Professional Documents

Culture Documents

The Velocity of Water Hammer Waves

Uploaded by

Nana LiuCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Velocity of Water Hammer Waves

Uploaded by

Nana LiuCopyright:

Available Formats

12

Paper 2

THE VELOCITY OF WATER HAMMER WAVES

By I. S. Pearsall*

Sudden flow changes in a pipeline cause water hammer waves to be transmitted up the pipe. The magnitude

of these pressure waves is directly proportioned to the acoustic velocity.

The value of the acoustic velocity depends on the bulk modulus or compressibility of the liquid. It is thus

affected by pressure, temperature and gas content of the liquid, as well as by the elasticity of the pipe.

For water, considerable data are available on the variation of acoustic velocity with temperature and

pressure. These are summarized and it is shown that, whereas temperature causes changes of the order of

1 per cent per 5 degC, the variation due to pressure is negligible except at very high pressures.

The presence of free gas causes a considerable increase in compressibility, and it is shown that even as little

as 1 part of air in lo4 parts of water by volume causes a 50 per cent reduction in acoustic velocity. The

damping of the pressure waves, which has an overall beneficial effect, is also greatly increased by the

presence of free gas, and data are given on these effects. Solids in liquid have a similar but less drastic

influence.

Experimental results are given of some tests on two sewage pumping stations in which good agreement was

obtained between theory and experiment.

The elasticity of the pipe also affects the acoustic velocity and a summary is given of the data available for

steel, concrete, and rock-lined tunnels ,with different types of pipe fixing.

INTRODUCTION a Mean pipe diameter.

IN MANY HYDRAULIC SYSTEMS sudden changes or complete E Young’s modulus of material of pipe wall.

stoppages of flow occur. The kinetic energy destroyed F Function representing direct wave.

during these changes is converted into potential energy, f Function representing reflected wave.

which is transmitted through the fluid as pressure waves. g Gravitational constant.

These pressure or water hammer waves are propagated H Static head on pipeline.

through the liquid at the acoustic velocity (or velocity of K Bulk modulus of liquid.

sound). The value of the acoustic velocity depends on the I Distance apart-reinforcement rods.

compressibility of the liquid and its container. Its value P Pressure.

for water and other pure liquids is accurately known, and Q Flow in pipeline.

this value, together with allowance for elasticity of pipe R Reflection coefficient.

walls, is normally used in water hammer calculations. r Radius of pipe.

The acoustic velocity is however affected by temperature, S Salinity in parts per thousand.

pressure and the presence of air or solid matter in the T Temperature.

liquid. It is shown how allowance can be made for these t Time.

factors. V Volume.

V Velocity in pipeline.

Notation X Distance from valve.

A Cross-section area of pipe. Y Proportion of gas (or solid) in liquid by volume.

a Acoustic velocity. a Acoustic velocity ratio

b Pipe wall thickness. Velocity in elastic media

d Pipe diameter. Velocity in rigid pipe at 20°C & atmosphericpressure

B Wave height.

The M S . of this paper was received at the Institution on 16th May S Diameter reinforcement rods.

1965.

* National Engineering Laboratory, East Kilbride, Glasgow. Y Ratio of specific heats (Cp/Cv).

Proc Instn Mech Engrs 1965-66 Vo1180 Pt 3E

Downloaded from pcp.sagepub.com by guest on January 19, 2015

THE VELOCITY OF WATER HAMMER WAVES 13

v Poisson's ratio. the pressure of the gas. In a liquid, y can usually be ignored

p Mass density. as it is nearly unity for an incompressible liquid. If great

I) Wall fixing constant (see Appendix 2.11). accuracy is required, or if the liquid is compressible, y must

be considered, thus y=1.001, for water at 8"C, so the

Subscr+ts change in a is 1 part in 2000. For sea water y = 1.0207 at

a Air. 30°C, which is sigdicant, but for ethyl ether at 18"C,

B Other fluids or solids. y = 1.32 and the effect is important.

c Concrete. Table 2.1 shows values of K for common liquids.

I Inner.

m Mixture. Table 2.1. Values of bulk modulus at atmospheric pressure

0 outer. for common liquids

R Reflection coefficient.

s Steel. T K

("C) (lb/in*)

T Total.

w Water. Water . 20

BASIC EQUATIONS oil (viscosity 20 &)

Oil (viscosity 500 c/s)

:. 22

22

It can be shown (I) (2)" that the basic equations for the Kerosene . 20 1.91 x 10-5'

propagation of pressure waves through a compressible fluid Paraffinoil . 34 1.76 x 10-6

Mobil A 40 2.56 x 105

in an elastic pipe, if friction is neglected, are Methyl alcohol

Ethyl alcohol

: 20

20

1.76 x 105

1.75 x 106

aH 1 av Carbon tetrachloiide

-=_ -

a x g a t -

* *

(2.1) - 20 1.63 x 105

Considerable differences in values of bulk moduli are

and quoted by different sources. Except where tolerances are

quoted the values used in these tables are therefore approxi-

mate. More comprehensive examination of data for water

is given by Dorsey (19).

where H i s head, t is time, v is velocity, with sign opposite

to that of the distance x, and a is the acoustic velocity. TEMPERATURE EFFECTS

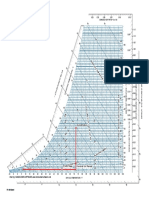

These equations can be solved in the form The acoustic velocity has been measured at a number of

temperatures by a number of workers. Representative

values, as given by Greenspan and Tschiegg (4), are given

in Table 2.2 at atmospheric pressure for distilled water.

Linear interpolation will give errors less than 0.2 ft/s. It

a can be expressed by the polynomial (4), if T is in degrees

where F and f are functions representing the direct wave Celsius,t

and the reflected wave respectively. On a graph of head H, u = 4602.1566 + 16.5144T- 0.190 127T2+ 10.8804 10-4T3

against velocity v, these become straight lines, leading to - 4.765 82 10-'T4 + 9.989 84 10-'T5,

the graphical method of solution (Schnyder-Bergeron giving values accurate to 0.08 ft/s.

Method) (2) (3). The slope of these lines, or the 'pipeline For sea water (between 6" and 17°C) Wood ( 5 ) gives the

a

characteristic', is - ,or if transposed on to an H-Q diagram, equation

g u =4626 + 13.8T - 0.12T2+ 3.73s ft/~,

U

is -, where A is the cross-sectional area of the pipe. where s is the salinity in parts per thousand. Alternative

gA values are given by Wilson (6).

Thus the magnitude of the excess pressure generated

during a flow change is directly proportional to the acoustic It can be seen that the variation of acoustic velocity due

velocity. to temperature is some 1 per cent per 5 degC, which is a

The acoustic velocity can be shown to be, for a homo- significant factor. Table 2.2 and Fig. 2.1 also express the

geneous fluid, as differences as ratios with respect to the speed at 20°C.

