Professional Documents

Culture Documents

P2i3-Edu-Full Paper 14-21 Dr. Meenu Srivastava May-June-2017

Uploaded by

Paula RoblesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

P2i3-Edu-Full Paper 14-21 Dr. Meenu Srivastava May-June-2017

Uploaded by

Paula RoblesCopyright:

Available Formats

Meenu Srivastava & Kalindri Vema, Development of Microcapsules of Peppermint oil

www.arseam.com

Impact Factor: 2.525

Cite this paper as: Meenu Srivastava & Kalindri Vema (2017) “Development of

Microcapsules of Peppermint oil” International Journal of Education & Applied Sciences

Research, Vol.4, Issue 03, May-Jun-2017, pp 01-08 ISSN: 2349 –2899 (Online) ,

ISSN: 2349 –4808 (Print),

DEVELOPMENT OF MICROCAPSULES OF PEPPERMINT OIL

Dr. Meenu Srivastava1 and Ms. Kalindri Vema2

Dept. of Textiles & Apparel Designing, College of Home Science, MPUAT, Udaipur (Raj.)

Abstract

Microencapsulation is an effective and important tool to prepare oil-based high-quality and health-beneficial

products in various industries in order to enhance their chemical, oxidative, and thermal stability. Peppermint or

Mentha piperta is a common herb that is grown in Europe and north America and even in India. Peppermint also

known as a hybrid mint, a cross between watermint and spearmint. The concentrated oil of peppermint has a high

menthol content. In order to protect and maintain its stability by microencapsulation process, present research was

conducted on development of peppermint oil microcapsules by process optimization using coacervation technique.

Findings of the study revealed that best results of microcapsules formation using peppermint oil were obtained when

the ratio of oil:gum:gelatin was kept 2:4:4, at optimized 50ºC temperature having initial pH 4.0 and final pH 9.0.

Key words: Development, microcapsules, peppermint, essential, oil

1. Introduction

Microencapsulation systems protect the essential oil from degradation and evaporation, and, at the same

time, allow a sustained release.1 Microencapsulation is an effective and important tool to prepare oil-based high-

quality and health-beneficial products in various industries in order to enhance their chemical, oxidative, and

thermal stability.2 The use of medicinal plants is a universal phenomenon. Natural products from plants are rich

source to identify, select and process new drugs for medicinal use. Peppermint or Mentha piperta is a common herb

that is grown in Europe and north America and even in India. Peppermint also known as a hybrid mint, a cross

between watermint and spearmint. The concentrated oil of peppermint has a high menthol content. The oil also

contains menthone and menthyl esters, particularly menthyl acetate. Dried peppermint typically has volatile oil

containing menthol, menthone , menthyl acetate ,menthofuran and 1,8-cineol. Peppermint oil also contains small

amounts of many additional compounds including limonene, pulegone, caryophyllene and pinene. 2 Peppermint oil is

the most extensively used of all the volatile oils. 3

Peppermint oil has a fresh, sharp, menthol smell, is clear to pale yellow in color and watery in viscosity.

India is world’s largest producer and exporter of mint oil. Mint oil and its constituents and derivatives are used in

food, pharmaceutical, perfumery flavouring industry and in textile industry also. The oil is used for treating certain

stomach disorders like indigestion, gas problem, acidity, etc. It is the main ingredient of ayurvedic medicines. 4

Peppermint is currently one of the most economically important aromatic and medicinal crops produced in the U.S.

The world production of peppermint oil is about 8000 tons per year.5 Peppermint leaf and oil are used for folk

medicine, as flavoring agents, and in cosmetic, textiles and pharmaceutical products throughout the world. 6

| submit paper : editor@arseam.com download full paper : www.arseam.com 14

International Journal of Education & Applied Sciences Research, Vol.4, Issue 03, May-Jun- 2017,

EISSN: 2349 –2899 , ISSN: 2349 –4808 (Print) pp 14-21

Herbalists consider peppermint an astringent, antiseptic, antipruritic, antispasmodic, antiemetic, carminative,

diaphoretic, mild bitter, analgesic, anticatarrhal, antimicrobial, rubefacient, stimulant, and emmenagogue .7,8.

Antimicrobial effect : Menthol is virucidal against Influenza, Herpes and other viruses in vitro. Aqueous extracts of

peppermint . Peppermint oil and menthol have mild antibacterial effects against both Gram-positive and Gram-

negative bacteria.9,10,11. Peppermint extracts are bacteriostatic against Streptococcus thermophilus and Lactobacillus

bulgaricus.12Present research is based on development of microcapsules of volatile oil of peppermint by process

optimization to protect and maintain its stability by coacervation technique for its effective application as fragrance

and antibacterial finishing in various health care textile products.

2. Material and Method

The raw material used in this study was the essential peppermint oil and coating materials such as gum

arabic, gelatin. Other materials used were dilute acetic acid, 0.4 N sodium hydroxide solution, gluteraldehyde

aqueous solution and sodium sulphate solution.

Selection of essential oil

Essential oils are a complex liquid mixture of volatile, lipophilic and odoriferous compounds

biosynthesized by living organisms, predominantly aromatic plants.13 Researcher explored the availability of

essential oil-clove oil in the market, for the sake of purity and maintaining uniformity in quality parameter, It was

procured from.

