Professional Documents

Culture Documents

Lab Manual Concrete

Uploaded by

MariYam AliOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lab Manual Concrete

Uploaded by

MariYam AliCopyright:

Available Formats

SUBMITTED TO: ENGR.

RIZWAN

MUAAZ ANUS

BSCE-01143050 PRC-2 (LAB MANUAL)

SECTION – B-1

CIVIL ENGINEERING DEPT .

THE UNIVERSITY OF LAHORE

PRC-2 (LAB MANUAL) MUAAZ ANUS -BSCE-01143050

TABLE OF CONTENTS

EXPERIMENT NO. PAGE NO

EXPERIMENT 1……………………………………………………………1

EXPERIMENT 2………………………………………………....................9

EXPERIMENT 3……………………………………………………………14

EXPERIMENT 4……………………………………………………………17

EXPERIMENT 5…………………………………………………………....20

EXPERIMENT 6………………………………………………….…...........24

.

EXPERIMENT 7……………………………………………………………26

EXPERIMENT 8……………………………………………………………29

EXPERIMENT 9………………………………………………....................35

EXPERIMENT 10…………………………………………………………..38

THE UNIVERSITY OF LAHORE 1

PRC-2 (LAB MANUAL) MUAAZ ANUS -BSCE-01143050

EXPERIEMNT NO 1

CONCRETE MIX DESIGN

OBJECTIVE OF CONCRETE MIX DESIGN

To determine the most economical and practical combination of available

materials (i.e. aggregates, cements, water, admixtures, etc.)

To produce a concrete that will satisfy the performance requirements which

includes workability, durability and strength.

APPARATUS

Concrete mixer

Weighing balance

Cement

Sand/Fine Aggregate

Crush/Coarse Aggregate

Water

Moulds to be prepared:

a. Cylinders150mm(dia) x 300mm (length) (4)

b. Cubes150mm x 150mm x 150mm (3)

DESIGN OBJECTIVES FOR TRIAL MIX METHOD:

Required 28-day compressive strength, fc’, or some other strength parameter such

as the modulus of rupture.

Maximum/minimum allowable w/c ratio.

Maximum size of the coarse aggregates.

Minimum Portland cement content requirement.

Acceptable range of slumps and the percent of air for an air- entrained concrete.

PARAMETERS REQUIRED FOR TRIAL MIX DESIGN

Apparent specific gravity of the Portland cement.

Bulk specific gravities and percent of moisture present in the saturated surface dry

(SSD) condition for both the coarse and fine aggregates.

Rodded unit weight of the coarse aggregates.

Fineness modulus of the fine aggregates.

Free moisture present both fine and coarse aggregate.

THE UNIVERSITY OF LAHORE 2

PRC-2 (LAB MANUAL) MUAAZ ANUS -BSCE-01143050

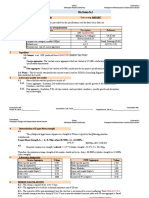

MIX DESIGN

Specified strength = fc’ = 20 MPa

Required slump = 50 mm

Maximum size of aggregates = 20 mm

Type of concrete = ordinary Portland cement

Finess modulus of Fine Aggregates = 2.40

Bulk density of Coarse Aggregates = 1600 kg/m3

Assumed Specific Gravity of Cement = 3.15

Specific Gravity of Coarse Aggregate = 2.65

Specific Gravity of Fine Aggregates = 2.65

Water Absorption of Coarse Aggregates = 0.5 %

Water Absorption of Fine Aggregates = 0.7 %

Step # 1:

Determine required/design compressive strength, fcr’

fcr’=fc’+7.0 Mpa for fc’<21 Mpa

fcr’=fc’+8.5 Mpa for fc’= 21 to 35 Mpa

fcr’=1.10fc’+5.0 Mpa for fc’>35 Mpa

In our case fcr’= 20 + 7 = 27

Step #2:

Select type of cement based on:

Rate of gain of strength

Likelihood of chemical attack

Thermal behavior (fire resisting period)

Exposure condition

We will use Ordinary Portland cement for Normal Exposure Condition.

Step # 3:

Select w/c ratio corresponding to fcr’.

By using the table below we will find out water cement ratio i.e.

Interpolating for fcr’= 27

THE UNIVERSITY OF LAHORE 3

PRC-2 (LAB MANUAL) MUAAZ ANUS -BSCE-01143050

Water to cement ratio = 0.58

Step # 4:

Select amount of water per unit volume corresponding to slump value and coarse

aggregate size.

Amount of water = 190 kg/m3

Step # 5:

𝑊𝑎𝑡𝑒𝑟 𝑐𝑜𝑛𝑡𝑒𝑛𝑡

Amount of cement C (kg/ m3 of concrete) ==

𝑤/𝑐

THE UNIVERSITY OF LAHORE 4

PRC-2 (LAB MANUAL) MUAAZ ANUS -BSCE-01143050

Cement content = 190/0.58= 328 kg/m3

Step # 6:

Calculate mass of coarse aggregate:

Mass of Coarse Aggregates = Dry Rodded volume of coarse aggregate x density of coarse

aggregate

Mass of Coarse Aggregates = 1072 kg/m3

Step # 7:

Select dry bulk volume of coarse aggregate per unit volume of concrete corresponding to

aggregate size and fineness modulus of fine aggregate.

Comparing aggregate size and finess modulus of fine aggregate we will get bulk volume

of coarse aggregate

𝒅𝒆𝒏𝒔𝒊𝒕𝒚 𝒐𝒇 𝒄𝒐𝒂𝒓𝒔𝒆 𝒂𝒈𝒈𝒓𝒆𝒈𝒂𝒕𝒆

Specific gravity = 𝒅𝒆𝒏𝒔𝒊𝒕𝒚 𝒐𝒇 𝒘𝒂𝒕𝒆𝒓

Density of coarse aggregate = 2.65 × 1000 = 2650 kg/m3

Density of fine aggregate = 2.65 × 1000 = 2650 kg/m3

THE UNIVERSITY OF LAHORE 5

PRC-2 (LAB MANUAL) MUAAZ ANUS -BSCE-01143050

Density of cement = 3.15× 1000 = 3150 kg/m3

MATERIALS PER METER CUBE

Materials Volume per m3

Cement 0.103

Fine Aggregates 0.306

Coarse Aggregates 0.41

Water Content 0.190

Step # 8:

Estimation of Fine Aggregate Content

Mass of Fine Aggregate = density × volume = 8190 kg/m3

Step # 9:

Adjust water content for absorption of coarse and fine aggregate and free surface water

present on the aggregates.

Extra water required= %age absorption * mass of aggregate

For coarse = 0.5 × 1072 = 5.36 kg/m3

For fine = 0.7× 810.9 = 5.67 kg/m3

Total Water = 190+11.03 = 201 kg/m3

Step # 10:

Determine simplified ratio of ingredients of concrete

Cement: Sand: Crush

327.5/327.5: 810.9/327.5 : 1072/327.5

1:2.5: 3.3

THE UNIVERSITY OF LAHORE 6

PRC-2 (LAB MANUAL) MUAAZ ANUS -BSCE-01143050

Prepare trial mixes and check for required properties i.e. workability and strength.