P R E S S U R E EFFECTS

Numerous measurements have been made of the acoustic

where y is the ratio of the specific heats of the fluid, p is the velocity, but only a few have considered the effects of both

density and K is the bulk modulus. The bulk modulus is temperature and pressure. Wilson (7) has reviewed the

the reciprocal of the compressibility, defined by the existing information on these effects in distilled water and

relationship supplemented these with experimental results at up to

compressibility = -

K

1= -1 --dv

v dp

. 100°C and 14000 lb/in2. From these results he has

In a gas, K is measured isothermally and is equal to p, t The values are quoted verbatim from the onginal papers. It seems

unlikely that the number of significant figures is justified, in view

of the differences shown by dirfetent workers (Tables 2.2'2.3' and

References are given in Appendix 2.111 2.4).

Proc Instn Mech Engrs 1965-66 Vol180 P t 3E

Downloaded from pcp.sagepub.com by guest on January 19, 2015

14 I. S. PEARSALL

Table 2.2. Values of acoustic velocity and acoustic velocity a =ao +a,T + a2T2+ a 3 P +a4T4,

ratio for distilled water where + 3.4460 10-2p + 5.3602 10-'p2

a0 = 4602.56

Atmospheric pressure - 12.7600 1 0 - 1 2 ~ ~

a, = 16.4825 +20.1381 10-5p - 3.5439 10-*p2

Temperature Velocity, a Velocity ratio +8.1289 1 0 - 1 3 ~ ~

"C (ft/s) to 20°C

a2 = - 0.1867 - 3.5143 10Vp

0 4602.17 0.9461 + 7.2696 1 0 - 1 0 ~-~1.6696 1 0 - 1 4 ~ ~

5

10

4680.12

4749.32

0.9621

0.9763

a3= +9.4650 + 5.1916 10Vp

15 4810.53 0.9889 - 7.9428 1 0 - 1 2 ~+~1.6687 1 0 - 1 6 ~ ~

20 4864.37 1 .oooo a4= - 2.0703 10-6 - 2.2440 10-lop

25

30

4911.42

4952.23

1.0130

1.0181

+ 3.1862 1 0 - 1 4 ~-~6.0538 10-19~~.

35 4987.27 1.0253 Table 2.3 shows the values of velocity and its ratio to

40 5017.00 1.0314

45 5041.74 1.0365 that at 20°C and at atmospheric pressure for various

50 5061.91 1.0406 pressures and temperatures (see footnote t page 13).

55 5077.76 1.0439

60 5089.57 1.0463

65 5097.64 1.0479

70 5102.10 1.0489

75 5103.19 1.0471

80 5101.08 1.0487

85 5095.97 1.0476

90 5087.90 1.0459

95 5077.10 1.0437

100 5063.68 1.0410

Greenspan and Tschiegg (4) report that the difference in

velocity of sound between distilled and tap water is less

than 0.15ft/s.

deduced the following expression (the standard deviation

0.94! lb io io do o;

TEMPERATURE-'C

60 o; 40 io b

1 0

being less than 19 parts in 10000 from experimental

values). Fig. 2.1. Acoustic velocity ratio as a function of temperature

Table 2.3. Values of acoustic velocity and acoustic velocity ratio as functions of temperature and pressure for distilled water

I

Temperature

"C

0

1

I

14.7

4603.05

2000

4673.53

Pressure lb/in2 abs.

4000

4748.17

6000

4825.90

8000

4906.04

I 10000

4988.06

10 4750.16 4822.94 4897.90 4974.25 5051.71 5 129.92

20 4865.22 4939.83 5015.36 5091.18 5167-23 5243.34

30 4952.96 5029.27 5105.68 5181.66 5257.25 5332.45

40 5017.39 5095.51 5173.20 5249.90 5325.79 5400.89

50 5061.95 5142.20 5221.49 5299.41 5376.08 5451.71

60 5089.44 5 172.15 5253.45 5332.98 5410.86 5487.34

70 5101.90 5187.47 5271.16 5352.59 5432.02 5509.72

80 5 100.85 5189.54 5275.92 5359.65 5440.95 5520.15

90 5087.08 5179.07 5268.38 5354.66 5438.22 5519.46

100 5060.73 5155.97 5248.36 5337.54 5423.89 5507.81

Temperature Pressure lb/in2 abs.

"C

14.7 I 2000 I 4000 I 6000 I 8000 I 10000

0

10

20 I 0.9461

0.9763

1.0000 1 0.9606

0.9913

1.0153 1 0.9759

1.0067

1.0309 1 0.9919

1.0224

1.0464

1.0084

1.0383

1.0621

1.0252

1.0544

1.0777

40

50

i

1.0313

1.0404

1.0461

1.0473

1.0569

1.0631 1 1.0633

1.0732

1.0798

1.0791

1.0892

1.0961

I

I

i.094-I

1.1050

1.1121

1.1101

1.1205

1.1279

1 1 1 1

70

60 1.0486 1.0662 1.0834 1.1002 1.1165 1.1325

1

80 1.0484 1.0667 1.0844 1.1016 1.1183 1.1346

90 1.0456 1.0645 1.0829 1.1006 1.1128 1.1345

100 1.0402 1.0597 ~ 1.0787 1.0971 1.1148 1.1321

Greenspan and Tschiegg (4) report that the difference in velocity of sound between distilled and tap water is less than 0.15ft/s.

Proc Instn Mech Engrs 1965-66 VoZ 180 Pt 3E

Downloaded from pcp.sagepub.com by guest on January 19, 2015

THE VELOCITY OF WATER HAMMER WAVES 15

Wilson also estimated the systematic and problematic or

errors in measuring the velocity of sound and showed that

at pressures up to 14000 lb/in2 the overall accuracy is

1 part in 10 000. Table 2.4 compares results given by hence

1 l-Y+y.

Table 2.4. Values of velocity of sound (1s assessed by dijfment Ka KT=K

authors at 14-7lblin2 30°C At low pressures and ordinary temperatures the process is

isothermal rather than adiabatic, thus Ka becomes equal to

Distilled water Sea-water the absolute pressure of the gas pa,

35 per cent salinity

~ ~~~

thus

Mathews 1939 4935.7 5062.67

Kuwahara 1939 - 5063.00

Del Grosso 1952 4952.76 5073.17 and the acoustic velocity becomes

Greenspan 1958 4952.23 -

Wilson 1959 4952.96 5072.71

I I

Greenspan and Tschiegg (4) report that the difference in

velocity of sound between distilled and tap water is less

than 0.15ft/s.

different authors. From Table 2.3 it can be seen that over

the range 0 to 2000 lb/in2 at 20”C, the change in acoustic

For gas concentrations of less than 1 in by volume

velocity is some 1-3 per cent. Hence it can be considered

that, for normal pressures encountered in pumping and ypa<(l - Y ) P ~and ( 1 -y)’)pwEpw

turbine installations, the effect of pressure on the acoustic hence

velocity is negligible.