Selection of wall material:

Gelatine was used as an encapsulating agent, as wall material to encapsulate the inner core material (oil).

Preparation of microcapsules by coacervation method usually involves a combination of gelatine and a carboxyl

bearing polymer. Gum Arabic, a polymer most widely used for complex coacervation with a gelatine was used in

this process with other naturally occurring polymer and synthetic polymer compatible with cotton fabric and other

ingredients of microencapsulation process based on the past studies.

2.2. Method

Selection of Microencapsulation Technique

Out of the many physical and chemical techniques of microencapsulation i.e. solvent evaporation,

polymerization, spray drying, pan coating, phase separation centrifugal extrusion etc. The phase separation -complex

coacervation technique was selected for present study by the researcher on the basis of review and the suitability of

the process to be carried out in the laboratory of the department.

Complex coacervation technique

Gum acacia was taken as the wall material and essential oil as the core material. Gelatin is the common

ingredient in all the processes of complex coacervation. The basic recipe (Teli,et.al, 2005) was followed to

optimized the various concentrations of the raw material used in microencapsulation process.

2.3 Development of microencapsulation-process optimization

The researcher conducted laboratory experiments for development of microencapsulation process of

peppermint oil. The resultant precipitate obtained after each process was analyzed under inverted microscope to

ensure the formation of microcapsules and images were captured. The combination of ratio of oil, gum and gelatin

which produced best results was further subjected to optimization of the other variables. At a time, the ratio of only

one variable was varied and other variables were kept constant.

| submit paper : editor@arseam.com download full paper : www.arseam.com 15

Meenu Srivastava & Kalindri Vema, Development of Microcapsules of Peppermint oil

a) Optimization of ratio of essential oil: To optimize ratio of essential oil, five different ratio of oil i.e. 0.5,

1.0, 1.5. 2.0, 2.5 were taken while other variables i.e. gum, gelatin, temperature and pH were kept constant

to carry out microencapsulation process. The resultant precipitate obtained was analyzed under inverted

microscope to ensure the formation of microcapsules and optimization was done on the basis of the visual

assessment of the microcapsules size, uniformity in size and distribution and wall of the microcapsules on

comparative basis. The ratio giving best results was selected for next stage of optimization.

b) Optimization of ratio of gum: For determination of optimum ratio of gum, five different ratio of gum i.e.

1, 2, 3, 4 and 5 were taken with optimized ratio of essential oils whereas ratio of gelatin was kept constant

along with all other variables. Microencapsulation was carried out and optimum ratio of gum was

optimized on the basis of visual assessment.

c) Optimization of ratio of gelatin: For determination of optimum ratio of gelatin, five different ratio of

gelatin i.e. 1, 2, 3, 4 and 5 were taken with optimized proportion of oil and gum and all other variables were

kept constant. Microencapsulation was carried out and optimum ratio of gelatin was optimized on the basis

of visual assessment.

d) Optimization of temperature: For determination of optimum temperature for microencapsulation, the

process was carried out at six different temperatures i.e. 30, 40, 50, 60 and 70ᴼC with optimized ratio of

oils, gum and gelatin and other variables were kept constant. Optimized temperature was selected on the

basis of visual assessment.

e) Optimization of initial and final pH: pH plays very important role in microencapsulation as it is

responsible for phase separation which leads to capsule formation. For optimization of pH, the optimized

ratio of essential oil, gum and gelatin at optimized temperature was set to initial pH 4.0, 4.5, 5.0, 5.5, 6.0,

6.5 and 7.0. The microencapsulation process was carried out till gel formation took place and then final pH

was maintained at 7.0, 7.5, 8.0, 8.5, 9.0, 9.5 and 10.0 with each initial pH. The initial and final pH was

optimized on the basis of visual assessment of microcapsule gel.

3. Results and discussions

3.1 Preparation of microcapsule gel

Microcapsule gel was prepared by mixing selected essential oil, gum acacia and gelatin using the complex

coacervation technique and optimization of various variables i.e. ratio of essential oil:gum:gelatin, temperature and

pH was carried out to obtain the best results.

3.2 Optimization of the ratio of essential oils in microcapsule gel:

Essential oils form the core material of the microcapsules and is basically responsible for multifunctional

properties. Microcapsule gel was prepared using different ratio of selected clove oil i.e. 0.5, 1.0, 1.5, 2.0 and 2.5

keeping other variables constant. The gel was observed under inverted microscope to ensure the presence of

microcapsules. The ratio of essential oil was optimized on the basis of visual assessment on three parameters i.e. size

of microcapsules, uniformity in size and distribution and wall of microcapsules.