CALCULATIONS FOR MATERIAL TO BE CAST

Volume of 1 cube = 3.375 × 10-3 m3

Volume of 3 cube = 0.010125 m3

Volume of 1 cylinder = 5.301 × 10-3 m3

Volume of 4 cylinders = 0.0212 m3

Wet Volume = 0.031326 m3

Dry Volume= 0.046989 m3

Note:

1. Dry to wet volume ratio is 1.5 approximately.

2. For 25mm slump ×add 6kg of water per unit volume

Mass = 2300 × 0.046989 = 108 kg

Cement Sand Aggregate

1 2 4

× 108 × 108 × 108

7 7 7

15.5 kg 31 kg 62 kg

Water = 15.5 × 0.65 = 10 kg

After preparing the mixture slump observed was = 60 mm

THE UNIVERSITY OF LAHORE 7

PRC-2 (LAB MANUAL) MUAAZ ANUS -BSCE-01143050

It was true slump and workability was medium as slump value ranges between 50 – 100

mm

Figure 1-slump cone test

COMMENTS

In this job we find out the amount of concrete use in design mixing. The purpose of this

job is to select suitable ingredients of concrete and determining their relative amounts

with the objective of producing a concrete of the required, strength, durability, and

workability as economically as possible. A material obtained by mixing water,

aggregates, and binding material. Cement and water chemically interact to bind the

aggregates particle into solid mass. Density of concrete is P.C.C 2300 kg/m3.

THE UNIVERSITY OF LAHORE 8

PRC-2 (LAB MANUAL) MUAAZ ANUS -BSCE-01143050

EXPERIMENT NO 2

COMPARISON OF COMPRESSIVE STRENGTH OF CONCRETE

CYLINDER AND CUBE

REFERENCE:ASTMC 39(Only for cylinders)

SCOPE & SIGNIFICANCE:

The purpose of this experiment is to determine the compressive strength of

cylindrical specimens and cubes. The method is limited to concrete having a

density at least 800kg/m3 (50lb/ft3).The 28-day compressive strength (fc’) of

molded cylinders is normally used in design.

APPARATUS

Universal Testing Machine

Cylindrical Concrete Specimens

Cubical Concrete Specimens

Figure 2-compression testing machine Figure 3-cube mould Figure 4-cylinder mould

RELATED THEORY

This test method consists of applying a compressive axial load to moulded cylinders at a

prescribed manner until it failure. The compressive strength of concrete is calculated by

dividing the maximum load attains by the test by the cross-sectional area of the

specimen.The results of this test method are used as a basis for quality control of concrete

proportioning, mixing, and placing operations; determination of compliance with

specifications; control for evaluating effectiveness of admixtures; and similar uses.

PROCEDURE

Compression test of the moist cured specimen shall be made as soon as possible after the

removal from moist storage.

THE UNIVERSITY OF LAHORE 9

PRC-2 (LAB MANUAL) MUAAZ ANUS -BSCE-01143050

CAPPING

Do the capping of sample with sulphur or POP for 2 hours to make the surface smooth

and even so that uniform load can be apply all over the surface. We do capping of

cylinders only.

DIMENSIONS

Measure the dimensions of cubes and cylinders and then calculate the volume of samples.

Also find the density of concrete by mass/ volume

PLACING OF THE SPECIMEN

Place the specimen in centre with proper orientation in compression testing machine.

RATE OF LOADING

Apply the load continuously and without shock. The load shall be applied at the rate of

movement corresponding to a stressed rate on specimen of 35+7 psi/sec or

0.25+0.05MPa/s. During the application of first half of anticipated loading phase, higher

rate of loading shall be permitted. Higher rate of loading shall be applied in a control

manner so that the specimen should not be shock loading. Make no adjustment in the rate

of movement as the ultimate load is been approach. And the stress rate decrease due to

the cracking in the specimen.

COMPRESSIVE STRENGTH

Compressive strength can be find out by using the relation Load / Area

IMAGES OF TEST

THE UNIVERSITY OF LAHORE 10

PRC-2 (LAB MANUAL) MUAAZ ANUS -BSCE-01143050

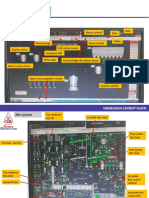

TREND LINE (COMPRESSION TESTING MACHINE)

THE UNIVERSITY OF LAHORE 11

PRC-2 (LAB MANUAL) MUAAZ ANUS -BSCE-01143050

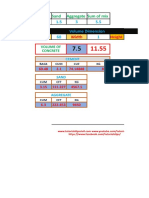

OBSERVATION & CALCULATIONS

Description: 150mm x 300 mm cylinder and 300 mm x 300 mmx 300 mm cube

Concrete mix design= 1:2:4

W/C= 0.60

TEST PERFORMED AFTER 7 DAYS

SR-NO SPECIMEN COMPRESSIVE FAILURE TYPE

STRENGTH

Mpa

1 CUBE 19.5 Cone and split

2 CYLINDER 16.1 Cone and shear

3 CYLINDER 14.2 Cone and shear

TEST PERFORMED AFTER 28 DAYS

SR-NO SPECIMEN COMPRESSIVE FAILURE TYPE

STRENGTH

Mpa

1 CUBE 26.41 Cone and split

2 CUBE 23.53 Shear

3 CYLINDER 21.56 Cone and shear

4 CYLINDER 19.39 Cone and shear

Figure5- Failure types

THE UNIVERSITY OF LAHORE 12

PRC-2 (LAB MANUAL) MUAAZ ANUS -BSCE-01143050

COMPRESSIVE STRENGTH (Cylinder VS Cube)

30

25 Cube

Cylinder

Comp. Strength (MPa)

20

15

10

0

0 5 10 15 20 25 30

No. of days

COMMENTS

In this experiment to determine the compressive strength of cylindrical specimens and

cubes. The method is limited to concrete having a density at least 800kg/m3(50lb/ft3).

The 28-day compressive strength (fc’) of melded cylinders is normally used in design.

We compare compressive strength of cylinder and cube, show that cube has greater

strength than cylinder. This is because cube has equal dimension and bear more

compressive load while when load apply on cylinder has bulked produced cracks

THE UNIVERSITY OF LAHORE 13

PRC-2 (LAB MANUAL) MUAAZ ANUS -BSCE-01143050

EXPERIMENT NO 3

COMPARISON BETWEEN DIFFERENT WATER -CEMENT RATIO

ON COMPRESSIVE STRENGTH OF CONCRETE.

REFERENCE:ASTMC 39(Only for cylinders)

SCOPE & SIGNIFICANCE:

The purpose of this experiment is to determine the compressive strength of

cylindrical specimens and cubes. The method is limited to concrete having a

density at least 800kg/m3 (50lb/ft3).The 28-day compressive strength (fc’) of

molded cylinders is normally used in design.

We are going to check the relation of w/c ratio with the strength of concrete that

how it behaves when we change the amount of water for preparation of mixture.