The actual velocities of sound derived by this equation

G A S CONTENTS EFFECTS

are given in Table 2.5 for various pressures at 20”C, whilst

If the liquid contains even a small quantity of undissolved the relative values are given in Fig. 2.2. Values measured

gas bubbles, the acoustic velocity is greatly reduced by Silberman (9) are given for comparison. A proportion of

(5) (8) (9). For a non-resonant system, i f y is the proportion the bubbles may be resonant, but this will be small and

of gas by volume, then the mean density of the liquid and there is no need to use the more complicated equations and

gas is temperature of Spitzer (10)for the resonant case.

pm=YPa+(l-y)pw. . . .

(2.3)

Considering the volumetric changes that occur if we con- .loo-

150 f t GAUGE

sider a pressure wave to compress a volume of water V by P -

I-

80- 100 f t GAUGE

an amount dV, 4

K

> -

then for the water

60-

9 -

dV,= - -

vwdp by definition,

KW ’4 0 -

0

and for the air In

0’ 20- o EXPERIMENTAL V A L U E S ( ~ * ~ )

u -

I I I I I

I , , , , I I I I ,,,,I , , , , ,,,,I

:0-e

1 0 -RATIO

~ OF AIR

10-4 TO WATER 1 0-3

BY VOLUME 10-2

F%. 2.2. Acoustic velocity as a function of gas content

Table 2.5. The effect of gas content on acoustic velocity and acoustic velocity ratio

Pressure

(ft

lb/in2

(abs.)

I Proportion of air by volume

head) I 10-6 I 10-6 I 10-4 I 10-3

0

30

50

100

150

14.70

27.68

36.34

57.98

79.61

II 4810.8

4837.6

4843.9

4851.2

4855.0

1I 0.9889

0.9944

0.9957

0.9972

0.9980

II 4414.8

4608.9

4665.3

4737.8

4772.4

1I 0.9075

0.9474

0,9590

0.9739

0.9810

II 2741.3

3324.6

3558.6

3914.2

4115.6

1I 0.5635

0.6834

0.7315

0.8046

0.8460

II :%::II

10265

1916.7

2184.3

0.2110

0.2839

0,3220

0.3940

0.4490

332.75

455.30

520.50

651.90

763.80

0.0684

0.0936

0.1070

0.1340

0.1570

a. =Acoustic velocity in gas-free liquid (taken at 14.7 lb/in2 and 20°C)

Proc Instn Mech Engrs 1965-66 Vo1180 Pt 3E

Downloaded from pcp.sagepub.com by guest on January 19, 2015

16 I. S. PEARSALL

M I X T U R E S O F WATER WITH S O L I D S OR Table 2.6. Values of Young's modulus for various pipe

LIQUIDS materials

In sewage pumping installations or in chemical plant,

I

mixtures of liquids or liquids and solids may occur. In

these cases some reduction in acoustic velocity is caused;

the amount is calculable by a similar technique to that

Material

I E

(lb/in2)

V

given in the foregoing section.

Steel . I 29 t o 3 1 x106 0.30

Cast iron . 11.6 to 16.0 x 106 0.25

If the proportion of fluid (or solid) B in water (or second Transite 3.4 x 106

fluid) is y, then the ratio of the acoustic velocity in the Asbestos cement} . .

Aluminiumalloys . 10 x 106

fluid to that in water is Brass . 11.4 to 16 x 106 0.33

-=[ ((1-Y)KB Concrete

.

. 2.8 to 4.3 x 106 0.1 to 0.3

a"

a0

PwKB

+(I -Y>PW>

+YKW}(YPB I'

where subscript B refers to the fluid (or solid) B and sub-

Copper

Glass

Lead

.

Soft rubber

15.6 to 19 x 106

9.9 x 106

0.7 to 2.4 x 106

0.1 to 1.04 x 106

0.34

0.24

0.44

0.46 to 0.49

Rocks*

script w refers to water (or second fluid). It can be seen Sandstones . 0.285 to 0.70 x 106

that, unless KB and Kw are very different, this ratio will Quartzites . 3.55 to 6.5 x 106

Schists . 0.94 to 2.7 x 106t

be about 1. Plastics

ABS . . 2.5 x 105

P I P E WALL ELASTICITY PVC rigid . 3.5 to 4 x 106

Nylon . 2 to 4 x 105

The effect of the pipe walls is similar to that of compressible Phenalic glass reinforced 34 x 105

gas bubbles, in that the elasticity of the walls reduces the Polvethvlene . 0.21 to 0.27 x 105

wave velocity. Thus if we imagine a section of pipe of

radius r (diameter d and thickness b) and length 6x being

subjected to a pressure wave Sp, then the increase of

volume in the pipe is

*

Poljrpripylene

PTFE .

.

:I 1.4 to 1.7 x 105

0.5 x 106

Lower value corresponds to normal to strata, anc higher value

corresponds to parallel to strata.

t Grouting of the rock improved this to 3.45 x 106.

dVp =

2ddpSxT

(see Appendix 2.1)

by Linton (11). For thick-walled pipes or pipes of concrete

or, as the original volume V = m 2Sx, or other materials, some revision of this basic formula is

necessary. A summary of the information from different

d

dVp=Eb Vdp. authors has been collected in Appendix 2.11 for reference.

The decrease in volume in the water is (by definition) A C O U S T I C VELOCITY-GENERAL EQUATION

The adoption of a general equation is to some degree

dVw= --VdP dependent on the form in which data are available. The

Kw

temperature (and pressure) effects on the water alone are

therefore the total change in volume is presented in Tables 2.2. and 2.3. It is then easiest to allow

dVp -dVw= ( t-b + - Vdp,iw) for these effects by utilizing the appropriate data. The other

effects, however (gas content and wall elasticity), have been

incorporated by revision of the bulk modulus, thus

and, if we imagine an effective K value for the pipe and

water,

and

1 dVT-dVl+dV2+dV3

e)

-

(A+&) =-Vdp Y1

-+-+-...

