Professional Documents

Culture Documents

Ex Gland Installation Leaflet

Ex Gland Installation Leaflet

Uploaded by

FelisbeloOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ex Gland Installation Leaflet

Ex Gland Installation Leaflet

Uploaded by

FelisbeloCopyright:

Available Formats

www.cmp-products.

com

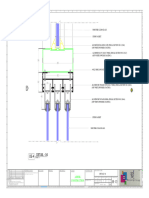

INSTALLATION

INSTRUCTIONS FOR

1 2

Prepare the gland so that Tear open the foil bags and remove

it is ready to install before * the RapidEx resin pouch.

CMP RAPIDEX RESIN opening the RapidEx resin

foil bag. THREAD

0

DO NOT USE KNIVES TO OPEN FOIL

E

S

IN

BAGS

TIME GUID

TIME GUID

M

Cores may need to be SHIELD 5 1

separated slightly to allow MIX

resin to flow between TOP UP

them. 4 2

INSTALL

EX

EX

Preparation should

PLEASE READ ALL INSTRUCTIONS BEFORE include fitting the thread ID 3 ID

OPENING FOIL BAG shield to the entry thread.

RAP RAP

ALL BAGS SHOULD BE MIXED BEFORE DISPOSAL

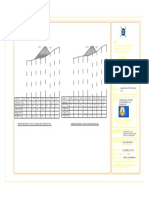

TIME GUIDE @ 20°C (68°F)

If the foil bags have been subjected to Times will be reduced at

temperatures below 0°C (32°F) for more than 24 *Minimum mix time 100 seconds Typical Gland Temperatures above 20°C

hours then the bags must be brought up to room

temperature prior to mixing.

The liquid seal should not be poured below

an ambient temperature of 5°C (41°F) . If

7

Without delay remove clip B and insert the

3 4

temperatures are below 5°C, please refer to If the blue section appears cloudy Adaptor tube may need

(as pictured), carefully mix until to be fitted on smaller nozzle into the edge of the cable cores so that

TDS613 for further guidance. it is 20mm (3/4”) below the surface of the

an even blue is achieved making sizes to ensure the nozzle

AGE SENSITIVE MATERIAL. sure not to remove clips. fits between the cable thread.

SENSITIVE TO MOISTURE. cores. Roll the tube to force out the resin. Continue

PROTECT FROM FROST. until the gland is filled and some RapidEx

BLUE (BASE) & YELLOW (HARDENER)

CLIP A liquid compound is visible in the shield.

Wear protective clothing. Avoid contact with Immediately after the pour, hold the gland

skin, wash immediately if contacted. In case of firmly and shake the conductors

contact with eyes, rinse immediately and seek f it to enable the liquid to disperse

to fully and ensure there are no

medical advice. In case of accident or if you feel sh

unwell, seek medical advice immediately and Pu air bubbles or pockets trapped

show product label where possible. Do not induce

CLIP B inside; the fill level should be

vomiting. checked after this and more

Once the foil bag is opened the RapidEx poured if necessary. This

YELLOW (HARDENER) resin must be used within 12 hours. Nozzle found in inner foil bag. process will also ensure that the

Do not breathe dust/fume/gas/mist/ resin has come into contact with

Vapours/spray. If skin, eyes or respiratory system all of the conductors.

display irritation, seek medical advice. May cause Once hardened, the thread shield

allergy, asthma symptoms, or breathing difficulties can be removed, the cables

5 6

if inhaled. May cause allergic reaction. Causes When ready to mix the RapidEx Thoroughly and vigorously

resin, remove CLIP A between mix the blue base and yellow manipulated and product fitted.

serious eye irritation. Harmful if inhaled. Irritating Once cured, the equipment may

to eyes, respiratory system and skin. Contains the two resin components. hardener, ensuring not to miss

product from the corners be energised.

isocyanates. Suspected of causing cancer. May DO NOT remove CLIP B at this

cause damage to organs through prolonged or of the bag and until an even ATEX & IECEx

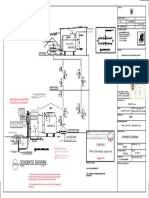

stage. green colour is achieved. 50 RapidEx Cure Time 121

repeated exposure. Installers must use Personal

Protective Equipment (PPE) to protect against Begin to pour immediately. 45 vs. 111

Temperature

these risks. Pull bag to remove clip 40 101

Temperature (°C)

Temperature (°F)

Use in well 35

ventilated area. 91

30 5°C - 720 Mins

See CMP Material 10°C - 100 Mins 81

Safety Data 25 15°C - 50 Mins

71

Sheet (MSDS) 20 20°C - 35 Mins

for further 25°C - 25 Mins

61

15 30°C - 17 Mins

information.

10 35°C - 14 Mins 51

40°C - 11 Mins

DO NOT mix for longer than 5 41

necessary as the resin may begin 0 1 2 3 4 5 6 7 8 9 10 11 12 13

CMP PRODUCTS

36 Nelson Way, Nelson Park East,

to gel. If the resin has begun to gel Time (hours)

Cramlington, Northumberland, before installation then dispose of TIMES WILL VARY DEPENDING ON THE VOLUME OF RESIN

NE23 1WH the bag and use a new pack.

UL complete cure time: 24 hours

t: +44 (0)191 2657411

e: customerservices@cmp-products.com PATENT GRANTED: ES 2287986, NO 2287986, TR 2287986, AU 2010284848, AU 2014274614 CMP FI320 07/20 REV 15

GB 2485114, SG 178839, US 8872027, US 9484133, US 9774178, US 10193321, US 10348078, MY 153846

You might also like

- Interview Master GuideDocument133 pagesInterview Master GuideDanh Michael MujarNo ratings yet

- Ateco Tank Geodesic Dome Drawings For Information PDFDocument47 pagesAteco Tank Geodesic Dome Drawings For Information PDFJavierfox98100% (1)

- Grinding Mill Drawings PDFDocument1 pageGrinding Mill Drawings PDFBender Doblador Rodriguez100% (1)

- Pol808 3Document4 pagesPol808 3robert.leon007No ratings yet

- Flue Gas Outlet DamperDocument1 pageFlue Gas Outlet Damperprth valveNo ratings yet

- System "A" System "B": 34.0in (863mm)Document1 pageSystem "A" System "B": 34.0in (863mm)MILLER ARIZANo ratings yet

- Drawn On Zuken E3 File Stored in Teamcenter Engineering Do Not Scale Do Not Modify Manually All Dimensions in MMDocument10 pagesDrawn On Zuken E3 File Stored in Teamcenter Engineering Do Not Scale Do Not Modify Manually All Dimensions in MMPhomma KhinphommavongNo ratings yet

- A3947 Liberty 4 NC QSGDocument2 pagesA3947 Liberty 4 NC QSGMichel JeanNo ratings yet

- Five Panel Hat LydiaNaomiDocument7 pagesFive Panel Hat LydiaNaomiGrace JanuartyNo ratings yet

- Carga de Pilotes Rev.2 (02!08!2023)Document7 pagesCarga de Pilotes Rev.2 (02!08!2023)marco chavezNo ratings yet

- Masonry Non Load BearingDocument1 pageMasonry Non Load BearingJorge AmadorNo ratings yet

- Designed For Offshore-, Petrochemical-And Power Industries: MammoetDocument12 pagesDesigned For Offshore-, Petrochemical-And Power Industries: MammoetCuong DinhNo ratings yet

- Hump and VIG DetailsDocument1 pageHump and VIG DetailsClarence BuenaventuraNo ratings yet

- The Jerusalem Post November 2023Document24 pagesThe Jerusalem Post November 2023Luis AdrianNo ratings yet

- RL20.1880-D-GEN-1021-00 - Route Simulation - 3Document1 pageRL20.1880-D-GEN-1021-00 - Route Simulation - 3Nob Odyk NowsNo ratings yet