APPARATUS

Universal Testing Machine

Cylindrical Concrete Specimens

Cubical Concrete Specimens

Figure 5-compression testing machine Figure 6-cube mould Figure 7-cylinder mould

WATER CEMENT RATIO.

0.45

0.50

0.55

0.60

0.65

AGGREGATE CEMENT RATIO

1:2:4

THE UNIVERSITY OF LAHORE 14

PRC-2 (LAB MANUAL) MUAAZ ANUS -BSCE-01143050

OBSERVATION & CALCULATIONS

For 7 Days

COMPRESSIVE COMPRESSIVE

W/C RATIO STRENGTH FOR STRENGTH FOR CUBE

CYLINDER (MPa) (MPa)

0.45 20.10 22.89

0.50 19.33 21.01

0.60 18.03 20.11

0.65 16.33 18.68

STRENGTH AND W/C RATIO

25

20

Comp. Strength

15

Cylinder

10

Cube

0

0.45 0.5 0.6 0.65

W/C

For 28 Days

COMPRESSIVE COMPRESSIVE

W/C RATIO STRENGTH FOR STRENGTH FOR CUBE

CYLINDER (MPa) (MPa)

0.45 23.10 26.89

0.50 21.33 21.01

0.60 22.03 19.11

0.65 20.33 20.68

THE UNIVERSITY OF LAHORE 15

PRC-2 (LAB MANUAL) MUAAZ ANUS -BSCE-01143050

STRENGTH AND W/C RATIO

30

25

20

Comp. Strength

15

Cylinder

10 Cube

0

0.45 0.5 0.6 0.65

W/C

COMMENTS

The purpose of this experiment is to determine the compressive strength of cylindrical

specimens and cubes. The method is limited to concrete having a density at least

800kg/m3 (50lb/ft3).The 28-day compressive strength (fc’) of melded cylinders is

normally used in design. We are going to check the relation of w/c ratio with the strength

of concrete that how it behaves when we change the amount of water for preparation of

mixture. In this experiment show that as water cement ratio increase then compressive

decreased of cube and cylinder

THE UNIVERSITY OF LAHORE 16

PRC-2 (LAB MANUAL) MUAAZ ANUS -BSCE-01143050

EXPERIMENT NO 4

EFFEC OF VARING A/C ON THE COMPRESSIVE

STRENGTH CONCRETE MIXING RATIO

OBJECTIVE

To determine the effect on compressive strength of concrete by varying aggregate cement

ratio.

RELATED THEORY

Aggregate-cement ratio

The ratio of cement to aggregate in a mixture, as determined by weight or volume.

Effect of aggregate-cement ratio on strength of concrete

Aggregate and cement ratios are important as they are used to arrive at optimized,

workable and cohesive concrete for a set of locally available concrete ingredients.

While analyzing/designing a concrete mix, Aggregate cement ratio plays following

important roles.

1. Total Aggregate by cement ratio (A/C) decreases with increase in grade of concrete.

For example, M20 grade of aggregate will have a higher A/C ratio than of M30. Higher

the A/C ratio leaner the concrete mix, as cement content is lower.

2. A/C ratio may be fine-tuned to get a concrete mix more workable. The same is

governed by particle size and shape of aggregate used. A flaky and elongated aggregate

will demand higher cement content (as they have higher surface area for

PRC-II LAB MANUAL

the same volume occupied, requiring higher cement paste). On the other hand, an angular

aggregate will require lower cement to achieve at par work ability

Note: Total Aggregate includes both Sand (Fine Aggregate) and Aggregate (usually

called Coarse Aggregate)

Also, while analyzing/designing a concrete mix, Sand to total Aggregate ratio plays

following important roles

1. In total aggregate the proportion of sand to coarse aggregate (C.A) is altered depending

on fineness of sand

2. A fine sand reduces the sand requirement % in the total aggregate proportion. On the

other hand, a coarse sand will require higher sand % in the total aggregate proportion to

give a cohesive concrete mix

THE UNIVERSITY OF LAHORE 17

PRC-2 (LAB MANUAL) MUAAZ ANUS -BSCE-01143050

Compressive Strength of Cube (W/C = 0.60)

Days Strength (1:2:4) Strength (1:1.75:3.5)

7 20 22

14 22 24

28 26.89 25.76

For Cube

Agg. Cement Ratio VS Strength

30

25

20

Strength MPa

15

1:1.75:3.5

10 1:02:04

0

7 14 28

Days

Compressive Strength of Cylinder (W/C = 0.60)

Days Strength (1:2:4) Strength (1:1.75:3.5)

7 19.03 13.05

14 20.36 18.06

28 21.35 16.37

THE UNIVERSITY OF LAHORE 18

PRC-2 (LAB MANUAL) MUAAZ ANUS -BSCE-01143050

For Cylinder

Agg. Cement Ratio VS Strength

25

20

Strength MPa

15

1:02:04

10

1:1.75:3.5

0

7 14 28

Days

COMMENTS

We perform this experiment to determine the effect on compressive strength of concrete

by varying aggregate cement ratio. This experiment show that as aggregate cement ratio

increase then compressive strength also increases. Aggregate and cement ratios are

important as they are used to arrive at optimized, workable and cohesive concrete for a set

of locally available concrete ingredients.

THE UNIVERSITY OF LAHORE 19

PRC-2 (LAB MANUAL) MUAAZ ANUS -BSCE-01143050

EXPERIMENT NO 5

STANDARD TEST METHOD FOR THE DETERMINATION OF

BULK DENSITY OF COARSE AND FINE AGGREGATES

REFERENCE:ASTMC-29/C-29M

SCOPE & SIGNIFICANCE

This test method is used to determine the bulk density of the given coarse and fine

grained specimen.

During the concrete mix design, when the aggregate is to be batch by volume or

by weight, then it becomes necessary to know the mass of the aggregates that will

fill the container of unit volume. If we know the bulk density of the aggregate

material then we can easily determine the mass required to fill a unit volume

container.

Density also indicates the percentage of voids present in the aggregate material.

This Bulk percentage of voids affects the grading of the aggregates which is

important in high strength concrete.

Bulk density also indicates the compacting effort required to compact the concrete.

APPARATUS

Balance (graduated to at least 0.05kg).

Tamping Rod (16mm dia. and 600mm length).

Measuring Cylinders.

Shovel or Scoop.

THE UNIVERSITY OF LAHORE 20

PRC-2 (LAB MANUAL) MUAAZ ANUS -BSCE-01143050

RELATED THEORY

BULK DENSITY

It is the mass of unit volume of bulk aggregate material in which the volume includes the volume

of individual particles and volume of voids between the particles. It is expressed in kg/m3. Bulk

density is used in weight and volume batching.

VOIDS

It is the space between the individual particles in a unit volume of the aggregate mass and is not

occupied by the solid mineral matter. Voids within the particles, either permeable or impermeable

are not included in the voids for the determination of bulk density by this method.

FACTS ABOUT BULK DENSITY

Bulk density depends upon how densely the aggregate is packed. It also depends upon the size,

distribution and shape of the particles. If the particles are of the same size, then it can be packed to

a limited extent but when the smaller particles are added, the voids get filled with them and thus

the bulk density increases.

