.

6.3.2 Valve Regulated Lead Acid (VRLA) Batteries

The manufacturer shall provide a full replacement warranty for 2 years

from the date of commissioning, However, the manufacturer shall accept

a pro-rata warrantee for 10 years in case it was proven that battery failure

happened due to manufacturer defect.

6.3.3 Lithium Iron Phosphate Batteries (LiFEPO4)

The manufacturer shall provide a full replacement warranty for 3 years

from the date of commissioning.

6.4 Cyclic Performance

The battery shall have the following minimum cycle-life capability during its

design lifetime at the 1-hour discharge rate, at 25°C. The cyclic performance is

stated in terms of the number of full charge/discharge cycles that the cell can

sustain during its useful life to 80% depth of discharge (DOD), and end of

discharge voltage of 2.8 VPC 1.7 VPC and 1.1 VPC, for lithium iron phosphate,

lead acid battery and nickel cadmium battery, respectively.

Table 1 – Cyclic Performance to 80% DOD at 25 C

(1.7 VPC for lead acid; 1.1 VPC for Ni-Cd, 3.0 VPC for LiFEPO4)

Lead-Calcium Plate 100 Cycles

Lead-Antimony Plate 350 Cycles

Lead-Antimony Tubular or Rod Plate 1,200 Cycles

Nickel-Cadmium Pocket Plate 1,200 Cycles

Valve Regulated Lead-Acid (VRLA) 1,000 Cycles

Lithium Iron Phosphate (LiFePO4) 2,000 Cycles

6.5 Ampere-hour Capacity

Page 9 of 26

Saudi Aramco: Company General Use

Document Responsibility: UPS, DC Systems, and Power Electronics Standards Committee 17-SAMSS-511

Issue Date: 22 June 2020

Next Planned Update: 22 June 2025 Stationary Storage Batteries

Ampere-hour capacity of the new cell shall be indicated by the manufacturer on

Data Schedule-2. This data shall be provided for C8 or C10 for lead acid battery,

C5 for nickel cadmium battery, and C2 or C5 for Lithium Iron Phosphate battery

at 25°C, to the final voltage (end-of-discharge voltage) between 1.65 VPC and

1.75 VPC for lead-acid batteries, and between 1.0 VPC and 1.14 VPC for

nickel-cadmium batteries. For Lithium Iron Phosphate (LiFePO4) batteries

between 2.8VPC and 2.85VPC.

6.6 Battery Sizing

The battery shall be sized to support the system's rated load for the time period

specified on Data Schedule-1.

The Buyer has the option of specifying the battery capacity in ampere-hours or

providing the Bidder with a load profile of the battery duty cycle. If the latter

option is selected, the Bidder shall provide the Buyer with the calculations used

in selecting the battery capacity. The method of determining battery capacity

shall be as defined in IEEE 485 “Sizing Stationary Lead Acid Batteries”, or

IEEE 1013 “Sizing Lead Acid Batteries for PV” or , or IEEE 1115 “Sizing

Stationary Nickel Cadmium Batteries”, or IEEE 1184 “Sizing UPS Batteries”, or

equivalent IEC standards as applicable to the application. Battery selection shall

be based on the following minimum volts per cell:

Table 2 - Battery Cell End of Discharge Voltage

General Applications PV Applications*

Lead-Acid 1.65 VPC to 1.75 VPC 1.85 VPC

Nickel-Cadmium 1.0 VPC to 1.14 VPC 1.14 VPC to 1.2 VPC

Lithium Iron 2.8 VPC to 2.85 VPC 2.85 VPC

Phosphate

* For PV applications, battery manufacturer recommended end discharge voltage shall be followed.

6.6.1 The following sizing factors shall be applied to calculate the battery

capacity:

a. Design margin : 10 % (all applications)

b. Aging factor (AF) : 25 % for all types of battery

Exception:

Use AF = 1.0 for Plante and Modified Plante types, since these types

maintain a firmly constant Ah capacity throughout their design life.

Page 10 of 26

Saudi Aramco: Company General Use

Document Responsibility: UPS, DC Systems, and Power Electronics Standards Committee 17-SAMSS-511

Issue Date: 22 June 2020

Next Planned Update: 22 June 2025 Stationary Storage Batteries

c. Temperature factor : Cell size correction factor

Flooded Lead Acid Battery

Ni-Cd Battery

- Consult Battery Manufacturer

Lithium Iron Phosphate Battery

- Consult Battery Manufacturer

6.6.2 If the specified or calculated battery capacity exceeds a manufacturer's

standard rating by more than 5%; then, the larger standard rating shall be

selected.

Page 11 of 26

Saudi Aramco: Company General Use

Document Responsibility: UPS, DC Systems, and Power Electronics Standards Committee 17-SAMSS-511

Issue Date: 22 June 2020

Next Planned Update: 22 June 2025 Stationary Storage Batteries

6.7 Paralleling of Batteries

Paralleling up to 4 sets of battery strings of identical Ah capacity and potential

shall be allowed, to achieve required Ampere Hour capacity.

6.8 Connections

All connections shall be bolted to the cell posts. All cell-to-cell connections in

the same row shall be made by plated copper bus bars using 316 stainless steel

hardware or nickel plated copper or equivalent. Tier-to-tier connections shall be

made by insulated copper cables with 316 stainless steel hardware or nickel

plated copper or equivalent. The cell-to-cell interconnecting hardware shall be

sized to allow discharge current at the 30-minute rate with no more than 15 mV

drop between adjacent cells. The inter-cell connectors shall withstand the

available short circuit current without damaging the unit. Insulated copper

busbars or covers for the inter-cell connecters and the terminals shall be supplied

with the batteries.

