Professional Documents

Culture Documents

Avox 803139 Um Oxygen Inhalators User Manual Rev 3 0

Uploaded by

Lemuel RodríguezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Avox 803139 Um Oxygen Inhalators User Manual Rev 3 0

Uploaded by

Lemuel RodríguezCopyright:

Available Formats

USER MANUAL

AVOX SYSTEMS™

OXYGEN INHALATORS

803139 Series Pressur Vak II Inhalator

801238 Series Overboard Discharge Inhalator

803600 Series Single Hose Inhalator

803139-UM REV 3.0 Amron International, Inc.

TABLE OF CONTENTS Section

General Information 1

Introduction 1.1

Care and Cleaning 2

General Inspection 2.1

Minimum Care Requirements 2.2

Standard Cleaning Procedures 2.3

Disinfecting 2.4

Storage and Preservation 2.5

Hose Assembly Maintenance 3

Hose Assembly Component Parts Installation 3.1

Demand Regulator Maintenance 4

Demand Regulator Maintenance Instructions 4.1

Exhaust Regulator Maintenance 5

Exhaust Regulator Maintenance Instructions 5.1

Pressur Vak II Inhalator 6

Assembly / Disassembly of Pressur Vak II 6.1

Attaching Face Seal to Manifold Assembly 6.2

Detaching Face Seal from Manifold Assembly 6.3

Regulators to Manifold Installation 6.4

Pressur Vak II Inhalator Parts Drawing 6.5

Pressur Vak II Inhalator Parts Listing 6.6

Retrofit Kit 7

Avox Retrofit Kit (Part No. 803200-XX) 7.1

Retrofit Kit – Disassembly of 801238 Face Piece Assy. 7.2

801238 Series Overboard Discharge Inhalator 8

General Information 8.1

801238 Series Parts Drawing 8.2

801238 Series Parts Listing 8.3

803600 Series Single Hose Inhalator 9

General Information 9.1

Troubleshooting 10

Inhalation / Exhalation Performance Chart 11

Inhalation Performance Chart 11.1

Exhalation Performance Chart 11.2

Repair Log 12

803139-UM REV 3.0 Amron International, Inc.

Section 1 GENERAL INFORMATION

WARNING!

Read user manual prior to operating inhalator to ensure user safety and proper use.

WARNING!

To prevent a vacuum from occurring in the oral nasal cavity and possible user

injury, proper gas supply/exhaust settings must be established and

supply/exhaust valves must remain on while mask is donned and in use.

WARNING!

Remove mask BEFORE turning off gas supply or injury can result.

WARNING!

Any service or overhaul performed on this apparatus shall be done only by those

facilities experienced in, or by personnel knowledgeable in oxygen equipment. All

procedures described in this manual shall be performed in an area free of oil,

grease, flammable solvents or other combustible materials. Such materials, as

well as dust, lint and fine metal filings are all potential combustibles which might,

when exposed to oxygen under pressure, ignite and result in an explosion and/or

fire.

1.1 Introduction

1. This manual delineates operation, maintenance, and replaceable parts

information for the following Avox Oxygen Inhalators:

o Pressur Vak II– Series 803139 Inhalator with overboard discharge

o 801238 Series Inhalator with overboard discharge

o 803600 Series Single Hose Inhalator without overboard discharge

o 803200 Retrofit Kit which converts the 801238 Series Inhalator to the

newer Pressur Vak II Series 803139 Inhalator.

2. The Avox Oxygen Inhalators are designed to administer breathing oxygen or

mixed breathing media to a diver or patient in a hyperbaric chamber

environment.

3. The use of Pressur Vak II or the Duo-Seal Inhalator with overboard

discharge eliminates oxygen buildup or contamination of the chamber

environment by dumping the exhaled gases directly out of the chamber.

803139-UM REV 3.0 Amron International, Inc. 1

GENERAL INFORMATION Section 1

1.1 Introduction (continued)

4. The demand regulator assembly provides breathing gas on demand

(inhalation). The regulator is designed to operate with a constant inlet

pressure of 65 - 125 psi over chamber pressure. You can set the over

bottom pressure to the pressure that meets your system breathing

requirement. Setting the over bottom pressure over 100 psig may result in

labored breathing resistance. Under normal conditions, the regulator will

provide adequate flow rates at acceptable breathing resistance. The demand

regulator can be adjusted to free-flow by turning the control knob clockwise

until desired free flow is achieved.

5. The vacuum regulator on the inhalators with overboard discharge allows the

exhaled gases to be carried to outside the chamber. The vacuum of the

exhaled gas is a direct function of the differential pressure of the chamber

and the ambient environment. For chamber depths over 60 F.S.W., a

secondary vacuum regulator must be installed. It is recommended to use a

negative spring biased back pressure differential regulator such as the

Tescom 26-2912-282A. This type of regulator is recommended but not

required for systems operating under 60 F.S.W.

6. It is recommended that a shut off valve be incorporated between the outside

of the chamber and the exhaust valve on the mask so the vacuum in the

chamber can be shut off.

7. Both the BIBS supply and exhaust valves must be turned on prior to placing

the inhalator on the user’s face and must remain open until the inhalator is

removed to prevent a vacuum from occurring in the oral nasal cavity.

8. It may be desirable to use a single high pressure regulator located at the

high pressure source to increase the pressure to the second stage regulator

on the inhalator. This may also be desirable when operating a multiple

number of masks.