For a coarse aggregate, a higher bulk density means that there are few voids which are to be filled

by the fine aggregate and cement. Thus bulk density also depends upon the degree of packing.

PROCEDURE

Note down the dimensions and empty weight of the measuring container and compute its

volume.

For the determination of the loose bulk density, fill the container with the aggregate

material by means of a shovel and level its top surface.

Weigh the container filled with the aggregate and note down its reading.

Then the loose bulk density of the aggregate material can be computed by using the

(Weight of cylinder + loose agg.) − Weight of empty cylinder

LooseBulkDensity =

Volumeofcylinder

Now for the determination of the compacted bulk density, the only difference is in filling

the container.

In this case, the container is filled in three equal layers. Fill the container about onethird

full and level the surface with the fingers.

Rod the layer of the aggregate with 25 strokes of the temping rod evenly distributed over

the surface.

THE UNIVERSITY OF LAHORE 21

PRC-2 (LAB MANUAL) MUAAZ ANUS -BSCE-01143050

Next fill the container two-third full and again rod it with 25 strokes of the temping rod.

Finally, fill the container to overflowing and rod again in the manner previously

mentioned.

Now level the top surface and weigh the container. Calculate the compacted bulk density

by using the relation;

(Weight of cylinder + comp agg.) − Weight of empty cylinder

Comp. BulkDensity =

Volumeofcylinder

PRECAUTIONS

1. Dimensions (Diameter and Height) of the container is measured internally

2. Reading should be measured carefully

3. Tempering should be done throughout the sample.

OBSERVATIONS AND CALCULATIONS

FOR COARSE AGGREGATE

Sample Name: Marghalla crush

Height= 12” =0.305 m Diameter=6” = 0.152m

3

Volume=0.00554m

1. LOOSE DENSITY

A = weight of empty mould = 5.9 kg

B = weight of mould + Aggregate = 13.7 kg

Density = 13.7 – 5.9 / 0.0053 =1472 kg/m3

2. COMPACTED DENSITY

C = weight of empty mould = 5.9 kg

D = weight of mould + Aggregate = 14.29 kg

Density = 14.29 – 5.9 / 0.0053 =1579.5kg/m3

THE UNIVERSITY OF LAHORE 22

PRC-2 (LAB MANUAL) MUAAZ ANUS -BSCE-01143050

FOR FINE AGGREGATE

Sample name: Chenab sand

Height= 5” =0.127 m Diameter=4” = 0.106m

3

Volume=0.00112m

3. LOOSE DENSITY

E = weight of empty mould = 0.87 kg

F = weight of mould + Aggregate =2.375 kg

Density = 2.375 – 0.87 / 0.00112 =1343kg/m3

4. COMPACTED DENSITY

G = weight of empty mould = 0.87 kg

H = weight of mould + Aggregate = 2.85 kg

Density = 2.85 – 0.87/ 0.00112 = 1767.8kg/m3

COMMENTS

This test method is used to determine the bulk density of the given coarse and fine

grained specimen. During the concrete mix design, when the aggregate is to be batch by

volume or by weight, then it becomes necessary to know the mass of the aggregates that

will fill the container of unit volume. If we know the bulk density of the aggregate

material then we can easily determine the mass required to fill a unit volume container.

Density also indicates the percentage of voids present in the aggregate material. This Bulk

percentage of voids affects the grading of the aggregates which is important in high

strength concrete. Bulk density also indicates the compacting effort required to compact the

concrete.

THE UNIVERSITY OF LAHORE 23

PRC-2 (LAB MANUAL) MUAAZ ANUS -BSCE-01143050

EXPERIMENT NO 6

TO DETERMINE THE AGGREGATE CRUSHING VALUE OF

COARSE AGGREGATE

REFERENCE: ASTM C-31

SCOPE

It is used to measure the crushing resistance of aggregate under gradually applied

loads.

APPARATUS

Steel mould

Tamping rod (ø=16mm & L=600mm)

Weighing balance

Test sieves (BS Standards, # ½, # 3/8, #8)

Oven with capacity of 105°C ±5°C

Compression testing machine (stress controlled)

PROCEDURE

Separate the fraction of sieve of size 14mm and retaining on 10mm sieve.

Ovens dry the sample at 105°C±5°C for 3 – 4 hours.

Place the cylinder on base plate, and then fill it in 3 layers giving 25 blows to each

layer with temping rod.

Insert the plunger in cylinder

Place the cylinder between battens of machines

Load the sample with uniform rate so as to apply 400KN of load in 10 minutes ±

30 seconds.

After completion of application of loads, remove the sample from the cylinder

carefully without any loss of aggregate.

Weigh the sample, w2 = crushed aggregate.

Sieve the crushed material through sieve of size 2.36mm (#8) and record the

weight passing and retaining respectively.

THE UNIVERSITY OF LAHORE 24

PRC-2 (LAB MANUAL) MUAAZ ANUS -BSCE-01143050

CALCULATION AND OBSERVATION

Sample Name: Marghalla Crush

𝑤1= weight of cylinder=19.075 kg

𝑤2 = weight of cylinder + aggregate = 22.075 kg

𝑤3 = passing weight = 620.9 g

A.C.V =𝑤3 / 𝑤2 - 𝑤1

A.C.V = 0.2096 × 100

A.C.V = 20 %

COMMENTS

This experiment performed to find out the crushing value of fine and coarse aggregate. It

is used to measure the crushing resistance of aggregate under gradually applied loads.

When we find this value then we know the what kind of aggregate where it used. There is

limitation of crushing value i.e less than 10 is good, 10-20 is normal, 20-40 is weak and

>40 is very weak. So our aggregate is normal

THE UNIVERSITY OF LAHORE 25

PRC-2 (LAB MANUAL) MUAAZ ANUS -BSCE-01143050

EXPERIMENT NO 7

TO DETERMINE THE SOUNDNESS OF CEMENT BY LE-

CHATLIER APPARATUS

REFERENCE: BS-4550

OBJECTIVE

To find out the soundness of cement.

To find out the amount of free CaO.

IMPORTANCE OF TEST

It is very important test to ensure the quality of cement as unsound cement produces

cracks, distortion and disintegration ultimately leading toward failure.(10 mm is the

limit).

APPARATUS AND MATERIALS

Le-Chatelier apparatus

Weighing balance accurate up to 0.1gm

Water bath with electric heating arrangement

Measuring cylinder

Glass plates

Stop watch

Trowel

Tray

MATERIALS

Cement

Water

Figure 8: Le- Chatelier Apparatus

THE UNIVERSITY OF LAHORE 26

PRC-2 (LAB MANUAL) MUAAZ ANUS -BSCE-01143050

PROCEDURE

Prepare a cement paste formed by gauging cement with 0.78 times water required

to give a paste of standard consistency. The gauging time should not be less than 3

minutes nor greater than 5 minutes.

Oil the inner surface of the mould. Place the mould on a glass sheet and fill it with

cement paste, taking care to keep the edges of the mould gently together. Cover

the mould with another piece of glass sheet and peace a small weight on this

covering glass sheet and immediately submerge the whole assembly in water at a

temperature of 27°Cand keep it for 24 hours.

