Professional Documents

Culture Documents

Protection Methods For Optics: 9.1 Tissue

Protection Methods For Optics: 9.1 Tissue

Uploaded by

bobOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Protection Methods For Optics: 9.1 Tissue

Protection Methods For Optics: 9.1 Tissue

Uploaded by

bobCopyright:

Available Formats

Chapter 9

Protection Methods

for Optics

This chapter explains how to wrap and package optics for short- and

long-term storage. It also explains how to wrap components for

shipping to a vendor or customer.

Once an optic is cleaned, the next steps are to wrap and/or store it,

protect it from the elements, keep it free of contaminants, and prevent

any possible damage. The methods presented have been developed over

many years and have been used by the military, commercial, and optical

industries. Wrapping methods use tissue, envelopes, and clamshell

packaging, or a mixture of these materials.

9.1 Tissue

Wrapping optics with tissue is the most common method used to protect

them. There are two basic types of tissue, white and brown. White tissue

is processed with acid, whereas brown is not. The issue with white tissue

is that moisture will leach acid used in the manufacturing process onto

the optic and etch the glass or coatings. The MIL specs call for wrapping

glass with brown tissue only, and this tradition is still carried on today.

Acid-free white tissue is now available for archival use; it is suggested for use with

uncoated optics, although brown tissue should be used with coated optics such

as metallic coated mirrors. Either tissue can be used so long as it is acid free.

171

Downloaded From: https://www.spiedigitallibrary.org/ebooks/ on 13 Oct 2019

Terms of Use: https://www.spiedigitallibrary.org/terms-of-use

172 Chapter 9

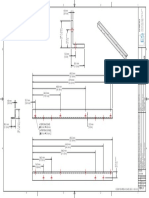

Figure 9.1 Different methods of wrapping optics.

The wrapping process is a series of simple steps. The tissue (1–2

layers thick) should be sized 10–20% larger than the part. There are

two popular methods: either cut the tissue short to allow the back

surface to be exposed or cut the tissue so that it overlaps the back

of the optic. Use the one that best protects the optic; Fig. 9.1

illustrates different methods. After the tissue is cut, place the optic

in the center of the tissue, fold top and bottom ends over the optic,

and tape in place. Fold the left and right ends over the optic, and

tape in place.

9.2 Envelopes

The envelope is a handy method to wrap optics for shipping or

storage; Fig. 9.2 illustrates several kinds. It has a cost advantage over

other types of packaging and is manufactured to standard sizes. Pick a

size slightly larger than the optic. If the shape of the optic has strong

curves or is thick, it may require an envelope two to three times its

size. The envelope can be sealed using the glue on the flap or by taping

the flap in place.

Downloaded From: https://www.spiedigitallibrary.org/ebooks/ on 13 Oct 2019

Terms of Use: https://www.spiedigitallibrary.org/terms-of-use

Protection Methods for Optics 173

Figure 9.2 Various types of envelopes: paper, plastic, vellum, pocket, and cloth.

Envelope paper fibers can damage optical surfaces. If the surface

quality of an optic is critical (laser or reticle), then other storage

methods should be used. For extra protection, the optic can be wrapped

in tissue; uncoated optics can be stored in the envelope as is. Transparent

glassine bags or envelopes are free of paper fibers and will reveal what is

inside.

Plastic bags with seals can also be used to store or cover optics.

The envelope can be labeled on the outside using a stamp or

attaching a pre-printed label. The envelopes can be bundled together

in groups of two to five using a rubber band. As with any wrapping or

storage method, test to see what works best.

9.3 Containers for Storage

Cardboard boxes (Fig. 9.3) are commonly used to contain optics.

They are inexpensive, easy to use, and readily available. They range in

size and type. The simple two-size box set (one box fits inside the

Downloaded From: https://www.spiedigitallibrary.org/ebooks/ on 13 Oct 2019

Terms of Use: https://www.spiedigitallibrary.org/terms-of-use

174 Chapter 9

Figure 9.3 Simple cardboard boxes.

other) can be secured by tape. The optic is wrapped in tissue or in an

envelope.

A clamshell is a molded plastic container for storing optics;

Figs. 9.4–9.6 illustrate different kinds of clamshell designs. This

Figure 9.4 Clamshell or molded container (image courtesy of Empire West

Company).

Downloaded From: https://www.spiedigitallibrary.org/ebooks/ on 13 Oct 2019

Terms of Use: https://www.spiedigitallibrary.org/terms-of-use

Protection Methods for Optics 175

Figure 9.5 Rectangle clamshell or molded container; note the different internal

shapes (image courtesy of Empire West Company).