NOTE: The regulator must be sized properly to maintain an outlet pressure within 65

to 125 psi range over bottom pressure, while providing proper flow rates for

the number of masks and source pressure.

803139-UM REV 3.0 Amron International, Inc. 2

Section 2 CARE and CLEANING

2.1 General Inspection

1. General inspection of this life support equipment should be performed

before and after each extended dive program.

2. Inspect all hoses, face seals, and gaskets for excessive wear.

3. Inspect all “soft” parts, especially diaphragms, for wear, rips, tears or

punctures.

4. Inspect regulator “tilt valves” for any debris or corrosion lodged below tilt

valve.

5. Inspect threaded fittings for burrs and cross-threading.

6. Inspect for missing or damaged hardware, like screws, washers and

clamps.

7. Inspect all metal parts for burrs, nicks, dents, cracks, and corrosion.

2.2 Minimum Care Requirements

1. External cleaning and drying of the complete assembly should be

performed after each extended treatment. See Cleaning Procedures.

2. Pressur Vak II, separate the face seal from the manifold assembly after

each session. Leaving the face seal connected to the system will result in

deterioration of the face seal and corrosion of the manifold quick-

disconnect system. Separate the manifold assembly from the regulator

assemblies on a regular basis. Inspect the inside of the regulators for

corrosion and debris. Clean or disinfect and dry regulators and manifold

completely before re-assembly.

801238 and 803600 masks should be periodically disassembled and cleaned

and dried.

3. Store the mask properly when not in use. See Storage Procedures.

4. Replace diaphragms, O-rings, and face seal straps yearly or as required.

Caution! Do not leave mask assembly connected to chamber ports for extended

periods after a dive without cleaning and drying the unit. Moisture build up within the

unit will lead to corrosion after a period of time.

803139-UM REV 3.0 Amron International, Inc. 3

CARE and CLEANING Section 2

2.3 Standard Cleaning Procedures

1. The information in this manual should be used as a guideline only. Every

company should have their own procedures in place for cleaning and /or

disinfecting safety equipment used in oxygen and breathing environments!

2. After Each Use – Clean facemasks with nonionic detergent such as “Ivory

Liquid” and warm water (110˚F maximum). Rinse with clear water and dry

completely before using or storing. Wipe and clean entire remaining

assembly as above and dry completely before using or storing. (Take care

that water does not enter the regulator assembly openings).

3. Every 6 Months – Disassemble entire assembly, manifold, regulators,

hoses, diaphragms. See Section for Assembly/Disassembly Procedures.

Clean all metal and non-metal parts with nonionic detergent. Rinse with

clear water and dry completely before storing or using.

4. You may also sponge external parts and components with a 70 percent

solution of Ethyl Isopropyl alcohol, or SaniZide-Plus. Allow to completely

dry for a minimum of two hours before storing or using.

5. An oxygen compatible lubricant, such as Christo-Lube, is recommended for

use as a lubricant. It is recommended to periodically lubricate all the

moving parts such as hose connection threads, manifold threads, etc.

WARNING!

Use precautions when handling alcohol, as alcohol is a flammable chemical!

803139-UM REV 3.0 Amron International, Inc. 4

Section 2 CARE and CLEANING

2.4 Disinfecting

SaniZide-Plus can be used for disinfecting the Avox Inhalators and found

on Amron’s website at www.amronintl.com. Use per manufacturer’s

instructions.

Avox Systems, Inc. or Amron International, Inc. is not responsible for

damage to equipment or improper cleaning. Each person or entity is

responsible for their own procedures for disinfecting oxygen breathing

masks.

2.5 Storage and Preservation

1. After extended treatment, the entire assembly should be disassembled,

cleaned, dried, and reassembled then stored in an air tight sealed plastic

bag until the next use.

2. Remove the complete mask assembly from the chamber when not in use. If

required to store mask in the chamber, insure that the mask is clean and

completely dry and stored in an air tight plastic bag.

3. After each dive, the Pressur Vak II face seal should be disconnected from

the manifold assembly. Clean and dry the face seal completely and store in

an air tight plastic bag until the next treatment.

Caution! Do not leave the mask assembly inside the chamber for extended periods

without cleaning, drying and proper storing.

803139-UM REV 3.0 Amron International, Inc. 5

HOSE ASSEMBLY MAINTENANCE Section 3

3.1 Hose Assembly Component Parts Installation

1. Slide grommets (Pos. E-

5), onto hoses (Pos. E-3

&E-4). Three grommets

are recommended per 10

foot hose assembly.

Distribute grommets

uniformly over entire

length of hoses.

2. Insert hose plug (Pos. E-

7) to end of exhaust hose

(Pos. E-4). Secure hose

clamp (Pos. E-8).

3. Insert gasket (Pos. E-2)

into demand hose

assembly (Pos. E-3).

4. Attach demand hose to

demand regulator

assembly (Pos. C-1).

Follow instructions

paragraph 3.2 through 3.7

for completion of hose

assembly.

5. It is important to attach the demand hose to the demand regulator (Pos. E-3) first.

6. Verify that the gasket (Pos. E-2) is inserted into the nut on the demand hose.

7. Screw hose nut to demand regulator assembly (Pos. C-1) and tighten moderately

with wrench, a quarter or half turn after finger tight.

8. Push hose assembly (Pos. E-4) onto exhaust regulator (Pos. C-2) until stem of

regulator is fully inserted into the hose.

9. Attach the hose clamp (Pos. E-8) around the hose at the top end, so the clamp firmly

grasps the regulator stem. Tighten the clamp.