Y2

(Kl K 2 K3

Y3

where K,, K,, K3, . . . Kn are the bulk moduli of the

Hence the velocity of sound becomes

respective elements in the fluid, or the equivalent bulk

+-i b ) } ' . . . modulus of the walls, and yl, y2 . . .y n are the proportions

a"= p

{ -

(iw

(2.5)

of the elements. The equivalent bulk modulus of a wall is

or the ratio to water in a rigid pipe is -

d for a simple wall, or one of the functions given in

K, Eb

- = ( 1 + = )dKw

a" -* Appendix 2.11 for more complicated walls.

ao Thus

Values of E for various common pipe materials are given

inTable 2.6. Values for pipes to B.S. Specificationsare given

Proc Instn Mech Engrs 1965-66 Vo1180 P t 3E

Downloaded from pcp.sagepub.com by guest on January 19, 2015

THE VELOCITY OF WATER HAMMER WAVES 17

and then the ratio of reflected to incident waves (reflection

Yi

a'= pm -

{ +-Y2 ...-+-

(Ki K2

Yn

Kn A)}-' . (2.6)

coefficient) is 0)

R2= pmam - p wa ( pmam + pwaw )

The ratio compared to the plain primary fluid is

hence the percentage of energy reflected can be related to

x, the proportion by volume of air in the water (Fig. 2.3).

where pm is the mean density of the mixture, ;100-

pm=YiPi + ~ 2 p 2 - - - Ynpn, - - (2.8) z

w0 80-

ATMOSPHERIC

and pw and Kw refer to the primary fluid, for instance, 5 0 f t GAUGE

water. 100 11 GAUGE

Alternatively, the acoustic velocity of the fluid can be z

2 40- 150 f t GAUGE

expressed as o

t- -

w

2 20-

w

L -

where y l , y 2 etc. are the proportions of the different ele- RATIO OF AIR TO WATER BY VOLUME

.

ments, such that y 1+ y 2 + y 3 . . y n = 1, and pm is the mean

Fig. 2.3. Reflectionfactor as a function of gas content

density of the fluid, equation (2.8).

The procedure is therefore, firstly to determine the The transmission is then 1 -R2, and if we assume the

relevant wave velocity in the pure liquid (Tables 2.2 and waves follow an exponential decay, the percentage trans-

2.3 for water). This value can then be amended by use mission is equal to the percentage decay of the pressure

of equation (2.7) to allow for gas bubbles, solid inclusions, wave. Referring to Fig. 2.4

mixtures of liquids, and pipe wall elasticity.

1 -RZ,&.

ATTENUATION O F P R E S S U R E WAVES PI

Any elasticity in the system will, in addition to reducing The above theory neglects frictional losses in the piping

the acoustic velocity, cause attenuation of the water system, which are small. These can, if necessary, be esti-

hammer waves owing to hysteresis in the energy cycle. In mated from conventional water hammer theory and be

most practical cases the first wave is the greatest in magni- included in the total attenuation.

tude and for this reason most attention is concentrated on

it. Attenuation caused by wall elasticity is negligible com-

pared to that caused by fiiction and other losses in the pipe

system. Attenuation caused by fluid elasticity is significant

in the case of a compressible fluid, or fluid containing gas

bubbles.

Attenuation caused by free gas bubbles

Most of the work done on attenuation of pressure waves in

liquids by gas bubbles concern resonant systems (9) (10). Fig. 2.4. Wave decay curve

Attenuation under these conditions is larger than in non-

resonant systems. Some of the bubbles in a pipeline will Attenuation caused by liquid and solid mixtures

correspond to resonant size, but the majority will be non- The further attenuation caused by a second component

resonant. will be small unless that component is very compressible.

From equation (2.3) the mean density is The theory given in the previous section is applicable to

pm =YPa + (1 - Y ~ W

this case if it is desired to calculate attenuation.

and the acoustic velocity EXPERIMENTAL RESULTS

[{ Acoustic velocity

a'= Kwpa

(1 - Y ) P ~+yKw 11 YPa + (1 -Y)PW

The acoustic resistance of the substance is pma' equal to

11'. The effects of pressure and temperature on the velocity in

pure water are based on experimental determinations and

confirmation can be found in Greenspan and Tschiegg (4)

and Wilson (7). The effects of gas content are also fairly

well established in the physical sense. Measured values are

plotted, where available, in Fig. 2.2. from Silberman (9).

If we assume that the layer of bubbly mixture is thick, Most water hammer tests reported have been conducted

Proc Instn Mech Engrs 1965-66 Vol180 Pt 3E

Downloaded from pcp.sagepub.com by guest on January 19, 2015

18 I. S. PEARSALL

on pure water systems, where very often the head is high It will be noted that although the total gas content of the

and it is unlikely that free gas is present, and no authors pipeline will remain substantially constant for any one test,

have reported unusual values of wave velocity. The origin the percentage value will increase as the lower pressure

of the present investigation was two sets of tests under- wave is transmitted. Hence one would expect a difference

taken on sewage pumping stations at Kingston (12) and between the positive and negative waves which is evident

Derby, in both of which considerably reduced values of in Figs. 2.5 and 2.6.

Table 2.7. Expm'mental wave velocity and attenuation results

- -

(11 Volume

Calculated air to Calculated Experimental

wave water Measured teflection ransmissiol decay

Test Nos and type of test

velocity

in water

wave -I

I

velocity (Fig. 2.4) 1 from a2

(Fig. 2.2)

gas

content

:oefficieni

R2

1-R2

(per cent)

82/81

(per cent)

Static

head

Kingston tests

K2, K10, K11. No 2 pump

stopped 3770 1844 34 26 10.49 4.5 x l O - 4 - 16 84 76.5 45

K4, K8. Nos 1 and 2 pump!

stopped 1844 45.2 35 0.49 4.5 x - 16 84 77.5 45

K13. Pumps 4,5 and 6

stopped 2340 59 48 0.62 2 x ~ O - ~ - 8 92 81.5 45

K17. Pumps 5 and 6 stoppec 2510 43.5 35.8 0.66 1.06 x - 6 94 82.3 45

K20. Pump 5 stopped 2560 34 26 0.68 1.05 x10-* - 5 95 76.5 45

----

Derby tests

Al. Pump 1 stopped from

750 revlmin 3090 697 28 19.5 0.226 1.5 x - 37 63 69.6 29.5

A3. Pump 1 stopped from

738 rev/min 888 36 23.5 0.287 1 x 10-3 - 31 69 65 29.5

A4. Pump 1 stopped from

625 revlmin 661 24 12.5 0.214 1.8 x 10-3 ~ . x2 10-3 40 60 52 29.5

A6. Pump 1 stopped from

550 rev/min 692 28.5 18.5 0.224 1.6 x 10-3 1.2 x 10-3 38 62 65 29.5

A7. Pumps 1 and 5 stopped

from 580 revlmin 545 58.7 27.5 0.176 2.7 x 10-3 1.2 x 10-3 43 39 47 29.5

A10. Pumps 1 and 5 stopped

from 700 revlmin 870 47.5 303 0.282 1 x 10-3 1.7 x 10-3 31 69 64 29.5

C1. Pump 5 stopped from

755 revlmin 418 26.5 11.5 0.135 3.8 x 10-3 saturated 54 46 43 29.5

C3. Pump 5 stopped from

750 revlmin 503 31.5 14.5 0.163' 3 x 10-3 saturated 48 52 46 29.5

C6. Pump 5 stopped from I

750 revlmin 550 30.5 14.8 0.178 2.7 x 10-3 1.5 x 10-3 43 57 48 293

-

wave velocity were observed (1850 ft/s in the former and

600 fils in the latter).

