Professional Documents

Culture Documents

Pump inspection report details issues

Uploaded by

Marine CaptainOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pump inspection report details issues

Uploaded by

Marine CaptainCopyright:

Available Formats

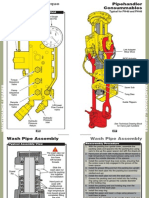

Service Department

Pump Inspection Report

Date Job No Service Engineer Customer Rig Name

06/08/13 317016 Gerry Thompson Transocean Deepwater

Millennium

Equipment Type Equipment S/N

14-P-220 Mud Pump 4 10930-H

I

H

G F

CONDTION

1 : AS NEW

2 : GOOD

3 : FAIR - Monitor

4 : POOR - Schedule replacement

5 : Urgent Replacement required

ACDEB

All dimensions in inches and from power end

Item Component Checks carried out Condition - Comments

A LH Main bearing Bearing 0.004” As new – Ok till next inspection

clearance

B RH Main bearing Bearing 0.006” As new – Ok till next inspection

clearance

C LH Eccentric Bearing Bearing 0.005” As new – Ok till next inspection

clearance

D CTR Eccentric Bearing Bearing 0.004” As new – Ok till next inspection

clearance

E RH Eccentric Bearing Bearing 0.002” As new – Ok till next inspection

clearance

F Bull gear Backlash LHS:- 0.031” Good, Minor pitting and scoring

RHS:-0.034” found on teeth- Ok till next

inspection

Run-Out 0.006” Good - Ok till next inspection

G Pinion Gear End Float 0.080” Good, Minor pitting and scoring

found on teeth-Ok till next

inspection

H LH Pinion Bearing Bearing 0.004” As new – Ok till next inspection

clearance

I RH Pinion Bearing Bearing 0.006” As new – Ok till next inspection

clearance

Crosshead bearing Clearance Recorded Condition & Recommendation

Left 0.004” As new – Ok till next inspection

Centre 0.002” As new – Ok till next inspection

Right. 0.004” As new – Ok till next inspection

Service Department

Pump Inspection Report

Crosshead clearances with rods and clamps connected

CROSSHEAD POSITIONED @ FLUID END

Clearance at fluid end Clearance at gear end Clearance under crosshead

LEFT 0.027” 0.015” 0.027”

CENTRE 0.031” 0.027” 0.003” for 12”

RIGHT 0.015” 0.019” 0.004”

CROSSHEAD POSITIONED @ GEAR END

Clearance at fluid end Clearance at gear end Clearance under crosshead

LEFT 0.025” 0.012” 0.025”

CENTRE 0.030” 0.025” 0.003 for 12”

RIGHT 0.016” 0.029” 0.003” for 6”

Crosshead clearances with rods and clamps disconnected

CROSSHEAD POSITIONED @ FLUID END

Clearance at fluid end Clearance at gear end Clearance under crosshead

LEFT 0.035” 0.033” 0.000”

CENTRE 0.034” 0.030” 0.003” for 6”

RIGHT 0.020” 0.022” 0.000"

CROSSHEAD POSITIONED @ GEAR END

Clearance at fluid end Clearance at gear end Clearance under crosshead

LEFT 0.033” 0.027” 0.006” for 12”

CENTRE 0.027” 0.027” 0.004” for 12”

RIGHT 0.020” 0.020” 0.000”

Comments/ Light scoring noted on RHS crosshead lower guide. CTR guides are good. LHS lower guide

Recommendations has light scoring across surface but one large score across 2/3 from front to back.

Difference between clearances under crosshead when rods connected and disconnected

indicate alignment problems.

Clearances under crosshead when rods disconnected indicate profile problem with crosshead

or guide or both.

INTERMEDIATE ROD RUNOUTS

WITHOUT PUMP RODS NOT INSTALLED

CONDITION/COMMENTS VERTICAL HORIZONTAL

Large run out concurrent with issues

found on clearances with crosshead.

LEFT Recommend crosshead and guides 0.017” 0.016”

are changed and shimmed where

required.

CENTRE Good 0.007” 0.007”

RIGHT Good 0.002” 0.001”

WITH PUMP RODS NOT INSTALLED

CONDITION/COMMENTS VERTICAL HORIZONTAL

Fair, large vertical should be address

LEFT 0.010” 0.001”

when guide is changed

CENTRE Good 0.000” 0.006”

RIGHT Good 0.005” 0.003”

Comments:

Service Department

Pump Inspection Report

Visual Condition (Maintenance, Oil Leaks):-

LHS Pinion -Oil residue found on underside of bearing retainer plate indicating possible worn pinion seal and shaft.