Table-1 : Optimization of ratio of peppermint (PM) oil in microcapsule gel

Ratio of Formation of Parameters

Oil: gum: microcapsules Size of Uniformity in Wall of Rank

gelatin microcapsules size and microcapsules

distribution

0.5:4:4 No - - - -

| submit paper : editor@arseam.com download full paper : www.arseam.com 16

International Journal of Education & Applied Sciences Research, Vol.4, Issue 03, May-Jun- 2017,

EISSN: 2349 –2899 , ISSN: 2349 –4808 (Print) pp 14-21

1:4:4 Yes Small Good Thick IV

1.5:4:4 Yes Medium + Small Average Very thick III

2:4:4 Yes medium Good Thick and sharp I

2.5:4:4 yes Medium Average Thick II

Image-1 Image-2 Image-3 Image-4

It is evident from Table-1 and visual assessment of microcapsule gel (Image- 1 to 4) that in case of peppermint oil

microcapsules were formed in four ratios of oil, gum and gelatin i.e. 1:4:4, 1.5:4:4, 2:4:4 and 2.5:4:4. Best capsules

were formed at 2:4:4 ratios of oil, gum and gelatin. Hence, ranked 1 st indicating medium sized microcapsules with

good uniformity in size having thick and sharp walls of capsules. Thus, the ratio four of peppermint oil was used for

further optimization to achieve the best results.

3.3 Optimization of ratio of gum acacia in microcapsule gel: Gum acacia forms the wall/outer core of the

microcapsule and protects the oil from abrasion, sunlight and biodegradation thus provides a controlled release to

the oil. Microcapsule gel was prepared using different ratios of gum acacia i.e. 1, 2, 3, 4, and 5.

The data presented in Table-2 and visual evaluation of microcapsule gel (Image-5 to 8) indicates that

microcapsules were formed in only in four ratios i.e. 2:3:4, 2:4:4, 2:5:4, and 2:2:4.

Table-2 Optimization of ratio of Gum acacia in microcapsule gel

Ratio of Formation of Parameters

Pippermint Oil: microcapsules Size of Uniformity in Wall of Rank

gum: gelatin microcapsules size and microcapsules

distribution

2:1:4 No - - - -

2:2:4 Yes Very Small Average Thin IV

2:3:4 Yes Medium Good Thick and sharp I

2:4:4 Yes Medium+ Large Average Thick II

2:5:4 yes Large Average Very Thick III

| submit paper : editor@arseam.com download full paper : www.arseam.com 17

Meenu Srivastava & Kalindri Vema, Development of Microcapsules of Peppermint oil

Image-5 Image-6 Image-7 Image-8

The microcapsules formed in the ratio of 2:3:4 were medium sized, having good uniformity in size and

distribution and the walls were also sharp and thick as compared to the capsules formed in the other ratios.

Therefore, the ratio 3 was optimized for peppermint oil.

3.4 Optimization of ratio of gelatin in microcapsule gel: Gelatin is a common ingredient of complex

coacervation process and gives best results with gum acacia and essential oils. Microcapsule gel was prepared using

different ratios of gelatin i.e. 1, 2, 3, 4 and 5.

Table-3.Optimization of ratio of Gelatin in microcapsule gel

Ratio of Formation of Parameters

PM Oil: gum: microcapsules Size of Uniformity in size Wall of Rank

gelatin microcapsules and distribution microcapsules

2:4:1 No - - - -

2:4:1 No - - - -

2:4:3 Yes Small Average Thick and sharp III

2:4:4 Yes Medium Average Thick and sharp I

2:4:5 yes Medium+Small Average Thick and sharp II

Image-9 Image-10 Image-11

The data presented in Table-3 and visual assessment of microcapsule gel indicates that microcapsules were

formed in the three ratios of oil, gum and gelatin i.e. 2:4:3, 2:4:4 and 2:4:5 (Image- 9 to11) with peppermint oil.

Microcapsules were not formed at ratio 2:4:1 and 2:4:2 respectively. The best microcapsules formed at the ratio of

2:4:4 which were characterized as medium sized having good uniformity in size and distribution and the thick walls

as compared to the capsules formed at other ratios. Therefore, the ratio 4 of gelatin was optimized for further

experimentation.

| submit paper : editor@arseam.com download full paper : www.arseam.com 18

International Journal of Education & Applied Sciences Research, Vol.4, Issue 03, May-Jun- 2017,

EISSN: 2349 –2899 , ISSN: 2349 –4808 (Print) pp 14-21

3.5 Optimization of temperature for microencapsulation process:

For optimization of temperature, microencapsulation process was carried out at five different temperatures

i.e. 30, 40, 50, 60 and 70°C.

The data presented in Table-4 and visual evaluation (Image-12 to14) reveals that the microcapsules formed

at 50°C were medium sized, had good uniformity and distribution and the walls were sharp and thick for Peppermint

oil.

Table-4. Optimization of temperature for microencapsulation of Peppermint oil

Temperature Formation of Parameters Rank

(ºC) microcapsules Size of Uniformity in size Wall of

microcapsules and distribution microcapsules

30 No - - - -

40 Yes Medium Average Thick and Sharp II

50 Yes Medium Good Thick and Sharp I

60 Yes Large Average Very Thin III

70 No - - - -

Gum:oil:gelatine- 2:2:4

Image-12 Image-13 Image-14

Microcapsules were not formed at temperature 30° and 70°C. Hence, 50°C temperature was optimized and

used for development of essential oil microcapsules.

3.6 Optimization of pH for microencapsulation process:

To optimize initial pH and the final pH, microencapsulation was carried out with optimized ratio of

oil:gum:gelatin and temperature. Microcapsule gel was initially started at pH 4.0, 4.5, 5.0, 5.5, 6.0, 6.5 and 7.0.