Figure 9.6 Round clamshell or molded container; note the different internal

shapes (image courtesy of Empire West Company).

type of containment has advantages over the envelope and tissue;

for one, it is manufactured in different shapes and styles. It is easy

to clean and can be reused several times by blowing any dust off or

wiping with a damp or dry cloth. Although the essential cost of the

plastic can be high for small volume quantities, the value is in its

reuse.

Downloaded From: https://www.spiedigitallibrary.org/ebooks/ on 13 Oct 2019

Terms of Use: https://www.spiedigitallibrary.org/terms-of-use

176 Chapter 9

Figure 9.7 Catalog and custom-made foam containers (courtesy of Tempo Plastic

Company).

The clamshell can be designed to hold optics on their edges. One

side has the shape to fit the optic, and the other side is molded to

secure the optic by holding it firmly in a shaped pocket.

Foam-style containers are molded to hold one part or any selected

amount (see Fig. 9.7). The container’s overall size is larger, given the

molded pockets or inserts. The pockets can be shaped to the outline of

the optical part. In most designs, the container is divided in half to

allow the lid to be lifted and provide easy access to the optic.

Membrane packaging is an alternative for critical or small optics. A plastic

membrane is stretched over the molded container; the optic is suspended

within the membrane.

Downloaded From: https://www.spiedigitallibrary.org/ebooks/ on 13 Oct 2019

Terms of Use: https://www.spiedigitallibrary.org/terms-of-use

You might also like

- Carton Packaging KnowledgeDocument93 pagesCarton Packaging KnowledgeAlex Xiao100% (5)

- Carton Packaging World v1.0 PDFDocument110 pagesCarton Packaging World v1.0 PDFAlex Xiao100% (3)

- (English) POLITICAL THEORY - Henry David Thoreau (DownSub - Com)Document5 pages(English) POLITICAL THEORY - Henry David Thoreau (DownSub - Com)SaurabhNo ratings yet

- SO-50 or SO-5S - HMIDocument2 pagesSO-50 or SO-5S - HMIBrett AtkinsNo ratings yet

- WILLIS TOWERpresentation PDFDocument37 pagesWILLIS TOWERpresentation PDFReshanth VangalapudiNo ratings yet

- 10.1 Short-Term Storage of OpticsDocument6 pages10.1 Short-Term Storage of OpticsbobNo ratings yet

- PM301 ch11Document8 pagesPM301 ch11bobNo ratings yet

- Wrap Around Packer DetailsDocument24 pagesWrap Around Packer DetailsUmair Younus100% (1)

- Case StudyDocument9 pagesCase Studymiera_zaNo ratings yet

- Closure System Used in Packaging IndustryDocument12 pagesClosure System Used in Packaging IndustryChelseaNo ratings yet

- Astha Kothari Generic BrandingDocument3 pagesAstha Kothari Generic BrandingAstha KothariNo ratings yet

- Shrink FilmDocument29 pagesShrink Filmhatharasinghe100% (2)

- Review Paper-Sushma Verma - RevisedDocument10 pagesReview Paper-Sushma Verma - RevisedBijender KaushikNo ratings yet

- Film Sheets (Polymer)Document5 pagesFilm Sheets (Polymer)Nemo Cyzar LiisNo ratings yet

- Most Disposable Diapers Are Made With The Following Basic ComponentsDocument4 pagesMost Disposable Diapers Are Made With The Following Basic ComponentsIvyNo ratings yet

- Packaging MaterialsDocument21 pagesPackaging Materialsmirobel455kezaNo ratings yet

- Packaging With Plastics and Polymeric MaterialsDocument17 pagesPackaging With Plastics and Polymeric MaterialsDavidsantiago Murillo AvilaNo ratings yet

- Packaging: 2 Package Requirements/FunctionsDocument8 pagesPackaging: 2 Package Requirements/FunctionserisNo ratings yet

- Double R Controls Technical Information On The Principles of SpoolingDocument30 pagesDouble R Controls Technical Information On The Principles of SpoolingKarim BiswasNo ratings yet

- PackagingDocument18 pagesPackagingbhavya.2021fth008No ratings yet

- ReportDocument8 pagesReportVandita NohwalNo ratings yet

- Polyester EncapsulationDocument4 pagesPolyester EncapsulationFlorencia De NicolaNo ratings yet

- Technical Report: Optimal Protection, Optimal Cost EfficiencyDocument7 pagesTechnical Report: Optimal Protection, Optimal Cost EfficiencyInternational BusinessNo ratings yet