No measurements of gas content were made at Kingston

but some measurements were made at Derby although, . STATIC .

because of the high proportion of gas, great accuracy was w LEVEL

unattainable. Table 2.7 shows the calculated values of wave

velocity for these stations (assuming pure water and allow- ~ o " " " " "5 " " " " " 10 15 20

TIME-s

ing only for the elasticity of the pipes) compared to the

measured values. Also included are the estimated gas Fig. 2.6. Derby test A4, pump 1 stopped from 42.6 cusecs

content from these values, as well as attenuation data as

described in the next section. The results from these tests support the theory although,

as the exact gas content was not known, it is not possible

to know how accurate is the agreement. However, it is seen

- 80 -

that variation in gas content may cause reduction in wave

velocity of as much as 75 per cent.

As far as the elasticity of the pipe walls affects the wave

velocity, the main difficulty is in estimating the type of

fixing and the particulars of the pipe wall. Comparison

between theory and practice has shown good agreement

I I (13) (14) (15) even where the elastic properties are not

4'0 20 30 40 50 60

TIME-s known exactly. Any errors from this source are likely to

Fig. 2.5. Kingston test K2, pump 2 stopped from 6 cusecs be less than 2 per cent, which is acceptable.

Froc Instn Mech Engrs 1965-66 V01180 Pt 3E

Downloaded from pcp.sagepub.com by guest on January 19, 2015

T H E VELOCITY OF WATER HAMMER WAVES 19

Attenuation have been found to substantiate the theory. In addition a

In normal water hammer calculations, attenuation is based section has been included giving results of tests on two

on frictional losses in the system and elasticity of the walls sewage pumping stations, to substantiate the theory on the

is ignored. There is no experimental or theoretical basis for presence of free gas. This appears to be a very important

supposing this leads to serious errors. However, where free factor in this type of installation, and has not previously

gas is present this is not the case and some eight tests on been noted.

sewage pumping stations are used to substantiate the Little mention is made of fluids other than water but all

theory in the previous section. the experimental and theoretical knowledge indicates that

In both sets of tests at Kingston and Derby the exact these follow the same laws, although uncertainty as to the

gas content was unknown, although at Derby some measure- bulk modulus may limit the accuracy of such calculations.

ments were made. However, knowledge of the wave

velocity, found from the periodic time, allows an estima- APPENDIX 2.1

tion of the gas content to be made, using Fig. 2.2, which Considering an element of water in a pipe, subject to a pressure

can then be used to calculate the attenuation. A comparison wave of magnitude 6p over a length ax, then the water will

between calculated values by this method and measured compress by a certain amount, by definition, equivalent to

values gives, on the whole, good agreement, Table 2.7. In dVw= --.SP V . . . . (2.9)

addition, the estimated free-gas content is substantiated to K

some extent by measurements on site. No allowance has The change in hoop stress will be

been made for solids content as this was less in both

magnitude and elasticity than the gas. (2.10)

Clearly the methods of calculation are approximate for, 6r

as well as experimental errors, the wave velocity and so that the strain - (neglecting axial stress) is

attenuation will vary as the pressure in the liquid varies. 6r -rap

- _- (2.11)

Thus one would expect a decrease of free gas in the r Eb‘ * . ’ ’

upsurges and an increase in the downsurges, hence the The increase in volume is

wave velocity would be higher and the attenuation less in 2rrr6r6x.

the upsurges than in the downsurges. Also one would Substituting for 6r from equation (2.3),

expect the free-gas content to decrease as the mean head 2Tr3

increased and the surges damped out. There is some increase in volume = --

Eb

6p6x. . (2.12)

evidence to support these observations but it is not con-

Axial strain will alter this value in a ratio varying from approxi-

clusive. mately 0.92 to unity according to the conditions.

This indirect experimental support for the theory seems

to confirm its usefulness, and show the major effect of free APPENDIX 2.11

gas in the liquid.

THICK-WALLED, CONCRETE AND ROCK-LINED T U N N E L S

CONCLUSIONS Perhaps the best summary of the effect of pipe fixture, and thick-

walled and rock tunnels is given by Halliwell (16),and is sum-

A summary has been given of the factors affecting the rate marized below. Concrete pipes are considered by Kennison (14).

of propagation of pressure waves in a piping system. It is Tests on a transite, or cement asbestos, pipe are reported by

dependent on the bulk modulus of the fluid and the Kessler (IS).

elasticity of the walls, and its prediction depends on the Table 2.6 contains a list of E values that can be used in equation

(2.5) for thin-walled pipes. If, however, the pipe has thick walls,

accuracy with which these are known. Even for water there or is made of a composite material (concrete), or is in rock, this

is considerable disagreement on exact values for bulk equation can no longer be used.

modulus but for engineering purposes the values are The general equation for such a case is (16)

- +-,:I}-*

sufficiently accurate.

Three factors can be computed separately. These are the a”= { (A

p . . (2.13)

variation of liquid bulk modulus with temperature and

pressure presented here as the change of velocity of sound

in which

* =E(2cr + c,)

in water with temperature and pressure, the effect of pipe where Zr represents the circumferential strain caused by unit

wall elasticity allowable by Young’s modulus of the material pressure inside the pipe, the longitudinal strain caused by unit

pressure rise inside the pipe. E’ is the Young’s modulus of the

and by a factor representing the method of fixture of the material in the pipeline immediately adjacent to the water.

pipes, and finally, the presence of free gas, allowance for

which can be made by modifying of the bulk modulus of Thick-walled pipes

the liquid. Strictly one should use a combined equation Halliwell’s results can be best expressed by the generalized

of the form of equation (2.6). However, in most cases a equation

satisfactory approximation can be made by using equa- A d b

+ = A -do2 +d12 + B = - - + -

tions relating the velocity to that in pure water for each do2 -d12 2( b a)+B

case, and then to combine the total effect. where do, d~and 2are respectively the outer, inner and mean pipe

Reference is made to sources where experimental data diameters, and b is the wall thickness.

Proc Instn Mech Engrs 1965-66 Vol 180 Pt 3 E

Downloaded from pcp.sagepub.com by guest on January 19, 2015

20 I. S. PEARSALL

The coefficients A and B are defined as follows. Equation (2.5) is then used with this value of b and E for steel

pipe.

