Professional Documents

Culture Documents

6A) Oil Filler Cap

6A) Oil Filler Cap

Uploaded by

Sonthi MooljindaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

6A) Oil Filler Cap

6A) Oil Filler Cap

Uploaded by

Sonthi MooljindaCopyright:

Available Formats

MISCELLANEOUS ITEMS

SCREW SECURED ENGINE OIL FILLER CAP

DESCRIPTION

As an added safety feature, the standard engine oil filler cap has been replaced by a screw

secured oil filler cap.

INSTALLATION

There are two different types of screw secured engine oil filler cap assembly.

The filler cap body of type ‘A’ is secured to the engine oil filler inlet using ‘Loctite’. Remove the

existing filler cap but retain the drain. Ensure that the non-threaded section of the filler cap body

is secured into the engine oil filler to a depth of between 35mm and 40mm with the threaded

section protruding upwards.

Gasket

Filler Cap Body

Cap

Type ‘A’

The filler cap body of type ‘B’ is secured to the engine valve cover using a locking nut and gasket.

Remove the valve cover from the engine. Place the gasket over the filler cap body, then push the

threaded section of the body through the underside of the engine valve cover. Secure the filler

cap body to the engine valve cover using the locking nut supplied and secure using ‘Loctite’.

Locking Nut

Gasket

Type ‘B’

For each type of filler cap assembly, push the gasket into the filler cap and screw the cap onto the

filler cap body.

MAINTENANCE

When assembling or reassembling ensure that the threads are clean and undamaged.

Where gaskets are fitted, these must always be replaced and not reused.

Copyright 2003 Issue 1

Pyroban Ltd, Endeavour Works, Dolphin Rd, Shoreham-by-Sea

West Sussex. BN43 6QG. United Kingdom.

Tel: +44(0) 1273 466200

You might also like

- 2001 FORD EXPLORER Service Repair Manual PDFDocument62 pages2001 FORD EXPLORER Service Repair Manual PDFdfjjskemmdm67% (3)

- Cylinder Head Gasket - Installation (01 - 2010 - ) (Cylinder Head Assembly) - ALLDATA Repair Toyota Camry 2.5LtsDocument17 pagesCylinder Head Gasket - Installation (01 - 2010 - ) (Cylinder Head Assembly) - ALLDATA Repair Toyota Camry 2.5LtsFran SanchezNo ratings yet

- EVK Seal ManualDocument18 pagesEVK Seal Manualgelo_17100% (1)

- HR Blowers Uk LTD: Installation & Operating ManualDocument20 pagesHR Blowers Uk LTD: Installation & Operating ManualAditya ShrivastavaNo ratings yet

- Key Points about Assembling or Di bli WD615 Di lE i Disassembling WD615 Diesel Engines 培训资料 培训资料 Training MaterialDocument36 pagesKey Points about Assembling or Di bli WD615 Di lE i Disassembling WD615 Diesel Engines 培训资料 培训资料 Training MaterialGino Biggio VNo ratings yet

- Key Points about Assembling or Disassembling WP6 Diesel Engines 培训资料 Training Material 国际配套服务部 徐衍国Document27 pagesKey Points about Assembling or Disassembling WP6 Diesel Engines 培训资料 Training Material 国际配套服务部 徐衍国Manutenção Base AnápolisNo ratings yet

- Trailer Buddy VaultDocument10 pagesTrailer Buddy VaultjeffNo ratings yet

- Mechanical Seal IOMDocument2 pagesMechanical Seal IOMEduardo SolisNo ratings yet

- 2531Document5 pages2531sangkil05No ratings yet

- The Key Process of Disassembling and Assembling WP12 Diesel EngineDocument40 pagesThe Key Process of Disassembling and Assembling WP12 Diesel EnginePaul100% (1)

- InstallationDocument2 pagesInstallationADNo ratings yet

- A Part 91Document1 pageA Part 91korogeokoroNo ratings yet

- Model Vff30 Repair Kit Installation Instructions: Suitable Fuel-Resistant Joint CompoundDocument8 pagesModel Vff30 Repair Kit Installation Instructions: Suitable Fuel-Resistant Joint CompoundmoviteknikaNo ratings yet

- T56 Mods For Speedo Cable 1997UPT56Document10 pagesT56 Mods For Speedo Cable 1997UPT56rhondafosNo ratings yet

- Installation Instructions: BW Seals Q, QB SeriesDocument8 pagesInstallation Instructions: BW Seals Q, QB SeriesJoseGarciaRNo ratings yet

