0% found this document useful (0 votes)

73 views7 pagesProject Proposal and Feasibility Study

This document provides details for a proposed industrial project, including:

- The project location, rationale, and alternatives considered;

- Major project components and supporting facilities;

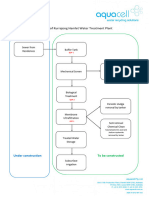

- Production processes, power/water systems, and waste management;

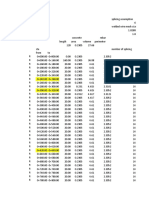

- Project size, phases, and timeframes from pre-construction to operation. Tables provide specifics on equipment, timelines, and raw materials.

Uploaded by

Jan Felix DonsalCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

73 views7 pagesProject Proposal and Feasibility Study

This document provides details for a proposed industrial project, including:

- The project location, rationale, and alternatives considered;

- Major project components and supporting facilities;

- Production processes, power/water systems, and waste management;

- Project size, phases, and timeframes from pre-construction to operation. Tables provide specifics on equipment, timelines, and raw materials.

Uploaded by

Jan Felix DonsalCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd