Professional Documents

Culture Documents

Natural Dyestuffs Prepratory & Dyeing Flow Chart: Cationizing Processing Chart at Recommended Liquor Ratio: 1 To 20 - 25

Uploaded by

FaisalOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Natural Dyestuffs Prepratory & Dyeing Flow Chart: Cationizing Processing Chart at Recommended Liquor Ratio: 1 To 20 - 25

Uploaded by

FaisalCopyright:

Available Formats

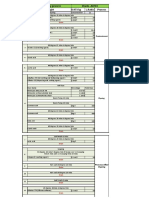

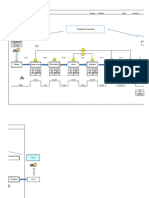

NATURAL DYESTUFFS PREPRATORY & DYEING FLOW CHART

1st:Preparatory cationization of cotton fabrics & garments well de-sized & scoured

Cationizing processing chart at recommended liquor ratio: 1 to 20 – 25

soaping

70oC 30min 10min

70oC

30min n10

℃ 分 Hot

cationization

Hot rinse

n カチオン 15min

10min rinse

化 n

30oC

Cationizer

Nonioic Soaping agent

1g/liter

Fibers Cationizier

Cotton, linen X% owf

Viscose, Tencel

Wool

Silk

Note: It is easier to cationize the cotton if it is mercerized in advance by NaOH.

2nd: Dyieng cotton fabrics & garments already cationized as above

Dyeing processing chart at recommended liquor ratio of 1 to 20 – 30

soaping

30min

70-90 o C

30 分 20min 10min

70oC 70oC

20 分 10 分

Hot

Hot rinse

rinse Hot

rinse

Dyestuff Mordant Nonionic Soaping agent

10%-20% owf

1g/liter

Mordant owf CAS

Ferric chloride 7705-08-0

Aluminum salt 10043-01-3

Sodium stannate 12058-66-1

Copper sulfate 7758-99-8

* When you use mordants please make sure to check its safety and RSL conformity.

Remarks:

Natural dyestuffs are from the natural based derivatives and it causes color variations in lot to lot in a

minimum manageable level.

The liquid dyes get separated by sedimentation at the bottom of the packing, but this will not cause

dyeing problems which is solved by re-mixing the separated color with water.

You might also like

- Invertebrate ZoologyDocument1,016 pagesInvertebrate ZoologyRACHANA PURKAYASTHA 2140623No ratings yet

- Seplite LSC750 PDFDocument6 pagesSeplite LSC750 PDFDiegoNo ratings yet

- Scouring: Scouring Is The Process by Which All Natural andDocument27 pagesScouring: Scouring Is The Process by Which All Natural andTuan Nguyen MinhNo ratings yet

- Housekeeping Product ListDocument4 pagesHousekeeping Product ListSeyed Ibrahim100% (3)

- 1926 PapionianDocument108 pages1926 PapionianPLCS_FoundationNo ratings yet

- Quiz 2 Principles of DesignDocument4 pagesQuiz 2 Principles of DesignJovito Reyes0% (1)

- Garment Wet Processing: Presented by Aart GeurtsenDocument49 pagesGarment Wet Processing: Presented by Aart GeurtsenDyeing DyeingNo ratings yet

- Cotoblanc PcsDocument3 pagesCotoblanc PcsMahlon GarridiganNo ratings yet

- Garment Dyeing With PigmentsDocument30 pagesGarment Dyeing With Pigmentsyadi haryadiNo ratings yet

- WashingDocument5 pagesWashingImtiaz AhmedNo ratings yet

- Syntheis of Chitosan Na-MMT GLA Bionanocomposite Film in Antimicrobial Activity Tests Againts S. Aureus and Salmonella SP BacteriaDocument13 pagesSyntheis of Chitosan Na-MMT GLA Bionanocomposite Film in Antimicrobial Activity Tests Againts S. Aureus and Salmonella SP BacteriaazizilhamidNo ratings yet