6.9 Hardware

All nuts, bolts, washers, and similar hardware shall be 316 stainless steel or

nickel plated copper or equivalent.

7 Vented (Flooded) Lead-Acid Batteries

Vented lead-acid cells shall meet the design, performance, and test requirements of

IEC 60896-11. In addition, the following paragraph shall apply:

7.1 Definition

Battery with an aqueous electrolyte based on dilute sulfuric acid, a positive

electrode of lead dioxide, and a negative electrode of lead.

7.2 Plates

The plate design (either Tubular or Pasted or Plante or Rod plate, lead-calcium

or lead-antimony or lead-tin or lead selenium alloys) shall be as specified on

Data Schedule-1. Lead-antimony alloys shall not contain more than 2%

antimony.

7.3 Positive Plate Growth

The cell design shall accommodate the total positive plate growth during the

design life of the cell. The plate growth shall not cause cracking, deformation,

or failure during the lifetime of the cell under normal operating conditions.

Page 12 of 26

Saudi Aramco: Company General Use

Document Responsibility: UPS, DC Systems, and Power Electronics Standards Committee 17-SAMSS-511

Issue Date: 22 June 2020

Next Planned Update: 22 June 2025 Stationary Storage Batteries

7.4 Cell containers and covers

Cell containers and covers shall be made of a high impact plastic material.

The cover shall be permanently attached to the container to form a leak-proof

seal.

7.5 Electrolyte Levels

Each cell shall have provisions for indicating the minimum and maximum

electrolyte levels. For transparent and translucent containers, the minimum

and maximum levels shall be permanently marked on each cell container.

Level indicating gauge shall be provided on cell containers made of an opaque

material.

7.6 Electrolyte Reserve

Electrolyte level readjustment period, under float conditions, shall be at least

one (1) year.

7.7 Terminals

Terminal posts shall be lead alloy. Cells larger than 150 ampere-hours capacity,

at 8/10 hour discharge rate, shall have lead plated copper posts or have a copper

or brass core insert for providing a reliable low-resistance interface with the

inter-cell connectors. Insulated copper busbars or covers for the inter-cell

connecters and the terminals shall be supplied with the batteries.

7.8 Vent Plugs

Flame-arrestor type vent plugs shall be provided to minimize the possibility of

internal battery explosion caused by an external spark or battery room fire.

The vent plug shall prevent any visible wetting of the cell lid when the cell is

being overcharged at the equalizing voltage at 25°C ambient temperature.

8 Valve Regulated Lead-Acid (VRLA) Batteries

Valve regulated lead-acid cells (also known as sealed cells) shall meet the design,

performance, and test requirements of IEC 60896-21 “Stationary lead-acid batteries.

General requirements and methods of test, Part 2, Valve regulated types”. In addition,

the following paragraph shall apply:

8.1 Definition of VRLA Batteries

Battery in which cells are closed but have a valve that allows the escape of gas if

the cell internal pressure exceeds a predetermined value. Normally, the cell can

not receive electrolyte additions.

Page 13 of 26

Saudi Aramco: Company General Use

Document Responsibility: UPS, DC Systems, and Power Electronics Standards Committee 17-SAMSS-511

Issue Date: 22 June 2020

Next Planned Update: 22 June 2025 Stationary Storage Batteries

8.2 Electrolyte

The electrolyte shall be immobilized in the cell through the use of a gelling

agent or absorbed in the separators and plates. The cells shall have no residual

free or bulk liquid electrolyte.

8.3 Separators

The separators shall be porous to electrolyte but electrically insulating.

Sufficient overlap of the separator to the edges of the plates shall be provided to

prevent short-circuiting of adjacent plates.

8.4 Plate Support

The plates shall be supported from the bottom of the container and shall not be

hung from the cell cover. Adequate allowance shall be made for the positive

grid growth. The grid growth shall not cause any distortion of the container or

the cover.

8.5 Positive Plate Growth

The cell design shall accommodate the total positive plate growth during the

design life of the cell. The plate growth shall not cause cracking, deformation,

or failure during the lifetime of the cell under normal operating conditions.

8.6 Flame Resistance

Cell containers and covers shall be made of a high impact, flame-retardant

plastic having a minimum oxygen index of 28%, and shall meet the criteria

needed to be rated class V-0 when tested in accordance with Underwriters

Laboratories Standard UL 94 “Tests for Flammability of Plastic Materials for

Parts in Devices and Appliances: Vertical Burning Tests for Classifying

Materials 94V-0, 94V-1, or 94V-2”, or class FV0 when tested in accordance

with IEC 60707 “Flammability of Solid Non-Metallic Materials When Exposed

to Flame Sources - List of Test Methods”.

8.7 Container and Cover

The cell containers and covers shall be designed to minimize flexing of the

surface under internal operating pressures. The cover shall be permanently

joined to the container to form a leak-proof seal. The complete assembly shall

be able to withstand an internal pressure equal to 5 times the normal operating

pressure without fracture for 5 hours at 25°C. The complete unit, including the

post-to-cover seal, shall remain gas-tight and electrolyte-tight during the design

life of the battery.

Page 14 of 26

Saudi Aramco: Company General Use

Document Responsibility: UPS, DC Systems, and Power Electronics Standards Committee 17-SAMSS-511

Issue Date: 22 June 2020

Next Planned Update: 22 June 2025 Stationary Storage Batteries

8.8 Terminal Posts

Terminal posts shall be cast in lead or lead alloy and have a copper core insert.

Insulated copper busbars or covers for the inter-cell connecters and the terminals

shall be supplied with the batteries.

8.9 Valve

The valve shall operate at the pressure limits specified by the manufacturer.

The valve shall not allow ingress of outside air into the unit.

8.10 Gas Emission

The manufacturer shall provide test data showing the hydrogen gas emission

rate of the cell type at float and equalize voltages.