10. Attach the demand quick disconnect (Pos. F-2to the demand hose assembly hose

plug (Pos. E-6).

11. Attach the quick disconnect (Pos. F-1) to the exhaust hose plug (Pos. E-7).

803139-UM REV 3.0 Amron International, Inc. 6

Section 4 DEMAND REGULATOR MAINTENANCE

4.1 Demand Regulator Maintenance (Pos. C-1)

1. Remove clamp (Pos. C-5) from Regulator Assembly by spreading and

removing. Lift cover (Pos. C-4)

2. Lift diaphragm (Pos. C-3) out of case assembly (Pos. C-2).

3. The spring, stem, clamp and case assembly parts (Pos. C-2, 6, 7, 8) are not

available as spare parts. If these parts become damaged or need replacing,

contact Amron International, Inc. for repair or replacement of regulator

assembly.

4. Inspect the diaphragm for tears or rips and be sure the diaphragm is free of

wrinkles and bulges. Replace if necessary. Diaphragm should be replaced on a

yearly basis as a minimum.

5. During reassembly the arrow on the diaphragm must be facing the regulator

cover and the metal disc on the diaphragm must point to the hose connection

(inlet). Diaphragm must be positioned so the tilt valve stem ball rides on the

metal disc.

6. Replace cover (C-4) and clamp assembly.

Note: Demand Regulator Valve Assembly (Items C-6, C-7, C-8) are not available

as spare parts. If these items become damaged you must purchase the

800956-01 Regulator Case Assembly with valve or complete Demand

Regulator Assembly 800954-01

803139-UM REV 3.0 Amron International, Inc. 7

EXHAUST REGULATOR MAINTENANCE Section 5

5.1 Exhaust Regulator Maintenance (Pos. D-1)

1. Remove cover (Pos. D-4) by spreading and removing clamp (Pos. D-5).

2. Lift diaphragm and stem guide assembly (Pos. D-3) out of case assembly (Pos.

D-2). Care should be taken to guide the stem assembly carefully out of the stem

guide on the diaphragm.

3. Inspect diaphragm for any cuts, tears, wear or bulges. Replace if necessary.

Diaphragm should be replaced on a yearly basis as a minimum.

4. To remove valve assembly (Pos. D-6 & D-7) from case assembly (Pos. D-2),

gently compress spring (Pos. D-7) and carefully remove entire spring and stem

assembly.

5. When reassembling the tilt valve stem in the exhaust regulator the stem must be

positioned between the diaphragm and tilt valve retainer bracket. The arrow on

the diaphragm must point toward the inlet.

6. Replace Diaphragm, cover and clamp assemblies.

803139-UM REV 3.0 Amron International, Inc. 8

Section 6 803139 SERIES PRESSUR VAK II INHALATOR

6.1 Assembly / Disassembly of Pressur Vak II

1. The Pressur Vak II face seal is designed to attach and detach with ease from the

manifold assembly via a quick disconnect arrangement. This allows each person

to have their own face seal and reduces infections associated with multi-user

type systems. This quick disconnect arrangement also facilitates convenient

cleaning and disinfecting of the mask.

2. The face seal assembly is available in five (5) sizes for a comfortable fit and to

insure proper seal to prevent leakage past the mask to face interface. The

harness assembly is designed to hold the face seal securely and does not loosen

once securely positioned.

6.2 Attaching Face Seal to Manifold Assembly

1. Align face seal front opening to manifold quick disconnect

2. Place thumb inside face seal and push the quick release inner flange down, while

pushing face seal onto the manifold quick disconnect.

3. Face seal will “lock on” the manifold assembly.

4. To verify face seal is securely attached to manifold, carefully attempt to pull face

seal assembly away from the manifold.

6.3 Detaching Face Seal from Manifold Assembly

1. Place thumb inside face seal and push the quick release inner flange down, while

pulling slightly on the face seal outer edges.

2. Manifold should disengage from face seal with little or no pressure exerted on the

face seal.

803139-UM REV 3.0 Amron International, Inc. 9

803139 SERIES PRESSUR VAK II INHALATOR Section 6

6.4 Regulators to Manifold Installation

1. Install exhaust and demand regulators to manifold assembly as follows:

2. Position the two O-rings (Pos. B-2) on Demand Regulator (Pos. C-1) and

Exhaust Regulator (Pos. D-1).

3. Screw regulator (C-1) into manifold (B-1).

4. Screw regulator (D-1) into opposite side of manifold (B-1).

Important:

Do not forget to place O-rings (B-2), one on each regulator, before

attaching regulators.

5. Insert a “cotter pin” or a small locking pin tool into the small tightening

holes located at top of the manifold (See Pos. B-4).

Note: There are two holes (one in the outer manifold case and one in the inner

swivel assembly). Align holes and insert pin to prevent inner swivel from

turning while tightening regulators.

6. Exert a small amount of pressure on the tool while rotating the regulator

onto the manifold until you feel the pin drop into the second hole which is

located inside the manifold. Hold this position firmly and tighten the

regulator

7. Insure that regulators are tightened correctly on manifold, twist the

regulator that you have just installed while exerting outward pressure on

the regulator. If regulator comes loose, you have not properly tightened

the regulator to the manifold.

8. Follow the above procedure for both the exhaust and the demand

regulators when installing and disassembling of the regulators to manifold

assembly.