Recommend repair iaw NOV PIB 03-03-01 MP utilising and wear sleeve and new seal.

Secondary Retention:- All secondary retention in place

Magnets (Cleanliness):- All magnets cleaned

Oil pipes and troughs: - Internal oil troughs and pipework all secure and in good order, all troughs cleaned and main brg

oil pipes cleaned.

Motors & Blowers (Operation, Security):- Both motors and blowers secure and in good order.

Belts & Sheaves (Condition, Tension, Alignment):- Alignment and tension not carry out, Mechanics recently changed

belts and used NOV tensioner to tighten belts

NDT: - MPI and eddy current carried out, no issues found.

Breather condition: - Good

Intermediate rods shouldered properly: - Yes

Oil shields in place: - LHS Oil shield broken, no replacements onboard. Rig welder is attempting to repair.

Wiper seals condition: - Good condition and greased

Liner Spray Condition and cleanliness: - Good

Rod clamps:- Good gap found between clamp faces and correct torque used to clamp bolts

Recommendations:

1. Replace LHS pinion seal due to oil leak. Advise doing RHS at the same time as the running hours will be the same for

both.

2. Change out LHS and CTR crosshead and lower guides due to incorrect profile to eliminate gap underneath crosshead.

3. Carry out fluid end alignment checks to correctly shim crosshead guides to reduce piston and liner wear problems.

Spare parts list

NAME QTY PART NO

Pinion Shaft

Original Seal

Pinion Bearing Oil Seal 2 YS-10750

Seal Upgrade

Pinion Bearing Oil Seal 2 YS-10755

Sleeve 2 1295860

Crosshead

Crosshead Liner 2 1295017

Crosshead Liner 0.075” thin 2 1295812

Shim(0.005”thick) 40 1295103

Capscrew, 7/8”x4-1/2” Drilled hex head 12 2404018

Capscrew, 7/8”x4-3/4” Drilled Hex Head Gr5 12 2405114

Washer, 7/8” Stat-O-Seal 36 7618026

Service Department

Pump Inspection Report

Crosshead (Left Hand) 1 1295090

Crosshead (Centre or Right Hand) 1 1295015

Shim (0.3125” thick), Pin Retainer 12 1290114

You might also like

- Torque TDS4 Pocket Guide-2 PDFDocument5 pagesTorque TDS4 Pocket Guide-2 PDFHaridev50% (2)

- Can Rig LWCV Actuator ManualDocument58 pagesCan Rig LWCV Actuator ManualAhmed Magd100% (2)

- Manual de ServicioDocument102 pagesManual de ServiciowiloNo ratings yet

- 200-Ton Hook Assembly ManualDocument29 pages200-Ton Hook Assembly ManualMaria Julieta Calderon Ortiz100% (2)

- Rotary Table D-375Document15 pagesRotary Table D-375adjoudj100% (2)

- TC450 Crown Block User ManualDocument11 pagesTC450 Crown Block User ManualHala Dawod100% (2)

- Forged Crankshaft Triplex Mud Pump Spec SheetDocument14 pagesForged Crankshaft Triplex Mud Pump Spec SheetRICHARD100% (1)

- Deadline AnchorDocument1 pageDeadline AnchorJesus Sanchez100% (2)

- SEC5 (1) WashpipeDocument22 pagesSEC5 (1) WashpipeCarlos Alberto PerdomoNo ratings yet

- F1300F1600 Mud Pump Parts Book-500HP-1600HPDocument14 pagesF1300F1600 Mud Pump Parts Book-500HP-1600HPwaleed100% (3)

- Anular Gk13-5 (0101a) CompactDocument28 pagesAnular Gk13-5 (0101a) CompactLeonardo SotilloNo ratings yet

- 7838 Brake Care and OperationDocument54 pages7838 Brake Care and OperationMarutpal Mukherjee100% (1)

- National General Service ManualDocument155 pagesNational General Service Manualmarwa mahmoud100% (4)

- 1625-De Dwks Parts ListDocument69 pages1625-De Dwks Parts ListSasan AbbasiNo ratings yet