- Como Instalar Sellos Cat 2Document2 pagesComo Instalar Sellos Cat 2jhonNo ratings yet

- ARB BP-51 RearDocument6 pagesARB BP-51 RearDaniel EcheverriaNo ratings yet

- Injectors STCDocument7 pagesInjectors STCLionnel ParantNo ratings yet

- Weichai Engine PrintDocument52 pagesWeichai Engine PrintKo ZayNo ratings yet

- Catalogo RHPDocument83 pagesCatalogo RHPLuisNovoaRivera100% (1)

- Flowserve Pusher Seal ManualDocument16 pagesFlowserve Pusher Seal ManualNikhil Princeton AndradeNo ratings yet

- 05 1964 CH-Rear AxleDocument3 pages05 1964 CH-Rear AxleJose LaproviteraNo ratings yet

- 6991 1252 01 - 1 - Gas SpringDocument18 pages6991 1252 01 - 1 - Gas SpringRaiza GabrielaNo ratings yet

- G.V. Manual (FC Type)Document20 pagesG.V. Manual (FC Type)sambhajiNo ratings yet

- Armado de Cabeza HiluxDocument5 pagesArmado de Cabeza HiluxOscar CAPSSANo ratings yet

- TimkenTT en Vol1 Iss3Document2 pagesTimkenTT en Vol1 Iss3grupa2904No ratings yet

- Manual EVK SealDocument18 pagesManual EVK Sealpanamajack26No ratings yet

- 001-054 Piston and Connecting Rod AssemblyDocument8 pages001-054 Piston and Connecting Rod AssemblyYè WințNo ratings yet

- SECTION 4.05: Cylinder Head AssemblyDocument8 pagesSECTION 4.05: Cylinder Head AssemblyLUISA FERNANDA TORRES MANOSALVANo ratings yet

- Procedimiento de Instalacion de La Culata Toyota 3sz-Ve PDFDocument12 pagesProcedimiento de Instalacion de La Culata Toyota 3sz-Ve PDFirvan hardiansyahNo ratings yet

- PDFDocument10 pagesPDFPaul HuaraychiriNo ratings yet

- Accumulator Piston Kit: Mitsubishi F4A, F5A & Hyundai/Kia A5HF1, A5GF1Document1 pageAccumulator Piston Kit: Mitsubishi F4A, F5A & Hyundai/Kia A5HF1, A5GF1ossoskiNo ratings yet

- AT Teansmisison JoycoDocument22 pagesAT Teansmisison JoycoAlliNo ratings yet

- Transfer CaseDocument6 pagesTransfer CaseTim SmithNo ratings yet

- Reverb Stealth Height Adjust Seatpost User ManualDocument128 pagesReverb Stealth Height Adjust Seatpost User ManualjackNo ratings yet

- Important!Document1 pageImportant!geronimojuarez179No ratings yet

- Casing Packer Setting Tool (SLB)Document12 pagesCasing Packer Setting Tool (SLB)Alexander KlmNo ratings yet

- WheelHorse Snow Thrower Completing Package Manual 6-9111Document4 pagesWheelHorse Snow Thrower Completing Package Manual 6-9111Kevins Small Engine and Tractor ServiceNo ratings yet

- B-02 Mechnical Seal For SBPO LubeDocument8 pagesB-02 Mechnical Seal For SBPO LubeMarvin DuarteNo ratings yet

- MAN B & W 35-98 MC Service LetterDocument22 pagesMAN B & W 35-98 MC Service LetterArun TiwariNo ratings yet

- Section H: 16SGTD Gas Engine Instruction ManualDocument3 pagesSection H: 16SGTD Gas Engine Instruction ManualJaadi 786No ratings yet

- BMW N54 Chargepipe Blow Off Valve Installation InstructionsDocument34 pagesBMW N54 Chargepipe Blow Off Valve Installation Instructionsabdull rehmanNo ratings yet

- HDBIDocument5 pagesHDBIkevlar315No ratings yet

- Free HubDocument4 pagesFree HubDony WinarnoNo ratings yet

- Catalogo de Servicos I Td226b Eng Rev1 2011Document26 pagesCatalogo de Servicos I Td226b Eng Rev1 2011AndreyIvanov100% (2)

- Fitting Fitting The Camshaft From The Front On 9, 11, 12 and 13 Litre Engines With PDE, HPI, XPI or GASDocument1 pageFitting Fitting The Camshaft From The Front On 9, 11, 12 and 13 Litre Engines With PDE, HPI, XPI or GASgeronimojuarez179No ratings yet