- Pioneer RMX-9 MD Datasheet xsr9Document80 pagesPioneer RMX-9 MD Datasheet xsr9Rodrigo AkibaNo ratings yet

- Mankhurd Drawings PDFDocument10 pagesMankhurd Drawings PDFSaurabh PandeyNo ratings yet

- Ubile: 63 YvelizDocument19 pagesUbile: 63 YvelizTravis HNo ratings yet

- Screenshot 2023-02-01 at 2.08.31 PMDocument1 pageScreenshot 2023-02-01 at 2.08.31 PMsubin msNo ratings yet

- Perimeter Fence Dvo Occ Ppo PDFDocument8 pagesPerimeter Fence Dvo Occ Ppo PDFmogsiNo ratings yet

- Perimeter Fence Dvo Occ Ppo PDFDocument8 pagesPerimeter Fence Dvo Occ Ppo PDFRoger Granfon Flores100% (1)

- Site Plumbing SamalDocument1 pageSite Plumbing SamalEngr. K3ianNo ratings yet

- De 04Document1 pageDe 04Sachin SharmaNo ratings yet

- Saudi Arabian Oil Company: Plant No. Index Drawing No. Sht. No. Rev. No. Dwg. TypeDocument1 pageSaudi Arabian Oil Company: Plant No. Index Drawing No. Sht. No. Rev. No. Dwg. TypeWork ForceNo ratings yet

- Hospital Block: Key PlanDocument1 pageHospital Block: Key PlanKripa SriramNo ratings yet

- Bertyl-7 PDFDocument1 pageBertyl-7 PDFKripa SriramNo ratings yet

- Finale 2009 - (Ele CHEGOU - Trumpet in BB)Document1 pageFinale 2009 - (Ele CHEGOU - Trumpet in BB)elis assadNo ratings yet

- DJ 302 o en Sco 01 0001 - 00 GF Mep Coordination Layout OverallDocument1 pageDJ 302 o en Sco 01 0001 - 00 GF Mep Coordination Layout Overallinfo.infinitytechnicalNo ratings yet

- Saeed Hamad Alrashdi - Schematic Diagram ApprovedDocument1 pageSaeed Hamad Alrashdi - Schematic Diagram ApprovedHoran HoranNo ratings yet

- Alp-Sd-P1-Fs 014Document1 pageAlp-Sd-P1-Fs 014Lipton KumarNo ratings yet

- Media Lifecyle FrameworkDocument1 pageMedia Lifecyle FrameworkTim StewardNo ratings yet

- False Ceiling Plan For Parent'S BedroomDocument1 pageFalse Ceiling Plan For Parent'S BedroomfrosterapNo ratings yet

- Top Level Diagram: See Also CommunicationsDocument18 pagesTop Level Diagram: See Also CommunicationsSandra Yanira Vivas DiázNo ratings yet

- Utility Deck - Ahu SectionDocument1 pageUtility Deck - Ahu SectionLorenzo NakpilNo ratings yet

- Gate 2 Service Entry / Exit: Archbishop Reyes AvenueDocument1 pageGate 2 Service Entry / Exit: Archbishop Reyes AvenueAb sungaNo ratings yet

- P790 Electrical Circuit 336-E4169 - 1 - plm-2Document11 pagesP790 Electrical Circuit 336-E4169 - 1 - plm-2shivji007No ratings yet

- S-23-01 Saraswati Singh TKDocument3 pagesS-23-01 Saraswati Singh TKTanweer KhanNo ratings yet

- OGM Office 1-1Document1 pageOGM Office 1-1John Kenneth Del ValleNo ratings yet

- Dual Shear BrochureDocument3 pagesDual Shear BrochureKshitiz MittalNo ratings yet

- AD790-A-700-Coordination Drawing - GF 12.12-A700part-3Document1 pageAD790-A-700-Coordination Drawing - GF 12.12-A700part-3noufal rafiNo ratings yet

- Algo Think4 MagazineDocument48 pagesAlgo Think4 Magazinekylep2112No ratings yet

- Flowmeter With ReedswitchDocument1 pageFlowmeter With ReedswitchKaye TrishaNo ratings yet