803139-UM REV 3.0 Amron International, Inc. 10

Section 6 803139 SERIERS PRESSUR VAK II INHALATOR

6.5 Pressur Vak II Inhalator Parts Drawing

A-1 thru A-4

Not Shown

Face Seal with microphone Assembly 803152(XX) M

Headnet/Harness Brass Blanking Plug: BIBS Manifold:

Assembly: Inserts in the exhaust quick Easy to use Brass

Headnet with light weight disconnect. Stops exhaust manifold available in 2

polyester netting and Velcro flow from chamber when or 4 port versions.

straps. Provides a snug fit mask is disconnected from

manifold.

Includes demand and

around the upper portion of

the head which evenly

exhaust ports.

distributes the weight of the

mask and regulators. An

alternative to the 803115-

01 head strap assembly

provided with the Pressur

Vak II Inhalator. 2 Port 8000-002

Order No. B-6QDP

Order No. 460-0001-01

4 Port 8000-004

803139-UM REV 3.0 Amron International, Inc. 11

803139 SERIES PRESSUR VAK II INHALATOR Section 6

6.6 Pressur Vak II Inhalator Parts Listing

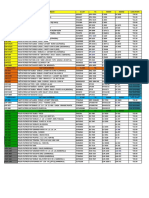

Item Part Number Description Material

A-1 Face seal Assembly with elastic

Polysulfone (Hard Shell)

thru 803152-(size) strap assy. (05=X-Sm, 01=Sm,

Silicone Rubber Soft Seal

A-5 02=Med, 03=Lg, 04=X Lg)

A-6 803115-01 Head Strap (Elastic) Elastic

Screw w/o-ring (inside face seal)

00-5401 Stainless Steel

(4)

834-12 Capped T-Nut (face seal) (4) Stainless Steel 303

801430-03 Buckle Bar (face seal) (4) CRCQ Low Carbon Steel

Noryl SE-1

Manifold Assembly

Teflon coated Alum.

B-1 803100-01 Housing & Plunger, Ball Lock

Alloy

Ball, Spring and Pins

Stainless Steel

B-2 18062-00 O-Ring, Manifold to Regulators (2) Silicone Rubber

B-3 21506-01 O-Ring, Manifold to Face seal (1) Silicone Rubber

B-4 N/A Illustration Only

C-1 800954-01 Demand Regulator Assembly See Lower Assembly

C-2 800956-01 Case Assembly, Includes C-6,7,8,9 Stainless Steel 316

Neoprene & natural

C-3 26004-01 Diaphragm, Demand Regulator

rubber blend

C-4 801276-00 Cover, Demand Regulator Stainless Steel 316

C-5 26010-01 Clamp, Regulator Cover Stainless Steel 316

C-

Not Available Valve Stem & Spring Stainless Steel 316

6,7

C8,9 Not Available Valve Clamp & Bearing Spring Stainless Steel 302

D-1 801274-00 Exhaust Regulator Assembly See Lower Assembly

D-2 801275-00 Case Assembly, Exhaust Regulator Stainless Steel 316

Diaphragm & Stem Guide

D-3 801272-00 Stainless Steel & Buna N

Assembly

D-4 100003027 Cover, Exhaust Regulator Stainless Steel 316

D-5 26010-01 Clamp, Regulator Cover Stainless Steel 316

D-6 800963-00 Valve, Exhalation Stainless Steel 316

D-7 13796-00 Spring, Exhalation Valve Stainless Steel 316

E-1 803166-10 Dual Hose Assy., with F-1 & F-2 See Lower Assembly

E-2 2827-49 Gasket, Demand Hose Teflon

803139-UM REV 3.0 Amron International, Inc. 12

Section 6 803139 SERIES PRESSUR VAK II INHALATOR

6.6 Pressur Vak II Inhalator Parts Listing (Continued)

Part

Item Description Material

Number

I.D. 3/16”

Demand Hose Assembly with E-2,

O.D. 7/16”

F-2

Working Pressure 250 psi

10 foot, Cleaned for Oxygen

E-3 26037-10 Burst Pressure 1500 psi

Breathing

Inner Tube Nitrile, Black

Mil-Spec MIL-H-2815 Section

Braid Single Fiber

4.5.10

Cover NBR/PVC

I.D. 3/8”

O.D. 5/8”

Exhaust Hose Assy, with E-8, F-1 Working Pressure 250 psi

E-4 59719-10 10 foot, Cleaned for Oxygen Burst Pressure 1000 psi

Breathing Inner Tube Nitrile, Black

Braid Single Fiber

Cover Neoprene

E-5 10002573 Hose Grommet (3) Krytox Thermoplastic

E-6 18970-00 Hose Plug, Demand Hose Brass

E-7 59852-00 Hose Plug, Exhaust Hose Brass

E-9 C.055 Spring, Spiral Stainless Steel

E-10 8900-001 ½-20 Female Fitting Brass, Nickel Plated

E-11 8900-002 1/8” Male NPT Fitting Brass, Nickel Plated

Not

E-12 Sleeve (Ferrule) Aluminum

Shown

Quick Disconnect, Exhaust 3/8

F-1 59853-00 Brass

NPT

Quick Disconnect, Demand 1/8

F-2 18969-00 Brass

NPT

F-3 B-6QDP Plug for Exhaust Q.D. (Optional) Brass

ITEMS NOT SHOWN ON PARTS DRAWING

460-0001-01 Head Net (Harness) Assembly

803152-(XX)M Face seal Assembly with 150 ohm Microphone - (XX) equals size

1408 Microphone element 150 ohm dynamic

803200-(XX) Retrofit Kit – upgrades Duo-Seal Inhalator to Pressur Vak II

Hoses and related fittings including Quick Disconnects Oxygen Cleaned to MIL STD. 1330D

