Professional Documents

Culture Documents

Module 9 Machine Safety 2015

Uploaded by

precious maningasCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Module 9 Machine Safety 2015

Uploaded by

precious maningasCopyright:

Available Formats

MODULE 9– Mechanical Safety

Module 9

Machine Safety

Engr. Robert C. Rubina

President & CEO - Synerquest

Accredited OSH Consultant - DOLE

Mechanical Hazards

The danger of handling

equipment with moving parts,

either motorized or manually

activated.

© 2015 by Synerquest Management Consultancy Services Inc.

All rights reserved. No part of this material shall be reproduced, stored in a retrieval system, or transmitted by any means, electronic, 1

mechanical, photocopying, recording, or otherwise, without written permission from Synerquest Management Consultancy Services Inc.

MODULE 9– Mechanical Safety

© 2015 by Synerquest Management Consultancy Services Inc.

All rights reserved. No part of this material shall be reproduced, stored in a retrieval system, or transmitted by any means, electronic, 2

mechanical, photocopying, recording, or otherwise, without written permission from Synerquest Management Consultancy Services Inc.

MODULE 9– Mechanical Safety

A good rule to remember is:

Any machine part, function, or

process which may cause injury

must be safeguarded.

Where the operation of a machine can

injure the operator or other workers,

the hazard must be controlled or

eliminated.

Causes of Machine Accidents

! Reaching in to “clear” equipment

! Not using Lockout/Tag-out

! Unauthorized persons doing

maintenance or using the

machines

! Missing or loose machine guards

© 2015 by Synerquest Management Consultancy Services Inc.

All rights reserved. No part of this material shall be reproduced, stored in a retrieval system, or transmitted by any means, electronic, 3

mechanical, photocopying, recording, or otherwise, without written permission from Synerquest Management Consultancy Services Inc.

MODULE 9– Mechanical Safety

Where Mechanical Hazards Occur

! Point of operation

! All parts of the machine which move,

such as:

> flywheels, pulleys, belts, couplings,

chains, cranks, gears, etc.

> feed mechanisms and auxiliary parts

of the machine

! In-running nip points

Point of Operation

That point where

work is performed on

the material, such as

cutting, shaping,

boring, or forming of

stock must be

guarded.

© 2015 by Synerquest Management Consultancy Services Inc.

All rights reserved. No part of this material shall be reproduced, stored in a retrieval system, or transmitted by any means, electronic, 4

mechanical, photocopying, recording, or otherwise, without written permission from Synerquest Management Consultancy Services Inc.

MODULE 9– Mechanical Safety

Point of Operation

Rotating Parts

© 2015 by Synerquest Management Consultancy Services Inc.

All rights reserved. No part of this material shall be reproduced, stored in a retrieval system, or transmitted by any means, electronic, 5

mechanical, photocopying, recording, or otherwise, without written permission from Synerquest Management Consultancy Services Inc.

MODULE 9– Mechanical Safety

Rotating Parts

In-Running Nip Points

Rotating Belt and

cylinders pulley

Chain and Rack and

sprocket pinion

© 2015 by Synerquest Management Consultancy Services Inc.

All rights reserved. No part of this material shall be reproduced, stored in a retrieval system, or transmitted by any means, electronic, 6

mechanical, photocopying, recording, or otherwise, without written permission from Synerquest Management Consultancy Services Inc.

MODULE 9– Mechanical Safety

In-Running Nip Points

Machine Safeguarding

The use of dynamic devices that

either activate or deactivate a

machine when accessed.

© 2015 by Synerquest Management Consultancy Services Inc.

All rights reserved. No part of this material shall be reproduced, stored in a retrieval system, or transmitted by any means, electronic, 7

mechanical, photocopying, recording, or otherwise, without written permission from Synerquest Management Consultancy Services Inc.