After the completion of microencapsulation process, the final pH of the gel was set at 7.0, 7.5, 8.0, 8.5, 9.0 9.5 and

10.

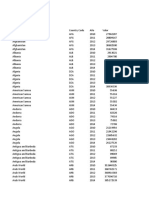

Table 5 : Optimization of pH for microcapsulation of Peppermint oil

pH Formation of Parameters

| submit paper : editor@arseam.com download full paper : www.arseam.com 19

Meenu Srivastava & Kalindri Vema, Development of Microcapsules of Peppermint oil

(initial / microcapsules Size of microcapsules Uniformity in Wall of Rank

final) size and microcapsules

distribution

4.0/8.5 Yes Small Very Poor Thin XII

4.0/9.0 Yes Medium Good Thick and Sharp I

4.0/9.5 Yes Medium+Large Average Thin V

4.0/10.0 Yes Medium+ small Average Thick IV

4.5/8.5 Yes small Average Very Thick VII

4.5/9.0 Yes Medium Average Thick and sharp II

4.5/9.5 Yes Very Small Poor Very Thin X

4.5/10.0 Yes Large Poor Thin VIII

5.0/8.5 Yes Small Poor Thick XI

5.0/9 Yes Medium Average Thin VI

5.0/9.5 Yes Medium Average Thick III

5.0/10.0 Yes Large Poor Very thin IX

Gum:oil:gelatin-2:2:4, temperature- 50ºC

As apparent from Table-5 and Image-15, microcapsules formed at initial pH 4.0 and final pH 9.0 were

medium sized with uniform distribution having thick and sharp walls in case of peppermint oil Hence, these pH

values may be used as optimum initial and final pH for development of microencapsules of essential oil of

peppermint.

Image-15 Optimization of pH for microencapsulation

4. Conclusion

Essential oils have been used to improve the health and to protect a body part against damage from the

environment since ancient times in human history. (Shaaban,,et.al 2012, and Yorgancioglu,et.al.2013). Findings of

the present study revealed that in development process of microcapsules with peppermint oil, best microcapsules

were formed at the optimized ratio 2:4:4 of oil: gum: gelatin , at optimized 50ºC temperature having initial pH 4.0

and final pH 9.0. The microcapsules formed with these optimized conditions were observed medium having good

uniformity in size and distribution with sharp and thick walls of capsules.

The standardized microencapsulation process can be effectively used in developing microcapsules gel with

peppermint oil for its wider applications as per end use to derive long term sustained benefit.

5. References

| submit paper : editor@arseam.com download full paper : www.arseam.com 20

International Journal of Education & Applied Sciences Research, Vol.4, Issue 03, May-Jun- 2017,

EISSN: 2349 –2899 , ISSN: 2349 –4808 (Print) pp 14-21

1. Marcela, F. , Lucía, C. , Eva, B. , David, G. , Ángeles, B. and Luis, B. (2015) Microencapsulation of

Essential Oils by Interfacial Polimerization Using Polyurea as a Wall Material. Journal of Encapsulation

and Adsorption Sciences, 5, 165-177. doi: 10.4236/jeas.2015.54014.

2. Balakrishnan A., (2015) Therapeutic Uses of Peppermint –A Review, Journal of pharmaceutical sciences

and research, Vol. 7(7), 2015, 474-476.

3. Murray MT. The healing power of herbs : the enlightened person's guide to the wonders of medicinal

plants. Rocklin, CA: Prima Pub., 1995:xiv, 410.

4. Paula Gardiner Peppermint Page 8 Longwood Herbal Task Force: http://www.mcp.edu/herbal/ Revised

May 2, 2000

5. Eccles R. Menthol and related cooling compounds. J Pharm Pharmacol 1994; 46:618-30.

6. Foster S. Peppermint: Mentha piperita. American Botanical Council - Botantical Series 1996; 306:3 - 8.

7. Hoffman D. The complete illustrated holistic herbal. Rockport, MA: Element Books Inc., 1996.

8. Bove M. An encyclopedia of natural healing for children & infants. New Canaan, CT: Keats Publishing,

Inc., 1996.

9. El-Kady IA, El-Maraghy SSM, Mostafa ME. Antibacterial and antidermatophyte activities of some

essential oils from spices. Qatar University Science Journal 1993; 13:63-69.

10. Pattnaik S, Subramanyam VR, Kole C. Antibacterial and antifungal activity of ten essential oils in vitro.

Microbios 1996; 86:237-46.

11. Moleyar V, Narasimham P. Antibacterial activity of essential oil components. Int J of Food Microbiology

1992; 16:337 - 342.

12. Pattnaik S, Subramanyam VR, Bapaji M, Kole CR. Antibacterial and antifungal activity of aromatic

constituents of essential oils. Microbios 1997; 89:39-46.

13. Berger, R.G. Flavours and Fragrances, pp. 43–86. Springer Science & Business Media, Heidelberg (2007).

14. Teli, M.D., Adivarker, R.V. and Kumar, A. 2005. Microencapsulation of disperse dyes by coacervation

methods. Journal of Textile Association, 66(1):27-34.