All other components cleaned to MIL-O-27210

803139-UM REV 3.0 Amron International, Inc. 13

RETROFIT KIT Section 7

7.1 Avox Retrofit Kit (Part Number 803200-XX)

The Avox Retrofit Kit is

used to update the older

version Avox overboard

discharge 801238 Series

Inhalator to the newer

Pressur Vak II Inhalator

with overboard

discharge. The kit allows

the reuse of all

components of the

801238 series mask with

the exception of the face

seal. The Retrofit Kit

includes the following:

Item Part Number Description Quantity

B-1 803100-01 Manifold Assembly 1

B-2 18062-00 O-ring, Manifold to Regulators 2

B-3 21506-01 O-ring, Manifold to Face seal 1

B-4 803152-XX Face seal & Harness Assembly 1

The part number for the Retrofit Kit is dependent upon your choice of Face Seal with Harness size.

Extra Small – 803200-05, Medium Small – 803200-01, Medium – 803200-02,

Large – 803200-03, Extra Large – 803200-04

7.2 Retrofit Kit – Disassembly of 801238 Face piece Assy.

1. Complete the following steps to retrofit

the Avox 801238 Series Diver Inhalator

to the Avox 803139 Series Pressur Vak

II Inhalator. Disassemble only to the

extent shown. Disassembly beyond the

extent shown may result in permanent

damage to the system.

2. Open clamp (Pos. 12) to allow removal

of exhaust hose.

3. Unthread-thread supply hose at the

Demand Regulator. (Pos. 26).

4. Remove the demand regulator (Pos. 26) from face seal assembly (Pos. 43), by

removing nut (Pos. 17) and washer (Pos. 18).

5. Remove the exhaust regulator (Pos. 29) from face seal assembly (Pos. 43), by

removing nut (Pos. 27) and washer (Pos. 28).

6. Reassemble components using assembly and installation instructions for Pressur

Vak II Inhalator.

803139-UM REV 3.0 Amron International, Inc. 14

Section 8 801238 SERIES OBD INHALATOR

8.1 General Information

The Avox 801238 Series Overboard Discharge Inhalator incorporates all of the

components of the Avox Pressur Vak II with the exception of the face seal and manifold

assembly.

8.2 801238 Series OBD Parts Drawing

803139-UM REV 3.0 Amron International, Inc. 15

801238 SERIES OBD INHALATOR Section 8

8.3 801238-(XX) – (XX) 801238 Series Inhalator Parts Listing

Item Part No. Description Item Part No. Description

Dual Hose Assy. 27 10002551 Teflon Nut

803166-10

Complete 28 10002550 Washer

4 18969-00 Socket, Q.D. Exhaust Regulator

29 801274-00

5 59853-00 Socket, Q.D. Assy

6 18970-00 Hose Plug 30 10003027 Cover

7 59852-00 Hose Stem 31 26010-01 Clamp

Replacement Hose Diaphragm & Stem

8 20433-00 32 801272-00

Clamp, Guide

Demand Hose, 10 ft. – 33 13796-00 Spring

10 26037-10

Oxygen Cleaned 34 800963-00 Exhalation Valve Assy

Demand Hose, 25 ft. 36 801275-00 Regulator Case

11 26037-25 (Optional) – Oxygen 37 801267-00 Guard and Plate Assy

Cleaned 38 10003063 Housing, Microphone

Hose Clamp – 40 10003054 Holder

12 MLT2S-CP Permanent (tool 41 801266-00 Mask Assy. with Straps

required) Strap Assy (2 left – 2

13 59719-10 Exhaust Hose, 10 ft. 42 604028-00

right)

Exhaust Hose, 25 ft. 43 801266-01 Mask without Straps

14 59719-25

(optional) Exhaust Plug for item 5

15 10002573 Hose Grommet 44 B-6QDP

(optional)

16 2827-49 Gasket, Demand Hose

17 10002551 Teflon Nut

Repair Kits

18 10002550 Washer

Demand Regulator RK-800954-01 Demand Regulator Kit

19 800954-01

Assy RK-801238 Mask Kit

20 801276-00 Cover

21 26010-01 Clamp

22 26004-01 Diaphragm

Case Assy., (includes

26 800956-01

23, 24, 25 & 25A)

Hoses and related fittings including Quick Disconnects are Oxygen Cleaned to MIL STD. 1330D

All other components cleaned to MIL-O-27210

803139-UM REV 3.0 Amron International, Inc. 16

Section 9 803600 SINGLE HOSE INHALATOR

9.1 General Information

The Avox 803600 Series Single Hose

Inhalator is designed for dry

atmosphere decompression and other

applications where it is desirable to

breathe mixtures other than ambient

air. The 803600 Inhalator vents the

exhaled gas directly to the chamber

atmosphere.

Item Part No. Description

5 18969-00 Quick Disconnect

6 18970-00 Hose Plug

7 26037-08 Hose Assy, 8 ft.

8 800227-00 Demand Regulator Assy.

9 26018-01 Cover, Regulator

10 26010-01 Clamp, Regulator

11 26004-01 Diaphragm

Gasket, Regulator to

12 2827-08

Face Seal

13 800228-00 Case Assy.

14 27495-00 Microphone Assy.

15 6232-00 Microphone only

16 708-8013 Cable, 2 cond. w/shield

17 27495-04 Housing, Microphone

18 803677-02 Face Seal with Straps

19 600118-00 Strap Assy.