- Testing Method - Soaping Agent Evaluation - Hydrolyzed Dye Removal With and Withot SaltDocument3 pagesTesting Method - Soaping Agent Evaluation - Hydrolyzed Dye Removal With and Withot Saltmubashir.h.hashmiNo ratings yet

- Ecodye: Ecodye - The Dyeing RevolutionDocument4 pagesEcodye: Ecodye - The Dyeing RevolutionRamzi HajjajiNo ratings yet

- Block Diagram Nitro-Cellulose Plant Inter Purification Zone: Mixing TankDocument5 pagesBlock Diagram Nitro-Cellulose Plant Inter Purification Zone: Mixing TankEngr. Asif malikNo ratings yet

- Chroma SPC Program - A8781Document9 pagesChroma SPC Program - A8781ShovonNo ratings yet

- Cong Thuc SonDocument23 pagesCong Thuc Sonvanhung68No ratings yet

- Jose Laboratory NotesDocument7 pagesJose Laboratory NotesJose YouNo ratings yet

- MAULIDocument5 pagesMAULIPulakPandeyNo ratings yet

- Flowchart Chitosan Beeswax FilmsDocument5 pagesFlowchart Chitosan Beeswax FilmsGiang Pham Thi ThuyNo ratings yet

- Cleaning Data Collection Sheet: Step 1: Alkaline Cleaning ProcessDocument9 pagesCleaning Data Collection Sheet: Step 1: Alkaline Cleaning ProcessArifEkoPrasetyoNo ratings yet

- Smooth Masonry PaintDocument1 pageSmooth Masonry Paintvanhung88No ratings yet

- Continuous PretreatmentDocument5 pagesContinuous PretreatmentNghia Phan TrungNo ratings yet

- Method of Polyester DyeingDocument11 pagesMethod of Polyester DyeingNUR NOBINo ratings yet

- Testing - Soaping Agent EvaluationDocument3 pagesTesting - Soaping Agent Evaluationmubashir.h.hashmiNo ratings yet

- Rojo Indanthrene FBB CaracterísticasDocument2 pagesRojo Indanthrene FBB CaracterísticasOOlii MejiaNo ratings yet

- Assignment 2 ChemesteryDocument26 pagesAssignment 2 ChemesterySIDDHARTH KOTHARINo ratings yet

- Benzene SpecificationDocument1 pageBenzene SpecificationNnadozie KennethNo ratings yet

- Rifacophor Byb Conc. 400%: Special PropertiesDocument4 pagesRifacophor Byb Conc. 400%: Special Propertieshamidrahmany3657No ratings yet

- Enchanting Beauty PricelistDocument2 pagesEnchanting Beauty Pricelistapi-351914090No ratings yet

- N1-72-1-632ColddSM Cold DyeingDocument2 pagesN1-72-1-632ColddSM Cold DyeingAneel ChandwaniNo ratings yet

- Rinsing Product For Thermal Bedpan-Washers: Automatic Dilution 0.5 To 7ml/LDocument1 pageRinsing Product For Thermal Bedpan-Washers: Automatic Dilution 0.5 To 7ml/LtaibkNo ratings yet

- Chroma SPC Program - A7900Document9 pagesChroma SPC Program - A7900ShovonNo ratings yet

- A704 Major ClearDocument2 pagesA704 Major ClearСергей БельковNo ratings yet

- Low Salt Tanning - Sixth TrialDocument2 pagesLow Salt Tanning - Sixth TrialSuril PanneerselvamNo ratings yet

- Wet Processing Pretreatment-LectureDocument28 pagesWet Processing Pretreatment-Lecturearafathosain100% (3)

- Paper RecyclingDocument209 pagesPaper RecyclingVishnu KollarethNo ratings yet

- MMB Brochure en 2011julDocument8 pagesMMB Brochure en 2011julKaran Kumar VermaNo ratings yet

- Cyclanon Washoff XC-W New: Technical InformationDocument6 pagesCyclanon Washoff XC-W New: Technical Informationعلی اکبر محرابیNo ratings yet