8.11 Module Cover Plate

Each module shall be provided with a full-length insulating cover plate or other

forms of covers to prevent contact with live cell terminals.

8.12 Module Floor Channel

The battery module assembly/battery rack shall be provided with base channels

for bolting to the floor.

9 Nickel-Cadmium Batteries

Nickel-cadmium cells shall meet the design, performance, and test requirements of

IEC 60623. In addition, the following paragraphs shall apply:

9.1 Definition

A battery with an alkaline electrolyte, a positive electrode containing nickel

oxide and a negative electrode of cadmium.

9.2 Plate Design

Nickel-cadmium cells shall be vented, pocket plate or fiber-structured positive

and negative plates.

9.3 Vent Plugs

The vent plugs shall be in accordance with Section 8.8.

9.4 Electrolyte Levels

Page 15 of 26

Saudi Aramco: Company General Use

Document Responsibility: UPS, DC Systems, and Power Electronics Standards Committee 17-SAMSS-511

Issue Date: 22 June 2020

Next Planned Update: 22 June 2025 Stationary Storage Batteries

The requirements of Section 8.5 apply.

9.5 Electrolyte Reserve

The requirements of Section 8.6 apply.

9.6 Life-Parts Covers for Safety

Covers for the inter-cell connecters and the terminals or insulated copper

busbars shall be supplied with the batteries.

10 Lithium Iron Phosphate Batteries

Lithium Iron Phosphate batteries shall meet the following design, performance, and test

requirements of IEC 61960-3. In addition, the following paragraphs shall apply:

10.1 Definition

A battery that uses LiFePO4 as a cathode material and graphite carbon electrode

with metallic backing as anode with an absorbed lithium salt electrolyte

dissolved into organic solvent.

10.2 Battery Design

LiFePO4 battery shall be constructed from a number of LiFePO4 cells

connected in series to supply the required voltage.

10.3 Battery Management System (BMS)

LiFePO4 batteries shall be equipped with battery management system to prevent

lithium plating, a phenomenon originates from improper management of cells,

which results irreversible capacity loss. Lithium plating is promoted by

excessive charge rates, cold temperature charging and trickle charging. Fast

charging followed by trickle charging shall be avoided. BMS shall equip with

cell balancing and over/under voltage, over current, short circuit, over

temperature protections. BMS shall avoid auto balance at the end of charge

cycle. BMS shall operate at higher temperatures to comply with battery

maximum operating temperature. BMS enclosure shall be rated minimum IP5x.

BMS shall also provide low temperature charge alarm (T < 5C). Manufacturer

recommendations shall apply.

10.4 Charge Voltage:

Recommended Charge Voltage: between 3.5VPC and 3.55VPC

Recommended Float Charge: 3.375VPC

Page 16 of 26

Saudi Aramco: Company General Use

Document Responsibility: UPS, DC Systems, and Power Electronics Standards Committee 17-SAMSS-511

Issue Date: 22 June 2020

Next Planned Update: 22 June 2025 Stationary Storage Batteries

Otherwise, manufacturer’s requirement shall supersedes

10.5 Efficiency

LiFePO4 batteries shall have minimum 90% round-trip efficiency.

10.6 Electrolyte

LiFePO4 batteries shall comply with UL1642

10.7 Performance

LiFePO4 batteries shall comply with IEC 61960-3.

10.8 Protection and String Size

Each parallel connection shall be protected by fuse. Up to four 12.8VPC

batteries shall be connected in series.

10.9 Transportation and Handling

11 Battery Racks (Indoors Mounting)

11.1 For Valve Regulated Batteries

11.1.1 Rack Construction (Seismic)

The modular battery rack shall be welded steel or bolted units.

Each module shall be designed to allow air circulation between

individual cells to maintain uniform cooling of each cell.

Alternatively, if a stackable battery rack-type is not available as a

standard product, racks shall be constructed of welded or bolted

structural steel frames with bolted steel runners and braces, and with

provisions for anchoring to the floor.

11.1.2 Rack Design

The modular rack design shall allow easy installation or removal of

individual cells from any module without disturbing the modular rack

assembly. Standard battery rack as specified in paragraph 11.1.1 shall

be acceptable as well since it facilitates removal and/or installation of

batteries. Clearance from the top of the battery cell highest point to the

bottom of the rack above it shall be approx. 350 mm, and airspace

between battery cells shall be approx. 10mm.

11.1.3 Stack Height

Page 17 of 26

Saudi Aramco: Company General Use

Document Responsibility: UPS, DC Systems, and Power Electronics Standards Committee 17-SAMSS-511

Issue Date: 22 June 2020

Next Planned Update: 22 June 2025 Stationary Storage Batteries

The vertically stacked height of valve regulated batteries shall not

exceed 1,700 mm above the floor. VRLA battery mounting on a

standard rack shall be allowed with its height not exceeding 1,700 mm.

11.1.4 Painting

All metallic components, excluding hardware and grounding

connectors, shall be coated with an acid resistant baked powder epoxy

or propylene or acid resistant plastic coating. Vendor shall supply a

sufficient quantity of field-applied coating for touching up scratches.

11.2 For Vented Lead-Acid and Nickel-Cadmium Batteries

11.2.1 Rack Construction (Seismic)

Racks shall be constructed of welded or bolted structural steel frames

with bolted steel runners and braces, and with provision for anchoring

to the floor and grounding.

11.2.2 Rack Design

Battery rack shall consist of up to 2 steps, and each step shall have only

one row for the ease in maintenance. Clearance from the top of the

battery cell highest point to the bottom of the rack above it shall be

approx. 350 mm, and airspace between battery cells shall be approx.