For higher pressure pipes, a thin steel membrane is often used.

Under these circumstances the material has two portions to its

Pipeline anchored against longitudinal

movement throughout its length I 2(1 -v*) 1 2v(l +v)

stresslstrain curve, initially, where the concrete is taking the load

and, secondly, where the majority of the load is taken by the steel

reinforcement cylinder. Kennison (14)shows that by these means

Pipeline anchored against longitudinal decrease in effective surge velocity of 30 per cent can be effected.

movement only at end remote from H e suggests using a mean value based on a mean value of the two

valve curves.

His data refer solely to pipes made to U.S.A. Waterworks

Pipeline with frequent expansion joints

1 2 1 2 v standards, for reinforced and prestressed pipes. The reinforce-

ment in all cases being of a cylinder type.

Thin-walled pipes A P P E N D I X 2.111

In this case a Ail

= 0 and 4 = - -

- 91, and radial stress is 0 so that B REFERENCES

b 2 b’ JAEGER, C. Engineeringfluid mechanics 1956 (English transl.,

values at A being taken from the previous table according to the Blackie, London).

end fixture. BERGERON, L. Water hammer in hydraulics and wave surges

Pipeline through solid rock in electricity 1961 (Wiley, New York and London).

d

This case can be covered by putting d o = to or - = 1 hence

SCHNYDER,0. ‘Druckstosse in pumpensteigleitungen’

b (Water hammer and discharge mains of pumps), Schweiz,

* = A + B = 2 ( 1 +v). Bauztg 1929 94, 271, 283.

GREENSPAN, M. and TSCHIEGG, C. E. ‘Tables of the speed

Lined tunnels of sound in water’, J. Acoust. SOC.Amer. 1959, 31, 75.

(i) Steel and concrete lining WOOD,A. B. A text-book of sound. Revised edition 1955

If the steel lining has a mean diameter isand thickness b, the (Bell & Sons, London).

concrete lining between it and the rock has mean diameter d and WILSON,W. D. ‘Speed of gas in sea water as a function of

thickness b. Halliwell’s expression simplifies to temperature, pressure and salinity’, J. Acoust. SOC.

Amer. 1960 32.

(1 - ”2) WILSON,W. D. ‘Speed of sound in distilled water as a

4=

function of temperature and pressure’, J. Acoust. SOC.

lbs 1-v E, Amer. 1959 31, 1067.

RIPKEN,J. F. and OLSEN,R. M. ‘A study of the gas nuclei

1 -2v on cavitation scale effects in water tunnel tests’, St.

Anrhony Falls Hyd. Lab. Proj. Report No. 58. Minnea-

In this equation Poisson’s ratio v is assumed to be the same for polis : University of Minnesota, 1958.

steel, concrete and rock. SILBERMAN, E. ‘Some velocity attenuation in bubbly mix-

tures measured in standing wave tubes’, 3. Acoust. SOC.

(ii) Concrete lining Amer. 1957 29, 925.

For a concrete lining alone the above equation can be used with SPITZER,L. ‘Acoustic properties of gas bubbles in a

bs = 0 , hence liquid’, Columbia Univ. O S R D Report No. 1705, Sect.

6.1/Sr20-911. New York 27, N.Y.: Columbia Univer-

sity, July 1943.

LINTON, P. ‘Notes on pressure surge calculations by the

graphical method’, B H R A Publ. No. TN477.

WHITEMAN,K. J. and PEARSALL, I. S. ‘Reflux-valve and

Substantially Halliwell’s equations agree with other workers, surge tests at a station’, Fluid Handling, 1962 (152), 248

the cases where they do not are cited in his paper, being generally (153),

. .~282.

due to over-simplification of equations by these workers. PARMAKIAN, J. Water hammer analysis, 1955 (Prentice Hall,

New York: Bailey and Swinfer, London).

Reinforced concrete pipes KENNISON, H. F. ‘Surge-wave velocity-concrete pressure

For concrete pipes used with reinforcement bars, then Kennison pipe’, Trans. Am. SOC.mech. Engrs 1956 78, 1323.

(14)states the strength is limited by the tensile strength of the KESSLER, L. H. ‘Speed of water hammer wave in transite

concrete and the modulus of elasticity is essentially that of the pipe’, Trans. Am. SOC.mech. Engrs 1939 61, 11.

concrete. Parmakian (13),however, makes an allowance for the HALLIWELL, A. R. ‘Velocity of a water hammer wave in an

reinforcement bars, by quoting an equivalent pipe thickness elastic pipe’, Proc. Amer. SOC.civil Engrs (J. Hyd. Div.)

1963 89 (Hy4), 1.

GIBSON,A. H. Hydraulics and its applications 5th edition

1952 (Constable, Londoii).

DUNCAN,W. J., THOM, A. and YOUNG,A. The mechanics

where 6 is the diameter of the reinforcing rods and 1 the distance of fluids 1960 (Edward Arnold, London).

apart (the factor J6 represents the ratio of the modulus of elasticity DORSEY,N. E. Properties of ordinary water substance

of concrete to that of steel (& to $6) with a margin of safety. 1940 (Reinhold Publ. Corp.).

Proc Instn Mech Engrs 1965-66 Vol180 P t 3E

Downloaded from pcp.sagepub.com by guest on January 19, 2015

You might also like

- Chapter Two 2.0. Fluid PropertiesDocument11 pagesChapter Two 2.0. Fluid Propertiesabdata wakjiraNo ratings yet

- Chapter One 2.0. Fluid Properties 2.1. General DescriptionDocument9 pagesChapter One 2.0. Fluid Properties 2.1. General DescriptionDegaga TesfaNo ratings yet

- Manual Fundamental Hydraulic SystmsDocument131 pagesManual Fundamental Hydraulic Systmssawmag123100% (3)

- Fluid Properties ME322 (Semester 372) - 1Document23 pagesFluid Properties ME322 (Semester 372) - 1AhmadNo ratings yet

- Evaluation of Heat-Transfer Coefficient at Direct-Contact Condensation of Cold Water and SteamDocument8 pagesEvaluation of Heat-Transfer Coefficient at Direct-Contact Condensation of Cold Water and Steamemanuele casuNo ratings yet

- Fund of Hydr - PressureDocument4 pagesFund of Hydr - PressuresantoshNo ratings yet

- Channel Flow Flow Velocity Formulas Specific Energy Nonuniform Flow Water Profiles Hydraulic Jump Channel Shapes Weirs ReferencesDocument21 pagesChannel Flow Flow Velocity Formulas Specific Energy Nonuniform Flow Water Profiles Hydraulic Jump Channel Shapes Weirs ReferencesGertjan DuniceriNo ratings yet