MODULE 9– Mechanical Safety

METHODS OF MACHINE

SAFEGUARDING

q Guards

q Devices

q Location/Distance

q Feeding & Ejecting Method

q Miscellaneous Aids

Methods of Machine Safeguarding

! Guards ! Location/distance

> fixed ! Feeding and ejection

> interlocked methods

> adjustable > automatic and/or semi-

> self-adjusting automatic feed and

ejection

! Devices

> robots

> presence sensing

! Miscellaneous aids

> pullback

> awareness barriers

> restraint

> protective shields

> safety controls (tripwire

cable, two-hand control, > hand-feeding tools

etc.)

> gates

© 2015 by Synerquest Management Consultancy Services Inc.

All rights reserved. No part of this material shall be reproduced, stored in a retrieval system, or transmitted by any means, electronic, 8

mechanical, photocopying, recording, or otherwise, without written permission from Synerquest Management Consultancy Services Inc.

MODULE 9– Mechanical Safety

#1

Fixed Guard

Provides a barrier - a permanent part of the

machine, preferable to all other types of guards.

Interlocked Guard

When this type of guard is opened or

removed, the tripping mechanism and/or

power automatically shuts off or

disengages, and the machine cannot cycle

or be started until the guard is back in

place.

Interlocked

guard on

revolving drum

© 2015 by Synerquest Management Consultancy Services Inc.

All rights reserved. No part of this material shall be reproduced, stored in a retrieval system, or transmitted by any means, electronic, 9

mechanical, photocopying, recording, or otherwise, without written permission from Synerquest Management Consultancy Services Inc.

MODULE 9– Mechanical Safety

Adjustable Guard

Provides a barrier

which may be

adjusted to

Bandsaw blade

facilitate a variety adjustable guard

of production

operations.

Self-Adjusting Guard

Provides a barrier which moves

according to the size of the stock

entering the danger area.

Circular table saw

self-adjusting guard

© 2015 by Synerquest Management Consultancy Services Inc.

All rights reserved. No part of this material shall be reproduced, stored in a retrieval system, or transmitted by any means, electronic, 10

mechanical, photocopying, recording, or otherwise, without written permission from Synerquest Management Consultancy Services Inc.

MODULE 9– Mechanical Safety

#2

Pullback Device

! Utilizes a series of cables

attached to the operator’s

hands, wrists, and/or arms

! Primarily used on machines

with stroking action

! Allows access to the point of

operation when the slide/ram

is up

! Withdraws hands when the

slide/ram begins to descend

Pullback Device (cont’d)

! Hands in die, feeding ! Die closed

! Point of operation ! Hands withdrawn from

exposed point of operation by

! Pullback device attached pullback device

and properly adjusted

© 2015 by Synerquest Management Consultancy Services Inc.

All rights reserved. No part of this material shall be reproduced, stored in a retrieval system, or transmitted by any means, electronic, 11

mechanical, photocopying, recording, or otherwise, without written permission from Synerquest Management Consultancy Services Inc.

MODULE 9– Mechanical Safety

Restraint Device

! Uses cables or straps

attached to the operator’s

hands and a fixed point

! Must be adjusted to let

the operator’s hands

travel within a

predetermined safe area

! Hand-feeding tools are

often necessary if the

operation involves placing

material into the danger

area

Safety Tripwire Cables

! Device located around The image cannot be displayed. Your computer may not

have enough memory to open the image, or the image may

have been corrupted. Restart your computer, and then open

the perimeter of or the file again. If the red x still appears, you may have to

delete the image and then insert it again.

near the danger area

! Operator must be able

to reach the cable to

stop the machine

© 2015 by Synerquest Management Consultancy Services Inc.

All rights reserved. No part of this material shall be reproduced, stored in a retrieval system, or transmitted by any means, electronic, 12

mechanical, photocopying, recording, or otherwise, without written permission from Synerquest Management Consultancy Services Inc.

MODULE 9– Mechanical Safety

Two-Hand Control

! Requires constant,

concurrent pressure to

activate the machine

! The operator’s hands are

required to be at a safe

location (on control

buttons) and at a safe

distance from the danger

area while the machine

. completes its closing cycle

Gate

! Movable barrier device which protects the operator at

the point of operation before the machine cycle can be

started

! If the gate does not fully close, machine will not function

Gate Open Gate Closed

© 2015 by Synerquest Management Consultancy Services Inc.

