Professional Documents

Culture Documents

Nicrobraz Cement 680

Uploaded by

brunizzaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nicrobraz Cement 680

Uploaded by

brunizzaCopyright:

Available Formats

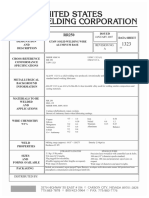

No. 2.2.2.

NICROBRAZ® CEMENT 680

A general-purpose, sprayable,

water-based braze binder

The cement can be mixed with powder to form

Nicrobraz® Cement 680 is a low viscosity, slurry for dip application, or for placement with an

water-based braze binder that can be used to eye dropper or syringe. Cement may also be used to

hold a wide variety of filler metals in place for infiltrate preplaced, dry powder, by soaking the filler

brazing. It is ideally suited for application of metal within the intended brazing joint. Thinning

nickel-based brazing filler metals with the should not be required, but if desirable, distilled or

NicroSpray® system. It has a low solids content, deionized water is recommended.

to minimize outgassing during the furnace cycle.

It will readily wet the surface of clean metal Suggested Atmospheres. Cement 680 is suitable

substrates, has excellent adherence, and a for use in vacuum, hydrogen, argon or nitrogen, or

relatively short drying time. blends of these gases.

Normally no residue remains on the parts after Drying Time. Drying times will vary, depending on

brazing, when using nickel-based filler metals. the atmosphere conditions and thickness of the

However, if using copper or silver containing applied coating. When drying at room temperature,

filler metals, a small amount of sooty residue with a typical coating thickness, loss of gloss will

may remain. occur in 20-30 minutes, product will be completely

dry in 50-60 minutes. Drying time may be reduced

Nicrobraz Cement 680 may also be mixed with by drying at 200°F for 10-15 minutes.

Nicrobraz White Stop-Off™ powder, and

applied to mating surfaces to prevent accidental Availability. Bulk liquid in 3-liter or 200-liter size.

brazing.

Viscosity. 375-475 centipoise (CPS) at 77°F.

Application Methods. For application using

the NicroSpray system (see data sheet NSG), or Shelf Life. Minimum of 12 months from the date of

similar spray-gun units, the required amount of manufacture, when stored in unopened containers.

binder should be 8-15%, by weight. If the binder May be suitable for use well after the minimum shelf

feed rates are not reduced, the sprayed coating life period has expired.

will be too wet, and may run when applied to

nonhorizontal surfaces. Copyright Wall Colmonoy Corporation 7/2006

You might also like

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Nitobond SBR Mortar AdditiveDocument4 pagesNitobond SBR Mortar AdditivehelloitskalaiNo ratings yet

- Mastercoat Chassis Black DatasheetDocument2 pagesMastercoat Chassis Black DatasheetJimDavisNo ratings yet

- Sika PDS - E - Sikagard - 680 SDocument5 pagesSika PDS - E - Sikagard - 680 Slwin_oo2435No ratings yet

- Carboguard 636 XT PDSDocument4 pagesCarboguard 636 XT PDSCarlos Rojas HandalNo ratings yet

- Teknomastic 80 Primer 8803-00 Tds enDocument6 pagesTeknomastic 80 Primer 8803-00 Tds en8q5tgtfn7tNo ratings yet

- Nitoseal MS600 sealant for immersed conditionsDocument4 pagesNitoseal MS600 sealant for immersed conditionsmilanbrasinaNo ratings yet

- Zincanode 402: Two Pack Zinc Rich Epoxy PrimerDocument2 pagesZincanode 402: Two Pack Zinc Rich Epoxy PrimerlivefreakNo ratings yet

- Zincanode 304 pc142Document3 pagesZincanode 304 pc142kushar_geoNo ratings yet

- Sika Poxitar MyDocument3 pagesSika Poxitar Myhijur ChenNo ratings yet

- Carboguard 635: Selection & Specification DataDocument5 pagesCarboguard 635: Selection & Specification DataPrakashNo ratings yet