- Paul Christian L. Domingo: Proposed Extension & Renovation of Two-Storey Residential BuildingDocument1 pagePaul Christian L. Domingo: Proposed Extension & Renovation of Two-Storey Residential Buildingdomingo.paulchristianNo ratings yet

- MG600 Eqs 600 V03 PPC01 001 02Document4 pagesMG600 Eqs 600 V03 PPC01 001 02Design polyplastNo ratings yet

- Ea 3Document1 pageEa 3cloydNo ratings yet

- Box Lifter With ConveyorsDocument1 pageBox Lifter With ConveyorsinfinityautomatedsolutionsNo ratings yet

- PW Show Daily at BookConDocument32 pagesPW Show Daily at BookConPublishers WeeklyNo ratings yet

- This Is New PDFDocument1 pageThis Is New PDFAnonymous BZQOJwWIh6No ratings yet

- 13.8Kv U/V Load Shedding Panel-2 +uvls.2: D HA555 P 3-1313003.03 EA-383186 4400004656Document1 page13.8Kv U/V Load Shedding Panel-2 +uvls.2: D HA555 P 3-1313003.03 EA-383186 4400004656Anonymous BZQOJwWIh6No ratings yet

- 966G Ii & 972G Ii Pilot Implement/Steering Metering Pump Hydraulic SchematicDocument2 pages966G Ii & 972G Ii Pilot Implement/Steering Metering Pump Hydraulic SchematicMahmoud SaudyNo ratings yet

- Cat 966G Hydr.&.Electr - DiagramDocument17 pagesCat 966G Hydr.&.Electr - DiagramDaniel Leon100% (2)

- Cross Section at Old Top Bund Level Cross Section at Old Maximum Water LevelDocument1 pageCross Section at Old Top Bund Level Cross Section at Old Maximum Water LevelSudeepSMenasinakaiNo ratings yet

- Te - Conozco - Bacalao-Saxo ContraltoDocument1 pageTe - Conozco - Bacalao-Saxo ContraltojuanmaNo ratings yet

- Detecto Balanza Neonatal - 8435Document1 pageDetecto Balanza Neonatal - 8435Biotecnologic ImportNo ratings yet

- UNITOP SANTA ROSA-Layout5Document1 pageUNITOP SANTA ROSA-Layout5alvin tolentinoNo ratings yet

- Kamareddy Alt 7Document1 pageKamareddy Alt 7SHYAM RAJNo ratings yet

- Untitled 1Document1 pageUntitled 1Abdur RahimNo ratings yet

- Cultural Centre at ThukkuguduDocument1 pageCultural Centre at ThukkuguduSatish ReddyNo ratings yet

- 2050 Pacific Northwest PDFDocument1 page2050 Pacific Northwest PDFClawsfingerNo ratings yet

- Power RelayDocument12 pagesPower RelayFelisbeloNo ratings yet

- Flooding Risk in MatolaDocument40 pagesFlooding Risk in MatolaFelisbeloNo ratings yet

- US Points OutDocument3 pagesUS Points OutFelisbeloNo ratings yet

- Installation Instructions For A2Fhc Cable GlandDocument2 pagesInstallation Instructions For A2Fhc Cable GlandFelisbeloNo ratings yet

- Installation Instructions For CMP Cable Gland Types Ss2K, Ss2K/Pb & Ss2K/TaDocument2 pagesInstallation Instructions For CMP Cable Gland Types Ss2K, Ss2K/Pb & Ss2K/TaFelisbeloNo ratings yet

- Different Views of Non-Nursing TheoriesDocument11 pagesDifferent Views of Non-Nursing TheoriesContessa Gabriel100% (1)

- Tobor NHS - Localized-Child-Protection-PolicyDocument12 pagesTobor NHS - Localized-Child-Protection-PolicyJanus SalinasNo ratings yet

- Nursing Care Plan HyperthyroidismDocument2 pagesNursing Care Plan HyperthyroidismAbdallah Alasal0% (1)

