Professional Documents

Culture Documents

Training: Regulator B Regulator B Regulator A Regulator A

Training: Regulator B Regulator B Regulator A Regulator A

Uploaded by

VICTOR BEMENGUEOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Training: Regulator B Regulator B Regulator A Regulator A

Training: Regulator B Regulator B Regulator A Regulator A

Uploaded by

VICTOR BEMENGUECopyright:

Available Formats

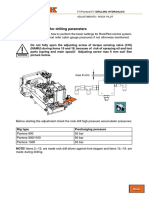

T/T/Pantera/T/7 DRILLING HYDRAULICS

training ADJUSTMENTS / VARIABLE DISPLACEMENT PUMP (1)

Regulator A Regulator B

Regulator B

Regulator A

Pump 50 Pump 1

1. Remove the caps from the flow regulator (A) and the pressure regulator (B) and open their

locking nuts.

2. Turn the pressure regulator (B) screw almost completely open (counterclockwise).

3. Turn the flow regulator (A) screw fully closed (clockwise). The pump operates now as a

constant pressure pump.

4. Connect a pressure gauge to the pressure measuring point M1 of the drilling control block.

5. Start the diesel engine and set it to full speed (2100 rpm).

6. Turn the pressure regulator (B) screw clockwise until the pressure reading at M1 is 250

bar.

7. Lock the pressure regulator (B) setting with the locking nut.

8. Turn the flow regulator (A) screw fully open (ccw).

9. Allow the pressure to settle. Adjust the stand–by pressure to 25 bar by turning the flow

regulator (A) screw clockwise. Read the pressure in the pressure gauge in M1.

10. Lock the setting of the flow regulator (A) with the locking nut.

11. Stop the diesel engine and allow the pressure reading at M1 to drop to 0 bar.

12. Restart the diesel engine and check that the pressure reading at M1 is 25 bar. If neces-

sary, readjust stand–by pressure. Stop the diesel engine.

13. Place back the caps of the flow regulator (A) and the pressure regulator (B).

14. Remove the pressure gauge in the measuring point M1.

NOTE! The reading 25 bar is stand–by pressure, which exists in the pump’s pres-

sure line when the pump output is minimum.

You might also like

- SE9105 - Hydraulic Pump, Standby Pressure, Checking and AdjustingDocument4 pagesSE9105 - Hydraulic Pump, Standby Pressure, Checking and AdjustingBrando ImanuelNo ratings yet

- Breaker Piping InstallationDocument11 pagesBreaker Piping InstallationZawminhtunNo ratings yet

- Adjusting The Hydraulic PumpDocument6 pagesAdjusting The Hydraulic PumpSugeng Ciko Darminto90% (10)

- Presure Limiting Load Sensing Compensator Pvb5 Thru Pvb29Document2 pagesPresure Limiting Load Sensing Compensator Pvb5 Thru Pvb29loloeasNo ratings yet

- Rtaa SB 4 - 10011991Document6 pagesRtaa SB 4 - 10011991alcomech100% (3)

- 320B Excavator Hydraulic SystemDocument4 pages320B Excavator Hydraulic Systemjohn ayengah100% (2)

- Introduction To PneumaticsDocument12 pagesIntroduction To PneumaticsANAND PANDEYNo ratings yet

- Relief Valve (Line) - Test and Adjust - Boom Lowering Control ValveDocument9 pagesRelief Valve (Line) - Test and Adjust - Boom Lowering Control ValveR I Santoso100% (1)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Wartsila Fuel Pump - MaintenanceDocument15 pagesWartsila Fuel Pump - MaintenanceAbhishek Singh Chauhan0% (1)

- Adjust Stand by PressDocument5 pagesAdjust Stand by PressKatarina KananiNo ratings yet

- Adjust Stand by PressDocument5 pagesAdjust Stand by PressKatarina KananiNo ratings yet

- Excavadora Hidraulica 345b (Relief Valve Pruebas - y - Ajustes)Document17 pagesExcavadora Hidraulica 345b (Relief Valve Pruebas - y - Ajustes)Maquinaria Pesada ServisNo ratings yet

- Relief Valve (Pilot) - Test and AdjustDocument2 pagesRelief Valve (Pilot) - Test and Adjustmekanicobucaro100% (1)

- Cargador 920 & 930 Sistema HidraulicoDocument19 pagesCargador 920 & 930 Sistema Hidraulicojulio100% (1)

- Power Ladder of Komatsu HD 785-7 (30001-UP)Document8 pagesPower Ladder of Komatsu HD 785-7 (30001-UP)gire_3pich2005No ratings yet

- Relief Valve (Main) - Test and Adjust - Heavy Lift: 320D Excavator Hydraulic SystemDocument6 pagesRelief Valve (Main) - Test and Adjust - Heavy Lift: 320D Excavator Hydraulic SystemKJDNKJZEFNo ratings yet

- TLB890 Hydraulic Pressure Testing PDFDocument13 pagesTLB890 Hydraulic Pressure Testing PDFjwd50% (2)