10 mm. The maximum height from the floor level to the top terminal

of the upper battery shall be 1,700 mm, which can allow up to 2 tiers

rack.

11.2.3 All metallic rack components that are in contact with the battery shall

be insulated by removable covers or the rack shall be plastic coated.

11.2.4 Painting

All metallic components of the rack, excluding hardware and

grounding connectors, shall be coated with plastic or acid resistant

baked powder epoxy or propylene. Racks for nickel-cadmium

batteries shall be coated with an alkali-resistant plastic coating.

Where applicable, Vendor shall supply sufficient quantity of field-

applied coating for touching up scratches.

12 Battery Enclosures for Indoors Mounting

Battery enclosures and cell supports shall be free-standing and made of fiberglass

reinforced material or steel and conforming to NEMA 250, Type 1 or IEC 60529 IP 21.

The enclosures shall have suitable ventilation, with provisions for anchoring to the floor

Page 18 of 26

Saudi Aramco: Company General Use

Document Responsibility: UPS, DC Systems, and Power Electronics Standards Committee 17-SAMSS-511

Issue Date: 22 June 2020

Next Planned Update: 22 June 2025 Stationary Storage Batteries

and grounding. Clearance from the top of the battery cell highest point to the bottom of

the shelf above it shall be approx. 350 mm, and airspace between battery cells shall be

approx. 10 mm.

13 Battery Enclosures for Outdoors Mounting

Battery enclosures for outdoors mounting applications shall be made of fiberglass-

reinforced material, shall be fire retardant and sunlight (unltraviolet radiation) resistant,

and shall have minimum IP 55 rating or NEMA equivalent. If IP 65 or IP 66 is used,

the enclosure shall have a minimum of two ventilation openings at the top. These

enclosures shall have suitable ventilation, and provisions for anchoring to the floor and

grounding. Clearance from the top of the battery cell highest point to the bottom of the

shelf above it shall be approx. 350 mm, and airspace between battery cells shall be

approx. 10 mm.

14 Battery Enclosures for Offshore Applications

Offshore applications battery enclosures shall be:

a) For Outdoors Mountings: Battery enclosure for offshore outdoors shall have

minimum IP 55 rating or NEMA equivalent with corrosion protection, and shall

be fire retardant and sunlight (unltraviolet radiation) resistant., and shall be made

of fiberglass-reinforced material, with suitable ventilation and provisions for

anchoring to the floor and grounding.

b) For Indoors Mountings: Battery enclosure for offshore indoors shall be dust-

protected and rain-protected with corrosion resistance. Minimum enclosure

protection class shall be NEMA 250 Type 12 (or IEC 60529 IP 54) with corrosion

protection, and shall be made of fiberglass reinforced material or steel, with

suitable ventilation and provisions for anchoring to the floor and grounding.

c) Clearance for Ease of Maintenance: Clearance from the top of the battery cell

highest point to the bottom of the shelf above it shall be approx. 350 mm, and

airspace between battery cells shall be approx. 10 mm.

15 Accessories

15.1 The following accessories shall be furnished with each new and complete

battery system.

15.1.1 Vented Lead-Acid and Nickel-Cadmium Batteries

a. Thermometer for measuring cell electrolyte temperature

b. Hydrometer (not required for nickel cadmium batteries)

Page 19 of 26

Saudi Aramco: Company General Use

Document Responsibility: UPS, DC Systems, and Power Electronics Standards Committee 17-SAMSS-511

Issue Date: 22 June 2020

Next Planned Update: 22 June 2025 Stationary Storage Batteries

c. Bottle or filling jar with pour spout for adding distilled water

d. Supply of NO-OX terminal grease (only if required by design)

e. All required intercell and inter-row connectors with covers, if

modular covers are not supplied

f. Cell /battery module mechanical lifting device and slings for

installation and removal of cells and modules weighing more

than 34 kg (75 lb.).

15.1.2 Valve Regulated Lead-Acid Batteries

a. Supply of NO-OX terminal grease (only if required by design)

b. All required intercell and inter-row connectors with covers, if

modular covers are not supplied

c. Cell/battery module mechanical lifting device and slings for

installation and removal of cells and modules weighing more

than 34 kg (75 lb.).

15.1.3 Lithium Iron Phosphate (LiFePO4) Batteries

a. Equipped with relay to protect over discharge

b. Equipped with battery management system shall have protection

against short circuit, over/under voltage and high/low

temperature, as well as shall have balancing temperature and

voltage control.

c. Equipped with extension cables as well as conjunction plates and

terminals

15.2 Replacement cells shall be provided with terminal grease (if required by design),

cell connectors, and connection hardware. Covers for the inter-cell connecters

and terminals (if modular covers are not supplied) shall be provided with the

batteries.

16 Markings (Follow IEC or Equivalent Standard)

The following information shall be permanently marked on each cell or multi-cell

module:

a. Manufacturer's name and address.

b. Manufacturer's catalog number or type reference.

c. Capacity (C8/C10 or C5, for lead acid battery or nickel cadmium battery, respectively)

Page 20 of 26

Saudi Aramco: Company General Use

Document Responsibility: UPS, DC Systems, and Power Electronics Standards Committee 17-SAMSS-511

Issue Date: 22 June 2020

Next Planned Update: 22 June 2025 Stationary Storage Batteries

d. Capacity (C2/C5/C10, for Lithium iron phosphate (LiFePO4) battery)

e. Electrolyte density (fully charged at 25°C) (not applicable for VRLA batteries).

f. Month and year of manufacture.

g. Electrolyte level markings (as described in Section 8.5).

17 Tests

17.1 Type Tests

17.1.1 All type tests prescribed in the referenced standards shall be performed

on a representative battery or on the first unit of every new design or

rating. Buyer has the option to request “type test” certificates to verify

that the supplied battery meets the performance requirements of this

specification and the purchase order.