- 12T1600 Mud Pump Clearance Check FormDocument1 page12T1600 Mud Pump Clearance Check FormMoataz Nazeem100% (1)

- RP 10.0 Drawworks Brake Load Path Components VFinal (March 2016)Document15 pagesRP 10.0 Drawworks Brake Load Path Components VFinal (March 2016)NataliyaLukovskaNo ratings yet

- NOV50000815Document394 pagesNOV50000815wilmercasfNo ratings yet

- SSW10 Spinning Wrench Assembly GuideDocument10 pagesSSW10 Spinning Wrench Assembly GuideGeorge Hans SterlingNo ratings yet

- Hydril GK Annular Blowout Preventers: 18-3/4"-10,000 Psi Ram BOP Automatic Multiple Position Lock (MPL) IllustratedDocument4 pagesHydril GK Annular Blowout Preventers: 18-3/4"-10,000 Psi Ram BOP Automatic Multiple Position Lock (MPL) IllustratedJose BarreroNo ratings yet

- Pj8 Service ManualDocument15 pagesPj8 Service ManualHugo TejadaNo ratings yet

- Varco (Manual) - Weldless, Toolpusher, Perfections Links - OptDocument2 pagesVarco (Manual) - Weldless, Toolpusher, Perfections Links - Optrenjith rsNo ratings yet

- Um199015 eDocument158 pagesUm199015 eingcalderon100% (1)

- Manual Operation HCUDocument27 pagesManual Operation HCUSon DDarrellNo ratings yet

- Ram BOP Manual PDFDocument68 pagesRam BOP Manual PDFhendriahmadi0410No ratings yet

- Continental Emsco F-800 F-1000 Fluid End ModuleDocument2 pagesContinental Emsco F-800 F-1000 Fluid End ModuleJohnny Sanchez0% (1)

- Cat III Inspection Mud 2021Document56 pagesCat III Inspection Mud 2021Fāōū ZīNo ratings yet

- Shaffer NOV Type 72 ShearsDocument2 pagesShaffer NOV Type 72 ShearsTitanBOP100% (1)

- M5329-R0 Dead Line AnchorDocument26 pagesM5329-R0 Dead Line Anchorandrei20041100% (2)

- Shenkai Bop FH2335 PARTSDocument4 pagesShenkai Bop FH2335 PARTSAlice MiNo ratings yet

- Manual Spider VarcoDocument45 pagesManual Spider VarcoJAVIER EDUARDO MANTILLA BUITRAGO100% (1)

- Bba de Lodos Dampener - Instruction - Manual - Rev - DDocument10 pagesBba de Lodos Dampener - Instruction - Manual - Rev - Desteban monterrosa lopez100% (3)

- HHF-1600L Drilling Pump Set Parts ListDocument21 pagesHHF-1600L Drilling Pump Set Parts ListAhmed SaeedNo ratings yet

- Tfi F-500 Mud PumpDocument6 pagesTfi F-500 Mud PumpCesar MoraNo ratings yet

- Guide to 13 5/8”-5000psi Single Ram BOP OperationDocument40 pagesGuide to 13 5/8”-5000psi Single Ram BOP OperationAlexsandro Cordeiro100% (5)

- 2 - Bearing Clearance MeasurementDocument5 pages2 - Bearing Clearance MeasurementMoataz Nazeem100% (1)

- American Block Swivels Model A-200Document20 pagesAmerican Block Swivels Model A-200aldino020203100% (2)

- Job 3395-Emsco FB1600 PumpDocument123 pagesJob 3395-Emsco FB1600 PumpCristian BoselliNo ratings yet

- Drawworks Operation Manual S0100707-OPM-200 - Rev. 0Document46 pagesDrawworks Operation Manual S0100707-OPM-200 - Rev. 0Mohammad Usman100% (2)

- InternationalDocument40 pagesInternationalayman akrabNo ratings yet

- Spare Parts Catalogue: DrawworksDocument167 pagesSpare Parts Catalogue: DrawworksHector BarriosNo ratings yet

- Washpipe Assembly Washpipe Assembly: Service ManualDocument60 pagesWashpipe Assembly Washpipe Assembly: Service ManualIvan Kawempy100% (4)

- 02 Pump Device Service ManualDocument60 pages02 Pump Device Service Manualrami100% (1)