15. Shaaban, H.A.E., El-Ghorab, A.H. and Shibamoto, T. Bioactivity of essential oils and their volatile aroma

components: review. J. Essent. Oil Res. 24, 203–212 (2012).

16. Yorgancioglu, A. and Bayramoglu, E.E. Production of cosmetic purpose collagen containing antimicrobial

emulsion with certain essential oils. Ind. Crops Prod. 44, 378–382 (2013).

**********************

| submit paper : editor@arseam.com download full paper : www.arseam.com 21

You might also like

- Essential Oils in Food Processing: Chemistry, Safety and ApplicationsFrom EverandEssential Oils in Food Processing: Chemistry, Safety and ApplicationsSeyed Mohammed Bagher HashemiNo ratings yet

- Formulation and Evaluation of Antibacterial, Antifungal Cream of Garlic OilDocument4 pagesFormulation and Evaluation of Antibacterial, Antifungal Cream of Garlic OilEditor IJTSRDNo ratings yet

- Processing Contaminants in Edible Oils: MCPD and Glycidyl EstersFrom EverandProcessing Contaminants in Edible Oils: MCPD and Glycidyl EstersShaun MacMahonNo ratings yet

- SynopsisDocument14 pagesSynopsisSushanth reddyNo ratings yet

- Gourmet and Health-Promoting Specialty OilsFrom EverandGourmet and Health-Promoting Specialty OilsRobert MoreauRating: 3 out of 5 stars3/5 (1)

- Pharmaceutical ProductsDocument6 pagesPharmaceutical ProductshishoNo ratings yet

- Acephate, Methamidophos and Monocrotophos Residues in A Laboratory Scale Oil Refining Processyeoh2009Document6 pagesAcephate, Methamidophos and Monocrotophos Residues in A Laboratory Scale Oil Refining Processyeoh2009paul WongNo ratings yet

- Microwave-Assisted Extraction and Physicochemical Evaluation of Oil From Hevea Brasiliensis SeedsDocument12 pagesMicrowave-Assisted Extraction and Physicochemical Evaluation of Oil From Hevea Brasiliensis SeedsSenuke TestNo ratings yet

- 2022 49 1 - 7Document8 pages2022 49 1 - 7MARIANE KATE PILOTON VELEZNo ratings yet

- Extraction of Lemongrass Oil Formation of PerfumeDocument6 pagesExtraction of Lemongrass Oil Formation of Perfumevraj ranaNo ratings yet

- ResearchDocument4 pagesResearchMacc Vasquez50% (2)

- JETIR2204484Document7 pagesJETIR2204484Dev KannanNo ratings yet

- Pecan TabelaDocument12 pagesPecan TabelaRama ShaktiNo ratings yet

- Ghazali 2016 IOP Conf. Ser. Earth Environ. Sci. 36 012053Document8 pagesGhazali 2016 IOP Conf. Ser. Earth Environ. Sci. 36 012053khalidNo ratings yet

- Biodiesel Production by Enzymatic Transesterification of Papaya Seed Oil and Rambutan Seed OilDocument5 pagesBiodiesel Production by Enzymatic Transesterification of Papaya Seed Oil and Rambutan Seed OilNilmar NasaanNo ratings yet

- International Journal of Chemistry and Materials Research: Azadiracha IndicaDocument10 pagesInternational Journal of Chemistry and Materials Research: Azadiracha IndicaAisha Mustapha FunmilayoNo ratings yet

- Improving Biopesticide Performance with Palm Oil SurfactantDocument11 pagesImproving Biopesticide Performance with Palm Oil SurfactantnityaNo ratings yet

- Sustainability 11 03104Document13 pagesSustainability 11 03104Nop PiromNo ratings yet

- A Report On Oil Extraction Process in Local Industry: Sainik Awasiya Mahavidhyala BhaktpurDocument18 pagesA Report On Oil Extraction Process in Local Industry: Sainik Awasiya Mahavidhyala Bhaktpurpokhrelkiran369No ratings yet

- Formulation and Evaluation of Herbal Mosquito Repellent Cream Section A-Research Paper EurDocument9 pagesFormulation and Evaluation of Herbal Mosquito Repellent Cream Section A-Research Paper EurSan Pedro MandanoNo ratings yet

- Journal Pre-Proofs: Food ChemistryDocument16 pagesJournal Pre-Proofs: Food ChemistryYudi SuwandaNo ratings yet

- Extraction of Oil From Wild Walnut and Some Nutritional Characteristics of Nut and Oil of Wild Walnut (JuglansDocument4 pagesExtraction of Oil From Wild Walnut and Some Nutritional Characteristics of Nut and Oil of Wild Walnut (JuglansCtNo ratings yet

- Phenolic compounds and some quality parameters of pumpkin seed oilDocument10 pagesPhenolic compounds and some quality parameters of pumpkin seed oilLarisa CatautaNo ratings yet

- Lemon Grass ArticleDocument17 pagesLemon Grass ArticleSunshine BaclaanNo ratings yet

- Formulation and Evaluation of Herbal Fairness CreaDocument7 pagesFormulation and Evaluation of Herbal Fairness CreashrikantmsdNo ratings yet