17.1.2 The ampere-hour capacity of the representative unit shall be tested in

accordance with IEEE 450 “Testing Stationary Vented Lead Acid

Batteries” or IEEE 1106 “Testing Stationary Vented Nickel Cadmium

Batteries”, or IEC 60896-11 & 21 for lead acid battery and IEC 60623

for nickel cadmium battery. The discharge duration for tests shall be

the number of hours on which the ampere-hour capacity rating is based

and as stated in Data Schedules 1 & 2.

17.2 Acceptance Tests

As part of the battery, Saudi Aramco shall witness the battery manufacturer

local representative performing a capacity test at the installation site.

17.2.1 VRLA Batteries

Vendor shall provide a capacity type test certificate on all VRLA

batteries in accordance with IEEE 1188 “Testing Stationary Valve

Regulated Lead Acid Batteries” or IEC 60896-21 with the battery.

The factory type test shall validate the capacity and performance of each

cell just before shipment. Vendor shall replace any cell delivering less

than 90% of the rated capacity during the site acceptance test.

17.2.2 Vented Batteries

Saudi Aramco shall witness the battery manufacturer local

representative performing initial commissioning and an acceptance test

as per the referenced IEEE Standards on all vented batteries at the job

site. Batteries will be prepared and charged in accordance with

manufacturer's recommendations. Batteries shall deliver a minimum

Page 21 of 26

Saudi Aramco: Company General Use

Document Responsibility: UPS, DC Systems, and Power Electronics Standards Committee 17-SAMSS-511

Issue Date: 22 June 2020

Next Planned Update: 22 June 2025 Stationary Storage Batteries

90% of their rated ampere-hour capacity at the initial site-

commissioning test. Batteries delivering less than 90% of the rated

capacity will be returned to the vendor for replacement.

17.2.3 Lithium Batteries

Electrical Test: compliance with IEC61960-3.

Mechanical Test: Compliance with IEC 61959.

Safety Test: Compliance with UL1642

18 Export Packing, Marking and Shipping

18.1 Vented lead-acid cells shall be shipped in dry charged condition (without

electrolyte). As part of the battery, local representative of the battery

manufacturer shall supply the electrolyte and fill the battery.

18.2 Valve-regulated cells and modules shall be shipped in a fully charged condition.

18.3 Nickel-cadmium cells shall be shipped empty from electrolyte and electrically

uncharged. The electrolyte shall be shipped in solid or liquid form in separate

containers.

18.4 Lithium Iron Phosphate (LiFePO4) batteries shall have 50% state of charge

before shipping. Batteries shall be charged fully on-site before the use. The

charge shall be at C/20 rate with constant voltage.

18.5 Individual cells shall be packed to provide protection against physical damage

and moisture.

18.6 Shipping crates shall be marked with handling and storage instructions.

Labels on the shipping crate shall state the storage conditions, date of

shipment, and the date beyond which the product must not be stored.

19 Drawings and Data Submittal in English Language

19.1 Drawings and Data

When requested, the following shall be submitted for Buyer's review and

approval:

a. Battery layout and dimensional outline drawings

b. Complete performance specifications

Page 22 of 26

Saudi Aramco: Company General Use

Document Responsibility: UPS, DC Systems, and Power Electronics Standards Committee 17-SAMSS-511

Issue Date: 22 June 2020

Next Planned Update: 22 June 2025 Stationary Storage Batteries

c. Certified battery capacity test reports accompanied by appropriate IEEE or

IEC sizing sheet for new installations (replacements are excluded from

battery sizing calculation)

d. Battery wiring diagram.

19.2 Buyer shall attach a completed Data Schedule-1 to the purchase requisition.

Bidder shall submit a Completed Data Schedule-2 to the Buyer along with other

bid documents.

19.3 Instruction Manuals

19.3.1 Each complete battery system shall be provided with instruction

manual(s) including the following information as a minimum.

The required number of sets shall be as specified in the Purchase Order.

a. Battery capacity type test report of VRLA batteries conducted at

the factory in accordance with IEEE 1188 “Testing Stationary

Valve Regulated Lead Acid Batteries” or IEC 60896-21.

The type test report shall document the performance of the

battery bank and each individual cell just prior to the shipment of

the battery. Factory testing is not required for flooded lead-acid

and nickel-cadmium batteries.

b. Installation and commissioning instructions

c. Required purity of the topping-up water and the electrolyte

d. Operating instructions

e. Maintenance instructions and the required maintenance schedule

f. Testing instructions and the recommended frequency of tests

g. Clearly identified warnings shall be provided in the

documentation for conditions where improper action by an

operator would create a safety hazard or damage the battery and

associated equipment.

19.3.2 If batteries are to be delivered to the Buyer in a fully charged

condition, the Vendor shall recommend a method of maintaining the

battery in charged condition until the battery is commissioned.

Detailed instructions and required equipment shall be provided for dry

charged batteries requiring on-site activation.

Page 23 of 26

Saudi Aramco: Company General Use

Document Responsibility: UPS, DC Systems, and Power Electronics Standards Committee 17-SAMSS-511

Issue Date: 22 June 2020

Next Planned Update: 22 June 2025 Stationary Storage Batteries

Revision Summary

11 July 2012 Revised the “Next Planned Update.” Reaffirmed the content of the document, and reissued

with minor revision.

20 February 2013 Minor revision to align NEMA standard with its IEC equivalent standard for outdoors

enclosures protection class.

7 June 2017 Major revision to maintain this standard up-to-date and in line with the industry to avoid any

over-specification in specifying and sizing those batteries.

22 June 2020 Major revision to maintain this standard up-to-date and in line with the industry to avoid any

over-specification in specifying and sizing batteries. In addition, this revision introduced the

Lithium Iron Phosphate batteries requirement and specifications.