- Novacron Blue EC-RDocument2 pagesNovacron Blue EC-RPhạm Văn ThắngNo ratings yet

- Fashionable EffectsDocument9 pagesFashionable Effectsakoncloud9No ratings yet

- A Comparative Study Between One Bath Dyeing Method For Polyester Cotton (PC) Blended Fabric Over Conventional Two Bath Dyeing MethodDocument11 pagesA Comparative Study Between One Bath Dyeing Method For Polyester Cotton (PC) Blended Fabric Over Conventional Two Bath Dyeing MethodMianAbrarAnjumNo ratings yet

- PolyesterDocument15 pagesPolyesterRITIKNo ratings yet

- Benzene SpecificationDocument1 pageBenzene SpecificationLalita KhakhlaryNo ratings yet

- Tannery Training Documentation - Kshikaa RajkumarDocument9 pagesTannery Training Documentation - Kshikaa RajkumarKshikaa RajkumarNo ratings yet

- Viscosity Chart: Fluid Specific Gravity Viscosity CPS Viscous Type Reference AdhesivesDocument2 pagesViscosity Chart: Fluid Specific Gravity Viscosity CPS Viscous Type Reference AdhesivesPhượng NguyễnNo ratings yet

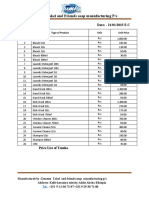

- Price List For TumhaDocument1 pagePrice List For Tumhagetachew techaneNo ratings yet

- Flowchart Chitosan PVA Incorporated Piper Betle ExtractDocument5 pagesFlowchart Chitosan PVA Incorporated Piper Betle ExtractGiang Pham Thi ThuyNo ratings yet

- Inventory Report June 2021Document8 pagesInventory Report June 2021Ketan SoniNo ratings yet

- N1 84 16 658corrosionDocument3 pagesN1 84 16 658corrosionAneel ChandwaniNo ratings yet

- Evaluation - Chemical Pit - 0Document8 pagesEvaluation - Chemical Pit - 0Aiman AmirullahNo ratings yet

- Indanthren Brilliant Blue RCL Coll: Short ProfileDocument2 pagesIndanthren Brilliant Blue RCL Coll: Short ProfileOOlii MejiaNo ratings yet

- Indbro - PDF Nutrient SpecificationDocument1 pageIndbro - PDF Nutrient SpecificationvetbcasNo ratings yet

- A Path To A Glove: 16-Curing Oven Section 1 (720 Sec. 120ºC)Document2 pagesA Path To A Glove: 16-Curing Oven Section 1 (720 Sec. 120ºC)Thaís SouzaNo ratings yet

- Value Stream VSM TemplateDocument2 pagesValue Stream VSM TemplateIvan BNo ratings yet

- 2RM Expt 36 4 Ans Check PDFDocument4 pages2RM Expt 36 4 Ans Check PDFCheung Yu KaiNo ratings yet

- T-03-SB. FWash 28.04.19 (Beeds) With RateDocument1 pageT-03-SB. FWash 28.04.19 (Beeds) With RateSohelNo ratings yet

- Scouring 1Document36 pagesScouring 1aminul islamNo ratings yet

- Cotton Treatment ProcessDocument3 pagesCotton Treatment ProcessSateesh Janardan GoreNo ratings yet

- Tds-Jp-Bitumen Solution-0209Document1 pageTds-Jp-Bitumen Solution-0209Eracai GeihanNo ratings yet

- Stain Removal GuideDocument1 pageStain Removal Guidekhamid arifNo ratings yet

- Chem Projects Class 12 BDocument11 pagesChem Projects Class 12 BAshit ModyNo ratings yet

- MyGlamm Invoice 1708269850-86Document1 pageMyGlamm Invoice 1708269850-86nr285377No ratings yet

- Extravagant - Bethel Music CHORDS PDFDocument2 pagesExtravagant - Bethel Music CHORDS PDFKamila Joseph Hernandez VanegasNo ratings yet