Take out the assembly from water after 24 hrs. Measure the distance between the

indicator points and record it (D1)

Submerge the mould again in water and bring the water to boiling in 25 to 30

minutes and keep it boiling for three hours.

Remove the mould from the water. Allow it to cool and measure the distance

between the indicator points and record it (D2).

Three samples should be tested and average of the results should be reported.

OBSERVATIONS

1. Types and brand of cement = Bestway

2. Water added to the cement sample = 0.78

For Soundness test of cement

Distance between pointer ends

Difference

Sample No. Before Heating After Heating Average

D1-D2

D1 D2

Sample A 11 15 4.3 13

Sample B 12 16 4 14

THE UNIVERSITY OF LAHORE 27

PRC-2 (LAB MANUAL) MUAAZ ANUS -BSCE-01143050

COMMENTS

It is very important test to ensure the quality of cement as unsound cement produces

cracks, distortion and disintegration ultimately leading toward failure.(10 mm is the

limit). To find out the soundness of cement.To find out the amount of free CaO.This

experiment has some limitation i.e if its value is within 10 mm then it has sound and if it

is out of 10 mm there is no sound. ourvalue lies out 10 mm then there is no sound

THE UNIVERSITY OF LAHORE 28

PRC-2 (LAB MANUAL) MUAAZ ANUS -BSCE-01143050

EXPERIMENT NO 8

“MODULUS OF RUPTURE TEST”

SIGNIFICANCE:

The significance of this experiment is to determination of the tensile strength of the

concrete using 3-point loading.

APPARATUS:

Flexural Test machine

Prisms/Beams

Beam Mould and Reinforcement

RELATED THEORY:

MODULUS OF RUPTURE:

It is defined as a material's ability to resist deformation under load.

MR 2

fc′ =( )

K

where k=0.7-0.8 (SI unit)

THE UNIVERSITY OF LAHORE 29

PRC-2 (LAB MANUAL) MUAAZ ANUS -BSCE-01143050

There are three indirect tests determine the flexure strength of the concrete:

Modulus of rupture test

Split cylinder test

Double punch test

SPLIT CYLINDER TEST:

A concrete cylinder is placed within platens of the testing machine such that its

longitudinal axis becomes horizontal. Steel strips are attached at top and bottom. This

load produce lateral tension in vertical failure plan through two strips. Failure load obtain

by splitting the specimen is loading.

2P

fst =

πld

DOUBLE PUNCH TEST:

This test is perform on the sides of 150×150mm on a cylinder specimen.

The load is applied on the top and bottom metallic punches. Punches radius

is “a” and cylinder is “b”. the height of the cylinder is noted by h and load

b H

is P. the size of the punches should be such that a ≥ 5 ,a≤ 10

The punches are centered on the specimen with the help of circular

template with holes corresponding to punch diameter. The tensile strength is obtained by

the following formula:

P

ft =π(1.2bH−a)

MODULUS OF RUPTURE TEST:

The strength determines will be where there is difference in size, preparation, moisture

condition, curing or where the beam has been molded or sort to size. The result from this

test is use as a basis for mix proportioning. According to specification the rate of loading

should be 0.014-0.02MPa/sec.

THE UNIVERSITY OF LAHORE 30

PRC-2 (LAB MANUAL) MUAAZ ANUS -BSCE-01143050

TYPE/SIZE OF THE SPECIMEN FOR THE TEST:

The specimen used is a prism, square in cross-section and having a certain length. There

are two standard sizes of the specimen that can be used for specified aggregate sizes.

150 x 150 x 750 (mm)

100 x 100 x 510 (mm)

The size (150 x 150 x750 mm) can be used for all sizes of the aggregate particles. The

size (100 x 100 x 510 mm) can only be used for the aggregate sizes less than 25mm. we

are using this size for our test.

AVERAGE VALUE OF MOR (fr):

There are some relationships which relate fr with compressive strength of concrete

fr = 0.69 √ f (fc’ and fr are in MPa)

ACI code gives formulae for fr.

fr = 0.5 √ fc’ (ACI code for Strength Calculation)

fr = 0.625√ fc’ (ACI code for Deflection Control)

As a rough estimate, we take 8 – 15% of compressive strength as the MOR.

MODULUS OF RUPTURE OF A PRISMOIDAL BEAM:

The MOR for the test specimen can be computed by using the relation derived below;

fr = MY/I

where as,

I = bd3/12 and Y = d/2

So,

S = I/Y = bd2/6

Thus

3Pa

fr = bd2 MPA

THE UNIVERSITY OF LAHORE 31

PRC-2 (LAB MANUAL) MUAAZ ANUS -BSCE-01143050

TYPE OF LOADING

The loading pattern on the beam is called the third-point/two-point loading. The main

advantage of third-point loading is that, the behavior of the beam can be studied under

pure bending as there is no shear at the central portion of the beam. The phenomenon is

depicted by the figure below.

PROCEDURE:

1. Position the specimen in the testing machine. Center the loading apparatus in

relation to the applied axial force.

2. Bring the load-applying block in contact with the upper surface of the specimen at

the third points between the lower supports. The span distance between the lower

supports is 18 in.

THE UNIVERSITY OF LAHORE 32

PRC-2 (LAB MANUAL) MUAAZ ANUS -BSCE-01143050

3. Apply the load continuously at a rate that increases the extreme fiber stress 125 to

275 psi/minute until rupture occurs (the load rate is 1500 to 3300 lb/minute for 6”

by 6” beams with a span of 18”). Note the peak load at failure.

4. If the fracture (rupture) occurs in the tension surface (the bottom surface) outside

the middle third of the span length by more than 5% of the span length (about

1 in.), discard the result of the test.

5. Calculate the modulus of rupture (MOR), neglecting the beam weight, as follows:

CALCULATIONS AND OBERSERVATIONS:

Case-1

If the fracture initiates in the tension surface within the middle third of the span length,

calculate the modulus of rupture as follows:

R = PL/bd2

Where:

R = modulus of rupture, psi, or MPa,

P = maximum applied load indicated by the testing machine, lbf, or N,

L = span length, in., or mm,

b = average width of specimen, in., or mm, at the fracture, and

d = average depth of specimen, in., or mm, at the fracture.

Note: The weight of the beam is not included in the above calculation.

Case-2

If the fracture occurs in the tension surface outside of the middle third of the span length

by not more than 5 % of the span length, calculate the modulus of rupture as follows:

R = 3Pa/bd2

Where:

THE UNIVERSITY OF LAHORE 33

PRC-2 (LAB MANUAL) MUAAZ ANUS -BSCE-01143050

a = average distance between line of fracture and the nearest support measured on the

tension surface of the beam, (in or mm).

Note: The weight of the beam is not included in the above calculation.

Case-3

If the fracture occurs in the tension surface outside of the middle third of the span length

by more than 5 % of the span length, discard the results of the test.