- Effects of Adulterated Palm Cooking Oil On The Quality of Fried Chicken NuggetsDocument11 pagesEffects of Adulterated Palm Cooking Oil On The Quality of Fried Chicken NuggetsKiruthick DonNo ratings yet

- Microemulsion of Clove and Peppermint OilsDocument5 pagesMicroemulsion of Clove and Peppermint OilsRenan PioliNo ratings yet

- JFNS2018 PDFDocument7 pagesJFNS2018 PDFZenaw AntenbiyeNo ratings yet

- Environmentally Friendly Products Based On Vegetable OilsDocument158 pagesEnvironmentally Friendly Products Based On Vegetable OilsAndrzej SzymańskiNo ratings yet

- The Use of Gum Arabic and Modified Starch in The Microencapsulation of A Food Flavoring AgentDocument7 pagesThe Use of Gum Arabic and Modified Starch in The Microencapsulation of A Food Flavoring AgentRayito HernándezNo ratings yet

- Fatty Acid Profile, Physico-Chemical and Functional Properties of Oil and Protein Isolate Simultaneously Extracted From Sesame (Sesamum Indicum) SEEDDocument11 pagesFatty Acid Profile, Physico-Chemical and Functional Properties of Oil and Protein Isolate Simultaneously Extracted From Sesame (Sesamum Indicum) SEEDDijana Dencic NalovskaNo ratings yet

- Ekstraksi NsoDocument10 pagesEkstraksi NsoerlanggawidyaputriNo ratings yet

- Studies On Medicinal Plant Resources of The Himalayas: GC-MS Analysis of Seed Fat of Chyuri (DiploknemaDocument3 pagesStudies On Medicinal Plant Resources of The Himalayas: GC-MS Analysis of Seed Fat of Chyuri (DiploknemafurqanNo ratings yet

- Balleza and MadredanoDocument7 pagesBalleza and MadredanoMerelle Paulino MadredanoNo ratings yet

- Watermelon PropertiesDocument9 pagesWatermelon PropertiesLouhana Moreira ReboucasNo ratings yet

- Exerimental Research Sample 1Document14 pagesExerimental Research Sample 1Arc Dela CruzNo ratings yet

- Chingakham B.2014Document4 pagesChingakham B.2014Rosnidar SumardiNo ratings yet

- Development of Mosquito Repellent FormulDocument8 pagesDevelopment of Mosquito Repellent Formulsri wahyuniNo ratings yet

- 12 2015cinamoncremfilledDocument7 pages12 2015cinamoncremfilledAlifia NurtianaNo ratings yet

- Extracción Verde de Aceite Vegetal de Ajonjolí Mediante EnzimasDocument7 pagesExtracción Verde de Aceite Vegetal de Ajonjolí Mediante EnzimasJ LakesNo ratings yet

- Quality of Cold-Pressed Edible Rapeseed Oil in GermanyDocument7 pagesQuality of Cold-Pressed Edible Rapeseed Oil in Germanyelcyionstar100% (1)

- Effect of Hydro Distillation Process On Extraction Time and Oil Recovery at Various Moisture Contents From Mentha LeavesDocument5 pagesEffect of Hydro Distillation Process On Extraction Time and Oil Recovery at Various Moisture Contents From Mentha LeavesinventyNo ratings yet

- 0 Ed 2Document9 pages0 Ed 2Fikka RuhaiyaNo ratings yet

- Solvent Assisted Extraction of Oil From Moringa Oleifera Lam. Seeds PDFDocument7 pagesSolvent Assisted Extraction of Oil From Moringa Oleifera Lam. Seeds PDFjii100% (1)

- Topical Ointment IMRAD ResearchDocument3 pagesTopical Ointment IMRAD ResearchKimberly LopezNo ratings yet

- Kim Ngan 2020Document4 pagesKim Ngan 2020Huy Hoàng Lê ĐứcNo ratings yet

- Formulation and Physical Stability Test of Pomade CONTAIN OLIVE OIL (Olea Europaea)Document12 pagesFormulation and Physical Stability Test of Pomade CONTAIN OLIVE OIL (Olea Europaea)Indra WanNo ratings yet

- RRL CitronellaDocument12 pagesRRL CitronellaJohn ColomaNo ratings yet

- Analysis of The Physical and Chemical Characteristics of Edible Vegetable Blended OilDocument6 pagesAnalysis of The Physical and Chemical Characteristics of Edible Vegetable Blended OilAlvina SuryadinataNo ratings yet

- Fatty Acid Composition and Biological ActivitiesDocument8 pagesFatty Acid Composition and Biological ActivitiesPablo AquinoNo ratings yet

- Cumin Oil Chemistry Project (R, S, J)Document19 pagesCumin Oil Chemistry Project (R, S, J)Piyush PathakNo ratings yet

- Asian Paci Fic Journal of Tropical BiomedicineDocument5 pagesAsian Paci Fic Journal of Tropical BiomedicineLuis Jaime Perez CordobaNo ratings yet

- FahimdaneshDocument6 pagesFahimdaneshAlfred Kouassi KouakouNo ratings yet

- Tetradecanoic Acid (Antioxidant)Document7 pagesTetradecanoic Acid (Antioxidant)permanadion41No ratings yet