- Chapter 1 - 202302221501Document59 pagesChapter 1 - 202302221501yolo louoNo ratings yet

- Fluid C1 03 (1) StudentDocument24 pagesFluid C1 03 (1) Studenteric0910160212No ratings yet

- Agustin - Mark Joshua - Ce142p-2 - E02 - CW2Document5 pagesAgustin - Mark Joshua - Ce142p-2 - E02 - CW2mark agustinNo ratings yet

- TRANSPORT MECHANICSDocument19 pagesTRANSPORT MECHANICSMariAntonetteChangNo ratings yet

- FMM QBDocument25 pagesFMM QBrkumaravelanNo ratings yet

- 1 2 PDFDocument5 pages1 2 PDFJohn GaviolaNo ratings yet

- 2023-Pulsating Pressurization of Two-Phase FluidDocument20 pages2023-Pulsating Pressurization of Two-Phase FluidTuong BuiNo ratings yet

- Spe 933170 GDocument20 pagesSpe 933170 GMagno Dos AnjosNo ratings yet

- Topic Time Frame: 9 Hours: Learning ModuleDocument13 pagesTopic Time Frame: 9 Hours: Learning ModuleJea Escabal MosenabreNo ratings yet

- Density, Specific Weight, Specific Volume, and Specific GravityDocument11 pagesDensity, Specific Weight, Specific Volume, and Specific GravitycristyryeNo ratings yet

- Microscopic Displacement of Fluids in A ReservoirDocument16 pagesMicroscopic Displacement of Fluids in A Reservoirعلي التميميNo ratings yet

- Liquid Distribution and Electrical: Conductivity in FoamDocument10 pagesLiquid Distribution and Electrical: Conductivity in FoamMohsen RiaziNo ratings yet

- Lecture2 Fluid PropertiesDocument40 pagesLecture2 Fluid PropertiesFFF ENNo ratings yet

- Fluid Mechanics CE241 Lecture 2 ExercisesDocument15 pagesFluid Mechanics CE241 Lecture 2 ExercisesMohamed ElgamalNo ratings yet

- 01 - Transferencia de Masa Por Difusion PDFDocument13 pages01 - Transferencia de Masa Por Difusion PDFNinoska EspinozaNo ratings yet

- Advanced Marine Hydrodynamics 1Document17 pagesAdvanced Marine Hydrodynamics 1Mohamad Abdul-Aziz FahmyNo ratings yet

- ExcerptDocument5 pagesExcerptprincessbarrameda691No ratings yet

- Fluid Forces in Gas Condensate ReservoirsDocument15 pagesFluid Forces in Gas Condensate ReservoirsaliNo ratings yet

- Water Resources EngineeringDocument128 pagesWater Resources Engineeringdist2235No ratings yet

- 11 Fluids 1Document13 pages11 Fluids 1Thaya GanapathyNo ratings yet

- Transport Mechanics: A. Reynolds Number C. Mach NumberDocument22 pagesTransport Mechanics: A. Reynolds Number C. Mach Numberjerome deiparineNo ratings yet

- CE 76B-Midterm - Module 2.1Document8 pagesCE 76B-Midterm - Module 2.1KristelleNo ratings yet

- MOF LectnotesDocument84 pagesMOF LectnotesKarar AL-DahlkiNo ratings yet

- Ch2 Fundamental ConceptsDocument62 pagesCh2 Fundamental ConceptsDavid RiveraNo ratings yet

- FRICTIONALDocument13 pagesFRICTIONALCleraNo ratings yet

- FM Unit I Two MarksDocument5 pagesFM Unit I Two MarksKomalaselvan VNo ratings yet

- HYDRAUDocument39 pagesHYDRAUjocelNo ratings yet

- Water Distribution ModelingDocument55 pagesWater Distribution ModelingEphrem GizachewNo ratings yet

- Hgpe Formulas 2022Document21 pagesHgpe Formulas 2022Malikah AliNo ratings yet

- Hydraulics Pressure DWFSOM147Document4 pagesHydraulics Pressure DWFSOM147p kishorNo ratings yet

- Water Flow in Saturated Soils Darcy's Law: CE/ENVE 320 - Vadose Zone Hydrology/Soil Physics Spring 2004Document41 pagesWater Flow in Saturated Soils Darcy's Law: CE/ENVE 320 - Vadose Zone Hydrology/Soil Physics Spring 2004joo12345678910No ratings yet

- Chapter 1-2 HydraulicsDocument26 pagesChapter 1-2 HydraulicsDawit HaileNo ratings yet

- Trial Manufacture of A Fluid-Type Static Induction TransistorDocument4 pagesTrial Manufacture of A Fluid-Type Static Induction TransistorStanley ClermontNo ratings yet

- Multiple Saturation QuestionsDocument14 pagesMultiple Saturation QuestionsrestofficalNo ratings yet

- IM BSCE 3 - Hydraulics 1 Chapter 1 2021-2022Document36 pagesIM BSCE 3 - Hydraulics 1 Chapter 1 2021-2022acurvz2005No ratings yet

- Tijsseling-Bergant 2018Document7 pagesTijsseling-Bergant 2018uroskNo ratings yet

- Groundwater Movement: 3.1: Darcy's LawDocument25 pagesGroundwater Movement: 3.1: Darcy's LawshambelNo ratings yet

- Groundwater Movement: 3.1: Darcy's LawDocument25 pagesGroundwater Movement: 3.1: Darcy's LawshambelNo ratings yet

- Fluid Properties-Unit 1Document19 pagesFluid Properties-Unit 1tanu01303No ratings yet

- PE-209 Lecture-01Document34 pagesPE-209 Lecture-01Adeem AbbasNo ratings yet

- Colloid Chemistry Chapter 2 UpdateDocument51 pagesColloid Chemistry Chapter 2 UpdateBasketball LoverNo ratings yet

- Fluid MechanicsDocument62 pagesFluid Mechanicss.yosores.janchristineNo ratings yet

- CHARACTERISTICS OF FLUIDSDocument30 pagesCHARACTERISTICS OF FLUIDSBlack SkyNo ratings yet

- Fluid MechanicsDocument49 pagesFluid MechanicsYeet server YesNo ratings yet

- Mechanisms of Natural ConvectionDocument7 pagesMechanisms of Natural ConvectionVISMAY PATELNo ratings yet

- Klinkenberg e Ffect For Gas Permeability and Its Comparison To Water Permeability For Porous Sedimentary RocksDocument24 pagesKlinkenberg e Ffect For Gas Permeability and Its Comparison To Water Permeability For Porous Sedimentary RocksMuhammad Haiqal MokhtarNo ratings yet