- Admin,+7 +MADE+VIOLINDocument9 pagesAdmin,+7 +MADE+VIOLINEllina HartonoNo ratings yet

- RISK ASSESSMENT CONTROL SHEET j80Document21 pagesRISK ASSESSMENT CONTROL SHEET j80SaberNo ratings yet

- Ballad Health's FY20 Annual ReportDocument100 pagesBallad Health's FY20 Annual ReportNews 5 WCYBNo ratings yet

- Biodiversity and The Healthy SocietyDocument25 pagesBiodiversity and The Healthy SocietyCarmela Grace RamosNo ratings yet

- Education For The Bodybuilder or Alibi For The PublisherDocument12 pagesEducation For The Bodybuilder or Alibi For The Publisherc_871488068No ratings yet

- Exam Paper Physical Agents and ElectrotherapyDocument10 pagesExam Paper Physical Agents and ElectrotherapyCHANGEZ KHAN SARDAR100% (4)

- Introduction To NGO Management - Capacity BuildingDocument14 pagesIntroduction To NGO Management - Capacity BuildingS.Rengasamy100% (9)

- WK5 Streamflow 20224Document48 pagesWK5 Streamflow 20224DEBRA DEIRDRE S. ONONG DEBRA DEIRDRE S. ONONGNo ratings yet

- Pe CourseworkDocument8 pagesPe CourseworkvkgzzphjfNo ratings yet

- Guidelines Dementia Age Related Cognitive ChangeDocument32 pagesGuidelines Dementia Age Related Cognitive ChangeFernanda Keren de PaulaNo ratings yet

- Gastroparesis. ACGDocument45 pagesGastroparesis. ACGNaser EsmailiNo ratings yet

- Mod 4 Workshop 2 WorkbookDocument20 pagesMod 4 Workshop 2 WorkbookkonradNo ratings yet

- Accountability in NursingDocument7 pagesAccountability in NursingmaakkanNo ratings yet

- Department of Education: Republic of The PhilippinesDocument10 pagesDepartment of Education: Republic of The PhilippinesMary Grace Delos Santos50% (2)

- Module 2 - The Non-Literary TextDocument12 pagesModule 2 - The Non-Literary TextJessabel FerrerasNo ratings yet

- Guide Catheters Guidewire Overview and Case Illustra5onsDocument45 pagesGuide Catheters Guidewire Overview and Case Illustra5onsNeet Aipg newstips100% (1)

- Social Mobilization For Polio in Angola, Ethiopia and IndiaDocument37 pagesSocial Mobilization For Polio in Angola, Ethiopia and IndiaAdil PashaNo ratings yet

- HOPE1-Lesson8 FinalDocument9 pagesHOPE1-Lesson8 FinalEian InganNo ratings yet

- Model of Argumentative Essay:: Separating The Sexes, Just For The Tough YearsDocument2 pagesModel of Argumentative Essay:: Separating The Sexes, Just For The Tough YearsEka AmaliaNo ratings yet

- Hipopresivos y Dolor Lumbar Cronico 2021Document9 pagesHipopresivos y Dolor Lumbar Cronico 2021klgarivasNo ratings yet

- Health Education PlanDocument2 pagesHealth Education PlanJeanette Pinkihan50% (2)

- VCM MSDSDocument9 pagesVCM MSDSFaisalNo ratings yet

- COVID Testing Labs 16122020Document149 pagesCOVID Testing Labs 16122020Fraston DlimaNo ratings yet

- Health 8 Q4 Week1 Mod1 Benigno MaryAnnDocument12 pagesHealth 8 Q4 Week1 Mod1 Benigno MaryAnnregie garciaNo ratings yet

- PCNTemplate&Guidelines - World BankDocument12 pagesPCNTemplate&Guidelines - World BankDennis Arn B. CariñoNo ratings yet

- Nursing Care of Male and Female Clients With General and Specific Problems in SexualityDocument22 pagesNursing Care of Male and Female Clients With General and Specific Problems in SexualityDecere PascualNo ratings yet