OBSERVATIONS AND CALCULATIONS:

Max. Applied

a' a – a' M.O.R Mean

Load

Sr.# Acceptance

(kg) (N) (mm) (mm) (MPa) (MPa)

1 420 42.81 310 200 ……. 0.02

2 410 41.79 280 230 ……. 0.015 0.0193

3 386 39.35 330 180 ------- 0.023

COMMENTS:

In this experiment we apply three point load method to find out the deformation of

resistance which shows that structure how much resist the deflection. The significance of

this experiment is to determination of the tensile strength of the concrete using 3-point

loading. If the fracture initiates in the tension surface within the middle third of the span

length, calculate the modulus of rupture. If the fracture occurs in the tension surface

outside of the middle third of the span length by not more than 5 % of the span length,

calculate the modulus of rupture. If the fracture occurs in the tension surface outside of

the middle third of the span length by more than 5 % of the span length, discard the

results of the test.

THE UNIVERSITY OF LAHORE 34

PRC-2 (LAB MANUAL) MUAAZ ANUS -BSCE-01143050

EXPERIMENT NO 9

SCHMIDT HAMMER TEST/ REBOUND HAMMER TEST

OBJECTIVE:

1. To determine the rebound no. of hardened concrete using a spring driven hammer.

2. To calibrate the Schmidt hammer for determination of concrete compressive

strength.

SIGNIFICANCE:

1. To assess the uniformity of concrete.

2. To determine the regions of poor quality and deterioration.

3. To asses inplace strength of concrete.

4. To establish relationship between rebound no. and compressive strength of

concrete.

5. To determine hardness of concrete.

APPARATUS:

1. Rebound Hammer (Casing, Plunger, Hammer Spring, Scale etc.)

2. Abrasive Stone (Carburandum Stone)

Selection of Test Surface/ Area:

1. Concrete to be tested should be at least 100mm thick and fixed with structure.

2. Area showing honey combing and high porosity should be avoided / make it

feasible with the abrasive stone.

3. Slab surface should be tested from the underside.

Preparation of Testing surface:

1. Test area should be at least 150 mm in dia.

2. Area having loose, surface with loose mortar should be ground smooth with

abrasive stone.

Factors effecting the rebound number:

1. Temperature of concrete and hammer.

THE UNIVERSITY OF LAHORE 35

PRC-2 (LAB MANUAL) MUAAZ ANUS -BSCE-01143050

2. Moisture content of concrete (Dry concrete gives more strength).

3. Location of test.

4. Orientation of Hammer

Orientation of Hammer during test.

To compensate the effect of inclination calibration curves are prepared for different

inclinations.

PROCEDURE:

1. After preparing and selecting the concrete surface hold the instrument firmly so

that the plunger is perpendicular to the test surface.

2. Gradually push the instrument towards the test surface until the hammer impacts.

3. Lock the plunger with the help of the button which is on the side of the

instrument.

4. Record the rebound number on the scale.

5. Take 10 readings for each test.

6. No two impact tests should be closed together then 25mm.

7. If the impact crushes the surface then discard that reading and take it again.

CALCULATIONS:

For 7 days Cylinder For 14 days Cylinder

REBOUND NO. STRENGTH (MPa) REBOUND NO. STRENGTH (MPa)

22.5 17.9 24 19.9

26 22 26 22

25 21 23 18

23 18 24 19.9

21 16 29 27

25 21 24 19.9

22 16.1 22 17

21 16 22 17

22 16.1 23 18

27 24 24 19.9

Average strength = 18.81 MPa Average strength = 24.55 MPa

THE UNIVERSITY OF LAHORE 36

PRC-2 (LAB MANUAL) MUAAZ ANUS -BSCE-01143050

For 28 days Cylinder

REBOUND NO. STRENGTH (MPa)

24 19.9

26 22

23 18

24 19.9

29 27

24 19.9

22 17

22 17

23 18

24 19.9

Average strength = 20.11MPa

Comments

In this experiment we have found compressive strength of different beams to establish

relationship between rebound number and compressive strength of concrete. By this test

we find out To assess the uniformity of concrete. To determine the regions of poor quality

and deterioration. To asses in place strength of concrete. To establish relationship

between rebound no. and compressive strength of concrete. To determine hardness of

concrete. We perform this test on cylinder for 7th, 14th,and 28th day and get average

compressive strength 18.81, 24.55 and 20.11 respectively.

THE UNIVERSITY OF LAHORE 37

PRC-2 (LAB MANUAL) MUAAZ ANUS -BSCE-01143050

EXPERIMENT NO 10

Determination of split tensile strength

STANDARED

ASTM C 496

SIGNIFICANCE

It is used in design of light weight concrete and to evaluate shear resistance of concrete. It

is also used to determine the development length of reinforcement.

Splitting tensile strength is generally greater than the direct tensile strength and

lower than the flexural strength (modulus of rupture).

Splitting tensile strength is used in the design of structural light weight concrete

members to evaluate the shear resistance provided by concrete and to determine

the development length of the reinforcement.

APPARATUS

Test machine

Cylindrical specimen

RELATED THEORY

Split tensile strength

Splitting tensile strength test on concrete cylinder is a method to determine the tensile

strength of concrete. The concrete is very weak in tension due to its brittle nature and is

not expected to resist the direct tension. The concrete develops cracks when subjected to

tensile forces.

Size of The Specimen

The specimen is a cylinder of 150mm diameter and

300mm height. Determine the diameter to the nearest

0.25mm by averaging the three diameters. Determine

the length to the nearest 2mm by averaging at least

two lengths. Split

THE UNIVERSITY OF LAHORE 38

PRC-2 (LAB MANUAL) MUAAZ ANUS -BSCE-01143050

Size of Bearing Strips

According to ASTM specifications, the bearing strips should be 3.2mm thick and 25mm

wide. There is no restriction on their length. Splitting Tensile Strength.

Rate of Loading

The rate of loading should be such that a stress of 0.7 – 1.4 MPa/min is produced.

PROCEDURE

This test method consists of applying a diametrical force along the length of a cylindrical

concrete at a rate that is within a prescribed range until failure. This loading induces

tensile stresses on the plane containing the applied load and relatively high compressive

stresses in the area immediately around the applied load. Although we are applying a

compressive load but due to Poisson’s effect, tension is produced and the specimen fails

in tension. Tensile failure occurs rather than compressive failure because the areas of load

application are in a state of triaxial compression, thereby allowing them to withstand

much higher compressive stresses than would be indicated by a uniaxial compressive

strength test result.

Split tensile strength is calculated by

T=2P/ (3.14*ld)

where:

T = splitting tensile strength

P = maximum applied load indicated by the testing machine

L= Length (in. or mm)

d = diameter, (in. or mm)

COMMENTS

It is used in design of light weight concrete and to evaluate shear resistance of concrete. It

is also used to determine the development length of reinforcement.

Splitting tensile strength is generally greater than the direct tensile strength and lower

than the flexural strength (modulus of rupture). Splitting tensile strength is used in the

design of structural light weight concrete members to evaluate the shear resistance

provided by concrete and to determine the development length of the reinforcement.