- Sigmazinc 158 New PDFDocument7 pagesSigmazinc 158 New PDFgst ajahNo ratings yet

- ZNT 500Document2 pagesZNT 500Faisal FaizNo ratings yet

- Terrace Water ProofingDocument3 pagesTerrace Water ProofingKvrd PrasadNo ratings yet

- Carboguard 635 Thinned 50% - Sealer PDSDocument5 pagesCarboguard 635 Thinned 50% - Sealer PDSjakeNo ratings yet

- Premium Zinc-Rich Coating Protects Metal SurfacesDocument2 pagesPremium Zinc-Rich Coating Protects Metal SurfacesJORGE HOLGUINNo ratings yet

- Thioflex 600Document4 pagesThioflex 600wikaNo ratings yet

- Nitobond ARDocument2 pagesNitobond ARJayesh KumarNo ratings yet

- Concure RB90 0606Document2 pagesConcure RB90 0606Thiyagarajan PanneerselvamNo ratings yet

- Interseal 670 HS EN O-FDocument4 pagesInterseal 670 HS EN O-Fapde06No ratings yet

- Sikagard 680 SG - PDSDocument4 pagesSikagard 680 SG - PDSNofella WahyudinNo ratings yet

- Nitobond SBR TDSDocument3 pagesNitobond SBR TDSHariom GuptaNo ratings yet

- SigmaZinc 9 Provides Excellent Corrosion Protection for Structural SteelDocument6 pagesSigmaZinc 9 Provides Excellent Corrosion Protection for Structural SteelAkhtar AnsariNo ratings yet

- Noxudolbrochure ENDocument8 pagesNoxudolbrochure ENausonNo ratings yet

- Nitobond AR UAEDocument2 pagesNitobond AR UAEPavan KrishnaNo ratings yet

- iKOTE CM 30R (TDS) 02-APRIL-2024Document2 pagesiKOTE CM 30R (TDS) 02-APRIL-2024nguyen hoang AnhNo ratings yet

- REMA TIP TOP SC2000 Cement Bonding Procedures Rev4Document5 pagesREMA TIP TOP SC2000 Cement Bonding Procedures Rev4LLNo ratings yet

- Nitobond ARDocument2 pagesNitobond ARDED 11 Pasar Jawa BaratNo ratings yet

- Steel Preparation and PaintDocument6 pagesSteel Preparation and PaintbernardinodinoNo ratings yet

- TDS Fosroc Nitoseal PS200 Saudi ArabiaDocument4 pagesTDS Fosroc Nitoseal PS200 Saudi ArabiaSHAIK ASIMUDDINNo ratings yet

- Nitoseal 290Document4 pagesNitoseal 290shanon33No ratings yet

- AI Hempadur Quattro XO 17870 EnglishDocument4 pagesAI Hempadur Quattro XO 17870 EnglishLuka BornaNo ratings yet

- Teknoplast Primer 5 3288-01 Tds enDocument5 pagesTeknoplast Primer 5 3288-01 Tds enHatef SardariNo ratings yet

- Masterflow: Cementitious High Strength Non-Shrink Precision GroutDocument3 pagesMasterflow: Cementitious High Strength Non-Shrink Precision GroutAydın VarolNo ratings yet

- Sanitile 755 PDSDocument4 pagesSanitile 755 PDSnarmathaNo ratings yet

- Product Data Sheet: Sikacor® Zinc RDocument4 pagesProduct Data Sheet: Sikacor® Zinc RMohammedBayrakdarNo ratings yet

- Nitobond SBR TDS PDFDocument3 pagesNitobond SBR TDS PDFJong Dollente Jr.No ratings yet

- Carboguard 893 SG MIO PDSDocument4 pagesCarboguard 893 SG MIO PDSMuthuKumarNo ratings yet

