Professional Documents

Culture Documents

1 s2.0 0022460X8390562X Main

1 s2.0 0022460X8390562X Main

Uploaded by

snailbookOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 s2.0 0022460X8390562X Main

1 s2.0 0022460X8390562X Main

Uploaded by

snailbookCopyright:

Available Formats

Journal of Sound and Vibration (1983) 87(2), 273

RAPPORTEUR’S REPORT, SESSION 4:

ELEVATED STRUCTURE NOISE

A. W. PAOLILLO

New York City Transit Authority, Brooklyn, New York 11201, U.S.A.

(Received 24 May 1982)

Session leader Dr L. Wittig of Bolt Beranek and Newman Inc., Cambridge, Massachusetts,

presented the lead paper entiled “Railway elevated structure noise-a review”. There

were no contributed papers. Dr Wittig reviewed the work being done by Bolt Beranek

and Newman for the U.S. Department of Transportation to quantify the problem of

elevated structure noise and recommend solutions. This work included the development

of a noise rating criterion, a noise impact inventory of U.S. elevated rail rapid transit

structures, an analytical model, a noise control design guide, and a case study analysis.

Dr Wittig also briefly discussed the study Bolt Beranek and Newman is conducting for

the New York City Transit Authority to develop cost effective noise control designs for

New York City’s elevated structures.

Mr Christopher Morris of the Urban Transit Development Corporation, Ontario,

Canada commented on Dr Wittig’s description of noise benefits composition brake shoes

may provide compared with cast iron brake shoes on tread brake systems. The literature

suggests composition brake shoes result in smoother wheel surfaces and therefore lower

noise levels. Mr Morris indicated that cast iron brake shoes have better wet fade resistance

than composition shoes.

Dr George Wilson, of Wilson, Ihrig and Associates, Oakland, California, discussed

damping of new elevated structures in the U.S.A. to reduce low frequency rumbling

noise that easily transmits into residential buildings, causing more annoyance than the

“A’‘-weighted sound level would predict. A discussion also followed concerned with

reported noise level reductions provided by track ballast.

Mr E. L. Bovey of London Transport, London, England, questioned the effect a stiff

resilient rail fastener would have on groundborne noise and vibration near elevated

structures. Dr L. Kurzweil (BBN) and Dr P. Remington (BBN) explained that the natural

frequency of a soft resilient fastener is 100 Hz and the stiff fastener Dr Wittig talked

about to optimize the “thickness resonance” has a natural frequency of 300 Hz. Because

the groundborne vibration occurs at frequencies below 100 Hz, stiffening the fastener

would not affect the groundborne vibration. Another point brought out by Dr Remington

in response to a question from Dr H. Saurenman of Wilson, Ihrig and Associates, is that

the wood ties are quite soft, having a spring constant of approximately 170 000 lb/in.

273

0022-460X/83/060273 +01$03.00/O @ 1983 Academic Press Inc. (London) Limited

You might also like

- Sailaway The Sailing Simulator Crack Serial KeyDocument3 pagesSailaway The Sailing Simulator Crack Serial Keysnailbook100% (1)

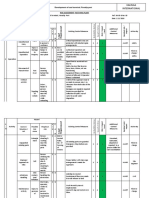

- Risk Assessment of Chiller RoomDocument3 pagesRisk Assessment of Chiller RoomPraveen0% (1)

- Transportation Literature Search: Construction Vibration Impacts On Early-Age ConcreteDocument6 pagesTransportation Literature Search: Construction Vibration Impacts On Early-Age Concretem_shafieianNo ratings yet

- Akay Acoustics of FrictionDocument24 pagesAkay Acoustics of Frictiondhananjay176No ratings yet

- Acoustic EmissionDocument3 pagesAcoustic Emissioneldhopaul19894886No ratings yet

- 1 s2.0 S0889974602000919 MainDocument17 pages1 s2.0 S0889974602000919 MainVarun PathakNo ratings yet

- Wavelet Transform Analysis of Guided Waves TestingDocument12 pagesWavelet Transform Analysis of Guided Waves Testingrotero_pujolNo ratings yet

- VibrationsDocument35 pagesVibrationsIvka MalaNo ratings yet

- Sound and Vibration Considerations of Some Materials For Automotive Engineering ApplicationsDocument14 pagesSound and Vibration Considerations of Some Materials For Automotive Engineering ApplicationshocdehieuNo ratings yet

- Impact of Traffic Vibration On HeritageDocument10 pagesImpact of Traffic Vibration On HeritageMohamad HabibiNo ratings yet

- Acoustic Emission TestingDocument17 pagesAcoustic Emission TestingSaathvik BhatNo ratings yet