- 150C VOLVO Steering.&.Hydraulic DiagramDocument5 pages150C VOLVO Steering.&.Hydraulic Diagramgabriel pomaNo ratings yet

- Data and Specifications: HMR Regulated MotorsDocument21 pagesData and Specifications: HMR Regulated MotorsBeniamin KowollNo ratings yet

- 5220 Carrier Pressure AdjustementDocument13 pages5220 Carrier Pressure AdjustementSarra ChoucheneNo ratings yet

- Valvula Placa RexrothDocument36 pagesValvula Placa RexrothRafael Koppe100% (2)

- Adjust Stand by PressDocument5 pagesAdjust Stand by PressKatarina KananiNo ratings yet

- Setting The HYDRAULIC VALVE BANKDocument6 pagesSetting The HYDRAULIC VALVE BANKAlex RamirezNo ratings yet

- Adjust Stand by PressDocument5 pagesAdjust Stand by PressKatarina KananiNo ratings yet

- 320B Caterpillar, Testing in Adjusting Relief LineDocument8 pages320B Caterpillar, Testing in Adjusting Relief LineLuisNo ratings yet

- Automation LabDocument53 pagesAutomation LabMadhusudan BenzNo ratings yet

- 09GMK 6250 - Hydraulikanlage - EnglDocument8 pages09GMK 6250 - Hydraulikanlage - EnglВиталий РогожинскийNo ratings yet

- Hydrostatic Pump - 15HPDocument14 pagesHydrostatic Pump - 15HPMicheal Booka WhelanNo ratings yet

- Setting The Hydraulic Block ManifoldDocument6 pagesSetting The Hydraulic Block ManifoldJuan Pablo Villazon RichterNo ratings yet

- Kaltfrase - BM - 1000 - 1200 - 1300 - 30 - 2 - & - 2 - PB - BK HidraulicoDocument249 pagesKaltfrase - BM - 1000 - 1200 - 1300 - 30 - 2 - & - 2 - PB - BK Hidraulicosebastian blancoNo ratings yet

- Eaton: Pressure or Pressure-Flow Compensator Control Adjustment ProceduresDocument4 pagesEaton: Pressure or Pressure-Flow Compensator Control Adjustment ProceduresFernando SabinoNo ratings yet

- 4.oil Hydraulic Circuit Trainer KitDocument13 pages4.oil Hydraulic Circuit Trainer KitAlmas 1710No ratings yet

- SteeringDocument7 pagesSteeringyeremia kristianNo ratings yet

- Hydronic 300 Valve Setting Instructions - M04002enDocument14 pagesHydronic 300 Valve Setting Instructions - M04002enbdgnsNo ratings yet

- Hoist System Cat 777, 785, 789dDocument52 pagesHoist System Cat 777, 785, 789dHardani OutSiders100% (1)

- Armstrong Installation, Start-Up and Operating Instructions Armstrong Differential Condensate ControllerDocument4 pagesArmstrong Installation, Start-Up and Operating Instructions Armstrong Differential Condensate ControllerWalid SaifNo ratings yet

- Chapt 2 PumpsDocument6 pagesChapt 2 PumpsManuelNo ratings yet

- Hydraulic Pump, Standby Pressure, Checking and AdjustingDocument6 pagesHydraulic Pump, Standby Pressure, Checking and Adjustingalikuncoro1005No ratings yet

- ClutchDocument6 pagesClutchAlex CastilloNo ratings yet

- TransmisionDocument6 pagesTransmisionronal79No ratings yet

- CHP 3& 6 Ihp MsdteDocument10 pagesCHP 3& 6 Ihp MsdteRocky JNo ratings yet

- Wastegate Valve, Adjusting Special ToolsDocument4 pagesWastegate Valve, Adjusting Special ToolsInternal88No ratings yet

- Testing and Adjusting PRESION MARGINAL DE DIRECCIONDocument5 pagesTesting and Adjusting PRESION MARGINAL DE DIRECCIONEver MendozaNo ratings yet

- Cylinder Head: Section 12 - Base EngineDocument1 pageCylinder Head: Section 12 - Base EngineAli ZerifiNo ratings yet

- Relief Valve (Crossover) - Test and AdjustDocument7 pagesRelief Valve (Crossover) - Test and AdjustDANIEL VARGAS RODRIGUEZNo ratings yet

- Type Lrv2 Im p001 08 Us - AshxDocument4 pagesType Lrv2 Im p001 08 Us - AshxMUHAMMAD AIMAN BIN MOHD YUSOFNo ratings yet

- Training: Pressure Settings of Anti - JammingDocument2 pagesTraining: Pressure Settings of Anti - JammingAlexis Leonardo Vega ReyesNo ratings yet

- AMEE310 Lab3Document15 pagesAMEE310 Lab3Ya HooNo ratings yet

- SteeringDocument30 pagesSteeringanisa yuliaNo ratings yet

- 1.1.1 Functions of Flow-Control ValvesDocument24 pages1.1.1 Functions of Flow-Control Valvesatashi baran mohantyNo ratings yet