- WPI C or CHD Tubing Spider Manual Rev1Document14 pagesWPI C or CHD Tubing Spider Manual Rev1Dean Rein100% (1)

- E551 Dead Line AnchorDocument12 pagesE551 Dead Line AnchorHoward Berisford88% (8)

- ZY-ZJ-800&1000 Operation & Maintenance Manual PDFDocument69 pagesZY-ZJ-800&1000 Operation & Maintenance Manual PDFOperaciones Gep100% (1)

- Traveling Equipment Anti-Collision System Tac-Ii ManualDocument66 pagesTraveling Equipment Anti-Collision System Tac-Ii ManualAlex RamirezNo ratings yet

- Weco Wing Union Part ListDocument18 pagesWeco Wing Union Part ListAli100% (1)

- 3092834-Varco Bulletin On TDSDocument9 pages3092834-Varco Bulletin On TDSSushil GuptaNo ratings yet

- Annular Dissassembly ExtractDocument2 pagesAnnular Dissassembly ExtractAshraf GabrNo ratings yet

- BVM Catelogue New-2016 PDFDocument116 pagesBVM Catelogue New-2016 PDFOperation100% (1)

- Rutong DH 吊环使用说明书(ZY)2013 links - 1Document3 pagesRutong DH 吊环使用说明书(ZY)2013 links - 1QAMAR ALI KHANNo ratings yet

- Mud Pump Gardner Denver Maintenance Doc - SchlumbergerDocument9 pagesMud Pump Gardner Denver Maintenance Doc - SchlumbergerGlen AshwellNo ratings yet

- D744000102 Idx 001Document63 pagesD744000102 Idx 001Alejandro ZanellaNo ratings yet

- #HB-1-81 22SR Lip Manual PDFDocument22 pages#HB-1-81 22SR Lip Manual PDFLucas Maldonado100% (1)

- 1000012667-PIB Shot PinDocument3 pages1000012667-PIB Shot PinAdrian CantaragiuNo ratings yet

- KellyguardDSV (6845C)Document22 pagesKellyguardDSV (6845C)David0% (1)

- Hydrill 13'' - 5000 PsiDocument42 pagesHydrill 13'' - 5000 PsiAli Ali75% (4)

- Overhauling TP800C Gbox ME-810cDocument10 pagesOverhauling TP800C Gbox ME-810cwasay0% (1)

- Mud Pump Interview TechnicalDocument4 pagesMud Pump Interview TechnicalPremkamal .Olanchery.RavishankarNo ratings yet

- 8.1L John Deere Powertech Engine SpecsDocument1 page8.1L John Deere Powertech Engine SpecsNERI BENJAMIN BORTOLONNo ratings yet

- ChartsDocument4 pagesChartsMarine CaptainNo ratings yet

- Meivalvole SerieCD ENG 20150212Document4 pagesMeivalvole SerieCD ENG 20150212Marine CaptainNo ratings yet

- AVR R450 4531k - en PDFDocument24 pagesAVR R450 4531k - en PDFroy fadliNo ratings yet

- 12cbm Radio Remote Control Grab Technical Specs PDFDocument5 pages12cbm Radio Remote Control Grab Technical Specs PDFMarine CaptainNo ratings yet

- CTRLX - Manual Carlo Gavazzi PDFDocument296 pagesCTRLX - Manual Carlo Gavazzi PDFMarine CaptainNo ratings yet

- Hipap: High Precision Acoustic PositioningDocument24 pagesHipap: High Precision Acoustic PositioningLi Ann ChungNo ratings yet

- Mobile Services: Your Account Summary This Month'S ChargesDocument3 pagesMobile Services: Your Account Summary This Month'S ChargesGopakumar G0% (1)

- Sonardyne Wide Band Computer 8026Document2 pagesSonardyne Wide Band Computer 8026Marine CaptainNo ratings yet

- Sonardyne Ranger 2 USBLDocument24 pagesSonardyne Ranger 2 USBLMarine CaptainNo ratings yet

- Good ManzilDocument9 pagesGood ManzilrathiikaNo ratings yet

- Wilden H800Document43 pagesWilden H800Marine CaptainNo ratings yet

- Title of Training Presentation: Presented by Your NameDocument14 pagesTitle of Training Presentation: Presented by Your NameJudy UnreinNo ratings yet