- Paintmasterwbmetalprimer TDSDocument2 pagesPaintmasterwbmetalprimer TDSMichael JoudalNo ratings yet

- C PLATE TdsDocument1 pageC PLATE TdsEdwin TacoNo ratings yet

- Carbocoat 8239: Selection & Specification DataDocument4 pagesCarbocoat 8239: Selection & Specification DataSHAIK ASIMUDDINNo ratings yet

- Fosroc Nitobond AR acrylic primerDocument2 pagesFosroc Nitobond AR acrylic primerVincent JavateNo ratings yet

- Nitobond AR: Constructive SolutionsDocument2 pagesNitobond AR: Constructive SolutionsMohammad ArslanNo ratings yet

- Surface Prep For Structural Adhesives Technical Bulletin Oct 2018Document13 pagesSurface Prep For Structural Adhesives Technical Bulletin Oct 2018أبومحمدالزياتNo ratings yet

- Sigmazinc 158: Description Principal CharacteristicsDocument7 pagesSigmazinc 158: Description Principal CharacteristicsRobert FrankyNo ratings yet

- Ai Hempadur 15600 English Imo PSPCDocument5 pagesAi Hempadur 15600 English Imo PSPCKarun DasNo ratings yet

- Carboguard 504 PDSDocument4 pagesCarboguard 504 PDSNicholas ColesNo ratings yet

- The KELATE® MR6 Product Information SheetDocument6 pagesThe KELATE® MR6 Product Information SheetTransporte GouveiaNo ratings yet

- SikaMonoTop-620 en - PDS - TR - (11-2018)Document3 pagesSikaMonoTop-620 en - PDS - TR - (11-2018)Subhasis BeraNo ratings yet

- Brush BondDocument4 pagesBrush BondGibbs PerNo ratings yet

- Sika® Concrete Crack Fix: Product Data SheetDocument3 pagesSika® Concrete Crack Fix: Product Data SheetHamidreza AraghianNo ratings yet

- Berger: Product SpecificationsDocument2 pagesBerger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- Sears Sand Blast Equipment - 106.168xxx - Owners Manual - Nov 1974Document8 pagesSears Sand Blast Equipment - 106.168xxx - Owners Manual - Nov 1974grand fir50% (2)

- Arocoat - Repair Paint Data SheetDocument3 pagesArocoat - Repair Paint Data SheetIsboNo ratings yet

- Al-Jazeera Firedamp 263Document2 pagesAl-Jazeera Firedamp 263EngTamer100% (1)

- Sikafloor - 957 SSDDocument3 pagesSikafloor - 957 SSDRodo Samuel SitorusNo ratings yet

- Basf Masterroc Sa 190 TdsDocument3 pagesBasf Masterroc Sa 190 TdsHalit Baris SertbakanNo ratings yet

- Basf Masterseal 640 TdsDocument2 pagesBasf Masterseal 640 TdsJassi Singh0% (1)

- OK Autrod 12.40 (S4)Document1 pageOK Autrod 12.40 (S4)brunizzaNo ratings yet

- Steel GradesDocument8 pagesSteel GradesSanket Arun MoreNo ratings yet

- OK Grain 21.85Document1 pageOK Grain 21.85brunizzaNo ratings yet

- Oxford Alloy 182 (ENiCrFe-3)Document1 pageOxford Alloy 182 (ENiCrFe-3)brunizzaNo ratings yet

- Oxford Alloy 385-16 (E385)Document1 pageOxford Alloy 385-16 (E385)brunizzaNo ratings yet

- Oxford Alloy 622 (ERNiCrMo-10)Document1 pageOxford Alloy 622 (ERNiCrMo-10)brunizzaNo ratings yet

- Oxford Alloy #12 (ECoCr-B)Document1 pageOxford Alloy #12 (ECoCr-B)brunizzaNo ratings yet