22 64001-00 Buckle Bar & Clip

23 64152-02 Exhaust Valve Assy.

24 2827-49 Gasket, Hose

25 10005711 Plug

Repair Kits

RK-803600 Repair Kit, Inhalator

RK-800227-00 Repair Kit, Regulator

Hoses and related fittings including Quick Disconnects are Oxygen Cleaned to MIL STD. 1330D

All other components cleaned to MIL-O-27210

803139-UM REV 3.0 Amron International, Inc. 17

TROUBLESHOOTING Section 10

Problem Probable Cause Remedy

• Loose connection • Tighten fittings

Leakage at chamber

supply or chamber vacuum

connection. • Cross threading • Replace fittings

• Loose fitting at demand • Tighten fittings

regulator

Leakage at connections to • Tighten or replace clamp

regulator assembly • Loose or damaged hose clamp

at exhaust regulator

• Loose nut or cross threading of • Tighten nut. Replace nut or

nut or regulator case regulator case

Leakage at mating or • Damaged O-ring • Replace O-ring

regulator and mask

assemblies • Stem Guide not positioned • Insert properly in stem

properly in diaphragm stem guide

guide assembly

• Open connection at chamber or • Reconnect fittings

demand regulator connection

• Foreign material lodged in hose • Replace hose assembly

No oxygen flow to mask

stem

assembly

• Straighten and inspect

• Damaged or crimped supply hose for damage. Replace

hose if necessary

• Differential pressure to high • Install secondary (BIBS)

exhaust regulator. See

Collapsed exhaust hose

Para. 1.7

• Foreign material lodged in • Inspect and remove

demand valve stem seat material (determine source

of contamination and

Free flow or continuous

correct)

flow to mask

• Damaged demand valve seat

• Replace valve seat

• Inlet pressure to high • Correct pressure as

High breathing resistance specified in Para 1.6 and

(inhalation) 1.9

High breathing resistance • Vacuum pressure too high or • Correct pressure as

(exhalation) too low specified in Para 1.7

803139-UM REV 3.0 Amron International, Inc. 18

Section 11 INHALATION/EXHALATION PERFORMANCE

11.1 Inhalation Performance Chart

803139-UM REV 3.0 Amron International, Inc. 19

INHALATION / EXHALATION PERFORMANCE Section 11

11.2 Exhalation Performance Chart

803139-UM REV 3.0 Amron International, Inc. 20

Section 12 REPAIR LOG

Model Number:

Serial Number:

Date Service Maintenance Performed Condition Repaired

Code and/or Parts Replaced of Unit By

803139-UM REV 3.0 Amron International, Inc. 21

For technical assistance, product information

and parts replacement contact:

Amron International, Inc.

1380 Aspen Way

Vista, California 92081 USA

Phone: 760-208-6500

Fax: 760-599-3857

E-mail: sales@amronintl.com

Order on-line www.amronintl.com

Avox, the Avox Logo and Pressur Vak II

are trademarks of

Avox Systems, Inc. DBA Zodiac Oxygen Systems US

803139-UM REV 3.0 Amron International, Inc.

You might also like

- Smiths Fluid Warmer - General Technical ManualDocument131 pagesSmiths Fluid Warmer - General Technical Manualmeet_vaghaniNo ratings yet

- Liferaft 606Document114 pagesLiferaft 606ranggaNo ratings yet

- Curtiss-Wright Controls Integrated Sensing (Cage Code: 03972)Document6 pagesCurtiss-Wright Controls Integrated Sensing (Cage Code: 03972)Huda LestraNo ratings yet

- 0564 03 Component Maintenance Manual For Learjet 45Document41 pages0564 03 Component Maintenance Manual For Learjet 45Aka MonuNo ratings yet

- Pa 18 150 - pcv1988Document164 pagesPa 18 150 - pcv1988Jessey StonerNo ratings yet

- Saeco LirikaDocument40 pagesSaeco LirikaGurin CorneliuNo ratings yet

- 51-42-00 - 2 Chapter ManualDocument18 pages51-42-00 - 2 Chapter ManualRobert KrižanovićNo ratings yet

- AVOX July2011Document6 pagesAVOX July2011Kriss JonesNo ratings yet

- 25-11-73 Safran SeatsDocument238 pages25-11-73 Safran SeatssebastienNo ratings yet

- 33 50 02 PDFDocument312 pages33 50 02 PDFbeggi90No ratings yet

- Sae Arp 5483-8 2002 (En)Document9 pagesSae Arp 5483-8 2002 (En)Oh No PotatoNo ratings yet

- SblistDocument12 pagesSblistgerezairNo ratings yet

- LAN Interface Module: Ricochet Voice Logging SystemDocument4 pagesLAN Interface Module: Ricochet Voice Logging SystemWynona Samuelle Fontanilla PingoyNo ratings yet

- Service Bulletin Information Sheet: MODEL BD-700-1A10 (BD-700)Document29 pagesService Bulletin Information Sheet: MODEL BD-700-1A10 (BD-700)romixrayzenNo ratings yet

- PDF - TBC Seds - CMM 26 10 48 89954 24033 24076Document152 pagesPDF - TBC Seds - CMM 26 10 48 89954 24033 24076Thiago FortiNo ratings yet

- Sandel SN3500 IM CDocument133 pagesSandel SN3500 IM CHouvenaghel100% (1)

- FAA 2019 0207 0011 - Attachment - 1Document6 pagesFAA 2019 0207 0011 - Attachment - 1Sa Be MirNo ratings yet