All rights reserved. No part of this material shall be reproduced, stored in a retrieval system, or transmitted by any means, electronic, 13

mechanical, photocopying, recording, or otherwise, without written permission from Synerquest Management Consultancy Services Inc.

MODULE 9– Mechanical Safety

#3

Safeguarding by Location/

Distance

! Locate the machine or

its dangerous moving

parts so that they are

not accessible or do not

present a hazard to a

worker during normal

operation

! Maintain a safe distance

from the danger area

#4 Automatic Feed

(shown on power press)

Transparent

Enclosure

Guard

Stock Feed

Roll

Danger

Area

Completed Work

© 2015 by Synerquest Management Consultancy Services Inc.

All rights reserved. No part of this material shall be reproduced, stored in a retrieval system, or transmitted by any means, electronic, 14

mechanical, photocopying, recording, or otherwise, without written permission from Synerquest Management Consultancy Services Inc.

MODULE 9– Mechanical Safety

Robots

! Machines that load and

unload stock, assemble

parts, transfer objects,

or perform other tasks

! Best used in high-

production processes

requiring repeated

routines where they

prevent other hazards

to employees

Protective Shields

These do not give complete protection from machine

hazards, but do provide some protection from flying

particles, splashing cutting oils, or coolants.

© 2015 by Synerquest Management Consultancy Services Inc.

All rights reserved. No part of this material shall be reproduced, stored in a retrieval system, or transmitted by any means, electronic, 15

mechanical, photocopying, recording, or otherwise, without written permission from Synerquest Management Consultancy Services Inc.

MODULE 9– Mechanical Safety

Holding Tools

! Used to place and

remove stock in the

danger area

! Not to be used instead

of other machine

safeguards, but as a

supplement

Machine Safety Responsibilities

! Management

> ensure all machinery is properly guarded

! Supervisors

> train employees on specific guard rules in their areas

> ensure machine guards remain in place and are

functional

> immediately correct machine guard deficiencies

! Employees

> do not remove guards unless machine is locked and

tagged

> report machine guard problems to supervisors

immediately

> do not operate equipment unless guards are in place

© 2015 by Synerquest Management Consultancy Services Inc.

All rights reserved. No part of this material shall be reproduced, stored in a retrieval system, or transmitted by any means, electronic, 16

mechanical, photocopying, recording, or otherwise, without written permission from Synerquest Management Consultancy Services Inc.

MODULE 9– Mechanical Safety

Training

Operators should receive training on the following:

! Hazards associated with particular machines

! How the safeguards provide protection and the

hazards for which they are intended

! How and why to use the safeguards

! How and when safeguards can be removed and by

whom

! What to do if a safeguard is damaged, missing, or

unable to provide adequate protection

Summary

! Safeguards are essential for protecting

workers from needless and preventable

machinery-related injuries

! The point of operation, as well as all parts

of the machine that move while the

machine is working, must be safeguarded

© 2015 by Synerquest Management Consultancy Services Inc.

All rights reserved. No part of this material shall be reproduced, stored in a retrieval system, or transmitted by any means, electronic, 17

mechanical, photocopying, recording, or otherwise, without written permission from Synerquest Management Consultancy Services Inc.

MODULE 9– Mechanical Safety

A good rule to remember is:

Any machine part, function,

or process which may

cause injury must be

safeguarded

© 2015 by Synerquest Management Consultancy Services Inc.

All rights reserved. No part of this material shall be reproduced, stored in a retrieval system, or transmitted by any means, electronic, 18

mechanical, photocopying, recording, or otherwise, without written permission from Synerquest Management Consultancy Services Inc.