Page 24 of 26

Saudi Aramco: Company General Use

Document Responsibility: UPS, DC Systems, and Power Electronics Standards Committee 17-SAMSS-511

Issue Date: 22 June 2020

Next Planned Update: 22 June 2025 Stationary Storage Batteries

Data Schedule-1

For 17-SAMSS-511, Storage Batteries

Information Supplied by the Buyer

1. Buyer's Quotation Request/Purchase Order No. ___________________________

2. Buyer's B.I./J.O No. ________________________________________________

3. Buyer's Line Item No. _______________________________________________

4. Service Conditions (check one): _______ Float Service; ______ Cyclic Service

5. Battery Application: ________UPS; _________Substation; _________Photovoltaics

___________Indoors; ____________Outdoors

6. Battery Type:

_______ Nickel-Cadmium

_______ Pure Lead _______ Lead-Selenium _______ Lead-Tin

_______ Lead-Calcium _______ Lead-Antimony (maximum 2% antimony)

_______ Tubular Positive Plate ________ Rod Positive Plate

_______ Plante Positive Plate ________ Pasted Positive Plate

_______ Valve Regulated Lead-Acid (sealed)

_______ Lithium Iron Phosphate (LiFePO4)

7. Battery Voltage: ___________________ volts (nominal)

8. Number of Cells: ___________________

9. Maximum Battery Float Voltage per Cell: _________________ Volts

10. Maximum Battery Boost Voltage per Cell: _________________ Volts

11. Maintenance interval: _________ Standard __________ Extended

12. Design Ambient Temperature: _______________________ °C

13. Minimum Electrolyte Temperature: _______________________ °C

14. Battery Load (select one):

______ Continuous Amperes _________ for ________ minutes

______ Load Profile (see attachment prepared in accordance with IEEE 485 “Sizing

Stationary Lead Acid Batteries”)

15. Battery ampere-hour capacity at the C5 for Nicad, C8/C10 for lead acid hour rate or

C2/C5/C10 for LiFEPO4 (replacement batteries): _________Ah at C________.

Approved: ________________________________

Date ___________________ Revision No. _____________________________

Page 25 of 26

Saudi Aramco: Company General Use

Document Responsibility: UPS, DC Systems, and Power Electronics Standards Committee 17-SAMSS-511

Issue Date: 22 June 2020

Next Planned Update: 22 June 2025 Stationary Storage Batteries

Data Schedule-2

For 17-SAMSS-511, Storage Batteries

Information Supplied by the Equipment Vendor

1. Buyer's Quotation Request/Purchase Order No. ________________________________

2. Buyer's Line Item No. ____________________________________________________

3. Service Conditions (check one): _______ Float Service; ______Cyclic Service

4. Battery Type:

_______ Nickel-Cadmium;

_______ Pure Lead, _______ Lead-Selenium, _______ Lead-Tin,

_______ Lead-Calcium, _______ Lead-Antimony (maximum antimony: ____ %);

_______ Tubular Positive Plate, ________ Rod Positive Plate,

_______ Plante Positive Plate, _______ Pasted Positive Plate,

_______ Valve Regulated Lead-Acid (sealed)

_______ Lithium Iron Phosphate (LiFePO4)

5. Battery Voltage: __________________ volts (nominal)

6. Number of Cells: ___________;

7. Float Voltage: _____ volts/cell; Equalize Voltage: _____ volts/cell; EOD VPC: ____

8. Maintenance interval: ___ Months; Cyclic Capability at C1 rate: ________

9. Electrolyte density: __________________ kg/L at 25°C

10. Battery Ampere-Hour Capacity: __________________ at C___.

(C8/C10 for lead acid battery and C5 for nickel cadmium battery, C2/C5/C10 for LiFEPO4)

Continuous Amperes _________ for ________ minutes

11. Battery gassing rate: _____ ft³/hour/cell _____ ft³/hour/string

12. Weight/Cell __________ kg Weight/Module ____________ kg

13. Battery Assembly Floor Loading ________________ kg/m²

14. Attach performance data sheet relevant to application

___________________________________________________________________________

Approved: ________________________________

Date ___________________ Revision No. ____________________________

Page 26 of 26

Saudi Aramco: Company General Use

You might also like

- Materials System SpecificationDocument21 pagesMaterials System SpecificationFlorante Nobleza100% (1)

- Materials System SpecificationDocument18 pagesMaterials System SpecificationEagle SpiritNo ratings yet

- 16 Samss 504Document45 pages16 Samss 504Abdullah GhannamNo ratings yet

- 17 Samss 516Document27 pages17 Samss 516Santhosh AliasNo ratings yet

- 16 Samss 507 PDFDocument27 pages16 Samss 507 PDFnadeemNo ratings yet

- Materials System SpecificationDocument21 pagesMaterials System SpecificationEagle SpiritNo ratings yet

- 17 Samss 012Document33 pages17 Samss 012Sangeeth Kavil PNo ratings yet

- SAIC-P-3007 Rev 7 FinalDocument20 pagesSAIC-P-3007 Rev 7 FinalEnginerShahzadGhaffarNo ratings yet

- 16 Samss 503Document43 pages16 Samss 503Florante Nobleza100% (2)

- 16-SAMSS-502 - LV SwitchgearsDocument24 pages16-SAMSS-502 - LV SwitchgearsHatemS.MashaGbehNo ratings yet

- 14 Samss 533 PDFDocument14 pages14 Samss 533 PDFMudabbir HussainNo ratings yet

- 15 Samss 502Document10 pages15 Samss 502Praba Hiruthya SNo ratings yet

- SAES-P-101 Vendors List For Electrical EquipmentDocument9 pagesSAES-P-101 Vendors List For Electrical EquipmentfaisalqrNo ratings yet