- Journal Ekstraksi Super Kritis PDFDocument7 pagesJournal Ekstraksi Super Kritis PDFAfifah S NNo ratings yet

- Herbal antiseptic cream developmentDocument19 pagesHerbal antiseptic cream developmentjesiloretaNo ratings yet

- Physico-Chemical Properties of Oil Extracted From Custard Apple (Annona Squamosha SeedsDocument7 pagesPhysico-Chemical Properties of Oil Extracted From Custard Apple (Annona Squamosha SeedsS Bharadwaj Reddy100% (3)

- Black Cumin Olina No EmulsionDocument9 pagesBlack Cumin Olina No EmulsionAdil PatelNo ratings yet

- Essential Oil Composition of Elettaria Cardamomum MatonDocument4 pagesEssential Oil Composition of Elettaria Cardamomum MatonNanda OktavianiNo ratings yet

- Effect of Using The Combination of Tween 80 and EtDocument5 pagesEffect of Using The Combination of Tween 80 and EtTaurusVõNo ratings yet

- Encapsulation Systems For Antimicrobial Food PackaDocument41 pagesEncapsulation Systems For Antimicrobial Food PackaPaula RoblesNo ratings yet

- Molecules: Encapsulation Systems For Antimicrobial Food Packaging Components: An UpdateDocument40 pagesMolecules: Encapsulation Systems For Antimicrobial Food Packaging Components: An UpdatePaula RoblesNo ratings yet

- Trends in Food Science & Technology: ReviewDocument22 pagesTrends in Food Science & Technology: ReviewPaula RoblesNo ratings yet

- Encapsulation Systems For Antimicrobial Food PackaDocument41 pagesEncapsulation Systems For Antimicrobial Food PackaPaula RoblesNo ratings yet

- Trends in Food Science & Technology: ReviewDocument22 pagesTrends in Food Science & Technology: ReviewPaula RoblesNo ratings yet

- Articles in English A2.3Document7 pagesArticles in English A2.3Paula RoblesNo ratings yet

- Molecules: Encapsulation Systems For Antimicrobial Food Packaging Components: An UpdateDocument40 pagesMolecules: Encapsulation Systems For Antimicrobial Food Packaging Components: An UpdatePaula RoblesNo ratings yet

- P2i3-Edu-Full Paper 14-21 Dr. Meenu Srivastava May-June-2017Document8 pagesP2i3-Edu-Full Paper 14-21 Dr. Meenu Srivastava May-June-2017Paula RoblesNo ratings yet

- Ejercicio Normalización de ColumnasDocument29 pagesEjercicio Normalización de ColumnasPaula RoblesNo ratings yet

- DialogoDocument1 pageDialogoPaula RoblesNo ratings yet

- Vocabulary List - en InglesDocument4 pagesVocabulary List - en InglesJhamir MartellNo ratings yet

- Fourier Transform Infrared Spectroscopy Analysis ODocument10 pagesFourier Transform Infrared Spectroscopy Analysis OPaula RoblesNo ratings yet

- Determinacion de Estabilidad comparacion-liofi-SDDocument12 pagesDeterminacion de Estabilidad comparacion-liofi-SDPaula RoblesNo ratings yet

- Solvent Extraction NoteeDocument13 pagesSolvent Extraction NoteeGandiyaNo ratings yet

- Activated Carbon Removes Silver from Photographic WasteDocument8 pagesActivated Carbon Removes Silver from Photographic Wasteاحمد الدلالNo ratings yet

- BARDAHL Food IndustryDocument4 pagesBARDAHL Food IndustryVaida Man KanNo ratings yet

- A Review On Active Packaging For Quality and Safety of Fo - 2022 - Food PackaginDocument12 pagesA Review On Active Packaging For Quality and Safety of Fo - 2022 - Food Packaginfernanda santosNo ratings yet

- Composite Material Offshore Corrosion SolutionsDocument15 pagesComposite Material Offshore Corrosion SolutionsaruchellamNo ratings yet

- Flush Soffit PanelDocument2 pagesFlush Soffit PanelCathy PrikhodkoNo ratings yet

- Polymer Controlled Drug DeliveryDocument6 pagesPolymer Controlled Drug DeliveryrajadcetNo ratings yet

- EJMCM - Volume 7 - Issue 7 - Pages 3481-349Document11 pagesEJMCM - Volume 7 - Issue 7 - Pages 3481-349Wassim LounissiNo ratings yet

- Pulp Tissue Dissolution in Endodontics-A Review: Subija K Narayanan Kutty, MS Lekshmi, Aparna Mohan E and Lija IsaacDocument4 pagesPulp Tissue Dissolution in Endodontics-A Review: Subija K Narayanan Kutty, MS Lekshmi, Aparna Mohan E and Lija IsaacSarah Ariefah SantriNo ratings yet

- Poly Phenylene Oxide (PPO) : Corporate Training and PlanningDocument27 pagesPoly Phenylene Oxide (PPO) : Corporate Training and PlanningAkash YadavNo ratings yet