- Rexroth Ra64960 - 2005-01Document20 pagesRexroth Ra64960 - 2005-01JustinNo ratings yet

- Pressure Build Up - SteeringDocument3 pagesPressure Build Up - Steeringwidanto0apriawanNo ratings yet

- Parker Wheel Turn Hydraulic SystemDocument12 pagesParker Wheel Turn Hydraulic SystemEdward Erney Salas ValenzuelaNo ratings yet

- Relief Valve (Line) - Test and Adjust: Pruebas y AjustesDocument8 pagesRelief Valve (Line) - Test and Adjust: Pruebas y AjustesRonaldo GaleanoNo ratings yet

- Service Manual: Back To Section Table of ContentsDocument29 pagesService Manual: Back To Section Table of ContentsasalinaspadillaNo ratings yet

- Relief Valve (Main) - Test and Adjust - Heavy Lift: Pruebas y AjustesDocument5 pagesRelief Valve (Main) - Test and Adjust - Heavy Lift: Pruebas y AjustesCristian LuqueNo ratings yet

- 28260-RPC-004 UsageDocument8 pages28260-RPC-004 Usagedouglas camposNo ratings yet

- Embrayade de Volant MoteurDocument8 pagesEmbrayade de Volant MoteurVICTOR BEMENGUENo ratings yet

- Remove Steering Clutch Hydraulic Control Valve: SENR70110019Document4 pagesRemove Steering Clutch Hydraulic Control Valve: SENR70110019VICTOR BEMENGUENo ratings yet

- Remove Torque Converter Outlet Relief Valve (Power Shift) : SENR70110033Document3 pagesRemove Torque Converter Outlet Relief Valve (Power Shift) : SENR70110033VICTOR BEMENGUENo ratings yet

- Training: T/T/Pan Tera/T/7 Drilling Hydraulics ComponentsDocument12 pagesTraining: T/T/Pan Tera/T/7 Drilling Hydraulics ComponentsVICTOR BEMENGUENo ratings yet

- Drilling JoystickDocument1 pageDrilling JoystickVICTOR BEMENGUENo ratings yet

- Demontage Moyeu Embrayages de Direction D8KDocument3 pagesDemontage Moyeu Embrayages de Direction D8KVICTOR BEMENGUENo ratings yet

- Démontage Pompe Commandes FinalesDocument3 pagesDémontage Pompe Commandes FinalesVICTOR BEMENGUENo ratings yet

- Training: T/T/Pantera/T/7 Drilling Hydraulics Adjustments / Fast Forward Feed Maximum Pressure ValveDocument1 pageTraining: T/T/Pantera/T/7 Drilling Hydraulics Adjustments / Fast Forward Feed Maximum Pressure ValveVICTOR BEMENGUENo ratings yet

- Pantera Selectorvalve 4-5-32Document1 pagePantera Selectorvalve 4-5-32VICTOR BEMENGUENo ratings yet

- Adj Valve 61Document1 pageAdj Valve 61VICTOR BEMENGUENo ratings yet

- Training: (4) Percussion Selector Valve (5) 1/2 Power Selector Valve (32) Tank Line Selector ValveDocument1 pageTraining: (4) Percussion Selector Valve (5) 1/2 Power Selector Valve (32) Tank Line Selector ValveVICTOR BEMENGUENo ratings yet

- Training: Threading Feed Speed (94) Threading Rotation SpeedDocument1 pageTraining: Threading Feed Speed (94) Threading Rotation SpeedVICTOR BEMENGUENo ratings yet

- Training: T/T/Pantera/T/7 Drilling Hydraulics Adjustments / Fast Feed Max. SpeedDocument1 pageTraining: T/T/Pantera/T/7 Drilling Hydraulics Adjustments / Fast Feed Max. SpeedVICTOR BEMENGUENo ratings yet

- Training: Selector Valve (81) Pressure Relief Valve (84) Check ValveDocument1 pageTraining: Selector Valve (81) Pressure Relief Valve (84) Check ValveVICTOR BEMENGUENo ratings yet

- Training: 1.1. Basic Settings For Drilling ParametersDocument8 pagesTraining: 1.1. Basic Settings For Drilling ParametersVICTOR BEMENGUENo ratings yet

- Training: Anti-Jamming ValveDocument1 pageTraining: Anti-Jamming ValveVICTOR BEMENGUENo ratings yet

- Training: T2 X6 X4 X5 X8Document1 pageTraining: T2 X6 X4 X5 X8VICTOR BEMENGUENo ratings yet

- Training: Feed Pressure Fine Tuning ValveDocument1 pageTraining: Feed Pressure Fine Tuning ValveVICTOR BEMENGUENo ratings yet

- Breakers: Make An ImpactDocument10 pagesBreakers: Make An ImpactVICTOR BEMENGUENo ratings yet