- Fluid MechancisDocument30 pagesFluid MechanciskarthipriyaNo ratings yet

- Natural ConvectionDocument7 pagesNatural ConvectionKasiita RobertNo ratings yet

- 001 Hydraulics Module 1 Common Properties of Fluids Part 2 of 2Document7 pages001 Hydraulics Module 1 Common Properties of Fluids Part 2 of 2Anjie CabalcarNo ratings yet

- Chapter 1Document41 pagesChapter 1masNo ratings yet

- Fundamentals of Fluid12Document6 pagesFundamentals of Fluid12Mike Adrian CerbitoNo ratings yet

- Experimental and Numerical Modeling of Sidewall Orifices: Weiping Cheng Yongxin Shen Gang XuDocument20 pagesExperimental and Numerical Modeling of Sidewall Orifices: Weiping Cheng Yongxin Shen Gang XuRodrigo LimaNo ratings yet

- Fluid Solid Interaction Benchmarking of An External Coupling of ANSYS With CFX For Cardiovascular ApplicationsDocument10 pagesFluid Solid Interaction Benchmarking of An External Coupling of ANSYS With CFX For Cardiovascular ApplicationsNana LiuNo ratings yet

- Waves in Elastic Fluid-Filled TubesDocument13 pagesWaves in Elastic Fluid-Filled TubesNana LiuNo ratings yet

- A Review of Water Hammer Theory and PracticeDocument28 pagesA Review of Water Hammer Theory and Practicejulio49No ratings yet

- The Dynamic Elastic Properties of The Arterial WallDocument12 pagesThe Dynamic Elastic Properties of The Arterial WallNana LiuNo ratings yet

- Wave Propagation in a Fluid-Filled Rubber TubeDocument43 pagesWave Propagation in a Fluid-Filled Rubber TubeNana LiuNo ratings yet

- Smoothed Particle Hydrodynamics Model For Diffusion Through Porous MediaDocument31 pagesSmoothed Particle Hydrodynamics Model For Diffusion Through Porous MediaNana LiuNo ratings yet

- Waves in Elastic Fluid-Filled TubesDocument13 pagesWaves in Elastic Fluid-Filled TubesNana LiuNo ratings yet

- Fall 2009 MTH301-Calculus II Time: 120 Min Marks: 80Document21 pagesFall 2009 MTH301-Calculus II Time: 120 Min Marks: 80rama520% (1)

- Model 570 Pressure TransmitterDocument4 pagesModel 570 Pressure TransmitterToan KeNo ratings yet

- Third Quarter-Module 4: Week 4Document11 pagesThird Quarter-Module 4: Week 4SHERLA PERENANo ratings yet

- ExcavatorDocument2 pagesExcavatorHelar W. Cutipa Machaca50% (2)

- Science Pre BoardDocument6 pagesScience Pre BoardvspkpracticalNo ratings yet

- Concentration of SolutionsDocument42 pagesConcentration of SolutionsAien RonquilloNo ratings yet

- CE Module 21 - Fluid Flow in Pipes (Answer Key)Document7 pagesCE Module 21 - Fluid Flow in Pipes (Answer Key)Angelice Alliah De la CruzNo ratings yet

- Lesson on Rotation with Constant Angular AccelerationDocument4 pagesLesson on Rotation with Constant Angular AccelerationNadjer C. AdamNo ratings yet

- 3 Rs-1180-0002 Room Temp. and Setpoint Module TwoDocument9 pages3 Rs-1180-0002 Room Temp. and Setpoint Module TwoAbiodun IloriNo ratings yet

- Ieee Guide For Evaluating The Effect of Solar Radiation On OutdoDocument25 pagesIeee Guide For Evaluating The Effect of Solar Radiation On OutdoIbrahim EspinozaNo ratings yet

- Experienced Welder ResumeDocument2 pagesExperienced Welder ResumeHarry DemeterioNo ratings yet

- Construction and Working Principles of BLDC MotorDocument24 pagesConstruction and Working Principles of BLDC Motormahadeva prasad m sNo ratings yet

- Percubaan 2 Matematik SPM 09Document6 pagesPercubaan 2 Matematik SPM 09khai_83No ratings yet

- CH 10Document83 pagesCH 10이잉No ratings yet

- Catalogue: Facing BricksDocument82 pagesCatalogue: Facing BricksBipu1978No ratings yet

- State Point & Process Report: Psychrometric Chart Psychrometric ChartDocument1 pageState Point & Process Report: Psychrometric Chart Psychrometric ChartLee ChorneyNo ratings yet

- Break Pressure TankDocument53 pagesBreak Pressure TankParomita Mukherjee Misra100% (11)

- Redutores RMI 85F3Document32 pagesRedutores RMI 85F3Jeferson DantasNo ratings yet

- What Are Cermets PDFDocument5 pagesWhat Are Cermets PDFKamranNo ratings yet

- Week 3 Reactions of AlkenesDocument39 pagesWeek 3 Reactions of AlkenesKate Arianne CabreraNo ratings yet

- FOR Approval Specification: 32.0" Wxga TFT LCD TitleDocument42 pagesFOR Approval Specification: 32.0" Wxga TFT LCD TitleJulio Alberto Cabrera RodriguezNo ratings yet

- Uk Exs Xl-Series DsDocument4 pagesUk Exs Xl-Series DsAndzar Muhammad FauziNo ratings yet

- Guideline To Reporting of MRI Lumbar Spine: Poster No.: Congress: Type: AuthorsDocument50 pagesGuideline To Reporting of MRI Lumbar Spine: Poster No.: Congress: Type: Authorsradiologirsck100% (1)

- Mech Micromachining ReportDocument21 pagesMech Micromachining ReportSWAPNALI KHANDARENo ratings yet

- Simbawa Oliver Task 2 Reading Report Calculus and Its Application To PhysicsDocument3 pagesSimbawa Oliver Task 2 Reading Report Calculus and Its Application To PhysicsOliver SimbawaNo ratings yet

- Making the Right Choice: Metal Detection vs. X-RayDocument27 pagesMaking the Right Choice: Metal Detection vs. X-RayCindy ChandraNo ratings yet

- Ritz Carlton-Residential Curtain Wall F19 - Calculation Note - Rev 01Document102 pagesRitz Carlton-Residential Curtain Wall F19 - Calculation Note - Rev 01hisambergNo ratings yet

- Sa-Ak970 Md0806005ceDocument143 pagesSa-Ak970 Md0806005cearturo ortegaNo ratings yet

- Tightening Torque of A Bolted Joint - MetricDocument2 pagesTightening Torque of A Bolted Joint - MetricgdwvcdNo ratings yet

- Physics Investigatory Project - Safa Azeem Zaina 2Document18 pagesPhysics Investigatory Project - Safa Azeem Zaina 2Reshma Mahjabeen100% (3)