THE UNIVERSITY OF LAHORE 39

You might also like

- Materials For Construction and Civil Engineering Science Processing and Design M Clara Goncalves PDFDocument938 pagesMaterials For Construction and Civil Engineering Science Processing and Design M Clara Goncalves PDFDania Marlen Valenzuela67% (3)

- General SpecsDocument12 pagesGeneral SpecsKelvene Boy Bravo Silva100% (1)

- Concrete Mixed Design MethodDocument11 pagesConcrete Mixed Design Methodabdicasis rashidNo ratings yet

- Concrete Mix Design ExplainedDocument21 pagesConcrete Mix Design ExplainedPratyush Kumar DoraNo ratings yet

- Properties and Testing of Hardened ConcreteDocument17 pagesProperties and Testing of Hardened ConcreteKannan KandappanNo ratings yet

- Concrete Mix DesignDocument23 pagesConcrete Mix DesignSyahmi FadziNo ratings yet

- AggregateDocument65 pagesAggregateShawonNo ratings yet

- Lab Concrete Mix Design C25aDocument17 pagesLab Concrete Mix Design C25aSoundar PachiappanNo ratings yet

- Concrete Mix Design GuideDocument42 pagesConcrete Mix Design GuidesereneNo ratings yet

- Concrete Mix Design Beng 2021Document31 pagesConcrete Mix Design Beng 2021musinguzi robertNo ratings yet

- CIVL354 Notes 1 Soil CompactionDocument20 pagesCIVL354 Notes 1 Soil Compactionmusiomi2005No ratings yet

- On MIX DesignDocument27 pagesOn MIX DesignGaurav naddaNo ratings yet

- Concret CementDocument29 pagesConcret CementKamal Hameed Al-taiy100% (1)

- Flexural Strength Test of Concrete BeamDocument2 pagesFlexural Strength Test of Concrete BeamdhanishaNo ratings yet

- Testing of AggregatesDocument6 pagesTesting of AggregatesMegelJoshuaRamiterreNo ratings yet

- Concrete NotesDocument37 pagesConcrete Notesကိုနေဝင်းNo ratings yet

- 3.3 Road Note No. 4-1Document40 pages3.3 Road Note No. 4-1Asad Choudhary100% (1)

- Building Material and Construction LabDocument40 pagesBuilding Material and Construction LabSaurabh Dubey100% (1)

- Concrete Mix Design CalculationDocument10 pagesConcrete Mix Design CalculationHari RNo ratings yet

- Mix DesignDocument29 pagesMix Designshahhassa9No ratings yet

- M-30 Concrete Mix Design As Per IS 10262-2009 & MORT&H A-1 Stipulations For Proportioning Grade Designation M30Document4 pagesM-30 Concrete Mix Design As Per IS 10262-2009 & MORT&H A-1 Stipulations For Proportioning Grade Designation M30Kumkum MukherjeeNo ratings yet

- Design and properties of high strength self compacting concreteDocument2 pagesDesign and properties of high strength self compacting concretePrachi TaoriNo ratings yet

- Various Lab Test On CementDocument4 pagesVarious Lab Test On Cementhncc ghazniNo ratings yet

- New Procedure To Investigate External Sulphate Attack On Cementitious MaterialsDocument8 pagesNew Procedure To Investigate External Sulphate Attack On Cementitious MaterialsCarlos Augusto Sánchez RondónNo ratings yet

- Hardened ConcreteDocument50 pagesHardened ConcreteMayank KapriNo ratings yet

- Project 8th SemDocument21 pagesProject 8th Semamish rajNo ratings yet

- Quantity of CementDocument19 pagesQuantity of CementAl Patrick Dela CalzadaNo ratings yet

- Concrete Mix DesignDocument7 pagesConcrete Mix Designadil271No ratings yet

- Concrete Mix Design: RequirmentsDocument56 pagesConcrete Mix Design: RequirmentssushilkumarNo ratings yet

- M-80 Grade Pumpable Concrete: by Kaushal Kishore Materials Engineer, RoorkeeDocument3 pagesM-80 Grade Pumpable Concrete: by Kaushal Kishore Materials Engineer, RoorkeeSai CharanNo ratings yet

- Sand & AggregateDocument75 pagesSand & AggregateCBIT CIVIL A1No ratings yet

- Building Materials Lab ManualDocument21 pagesBuilding Materials Lab Manualapi-348488925100% (3)

- ACI 211.1 Method Final 2Document21 pagesACI 211.1 Method Final 2Yemane KebedeNo ratings yet

- Quality Control in Concrete ConstructionDocument123 pagesQuality Control in Concrete ConstructionJustice ArjonaNo ratings yet

- Concrete Mix DesignDocument5 pagesConcrete Mix DesignGlyn A. Brinquez100% (1)

- The Effect of Excess Water in ConcreteDocument2 pagesThe Effect of Excess Water in ConcreteKevin NacalabanNo ratings yet

- Conrete Mix Design & Making and Curing of Test SpecimenDocument15 pagesConrete Mix Design & Making and Curing of Test SpecimenBlesNo ratings yet

- Aggregate Blending Absorption Specific GravityDocument44 pagesAggregate Blending Absorption Specific Gravityyusuf alhowaidi100% (1)

- Trial MixDocument4 pagesTrial MixShesha Shayan0% (1)

- Self Compacting ConcreteDocument26 pagesSelf Compacting ConcreteSavinaya Shankar0% (1)

- Concrete Mix DesignDocument92 pagesConcrete Mix Designtanveer100% (1)

- Experimental Study on Permeable Concrete Pavement for Storm Water ManagementDocument28 pagesExperimental Study on Permeable Concrete Pavement for Storm Water ManagementVaidyanathan SivasubramanianNo ratings yet

- Concrete Mix Design Examples for Target Strength and Restricted Water-Cement RatioDocument8 pagesConcrete Mix Design Examples for Target Strength and Restricted Water-Cement Ratioعابد خواجہNo ratings yet

- Concrete LabDocument97 pagesConcrete LabSiva NatNo ratings yet

- Fly ash aggregate concrete strength developmentDocument14 pagesFly ash aggregate concrete strength developmentnaveenthirumal67% (3)

- Concrete Admixture GuideDocument34 pagesConcrete Admixture GuideAnsari KhuzaimaNo ratings yet

- M-20 Mix Designs as per IS-10262-2009Document25 pagesM-20 Mix Designs as per IS-10262-2009Prasad MsrkNo ratings yet

- Design Concrete Mix Using IS CodeDocument27 pagesDesign Concrete Mix Using IS CodevassihayNo ratings yet

- Standard Consistency and Setting TimeDocument3 pagesStandard Consistency and Setting TimeFirdaus RoslimNo ratings yet

- Material Supplier or Certifier Type/Gradation Astm Date S.G. Quantity %Document1 pageMaterial Supplier or Certifier Type/Gradation Astm Date S.G. Quantity %Waqas SadiqNo ratings yet

- Brick Manufacturing Using Waste MaterialsDocument8 pagesBrick Manufacturing Using Waste MaterialsAnjana Kanwar RajawatNo ratings yet

- Unit 2 Aggregates: Concrete TechnologyDocument23 pagesUnit 2 Aggregates: Concrete TechnologyAnonymous WalvB8No ratings yet