- Ferrous Metal Manufacturing ProcessDocument7 pagesFerrous Metal Manufacturing Processsubhashini soundarNo ratings yet

- Lab Report Final 5206Document12 pagesLab Report Final 5206Tanvir AhamedNo ratings yet

- Engineering Chemistry 2019 Scheme SyllabusDocument9 pagesEngineering Chemistry 2019 Scheme SyllabusAfsal Sha MNo ratings yet

- Sylobloc Silica Anti-Blocking Additives: Product Portfolio & Selection GuideDocument4 pagesSylobloc Silica Anti-Blocking Additives: Product Portfolio & Selection Guide360907219No ratings yet

- Tds 1000 PPM COADocument1 pageTds 1000 PPM COAtechNo ratings yet

- Material Safety Data SheetDocument5 pagesMaterial Safety Data SheetFiqua Nurul Rafiqua SimsNo ratings yet

- Single Cell Gel Electrophoresis (Comet) AssayDocument5 pagesSingle Cell Gel Electrophoresis (Comet) AssayCoțovanu IulianNo ratings yet

- Hydrogen: 2. Spin Isomers of H MoleculeDocument11 pagesHydrogen: 2. Spin Isomers of H MoleculeNehal GautamNo ratings yet

- MicroSol - 685 Technical Data.Document2 pagesMicroSol - 685 Technical Data.Saulo TrejoNo ratings yet

- Prevention of Enzymatic Browning in Fruit and Vegetables: Irina Ioannou Mohamed GhoulDocument32 pagesPrevention of Enzymatic Browning in Fruit and Vegetables: Irina Ioannou Mohamed GhoulMyka ZoldyckNo ratings yet

- R11 MTSR Mar 2019Document42 pagesR11 MTSR Mar 2019Jaypee DebandinaNo ratings yet

- 15Document5 pages15gakocherNo ratings yet

- NACE MR 0175/ISO 15156 Corrosion AlloysDocument1 pageNACE MR 0175/ISO 15156 Corrosion Alloysnhirpara1100% (1)

- Plastic Fuel Alka ZadgaonkarDocument60 pagesPlastic Fuel Alka Zadgaonkarprashanth2812No ratings yet

- SC22b Reactions of Alkanes and AlkenesDocument14 pagesSC22b Reactions of Alkanes and AlkenesEmaadB EmaadBNo ratings yet

- Inorganic ChemistryDocument36 pagesInorganic ChemistryNada MerzougNo ratings yet

- Properties of Biobased Epoxy Resins From Epoxidized Soybean OilDocument9 pagesProperties of Biobased Epoxy Resins From Epoxidized Soybean OildivyaNo ratings yet

- ID Perbedaan Efektivitas Zeolit Dan ManganeDocument9 pagesID Perbedaan Efektivitas Zeolit Dan Manganefirman maulanaNo ratings yet

- Pharmaceutical Water RequirementsDocument8 pagesPharmaceutical Water RequirementsRambabu komati - QA100% (1)

- CocreteDocument62 pagesCocretesandhya rani bindhaniNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Process Plant Equipment: Operation, Control, and ReliabilityFrom EverandProcess Plant Equipment: Operation, Control, and ReliabilityRating: 5 out of 5 stars5/5 (1)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Physical and Chemical Equilibrium for Chemical EngineersFrom EverandPhysical and Chemical Equilibrium for Chemical EngineersRating: 5 out of 5 stars5/5 (1)

- The Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookFrom EverandThe Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookNo ratings yet

- The Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookFrom EverandThe Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookNo ratings yet

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- The HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesFrom EverandThe HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesNo ratings yet

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationFrom EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNo ratings yet

- An Applied Guide to Water and Effluent Treatment Plant DesignFrom EverandAn Applied Guide to Water and Effluent Treatment Plant DesignRating: 5 out of 5 stars5/5 (4)

- Guidelines for Engineering Design for Process SafetyFrom EverandGuidelines for Engineering Design for Process SafetyNo ratings yet

- Guidelines for the Management of Change for Process SafetyFrom EverandGuidelines for the Management of Change for Process SafetyNo ratings yet

- Operational Excellence: Journey to Creating Sustainable ValueFrom EverandOperational Excellence: Journey to Creating Sustainable ValueNo ratings yet

- Chemical Process Safety: Learning from Case HistoriesFrom EverandChemical Process Safety: Learning from Case HistoriesRating: 4 out of 5 stars4/5 (14)

- Pharmaceutical Blending and MixingFrom EverandPharmaceutical Blending and MixingP. J. CullenRating: 5 out of 5 stars5/5 (1)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Pharmaceutical Excipients: Properties, Functionality, and Applications in Research and IndustryFrom EverandPharmaceutical Excipients: Properties, Functionality, and Applications in Research and IndustryOtilia M. Y. KooNo ratings yet

- Understanding Process Equipment for Operators and EngineersFrom EverandUnderstanding Process Equipment for Operators and EngineersRating: 4.5 out of 5 stars4.5/5 (3)

- Major Accidents to the Environment: A Practical Guide to the Seveso II-Directive and COMAH RegulationsFrom EverandMajor Accidents to the Environment: A Practical Guide to the Seveso II-Directive and COMAH RegulationsNo ratings yet