You might also like

- Human Factors in Occupational Safety & HealthDocument34 pagesHuman Factors in Occupational Safety & Healthprecious maningasNo ratings yet

- Roles of SupervisorsDocument1 pageRoles of SupervisorsCheska TrinidadNo ratings yet

- Module 4 Basic Work Accident Causation Theories 2015Document8 pagesModule 4 Basic Work Accident Causation Theories 2015precious maningasNo ratings yet

- Control Measure2Document39 pagesControl Measure2precious maningasNo ratings yet

- Module 4 Basic Work Accident Causation Theories 2015Document8 pagesModule 4 Basic Work Accident Causation Theories 2015precious maningasNo ratings yet

- Fundamentals of Safety ManagementDocument9 pagesFundamentals of Safety Managementprecious maningasNo ratings yet

- Lesson-5: How The Human Brain WorksDocument14 pagesLesson-5: How The Human Brain Worksprecious maningasNo ratings yet

- Stress Mgmt. ModuleDocument23 pagesStress Mgmt. ModuleRidhiranjan MarthaNo ratings yet

- Module 1 Introduction (BOSH)Document11 pagesModule 1 Introduction (BOSH)Cheska TrinidadNo ratings yet

- Classroom Activity Health and Safety Laws AssignmentDocument1 pageClassroom Activity Health and Safety Laws Assignmentprecious maningasNo ratings yet

- Myths and Misconceptions About SexualityDocument33 pagesMyths and Misconceptions About Sexualityprecious maningasNo ratings yet

- BullyingDocument30 pagesBullyingprecious maningasNo ratings yet

- Quarantine Policy Template For Private SchoolsDocument9 pagesQuarantine Policy Template For Private Schoolsprecious maningasNo ratings yet

- The Powers of Mind 190821092324Document56 pagesThe Powers of Mind 190821092324precious maningasNo ratings yet

- Emotions SgbsjbehejDocument39 pagesEmotions SgbsjbehejManu HegdeNo ratings yet

- Safety at Workplace: Safety Start With YouDocument27 pagesSafety at Workplace: Safety Start With YouRosel SariegoNo ratings yet

- What Gets Us Together and Then Keeps Us That WayDocument29 pagesWhat Gets Us Together and Then Keeps Us That Wayprecious maningasNo ratings yet

- Personality: An Individual's Characteristic Pattern of Thinking, Feeling, and ActingDocument54 pagesPersonality: An Individual's Characteristic Pattern of Thinking, Feeling, and Actingprecious maningasNo ratings yet

- Enrollment Form BGEd PCU For Students EditableDocument1 pageEnrollment Form BGEd PCU For Students Editableprecious maningasNo ratings yet

- Function: General MathematicsDocument63 pagesFunction: General Mathematicsprecious maningasNo ratings yet

- Classroom Activity Health and Safety Laws CrosswordDocument1 pageClassroom Activity Health and Safety Laws Crosswordprecious maningasNo ratings yet

- THE 2020 Online and Self-Guided Pfa Modules: Supplemental To The SEES ManualDocument55 pagesTHE 2020 Online and Self-Guided Pfa Modules: Supplemental To The SEES ManualLiezel Sanchez87% (222)

- Sir Nor PowerpointDocument6 pagesSir Nor Powerpointprecious maningasNo ratings yet

- Professional Wardrobe NBSP PDFDocument64 pagesProfessional Wardrobe NBSP PDFAmadi OgbondaNo ratings yet

- Home Economics Lesson on Hazards and Risks in the WorkplaceDocument6 pagesHome Economics Lesson on Hazards and Risks in the Workplaceprecious maningasNo ratings yet

- COVID Lessons in JHS 7 10Document15 pagesCOVID Lessons in JHS 7 10precious maningasNo ratings yet

- Tongue TwisterDocument2 pagesTongue Twisterprecious maningasNo ratings yet

- Disaster Readiness and Risk ReductionDocument295 pagesDisaster Readiness and Risk ReductionAllanSalardaAdem89% (38)

- A. B. C. D.: Personality Development Evaluation ExamDocument4 pagesA. B. C. D.: Personality Development Evaluation Examprecious maningasNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Considerations For Large Scale CCUS DeploymentDocument59 pagesConsiderations For Large Scale CCUS Deploymentrecsco2No ratings yet

- Backup PolicyDocument2 pagesBackup Policybedorlehacker100% (1)