- Saes T 911Document60 pagesSaes T 911RijoNo ratings yet

- Saes P 119Document17 pagesSaes P 119drbabithameringeorgemdsorthoNo ratings yet

- Saes-T-151 2014Document13 pagesSaes-T-151 2014Aamer Fazal KhanNo ratings yet

- SAES P 123 LightingDocument19 pagesSAES P 123 LightingMuhammad Shahid100% (1)

- 16 Samss 523Document10 pages16 Samss 523Eagle SpiritNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerEagle SpiritNo ratings yet

- Satip P 121 01 Rev 7 MPDocument7 pagesSatip P 121 01 Rev 7 MPmohamedqcNo ratings yet

- SATIP-P-104-01 Rev 8 Final LV Cables PDFDocument2 pagesSATIP-P-104-01 Rev 8 Final LV Cables PDFSabheeh AliNo ratings yet

- Saes P 101Document9 pagesSaes P 101nuriaNo ratings yet

- 16 Samss 502 - PDFDocument12 pages16 Samss 502 - PDFShahraiz KhanNo ratings yet

- Aa 036025 002Document1 pageAa 036025 002Tarek YehiaNo ratings yet

- 26 Samss 059Document3 pages26 Samss 059Akash VermaNo ratings yet

- General Instruction Manual: Na Power Operations Department Certification of High Voltage Cable SplicersDocument8 pagesGeneral Instruction Manual: Na Power Operations Department Certification of High Voltage Cable SplicersJithuRajNo ratings yet

- Saes B 063Document6 pagesSaes B 063hasanmnhNo ratings yet

- Basic Electrical Requirment KSADocument10 pagesBasic Electrical Requirment KSAfarooq929No ratings yet

- Materials System SpecificationDocument14 pagesMaterials System Specificationnadeem shaikh100% (3)

- Saudi Aramco Test ReportDocument11 pagesSaudi Aramco Test Reportkarthi51289100% (1)

- Materials System SpecificationDocument6 pagesMaterials System SpecificationCherukunnon JubuNo ratings yet

- 34 Samss 815Document9 pages34 Samss 815Eagle SpiritNo ratings yet

- 16 Samss 514Document17 pages16 Samss 514HatemS.MashaGbehNo ratings yet

- 16 Samss 521Document8 pages16 Samss 521Eagle SpiritNo ratings yet

- Saudi Aramco Pre-Commissioning Form: Testing Guide LinesDocument4 pagesSaudi Aramco Pre-Commissioning Form: Testing Guide LinesSathiya SeelanNo ratings yet

- Saes X 400Document29 pagesSaes X 400Aravind Sivanesan100% (1)

- Saic J 6001Document7 pagesSaic J 6001sureshNo ratings yet

- 17 Samss 008Document8 pages17 Samss 008Eagle SpiritNo ratings yet

- 2.1, 2.2, 2.3, 2.4, 2.5, 2.6 PDFDocument21 pages2.1, 2.2, 2.3, 2.4, 2.5, 2.6 PDFPardeep KhosaNo ratings yet

- Junaid Khan C.VDocument8 pagesJunaid Khan C.VNikhatRizaviNo ratings yet

- Materials System SpecificationDocument10 pagesMaterials System SpecificationMudabbir Hussain100% (1)

- 16 Samss 512Document40 pages16 Samss 512HatemS.MashaGbehNo ratings yet

- 16-Samss-503 ControlgearDocument27 pages16-Samss-503 ControlgearShahraiz Khan0% (3)

- Saes P 114Document31 pagesSaes P 114aglegarteNo ratings yet

- Saes T 000 PDFDocument10 pagesSaes T 000 PDFsvrao4uNo ratings yet

- Saudi Aramco Test ReportDocument5 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saep 378Document67 pagesSaep 378Anonymous 4IpmN7OnNo ratings yet

- 23 Samss 701 PDFDocument17 pages23 Samss 701 PDFnadeem shaikhNo ratings yet

- Saes P 101Document9 pagesSaes P 101Shawkat Ali KhanNo ratings yet

- Summary of SAES-P-111Document5 pagesSummary of SAES-P-111Afzal Asif100% (2)

- Saes T 555Document21 pagesSaes T 555Jayvee Baradas ValdezNo ratings yet

- Specification ADWEADocument2 pagesSpecification ADWEASaad AkramNo ratings yet

- A-Ele-Lst-000-47961-B - Test Facility Schedule For Pipeline Cathodic Protection SystemDocument23 pagesA-Ele-Lst-000-47961-B - Test Facility Schedule For Pipeline Cathodic Protection SystemBadiNo ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- 34 Samss 718Document14 pages34 Samss 718Eagle SpiritNo ratings yet

- 17 Samss 511Document21 pages17 Samss 511FuzzzyLogNo ratings yet

- Saes P 113Document12 pagesSaes P 113wastazoheb_700349353100% (1)

- 16 Samss 518Document10 pages16 Samss 518adnanmppNo ratings yet

- 16 Samss 510Document11 pages16 Samss 510HatemS.MashaGbehNo ratings yet

- 1663145789advise For Safe Handling of NiCd Accu EnglischDocument6 pages1663145789advise For Safe Handling of NiCd Accu EnglischSanthosh AliasNo ratings yet

- Brochure Sunica PlusDocument12 pagesBrochure Sunica PlusSanthosh Alias100% (1)

- 1663145789advise For Safe Handling of NiCd Accu USADocument12 pages1663145789advise For Safe Handling of NiCd Accu USASanthosh AliasNo ratings yet