- Steel GradesDocument8 pagesSteel GradesSanket Arun MoreNo ratings yet

- Oxford Alloy A (ENiCrFe-2)Document1 pageOxford Alloy A (ENiCrFe-2)brunizzaNo ratings yet

- Oxford Alloy 330-16 (E330)Document1 pageOxford Alloy 330-16 (E330)brunizzaNo ratings yet

- Oxford Alloy 9015-B9Document1 pageOxford Alloy 9015-B9brunizzaNo ratings yet

- Hobart MAXAL 4943 WireDocument2 pagesHobart MAXAL 4943 WirebrunizzaNo ratings yet

- Oxford Alloy 9018-B3Document1 pageOxford Alloy 9018-B3brunizzaNo ratings yet

- Oxford Alloy 420 (ER420)Document1 pageOxford Alloy 420 (ER420)brunizzaNo ratings yet

- Oxford Alloy X (ENiCrMo-2)Document1 pageOxford Alloy X (ENiCrMo-2)brunizzaNo ratings yet

- Usw Alloy Designation AND Description Issued Data Sheet: Revision No. ADocument1 pageUsw Alloy Designation AND Description Issued Data Sheet: Revision No. AbrunizzaNo ratings yet

- Oxford Alloy 625T-1 (ENiCrMo3T1-1)Document1 pageOxford Alloy 625T-1 (ENiCrMo3T1-1)brunizzaNo ratings yet

- Hobart Maxal 1100Document2 pagesHobart Maxal 1100jclenerNo ratings yet

- USW ALLOY 357 DATA SHEETDocument1 pageUSW ALLOY 357 DATA SHEETbrunizzaNo ratings yet

- SK TOOL ALLOY C-S DIN 8555Document1 pageSK TOOL ALLOY C-S DIN 8555brunizzaNo ratings yet

- SK D 51-G (MF 1-GF-250-T) PDFDocument1 pageSK D 51-G (MF 1-GF-250-T) PDFborovniskiNo ratings yet

- Quality American Filler Metals ManufacturerDocument15 pagesQuality American Filler Metals ManufacturerbrunizzaNo ratings yet

- Usw Alloy Designation AND Description Issued Data Sheet: Revision No. ADocument1 pageUsw Alloy Designation AND Description Issued Data Sheet: Revision No. AbrunizzaNo ratings yet

- SK 858-M (NiAl5) Thermal SprayingDocument1 pageSK 858-M (NiAl5) Thermal SprayingbrunizzaNo ratings yet

- Uv 421 TT (Sa FB 1 65 DC h5)Document4 pagesUv 421 TT (Sa FB 1 65 DC h5)brunizzaNo ratings yet

- Thermanit MTS 3 solid wire for joining and surfacing high temperature resistant steelsDocument1 pageThermanit MTS 3 solid wire for joining and surfacing high temperature resistant steelsbrunizzaNo ratings yet

- Union TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20Document2 pagesUnion TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20brunizzaNo ratings yet

- SK 322-O (MF 3-GF-55-T)Document1 pageSK 322-O (MF 3-GF-55-T)brunizzaNo ratings yet

- Acrylic Acid - MohitDocument42 pagesAcrylic Acid - MohitvickuNo ratings yet

- E6013 Data Sheet: ISO 9001:2015 REGISTEREDDocument3 pagesE6013 Data Sheet: ISO 9001:2015 REGISTEREDThomas MacDonaldNo ratings yet

- Studi in Vitro Ekstrak Etanol Daun Kamboja (Plumeria Alba) Sebagai AntiDocument12 pagesStudi in Vitro Ekstrak Etanol Daun Kamboja (Plumeria Alba) Sebagai AntiingelitaNo ratings yet

- Delhi Milk SchemeDocument12 pagesDelhi Milk Schemeank29jplease67% (3)

- Mayaderm: Indian Institute of Management Ahmedabad IIMA/BP0385Document10 pagesMayaderm: Indian Institute of Management Ahmedabad IIMA/BP0385Vamsi Vasisht50% (2)