- Datasheet de Uma Memória Eeprom - 95640Document46 pagesDatasheet de Uma Memória Eeprom - 95640Anthony AndreyNo ratings yet

- Government Industrial Training Institute exam on desktop publishingDocument3 pagesGovernment Industrial Training Institute exam on desktop publishingamerican_guy10No ratings yet

- Mx0301-E (Pump) FlowserveDocument34 pagesMx0301-E (Pump) Flowservehasan099No ratings yet

- Pif 12 Vo Sta. Rosa II 1Document23 pagesPif 12 Vo Sta. Rosa II 1Elmer HerreraNo ratings yet

- ASTM International Standards Committee On Homeland Security Applications Response Robots (E54.09)Document28 pagesASTM International Standards Committee On Homeland Security Applications Response Robots (E54.09)Namelezz ShadowwNo ratings yet

- Detailed ResumeDocument3 pagesDetailed Resumevscs.198293% (15)

- Electrical Safety 3 Steps To Test Your RCCB PosterDocument1 pageElectrical Safety 3 Steps To Test Your RCCB PosterGoogool YNo ratings yet

- Maintenance Instructions PowerROC T35, T30 and T25Document120 pagesMaintenance Instructions PowerROC T35, T30 and T25defiunikasungti67% (6)

- Andoverinfineti 2 Seriescontrollertechnicalreference 35081Document190 pagesAndoverinfineti 2 Seriescontrollertechnicalreference 35081Aaron SperaNo ratings yet

- IEEE Recommended Practice For Exc. Sys Models 2Document4 pagesIEEE Recommended Practice For Exc. Sys Models 2Emmanuel ZamoranoNo ratings yet

- Scientific Design of Bamboo Structures for Rural DevelopmentDocument37 pagesScientific Design of Bamboo Structures for Rural Developmentniravhirpara67% (3)

- Altis WiringDocument80 pagesAltis Wiringjaesz80% (10)

- CBADocument7 pagesCBAAida Kamila ArzulkhaNo ratings yet

- Refurbishment / Rotatable MaintenanceDocument31 pagesRefurbishment / Rotatable MaintenanceShashanka KshetrapalasharmaNo ratings yet

- UIU EC-II Lecture#9Document18 pagesUIU EC-II Lecture#9Montosh RoyNo ratings yet

- Engine SensorsDocument6 pagesEngine SensorsVaibhav Vithoba NaikNo ratings yet

- 15 Programs On PythonDocument6 pages15 Programs On PythonREDDY SARAGADANo ratings yet

- IQSK Issue 29 3Document27 pagesIQSK Issue 29 3Rustono R100% (3)

- 2 - Introduction To Graphic CommunicationDocument34 pages2 - Introduction To Graphic Communicationapi-3815216100% (1)

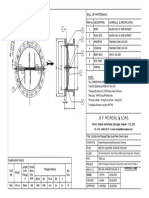

- Dual Plate 800 NB-ModelDocument1 pageDual Plate 800 NB-ModelTanmoy DuttaNo ratings yet

- 5.windings and InsulationDocument30 pages5.windings and InsulationAnjanNo ratings yet

- Sill HSpice Tutorial FinalDocument106 pagesSill HSpice Tutorial FinalSharan Kumar GoudNo ratings yet

- ShopNotes #99Document53 pagesShopNotes #99Hector100% (1)

- Tutorial 1 Phy250Document9 pagesTutorial 1 Phy250Muhammad AziziNo ratings yet

- Endorsement Letter - July 4, 2018Document3 pagesEndorsement Letter - July 4, 2018Ángela BernardoNo ratings yet

- Kouign Amann RecipeDocument59 pagesKouign Amann RecipeDanny DawsonNo ratings yet

- Patent Application Publication (10) Pub. No.: US 2011/0210008 A1Document9 pagesPatent Application Publication (10) Pub. No.: US 2011/0210008 A1AblaqNo ratings yet

- M7 Complete User Manual enDocument26 pagesM7 Complete User Manual enAnonymous qZY4l1aCEuNo ratings yet