- Chapter 34 - The Influence of Monetary and Fiscal Policy On Aggregate Demand (Compatibility Mode) PDFDocument19 pagesChapter 34 - The Influence of Monetary and Fiscal Policy On Aggregate Demand (Compatibility Mode) PDFthanhvu78No ratings yet

- Features and ComponentsDocument11 pagesFeatures and ComponentsJay SuguitanNo ratings yet

- Cisco 1 Reviewer For Final ExamDocument9 pagesCisco 1 Reviewer For Final ExamAlNo ratings yet

- LP Africa (11th Edition)Document406 pagesLP Africa (11th Edition)TucaVieiraNo ratings yet

- Nrel Ciberseguridad DerDocument31 pagesNrel Ciberseguridad Derroberto munguiaNo ratings yet

- Scientific Approaches For Impurity Profiling in New Pharmaceutical Substances and Its Products-An OverviewDocument18 pagesScientific Approaches For Impurity Profiling in New Pharmaceutical Substances and Its Products-An OverviewsrichainuluNo ratings yet

- Ecs C42iix Rev C Vit m2400 1Document36 pagesEcs C42iix Rev C Vit m2400 1Victor Pic100% (1)

- 15b. FANC - Focused Antenatal Care - Koros E.KDocument71 pages15b. FANC - Focused Antenatal Care - Koros E.KMercy KeruboNo ratings yet

- Coord Angle and BearingDocument18 pagesCoord Angle and BearingvNo ratings yet

- Design and Modeling of Zvs Resonantsepic Converter For High FrequencyapplicationsDocument8 pagesDesign and Modeling of Zvs Resonantsepic Converter For High FrequencyapplicationsMohamed WarkzizNo ratings yet

- Idioms & PhrasesDocument4 pagesIdioms & PhrasesHimadri Prosad RoyNo ratings yet

- S800 SCL SR - 2CCC413009B0201 PDFDocument16 pagesS800 SCL SR - 2CCC413009B0201 PDFBalan PalaniappanNo ratings yet

- 100 IC CircuitsDocument34 pages100 IC CircuitselektrorwbNo ratings yet

- Laying Out Compoud Curve and Reverse by Deflection Angle MethodDocument10 pagesLaying Out Compoud Curve and Reverse by Deflection Angle MethodEljenColanggo0% (2)

- Unit 2Document9 pagesUnit 2Quinn LilithNo ratings yet

- 8000series Tech Datasheet 2018Document3 pages8000series Tech Datasheet 2018lucky414No ratings yet

- Mary Szybist On Visual Poetry Compressed PDFDocument5 pagesMary Szybist On Visual Poetry Compressed PDFcarlos.enrique.fonseca1440No ratings yet

- 1 Aerodynamics Lecture - Viscous FlowDocument70 pages1 Aerodynamics Lecture - Viscous Flowccoyure100% (2)

- Numerical WindingDocument12 pagesNumerical Windingsujal jhaNo ratings yet

- Roberto Del RosarioDocument19 pagesRoberto Del RosarioCarl llamasNo ratings yet

- Island Super Kinis Skim Coat White (RP)Document4 pagesIsland Super Kinis Skim Coat White (RP)coldfeetNo ratings yet

- NUTRACEUTICALDocument8 pagesNUTRACEUTICALShubham GuptaNo ratings yet

- Wire Rope Lubricant: VSP Vitalife Spray ApplicatorsDocument1 pageWire Rope Lubricant: VSP Vitalife Spray ApplicatorsMulatua SiraitNo ratings yet

- Língua Inglesa: Reported SpeechDocument3 pagesLíngua Inglesa: Reported SpeechPatrick AlmeidaNo ratings yet

- Amotec 12864Q DisplayDocument17 pagesAmotec 12864Q DisplayEdgarNo ratings yet

- Lecture-I Introduction To Concrete TechnologyDocument102 pagesLecture-I Introduction To Concrete Technologyjs kalyana rama100% (4)