- Sil 26-0233eDocument13 pagesSil 26-0233eKhaled ElmabroukNo ratings yet

- Altimatic Iiic Service ManualDocument239 pagesAltimatic Iiic Service Manualjd beardenNo ratings yet

- Avianca RotablesDocument42 pagesAvianca RotablesEstevam Gomes de AzevedoNo ratings yet

- CMM 26 20 30 Rev 10 Dated Jan 2019Document34 pagesCMM 26 20 30 Rev 10 Dated Jan 2019TESTNo ratings yet

- Complete List of ETSO AuthorisationsDocument2 pagesComplete List of ETSO AuthorisationsMarlene SalazarNo ratings yet

- Air Data Attitude Heading Reference System: FeaturesDocument2 pagesAir Data Attitude Heading Reference System: FeaturesIventNo ratings yet

- ST-2 Product Description Version51Document28 pagesST-2 Product Description Version51Vlad PopaNo ratings yet

- MEP 15-018 - Eng - Rev PDocument32 pagesMEP 15-018 - Eng - Rev PTAR AEROLINEASNo ratings yet

- CMM 32C15034xx00xDocument226 pagesCMM 32C15034xx00xrusdiNo ratings yet

- Easa Pad 18-184 1Document4 pagesEasa Pad 18-184 1cf34No ratings yet

- 31 59 93 PDFDocument39 pages31 59 93 PDFjorge furtado de freitasNo ratings yet

- Learjet 45 Illustrated Parts CatalogDocument4 pagesLearjet 45 Illustrated Parts CatalogJosueFerreiraNo ratings yet

- 5-12-14 Inspection Phase 14Document1 page5-12-14 Inspection Phase 14Lady Laura Sierra RuizNo ratings yet

- CMM 26-05-01 - Inertia SwitchDocument48 pagesCMM 26-05-01 - Inertia Switchmuh mutaqinNo ratings yet

- 2017 Capabilities List - AeTRDocument696 pages2017 Capabilities List - AeTRcatseekit 캣시킷No ratings yet

- Zodiac Services: Transmittal SheetDocument225 pagesZodiac Services: Transmittal SheetNegin ForozeshNo ratings yet

- NCC Operations ManualDocument24 pagesNCC Operations Manuala320100% (1)

- Chapter 12Document28 pagesChapter 12lufro100% (1)

- 35-10-85 Rev 007 (Fullface Mask Stowage Box AssyDocument100 pages35-10-85 Rev 007 (Fullface Mask Stowage Box AssynoureldinkamalNo ratings yet

- G 406 570-5004 Rev JDocument69 pagesG 406 570-5004 Rev JKumaraswamy RSNo ratings yet

- A318/A319/A320/A321: Service BulletinDocument213 pagesA318/A319/A320/A321: Service BulletinPradeep K s100% (1)

- Mandatory: Bollettino TecnicoDocument61 pagesMandatory: Bollettino TecnicoAgustaNo ratings yet

- 5978357233e09 - Zodiac Aerospace - SB MXH-35-240 R7Document45 pages5978357233e09 - Zodiac Aerospace - SB MXH-35-240 R7Cpatrick DeLyonNo ratings yet

- User Manual 704904Document69 pagesUser Manual 704904Brad WincharNo ratings yet

- Turco 1495Document2 pagesTurco 1495Are Soo YantoNo ratings yet

- 25-25-085-3489 R0 (TR-1.01) PDFDocument264 pages25-25-085-3489 R0 (TR-1.01) PDFSuman BajracharyaNo ratings yet

- Mrf-Running FileDocument52 pagesMrf-Running Filenasser ondilloNo ratings yet

- 429E Operation Manual PDFDocument32 pages429E Operation Manual PDFjorge furtado de freitasNo ratings yet

- 8140B-30 Altimeter EncoderDocument48 pages8140B-30 Altimeter Encoderwilliam abraaoNo ratings yet

- Installation and Operation Manual: HSP-037-x, HSP-037C-x, HSP-045-x Headphone Switch Panel Document # 540083Document18 pagesInstallation and Operation Manual: HSP-037-x, HSP-037C-x, HSP-045-x Headphone Switch Panel Document # 540083PLHerrNo ratings yet

- Service Newsletter: SubjectDocument5 pagesService Newsletter: SubjectBrsaNo ratings yet

- SM60129 1Document12 pagesSM60129 1HENKO7659100% (1)

- CRU-120-P Oxygen RegulatorDocument1 pageCRU-120-P Oxygen RegulatorwillalizadeNo ratings yet

- Learjet 31 Customized Avionics and Optional Electrical Wiring ManualDocument215 pagesLearjet 31 Customized Avionics and Optional Electrical Wiring Manualfrancklin1912No ratings yet

- ME406 and ME406 HM Description, Operation, Installation and Maintenance ManualDocument68 pagesME406 and ME406 HM Description, Operation, Installation and Maintenance ManualFlyForFunNo ratings yet

- Component Maintenance Manual With Illustrated Parts ListDocument141 pagesComponent Maintenance Manual With Illustrated Parts ListDouglas de OliveiraNo ratings yet

- 1 1 PDFDocument266 pages1 1 PDFGeMoCon GmbHNo ratings yet

- TM 11-1520-217-34P-2 24-Oct-77 USAPADocument88 pagesTM 11-1520-217-34P-2 24-Oct-77 USAPAruiNo ratings yet