- Ppdunit 5Document25 pagesPpdunit 5Patel RushilNo ratings yet

- ZeoformDocument6 pagesZeoformRamonaNo ratings yet

- The Utilization of Coconut Shell Waste As The Helm PDFDocument8 pagesThe Utilization of Coconut Shell Waste As The Helm PDFJaan MukherjeeNo ratings yet

- Alternatives For StyrofoamDocument18 pagesAlternatives For Styrofoampiano tamil100% (1)

- Packaging TermsDocument32 pagesPackaging TermsAbhineet Shrivastava100% (1)

- Introduction Biocomponent FibersDocument5 pagesIntroduction Biocomponent Fibersblanca garciaNo ratings yet

- Ship 4 The World: Sustainability InitiativeDocument11 pagesShip 4 The World: Sustainability Initiativeapi-431724361No ratings yet

- Packaging Industry (71)Document13 pagesPackaging Industry (71)aparna aravamudhanNo ratings yet

- Smart Composites: Angel College of Engineering and TechnologyDocument12 pagesSmart Composites: Angel College of Engineering and Technologydolly707No ratings yet

- COG MicrofossilStorageDocument4 pagesCOG MicrofossilStoragedamfer09No ratings yet

- Optical Phenomenon Light Critical Angle Normal Refractive Index ReflectedDocument6 pagesOptical Phenomenon Light Critical Angle Normal Refractive Index ReflectedRicha PandeyNo ratings yet

- FiberglassDocument9 pagesFiberglassJennifer CharlesNo ratings yet

- PM301 ch1Document6 pagesPM301 ch1bobNo ratings yet

- FiberglassDocument17 pagesFiberglassqabdushami12No ratings yet

- Bubble Film Manufcturing ProcessDocument4 pagesBubble Film Manufcturing ProcessBrandon PuckettNo ratings yet

- Packaging Essential GlossaryDocument35 pagesPackaging Essential GlossarygisellaNo ratings yet

- Fiberglass: Glass Wool Glass FiberDocument8 pagesFiberglass: Glass Wool Glass FibernimigirlzNo ratings yet

- Designing A Bottle Through Injection Moulding System: Design Considerations For Packaging Water in Ingeo BottlesDocument5 pagesDesigning A Bottle Through Injection Moulding System: Design Considerations For Packaging Water in Ingeo Bottlesabhishek gautamNo ratings yet

- Film Sheet PresentationDocument24 pagesFilm Sheet PresentationNemo Cyzar Liis100% (1)

- Special Cleaning ProcessesDocument18 pagesSpecial Cleaning ProcessesbobNo ratings yet

- FiberglassDocument7 pagesFiberglasseipahNo ratings yet

- Properties: Fiberglass - Wikipedia, The Free EncyclopediaDocument3 pagesProperties: Fiberglass - Wikipedia, The Free EncyclopediazidaaanNo ratings yet

- Cleaning Optics in The FieldDocument8 pagesCleaning Optics in The FieldbobNo ratings yet

- Project Report On Glass WoolDocument8 pagesProject Report On Glass WoolEIRI Board of Consultants and PublishersNo ratings yet

- Ov Ov Ov Ov OvDocument6 pagesOv Ov Ov Ov Ovkasun148No ratings yet

- M1 EqDocument3 pagesM1 EqChristine TesoroNo ratings yet

- Optimised Shoe SoleDocument21 pagesOptimised Shoe SoleAdvait BawdekarNo ratings yet

- Fiberglass - Wikipedia The Free EncyclopediaDocument7 pagesFiberglass - Wikipedia The Free EncyclopediaruchiniftNo ratings yet

- FiberglassDocument17 pagesFiberglassHemali Shah100% (1)

- Plastic Sheeting: Its Use For Emergency Shelter and Other PurposesDocument44 pagesPlastic Sheeting: Its Use For Emergency Shelter and Other PurposesOxfamNo ratings yet

- Principles of Veterinary SuturingDocument25 pagesPrinciples of Veterinary Suturingnandhus2227No ratings yet

- Plastic Sheeting: Its Use For Emergency Shelter and Other PurposesDocument44 pagesPlastic Sheeting: Its Use For Emergency Shelter and Other PurposesOxfamNo ratings yet

- Shrink Sleeve Flexo InksDocument10 pagesShrink Sleeve Flexo Inksdammy888100% (1)

- Thin Film Thesis PDFDocument4 pagesThin Film Thesis PDFbeckiroymanchester100% (2)

- Polymer Banknotes - ThemesDocument7 pagesPolymer Banknotes - ThemesjayasriniNo ratings yet