- 1663145789safety Data Sheet Polfett Enth LT Metasov 706 EnglischDocument6 pages1663145789safety Data Sheet Polfett Enth LT Metasov 706 EnglischSanthosh AliasNo ratings yet

- 1663145789safety Data Sheet Batt FL Ssigkeit Alkalisch Englisch UN 2797Document5 pages1663145789safety Data Sheet Batt FL Ssigkeit Alkalisch Englisch UN 2797Santhosh AliasNo ratings yet

- Step 1:: If Not, The Software Cannot Be Installed On Your SystemDocument1 pageStep 1:: If Not, The Software Cannot Be Installed On Your SystemSanthosh AliasNo ratings yet

- NCEESExamGuide June-2021 OptDocument36 pagesNCEESExamGuide June-2021 OptSanthosh AliasNo ratings yet

- Electrical and Computer - Computer Engineering CBT Exam SpecificationsDocument2 pagesElectrical and Computer - Computer Engineering CBT Exam SpecificationsSanthosh AliasNo ratings yet

- 17 Samss 514Document20 pages17 Samss 514Santhosh AliasNo ratings yet

- Xor and Xnor Gate Using CMOS: Inputs Output (Y) A B 0 0 0 0 1 1 1 0 1 1 1 0Document1 pageXor and Xnor Gate Using CMOS: Inputs Output (Y) A B 0 0 0 0 1 1 1 0 1 1 1 0AdiseshuMiddeNo ratings yet

- FALLSEM2012-13 CP0991 03-Aug-2012 RM01Document4 pagesFALLSEM2012-13 CP0991 03-Aug-2012 RM01Ankit BhattNo ratings yet

- Sop TumDocument1 pageSop Tummssefullah130% (1)

- LX470 Toyota Lexus Audio System Head Unit - Suplement4Document8 pagesLX470 Toyota Lexus Audio System Head Unit - Suplement4Prestige FixNo ratings yet

- Parts Catalog: Generator SetDocument105 pagesParts Catalog: Generator SetVolador TorresNo ratings yet

- Masibus TT7S - R4F - 1118 Isolated and Programmable Temperature TransmitterDocument2 pagesMasibus TT7S - R4F - 1118 Isolated and Programmable Temperature Transmitterkapil.ieeplNo ratings yet

- Smart S Mk2 October 2010 HRDocument2 pagesSmart S Mk2 October 2010 HRbujor2000ajaNo ratings yet

- A New Antenna Feed Having Equal: E-And H-Plane PatternsDocument7 pagesA New Antenna Feed Having Equal: E-And H-Plane PatternsJulio CesarNo ratings yet

- Max 31865Document26 pagesMax 31865Văn CôngNo ratings yet

- As-T-T022 S11 Body Electric SystemDocument91 pagesAs-T-T022 S11 Body Electric SystemJunior Edder Aguilar Apolaya100% (1)

- Distributed Control SystemDocument10 pagesDistributed Control SystemRavenShieldX100% (1)

- En - Acsm1-204 HW - ADocument102 pagesEn - Acsm1-204 HW - ADavid VandermeerNo ratings yet

- IEE STD C37.104-2002 IEEE Guide For Automatic Reclosing PDFDocument55 pagesIEE STD C37.104-2002 IEEE Guide For Automatic Reclosing PDFJohnatan HernándezNo ratings yet

- Shift Register MethodDocument11 pagesShift Register MethodNikhil PandharpatteNo ratings yet

- BaflesDocument48 pagesBaflesCastañeda OlivaresNo ratings yet

- CLR07-02-000 - Sondakan RW 15 - BoqDocument11 pagesCLR07-02-000 - Sondakan RW 15 - BoqilhamNo ratings yet

- Tradoc LPSG PDFDocument21 pagesTradoc LPSG PDFDavid ChildersNo ratings yet

- Rohde&Schwarz ESMC HF Reciever DatasheetDocument10 pagesRohde&Schwarz ESMC HF Reciever DatasheetHanseaticLeague1993No ratings yet

- Republic of The Philippines Camarines Sur Polytechnic Colleges Nabua, Camarines SurDocument66 pagesRepublic of The Philippines Camarines Sur Polytechnic Colleges Nabua, Camarines SurMark Anthony RamosNo ratings yet

- Vdocuments - MX - Mimaki cg130 FX Service ManualDocument142 pagesVdocuments - MX - Mimaki cg130 FX Service ManualCarlos PaezNo ratings yet

- VTU Important SyllabusDocument115 pagesVTU Important SyllabusDan HawkNo ratings yet

- E002 Second Lighting LayoutDocument1 pageE002 Second Lighting Layoutcyrus juanezaNo ratings yet

- Protig III WaterDocument18 pagesProtig III WaterkiowacNo ratings yet

- Stacked Nanosheet Gate-All-Around Transistor Scaling Beyond FinFETDocument2 pagesStacked Nanosheet Gate-All-Around Transistor Scaling Beyond FinFETGary Ryan DonovanNo ratings yet

- EC574Document1 pageEC574utkarsh rajwanshNo ratings yet

- Unit-2: 2.1. Motivation For A Specialized MACDocument17 pagesUnit-2: 2.1. Motivation For A Specialized MACHarish SarkiNo ratings yet

- Patent Search & Analysis Report (PSAR)Document4 pagesPatent Search & Analysis Report (PSAR)mickyvirusNo ratings yet

- Report Computer NetworkingDocument45 pagesReport Computer NetworkingTayab AbdelrhimNo ratings yet

- Docu56902 VMAX3 Family With HYPERMAX OS 5977 Release NotesDocument71 pagesDocu56902 VMAX3 Family With HYPERMAX OS 5977 Release NotesDivesh Gopinath100% (1)

- Synchronous MCQDocument8 pagesSynchronous MCQSamachar Nepali80% (5)