- 02X1248C01XX - Rev02!03!20 - Operational and Service ManualDocument80 pages02X1248C01XX - Rev02!03!20 - Operational and Service Manualmario brosNo ratings yet

- LS-DYNA Cargo Net SimulationDocument11 pagesLS-DYNA Cargo Net SimulationPaulo César QueirozNo ratings yet

- Mil PRF 85285DDocument21 pagesMil PRF 85285DmmdominicNo ratings yet

- Manual Air Blast 300Document13 pagesManual Air Blast 300Mario EprataNo ratings yet

- CN DC 2 F2 TC SJ Te Mi C4 Xo Hky CRF XP SIWk DJX TFUn 3 eDocument24 pagesCN DC 2 F2 TC SJ Te Mi C4 Xo Hky CRF XP SIWk DJX TFUn 3 eAdi WiranataNo ratings yet

- Stationary Two-Stage Air Compressor: Description SpecificationsDocument12 pagesStationary Two-Stage Air Compressor: Description SpecificationsMireya Linares MoriNo ratings yet

- Enter Shaft Dia XDocument4 pagesEnter Shaft Dia Xsantosh awateNo ratings yet

- Hardinge Spindle Bearing Replacement PDFDocument4 pagesHardinge Spindle Bearing Replacement PDFJayakrishnaNo ratings yet

- Fusilera Citroen C3 Picasso 2008Document3 pagesFusilera Citroen C3 Picasso 2008skpppNo ratings yet

- Bajaj Maxima Z & WB LPG, CNG SPCDocument78 pagesBajaj Maxima Z & WB LPG, CNG SPCjai arora100% (2)

- Pre Use Inspection For Kubota TractorDocument2 pagesPre Use Inspection For Kubota TractorJannie CoetzeeNo ratings yet

- Trackon ProposalDocument7 pagesTrackon ProposalMahendra LamsalNo ratings yet

- Correct Operation and Maintenance of TC EngineDocument3 pagesCorrect Operation and Maintenance of TC EngineAdrian MacayaNo ratings yet

- RTR 4 V Spares Parts MRPDocument2 pagesRTR 4 V Spares Parts MRPRaju Khan100% (1)

- Recommended Spares ListDocument2 pagesRecommended Spares ListJorge Mario Perdomo PerdomoNo ratings yet

- Ori̇on (Kutulu) Li̇ste 11.2020 Naki̇tte 55+5Document24 pagesOri̇on (Kutulu) Li̇ste 11.2020 Naki̇tte 55+5AKILLI FİLMNo ratings yet

- Installing Seal Crankshaft 320DDocument3 pagesInstalling Seal Crankshaft 320DSteven Y.MNo ratings yet

- Water-Cooled Refrigerant Recovery and Recycling Units: Operation & MaintenanceDocument54 pagesWater-Cooled Refrigerant Recovery and Recycling Units: Operation & MaintenanceUmar MajeedNo ratings yet

- Telsmith Cone Sbs PDFDocument1 pageTelsmith Cone Sbs PDFoncombro100% (2)

- Unit Ii Robot Drive Systems AND End Effectors: Prepared by B.Balasubramanian Ap/Mech CcetDocument89 pagesUnit Ii Robot Drive Systems AND End Effectors: Prepared by B.Balasubramanian Ap/Mech CcetBala mechNo ratings yet

- Airbus A330 Landing Gear and DoorsDocument37 pagesAirbus A330 Landing Gear and DoorsSalemleviatan100% (1)

- Engineering Operation & Maintenance: Plastic PumpDocument24 pagesEngineering Operation & Maintenance: Plastic PumpCirilo Marcos RossiNo ratings yet

- Tundra Partes 9Document3 pagesTundra Partes 9alexander pintoNo ratings yet

- Accu 220 Manual T 03Document14 pagesAccu 220 Manual T 03Junior DíazNo ratings yet

- Auto Cone ComparisonDocument8 pagesAuto Cone ComparisonMuhammad Talha100% (1)

- Ship Particular TB STA 1 - 3000 HPDocument1 pageShip Particular TB STA 1 - 3000 HPMichael GunawanNo ratings yet

- HKS EVC 6 ManualDocument52 pagesHKS EVC 6 Manualkai_isman67% (3)

- Se 150-60 - 2015Document849 pagesSe 150-60 - 2015helijunior67151No ratings yet

- Drum BrakesDocument5 pagesDrum Brakesomer afridiNo ratings yet

- Sold Out: System Sku Chinese Mode NumberDocument16 pagesSold Out: System Sku Chinese Mode NumberSajjad AhmedNo ratings yet

- M38-5 EU 3-Axles Data Sheet enDocument2 pagesM38-5 EU 3-Axles Data Sheet enJuve De la CruzNo ratings yet

- Sandvik Dr412I Rotary / DTH Blast Hole Drill: Technical SpecificationDocument4 pagesSandvik Dr412I Rotary / DTH Blast Hole Drill: Technical SpecificationPablo Luis Ojeda PaezNo ratings yet

- Thermosiphon Engine Heaters: CB Model Weathertight Single PhaseDocument2 pagesThermosiphon Engine Heaters: CB Model Weathertight Single PhaseGerman O.No ratings yet

- Sp-Spv40-25-E 2-41693 1997-06-12 PDFDocument16 pagesSp-Spv40-25-E 2-41693 1997-06-12 PDFJose Manuel Barroso PantojaNo ratings yet

- Tuneland-Foton ProfileDocument18 pagesTuneland-Foton Profilem h habib m h kassamNo ratings yet