- Understanding Ancient Geopolymers Used in Egyptian Pyramids To Modernize Contemporary Concrete MasonryDocument8 pagesUnderstanding Ancient Geopolymers Used in Egyptian Pyramids To Modernize Contemporary Concrete MasonrySusan Wers100% (1)

- Excel Sheel For Concrete Quantity Calculation For Rectangular StructureDocument5 pagesExcel Sheel For Concrete Quantity Calculation For Rectangular Structurerafeh khattakNo ratings yet

- Concrete Mix Design C30 - ACI METHODDocument4 pagesConcrete Mix Design C30 - ACI METHODMitendra Kumar ChauhanNo ratings yet

- Exploratory Project 2Document43 pagesExploratory Project 2AMAN GUPTANo ratings yet

- Material Testing Laboratory ExperimentDocument25 pagesMaterial Testing Laboratory ExperimentPriyankaNo ratings yet

- 20JE0705 Exp5Document14 pages20JE0705 Exp5Priye RanjanNo ratings yet

- Partillay Replacement of Sand by Artifical Sand in Ferrocement Used in Road ConstructionDocument28 pagesPartillay Replacement of Sand by Artifical Sand in Ferrocement Used in Road ConstructionNagaraj GuptaNo ratings yet

- Job 1 Mix DesignDocument10 pagesJob 1 Mix DesignMazharYasinNo ratings yet

- Concrete Mix Design C30 - ACI METHODDocument4 pagesConcrete Mix Design C30 - ACI METHODMitendra Kumar ChauhanNo ratings yet

- Concrete Mix DesignDocument4 pagesConcrete Mix DesignZakir AliNo ratings yet

- AFM Lab. ManualDocument89 pagesAFM Lab. ManualMariYam AliNo ratings yet

- AFM Lab. ManualDocument89 pagesAFM Lab. ManualMariYam AliNo ratings yet

- (Compass Surveying/Traversing) : The University of Lahore, PakistanDocument55 pages(Compass Surveying/Traversing) : The University of Lahore, PakistanMariYam AliNo ratings yet

- (Compass Surveying/Traversing) : The University of Lahore, PakistanDocument55 pages(Compass Surveying/Traversing) : The University of Lahore, PakistanMariYam AliNo ratings yet

- Project Report Combined PDFDocument108 pagesProject Report Combined PDFsurendar kumarNo ratings yet

- IOP Conference Series: Earth and Environmental Science Development of Interlocking Masonry Bricks ReviewDocument9 pagesIOP Conference Series: Earth and Environmental Science Development of Interlocking Masonry Bricks ReviewShreedhar KulalNo ratings yet

- Sandwich Plus CVDocument199 pagesSandwich Plus CVapi-21699046No ratings yet

- Fosroc Catalogue 2011Document112 pagesFosroc Catalogue 2011Bahtiar AntanaNo ratings yet

- Durability Deterioration of Concrete Under Marine Envir - 2021 - Journal of Buil PDFDocument17 pagesDurability Deterioration of Concrete Under Marine Envir - 2021 - Journal of Buil PDFSunita ChayalNo ratings yet

- Cement PlannerDocument6 pagesCement PlannerscrbdgharaviNo ratings yet

- Gujarat AmbujaDocument14 pagesGujarat AmbujaAyush GoyalNo ratings yet

- National Cement Company Limited, Clinkerization Unit: Mis ReportDocument52 pagesNational Cement Company Limited, Clinkerization Unit: Mis ReportVaibhav KhodakeNo ratings yet

- The KCP Group of Companies Had Its Beginning in TheDocument2 pagesThe KCP Group of Companies Had Its Beginning in Thevenkat_badisa8262No ratings yet

- Roman Inventions. Concrete: ProjectDocument11 pagesRoman Inventions. Concrete: Projecttanea_1991No ratings yet

- Rate AnalysisDocument9 pagesRate AnalysisRajesh JujareNo ratings yet

- Soil-Cement Mixture Properties and Design Considerations For Reinforced ExcavationDocument8 pagesSoil-Cement Mixture Properties and Design Considerations For Reinforced ExcavationtehNo ratings yet

- Recent Trends in Replacement of Natural Sand With Different AlternativesDocument8 pagesRecent Trends in Replacement of Natural Sand With Different AlternativesNambi HarishNo ratings yet

- Interior Designing Market SurveyDocument32 pagesInterior Designing Market SurveyAditi DeshpandeNo ratings yet

- Ece 2206 - Civil Engineering Materials IDocument2 pagesEce 2206 - Civil Engineering Materials IJohn MbugiNo ratings yet

- Desempeño Técnico y Ambiental de La Cal de Cascarón de Huevo para La Estabilización de SuelosDocument12 pagesDesempeño Técnico y Ambiental de La Cal de Cascarón de Huevo para La Estabilización de Sueloscarlos enrique SosamoreNo ratings yet

- Performance of Geopolymer Concrete Reinforced With FRP Rebars - A ReviewDocument7 pagesPerformance of Geopolymer Concrete Reinforced With FRP Rebars - A ReviewSushil Singh BAGHELNo ratings yet

- Vol 4Document216 pagesVol 4Dharmendra SharmaNo ratings yet

- Aitcin Fib 2012 PDFDocument10 pagesAitcin Fib 2012 PDFBauEngenhariaNo ratings yet

- "Study of Brand Promotion of Jaypee Cement": Project Report ONDocument61 pages"Study of Brand Promotion of Jaypee Cement": Project Report ONAmar Rajput100% (1)

- Hazardous Waste DisposalDocument12 pagesHazardous Waste DisposalFrancisco MelendezNo ratings yet

- INSEE Knowledge Sharing Session #2 - High Performance Concrete in Construction V3Document10 pagesINSEE Knowledge Sharing Session #2 - High Performance Concrete in Construction V3KalindaMadusankaDasanayakaNo ratings yet

- Assignment 01Document3 pagesAssignment 01Shankar SaravananNo ratings yet

- ESTIMATE by Max Fajardo - Chapter 1 - ScannedDocument21 pagesESTIMATE by Max Fajardo - Chapter 1 - ScannedArnel AspeNo ratings yet

- Is 2645 (2003) - Integral Waterproofing Compounds For Cement Mortar and Concrete - SpecificationDocument16 pagesIs 2645 (2003) - Integral Waterproofing Compounds For Cement Mortar and Concrete - SpecificationMeet ChokshiNo ratings yet

- Effect of Different Sand Grading On Strength Properties of Cement Grout PDFDocument8 pagesEffect of Different Sand Grading On Strength Properties of Cement Grout PDFyoussefNo ratings yet

- Auramix 400: Advanced Low Viscosity High Performance Superplasticiser, Based On Polycarboxylic TechnologyDocument2 pagesAuramix 400: Advanced Low Viscosity High Performance Superplasticiser, Based On Polycarboxylic TechnologyABHI MITRANo ratings yet

- Display ABB: CO2 SystemDocument5 pagesDisplay ABB: CO2 SystemNova HeriNo ratings yet