- Design of A Small Scale Cereal Packaging Machine Suitable For Developing CountriesDocument12 pagesDesign of A Small Scale Cereal Packaging Machine Suitable For Developing CountriesqusayNo ratings yet

- Technical Textiles - Materials and Emerging TechnologiesDocument16 pagesTechnical Textiles - Materials and Emerging Technologiessanjay chandwaniNo ratings yet

- Packaging Industry 1Document5 pagesPackaging Industry 1SWAGAT SHOVANNo ratings yet

- Advanced Packaging Technologies For Fruits and Vegetables: For Fruits and VegetablesFrom EverandAdvanced Packaging Technologies For Fruits and Vegetables: For Fruits and VegetablesNo ratings yet

- Process-Structure-Property Relationships in Additively Manufactured Metal Matrix CompositesDocument68 pagesProcess-Structure-Property Relationships in Additively Manufactured Metal Matrix CompositesbobNo ratings yet

- Modeling Strength and Failure Variability Due To PDocument36 pagesModeling Strength and Failure Variability Due To PbobNo ratings yet

- Surface Morphology in Selective Laser Melting of Metal PowdersDocument8 pagesSurface Morphology in Selective Laser Melting of Metal PowdersbobNo ratings yet

- Structural Performance of Additive Manufactured MeDocument53 pagesStructural Performance of Additive Manufactured MebobNo ratings yet

- Anisotropic Mechanical Behaviors and Microstructural Evolution of Thin-Walled Additively Manufactured MetalsDocument69 pagesAnisotropic Mechanical Behaviors and Microstructural Evolution of Thin-Walled Additively Manufactured MetalsbobNo ratings yet

- Visual Texture-Based 3-D Roughness Measurement For-2Document11 pagesVisual Texture-Based 3-D Roughness Measurement For-2bobNo ratings yet

- Laser-Assisted Post-Processing of Additive Manufactured Metallic PartsDocument3 pagesLaser-Assisted Post-Processing of Additive Manufactured Metallic PartsbobNo ratings yet

- Additive Manufacturing: P. Bidare, R.R.J. Maier, R.J. Beck, J.D. Shephard, A.J. MooreDocument9 pagesAdditive Manufacturing: P. Bidare, R.R.J. Maier, R.J. Beck, J.D. Shephard, A.J. MoorebobNo ratings yet

- Review of Defects in Lattice Structures Manufactured by Powder Bed FusionDocument20 pagesReview of Defects in Lattice Structures Manufactured by Powder Bed FusionbobNo ratings yet

- Materials and DesignDocument13 pagesMaterials and DesignbobNo ratings yet

- Feature-Based Characterisation of Laser Powder Bed Fusion SurfacesDocument3 pagesFeature-Based Characterisation of Laser Powder Bed Fusion SurfacesbobNo ratings yet

- GE HTPro FebMar2019Document4 pagesGE HTPro FebMar2019bobNo ratings yet

- Analyz MSF in telescopemonolith-RevEDocument15 pagesAnalyz MSF in telescopemonolith-RevEbobNo ratings yet

- Experimental Analysis of Laser Post-Processing of Additive Manufactured Metallic PartsDocument2 pagesExperimental Analysis of Laser Post-Processing of Additive Manufactured Metallic PartsbobNo ratings yet

- MarSurf SC Modul2 - ISO4288 EN V01Document26 pagesMarSurf SC Modul2 - ISO4288 EN V01bobNo ratings yet

- Proceedings of SpieDocument10 pagesProceedings of SpiebobNo ratings yet

- MarSurf SC Modul1 - ISO3274 EN V01Document12 pagesMarSurf SC Modul1 - ISO3274 EN V01bobNo ratings yet

- Efficient Varients of The ICP AlgorithmDocument8 pagesEfficient Varients of The ICP AlgorithmbobNo ratings yet

- De Vathaire 81Document10 pagesDe Vathaire 81bobNo ratings yet

- MarSurf SC Modul3 - ISO4287 EN V01Document19 pagesMarSurf SC Modul3 - ISO4287 EN V01bobNo ratings yet

- Proceedings of Spie: Instrumental Effects in Surface Finish MeasurementDocument11 pagesProceedings of Spie: Instrumental Effects in Surface Finish MeasurementbobNo ratings yet

- Surface Finish Measurements of Diamond - TurnedDocument8 pagesSurface Finish Measurements of Diamond - TurnedbobNo ratings yet

- 15SIB01 Final Publishable ReportDocument36 pages15SIB01 Final Publishable ReportbobNo ratings yet