- Case Study of Haleeb FoodDocument18 pagesCase Study of Haleeb Foodjazi_4u86% (22)

- "Employee Payroll Management System": Miss - Priyanka Abhaynath YadavDocument31 pages"Employee Payroll Management System": Miss - Priyanka Abhaynath Yadavhabeb TubeNo ratings yet

- 1025 (1029) Anaerobic ChamberDocument8 pages1025 (1029) Anaerobic ChamberSoma GhoshNo ratings yet

- Har Rabia Bins Fax Tunisia 2018Document8 pagesHar Rabia Bins Fax Tunisia 2018vacomanoNo ratings yet

- Ruud RAWL SplitDocument24 pagesRuud RAWL SplitElvis Ruben Piza MerchanNo ratings yet

- Cissp NotesDocument83 pagesCissp NotesRobert Mota HawksNo ratings yet

- CPO Science Foundations of Physics: Unit 7, Chapter 24Document47 pagesCPO Science Foundations of Physics: Unit 7, Chapter 24dheerajbhagwatNo ratings yet

- CH 2 Financial Analysis Technoques PresentationDocument44 pagesCH 2 Financial Analysis Technoques PresentationHamza AsifNo ratings yet

- 342 Mechanical and Fluid Drive Maintenance Course DescriptionDocument2 pages342 Mechanical and Fluid Drive Maintenance Course Descriptionaa256850No ratings yet

- Remote Access Portal User GuideDocument3 pagesRemote Access Portal User GuidezeljavaNo ratings yet

- Icarus & DaedalusDocument2 pagesIcarus & DaedalusIsrael AsinasNo ratings yet

- CHAPTER 8 The Rise of Instrumental Music - 141-152Document8 pagesCHAPTER 8 The Rise of Instrumental Music - 141-152Aleksandre Roderick-LorenzNo ratings yet

- Awfpc 2022Document7 pagesAwfpc 2022Jay-p BayonaNo ratings yet

- Silent Spring: What's InsideDocument22 pagesSilent Spring: What's InsideDelina TedrosNo ratings yet

- W 2HotlineContacts2019 - 0 2 PDFDocument3 pagesW 2HotlineContacts2019 - 0 2 PDFNathan Townsend Levy100% (1)

- Detector Balance Induccion.Document11 pagesDetector Balance Induccion.Jesus OrtizNo ratings yet

- Literature StudyDocument7 pagesLiterature StudySilver ShadesNo ratings yet

- MCAS Forces and Equilibrium PracticeDocument51 pagesMCAS Forces and Equilibrium PracticeSyd MalaxosNo ratings yet

- ECT ModelDocument12 pagesECT Modelhii_bhartiNo ratings yet

- Anna University Project Work Submission FormDocument1 pageAnna University Project Work Submission FormaddssdfaNo ratings yet

- PEC ReviewerDocument17 pagesPEC ReviewerJunallyn ManigbasNo ratings yet

- Lippo Karawaci Review 30 September 2019 FINAL PDFDocument149 pagesLippo Karawaci Review 30 September 2019 FINAL PDFAndy AghastaNo ratings yet

- Cellulase ProductionDocument16 pagesCellulase ProductionTanvi JainNo ratings yet

- Cellular ManufacturingDocument61 pagesCellular Manufacturingapi-3852736100% (1)

- Name: K K ID#: Lab Partner: V S Date: Wednesday 22 Course Code: BIOL 2363 - Metabolism Title of Lab: Assay of Tissue GlycogenDocument7 pagesName: K K ID#: Lab Partner: V S Date: Wednesday 22 Course Code: BIOL 2363 - Metabolism Title of Lab: Assay of Tissue GlycogenKarina KhanNo ratings yet

- Epimastic 7200: Product DescriptionDocument2 pagesEpimastic 7200: Product DescriptionSu KaNo ratings yet

- Vocabulary - Vocabulario de Salud y de Sintomas en InglesDocument4 pagesVocabulary - Vocabulario de Salud y de Sintomas en InglesCarlos MiguelNo ratings yet

- Final Class 8 Science 20230828084415550Document5 pagesFinal Class 8 Science 20230828084415550aryantomar5112No ratings yet

- Assessment Rubric Coach Manual Oct 11 - FinalDocument9 pagesAssessment Rubric Coach Manual Oct 11 - Finalapi-246218373No ratings yet