- DVC Andal VT ReportDocument23 pagesDVC Andal VT Reportsatyakidutta00767% (3)

- Hydrogen Generation During In-Situ CombustionDocument15 pagesHydrogen Generation During In-Situ CombustionRoobinRZamirNo ratings yet

- ITDI Hand Sanitizer Production 07172020Document27 pagesITDI Hand Sanitizer Production 07172020Marilyn LaquindanumNo ratings yet

- Paragon Air FilterDocument8 pagesParagon Air FilterRandi WijayaNo ratings yet

- Q.1 The Major Product Formed in The Following Reaction IsDocument10 pagesQ.1 The Major Product Formed in The Following Reaction IsDoom RefugeNo ratings yet

- Indigenous Microorganisms Production and The EffecDocument6 pagesIndigenous Microorganisms Production and The EffecAndrea Margarette GanancialNo ratings yet

- Environmental Impacts of Oil Spills and Their Remediation by Magnetic NanomaterialsDocument23 pagesEnvironmental Impacts of Oil Spills and Their Remediation by Magnetic NanomaterialsrmvanginkelNo ratings yet

- Covestro Investor Presentation, June 2018Document156 pagesCovestro Investor Presentation, June 2018katie farrell100% (1)

- LC method for benzoate, caffeine, and saccharin in beveragesDocument1 pageLC method for benzoate, caffeine, and saccharin in beveragesblink scientificNo ratings yet

- Esd Safe Anti-Fatigue MatDocument1 pageEsd Safe Anti-Fatigue MatFerdinand EstanislaoNo ratings yet

- Periodic Table ClassificationDocument14 pagesPeriodic Table Classificationkrishna priyaNo ratings yet

- Ryton® PPS - Corrosion-Resistant-CoatingsDocument9 pagesRyton® PPS - Corrosion-Resistant-CoatingsAhmed FathyNo ratings yet

- 2020 F4 SCIENCE NOTES KSSM CHAPTER 1 3aDocument1 page2020 F4 SCIENCE NOTES KSSM CHAPTER 1 3aWani MesraNo ratings yet

- Basic Organic Chemistry (For IIT JEE)Document20 pagesBasic Organic Chemistry (For IIT JEE)Mokshit ThakkarNo ratings yet

- ASTM C1170-14e1Document7 pagesASTM C1170-14e1Ebi RahmaniNo ratings yet

- Simulation and optimization of ethanol amine productionDocument8 pagesSimulation and optimization of ethanol amine productionFatih FıratNo ratings yet

- The Hinsberg TestDocument1 pageThe Hinsberg TestPravin Negi50% (2)

- RAC Introduction ClassDocument32 pagesRAC Introduction ClassRuturaj UmaranikarNo ratings yet

- ChE Day 1 Mock Board 5.0Document6 pagesChE Day 1 Mock Board 5.0zzrot1No ratings yet

- Solublon: Innovative Packaging With Water Soluble PVAL-filmsDocument9 pagesSolublon: Innovative Packaging With Water Soluble PVAL-filmschayanunNo ratings yet

- Manual For: Wastewater Treatment SystemDocument14 pagesManual For: Wastewater Treatment SystemDOM POUCHNo ratings yet

- Hot Poured Heavy Duty Elastic Sealant for Joints and CracksDocument2 pagesHot Poured Heavy Duty Elastic Sealant for Joints and CracksSenthilkumar NarayananNo ratings yet

- Safety Data Sheet: Product Name: MOBIL RARUS 827Document10 pagesSafety Data Sheet: Product Name: MOBIL RARUS 827Anibal RiosNo ratings yet

- Machining Process-Ii: (Assignment)Document5 pagesMachining Process-Ii: (Assignment)Sobia JamilNo ratings yet

- Komplet Katalog Conmetal-NoviDocument404 pagesKomplet Katalog Conmetal-NovipredragstojicicNo ratings yet