- The Meaning and Measure of Lateral Resolution For Surface Profiling InterferometersDocument5 pagesThe Meaning and Measure of Lateral Resolution For Surface Profiling InterferometersbobNo ratings yet

- Improving The Surface Metrology Accuracy of Optical Profilers by Using Multiple MeasurementsDocument8 pagesImproving The Surface Metrology Accuracy of Optical Profilers by Using Multiple MeasurementsbobNo ratings yet

- Proceedings of Spie: Comparison of Optical and Mechanical Measurements of Surface FinishDocument18 pagesProceedings of Spie: Comparison of Optical and Mechanical Measurements of Surface FinishbobNo ratings yet

- Tutorial 2 - FTK WinHex - HashingDocument6 pagesTutorial 2 - FTK WinHex - HashingMD HOSSAINNo ratings yet

- Age and Gender With Mask ReportDocument15 pagesAge and Gender With Mask Reportsuryavamsi kakaraNo ratings yet

- Bs 5467 Copper Conductor Multi Core Swa PVC 1 9 3 3kv CableDocument2 pagesBs 5467 Copper Conductor Multi Core Swa PVC 1 9 3 3kv CableSaqib JavedNo ratings yet

- TZ150 2020Document76 pagesTZ150 2020Nelson RodrigoNo ratings yet

- Yr 8 Directed Numbers - Print - QuizizzDocument5 pagesYr 8 Directed Numbers - Print - QuizizzLabiba MahmudNo ratings yet

- Sanchez Information Assurance and SecurityDocument9 pagesSanchez Information Assurance and SecurityMarneil Allen SanchezNo ratings yet

- Dampers & Louvers Full Submittal PDFDocument51 pagesDampers & Louvers Full Submittal PDFRashedNo ratings yet

- Lenntech: 18 Frame Block-Style Stainless Steel Plunger PumpDocument4 pagesLenntech: 18 Frame Block-Style Stainless Steel Plunger Pumpdiv02No ratings yet

- N X N X: OscarzapataDocument1 pageN X N X: OscarzapataOscar Maurico ZapataNo ratings yet

- Sahil Bhanot ResumeDocument2 pagesSahil Bhanot Resumesahil bhanotNo ratings yet

- AI Learning FastDocument62 pagesAI Learning Fastnabilpop73No ratings yet

- So 2ND Ed Uin Read Extra U7Document2 pagesSo 2ND Ed Uin Read Extra U7თამარ ევგენიძეNo ratings yet

- Table QW/QB-422 Ferrous and Nonferrous P-Numbers Grouping of Base Metals For QualificationDocument1 pageTable QW/QB-422 Ferrous and Nonferrous P-Numbers Grouping of Base Metals For QualificationArturo DuqueNo ratings yet

- Asking About Hobbies: Lesson Notes and VideoDocument17 pagesAsking About Hobbies: Lesson Notes and VideoShaista Cruz BencosmeNo ratings yet

- Making A Cover Letter For ResumeDocument7 pagesMaking A Cover Letter For Resumes1telylawyn3100% (1)

- Earning Outcomes: LSPU Self-Paced Learning Module (SLM)Document7 pagesEarning Outcomes: LSPU Self-Paced Learning Module (SLM)Renalyn ManzanoNo ratings yet

- KWASU Admission ListDocument89 pagesKWASU Admission ListQuadri Quawiy TantolohunNo ratings yet

- The Ultimate Guide To Link Building by 99signals EbookDocument40 pagesThe Ultimate Guide To Link Building by 99signals EbookAhmad Ali0% (1)

- mc9 BrochureDocument8 pagesmc9 BrochureturricanNo ratings yet

- Assembly MIPS Quick TutorialDocument8 pagesAssembly MIPS Quick TutorialOthon OliveiraNo ratings yet

- APMM Sustainability Report 2018Document24 pagesAPMM Sustainability Report 2018FL 564No ratings yet

- Filling 1Document7 pagesFilling 1PAULNo ratings yet

- Adjetival Clauses 1Document5 pagesAdjetival Clauses 1Yuli HardinaNo ratings yet

- Gift Card 12-28Document1 pageGift Card 12-28AseadNo ratings yet

- A.Garcia BernabeuMayor VitoriaMas VerdDocument21 pagesA.Garcia BernabeuMayor VitoriaMas VerdkamaNo ratings yet

- ISMS Certificate 2021Document2 pagesISMS Certificate 2021BIKASH MOHANTYNo ratings yet

- g2 Data Sheet Non ApprovedDocument2 pagesg2 Data Sheet Non ApprovedKleberBuñayNo ratings yet