- Kawasaki Staffa Radial Hydraulic Motors 41 62Document22 pagesKawasaki Staffa Radial Hydraulic Motors 41 62Samuel Lopez BenitesNo ratings yet

- TT00041 - Injector Sleeve Installation On 2008 - 2017 Detroit DieselDocument2 pagesTT00041 - Injector Sleeve Installation On 2008 - 2017 Detroit DieselIonut-alexandru Iordache100% (1)

- 21 enDocument7 pages21 enJ Matthew LemieuxNo ratings yet

- 3A Tumbler InstructionsDocument8 pages3A Tumbler InstructionsNumismática Oliveira100% (1)

- CTJ2500QLG Trolley Jack - 020112802 PDFDocument12 pagesCTJ2500QLG Trolley Jack - 020112802 PDFAlain DefoeNo ratings yet

- Mounting Instructions: Cartridge Kit For Kawasaki Ninja 250R Ninja 300Document8 pagesMounting Instructions: Cartridge Kit For Kawasaki Ninja 250R Ninja 300Ivan TlNo ratings yet

- Spherical Pillow Block Manual (MN3085, 2018)Document13 pagesSpherical Pillow Block Manual (MN3085, 2018)Dillon BuyeNo ratings yet

- Combination Bearing Installation ProcedureDocument1 pageCombination Bearing Installation ProcedureFrancisNo ratings yet

- 2007 Kobelco Stern Tube Seal Installation ManualDocument18 pages2007 Kobelco Stern Tube Seal Installation Manualvjmariner100% (1)

- VW Eos Rear Brake CaliperDocument8 pagesVW Eos Rear Brake CaliperNick PNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Pitman's Motorists Library - The Book of the Austin Ten - A Fully Illustrated Instruction Book for All Owners of Models from 1932 to 1939From EverandPitman's Motorists Library - The Book of the Austin Ten - A Fully Illustrated Instruction Book for All Owners of Models from 1932 to 1939No ratings yet

- Lecture 10 - Ex NDocument11 pagesLecture 10 - Ex NMohamed HamedNo ratings yet

- Glanding: Glands Must Maintain Integrity of EnclosureDocument11 pagesGlanding: Glands Must Maintain Integrity of EnclosureMohamed HamedNo ratings yet

- Principles of Intrinsic SafetyDocument14 pagesPrinciples of Intrinsic SafetyMohamed HamedNo ratings yet

- Lecture 09 - Ex PDocument8 pagesLecture 09 - Ex PMohamed HamedNo ratings yet

- Pre - Run Check ListDocument2 pagesPre - Run Check ListMohamed HamedNo ratings yet

- Hazard Identification Prompt CDocument2 pagesHazard Identification Prompt CMohamed HamedNo ratings yet

- Apsey Application Form en r10 0Document3 pagesApsey Application Form en r10 0Mohamed HamedNo ratings yet

- 2D) SVG Inlet Valve SVG-12, SVG-9.5, SVG-4Document4 pages2D) SVG Inlet Valve SVG-12, SVG-9.5, SVG-4Mohamed HamedNo ratings yet

- 2I) ServicingDocument1 page2I) ServicingMohamed HamedNo ratings yet

- Cooling Circuit Installation and MaintenanceDocument1 pageCooling Circuit Installation and MaintenanceMohamed HamedNo ratings yet

- 2B) Inlet Air Shut-Off ValveDocument2 pages2B) Inlet Air Shut-Off ValveMohamed HamedNo ratings yet

- 2G) SVF Inlet Oil ValveDocument1 page2G) SVF Inlet Oil ValveMohamed HamedNo ratings yet

- Cleaning Stove TopDocument2 pagesCleaning Stove TopMohamed HamedNo ratings yet

- K06952 BomDocument2 pagesK06952 BomMohamed HamedNo ratings yet

- Heat Rejection and Coolant NotesDocument10 pagesHeat Rejection and Coolant NotesMohamed HamedNo ratings yet

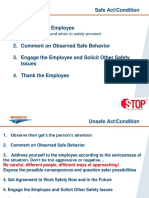

- Observe The Employee: Safe Act/ConditionDocument3 pagesObserve The Employee: Safe Act/ConditionMohamed HamedNo ratings yet

- Cleaning Hot FryerDocument18 pagesCleaning Hot FryerMohamed HamedNo ratings yet

- Ensco Ds-6 Work InstructionsDocument2 pagesEnsco Ds-6 Work InstructionsMohamed HamedNo ratings yet