- Jik 2013Document10 pagesJik 2013Edwin SilvaNo ratings yet

- Impact Echo Scanning For Discontinuity Detection and Imaging in Posttensioned Concrete Bridges and Other StructuresDocument6 pagesImpact Echo Scanning For Discontinuity Detection and Imaging in Posttensioned Concrete Bridges and Other StructuresPDDELUCANo ratings yet

- Tocci, G.C. - Room Noise Criteria-The State of The Art in The Year 2000 PDFDocument14 pagesTocci, G.C. - Room Noise Criteria-The State of The Art in The Year 2000 PDFmikelotingaNo ratings yet

- Vibration and Noise Generation in Gear Units Caused by Gear Teeth ImpactsDocument12 pagesVibration and Noise Generation in Gear Units Caused by Gear Teeth ImpactsMax GrandeNo ratings yet

- Jasi2010 PDFDocument248 pagesJasi2010 PDFSatish Dhandole100% (1)

- NDT Mod5@AzDOCUMENTS - inDocument22 pagesNDT Mod5@AzDOCUMENTS - inkrithikamurali1404No ratings yet

- A Field Investigation of Vibration-Based Structural Health Monitoring in A Steel Truss BridgeDocument7 pagesA Field Investigation of Vibration-Based Structural Health Monitoring in A Steel Truss Bridge정주호No ratings yet

- N D T Abstracts: The Ultrasonic Testing of ConcreteDocument1 pageN D T Abstracts: The Ultrasonic Testing of ConcreteElango PaulchamyNo ratings yet

- Vibro-Acoustics: A New Springer PublicationDocument9 pagesVibro-Acoustics: A New Springer PublicationcharcharNo ratings yet

- Heavy Weight Impact Sound - Concrete SlabDocument6 pagesHeavy Weight Impact Sound - Concrete SlabhadianatyaNo ratings yet

- Mohammad Rakibul Islam Khan, Zafrul Hakim Khan, Mohammad Fahim Raiyan and Khan Mahmud AmanatDocument14 pagesMohammad Rakibul Islam Khan, Zafrul Hakim Khan, Mohammad Fahim Raiyan and Khan Mahmud AmanatShoyeeb AhmedNo ratings yet

- Minimizing Floor Vibration by Design and RetrofitDocument0 pagesMinimizing Floor Vibration by Design and RetrofitCrosman StefanNo ratings yet

- Acoustic Emission Testing (AE)Document16 pagesAcoustic Emission Testing (AE)Engr Arfan Ali Dhamraho100% (1)

- Vibration Problems in Structures - Practical GuideDocument3 pagesVibration Problems in Structures - Practical GuideAhmad WaalNo ratings yet

- BSCE 2003-11 - Paikowsky & Chernauskas - tcm18-106947Document30 pagesBSCE 2003-11 - Paikowsky & Chernauskas - tcm18-106947BaraNo ratings yet

- Traffic Noise Level Predictions For Buildings With Windows Opened For Natural Ventilation in Urban EnvironmentsDocument11 pagesTraffic Noise Level Predictions For Buildings With Windows Opened For Natural Ventilation in Urban EnvironmentspighonNo ratings yet

- Impact Eco NDTDocument11 pagesImpact Eco NDTChalakAhmedNo ratings yet

- Validation Blast JATCDocument18 pagesValidation Blast JATCPrasannaNo ratings yet

- A Study of The in Uence of Ribs Shape On The Gear Transmission Housing VibroactivityDocument8 pagesA Study of The in Uence of Ribs Shape On The Gear Transmission Housing VibroactivityPietroNo ratings yet

- Ploemen2011 Wind-Induced Sound On Buildings and StructuresDocument8 pagesPloemen2011 Wind-Induced Sound On Buildings and StructuresNguyen QuangNo ratings yet

- Maryami JSV-2022 SPCC-NearField RGArchiveDocument24 pagesMaryami JSV-2022 SPCC-NearField RGArchive陈冠江No ratings yet

- Journal of Sound and Vibration: R.P. Blood, J.D. Ploger, M.G. Yost, R.P. Ching, P.W. JohnsonDocument12 pagesJournal of Sound and Vibration: R.P. Blood, J.D. Ploger, M.G. Yost, R.P. Ching, P.W. JohnsonAnand sharmaNo ratings yet

- Vibration Characteristics of Double Tee Building FloorsDocument12 pagesVibration Characteristics of Double Tee Building FloorsHugo VerissimoNo ratings yet

- Hammer SoundingDocument2 pagesHammer SoundingAnonymous G6ceYCzwtNo ratings yet

- Acoustic Emission Monitoring of A High Pressure Test of A Steel Reactor Containment Vessel ModelDocument17 pagesAcoustic Emission Monitoring of A High Pressure Test of A Steel Reactor Containment Vessel ModelMOHAMMED ABDUL RAHEMANNo ratings yet

- Acoustic Emission TestingDocument24 pagesAcoustic Emission TestingWoodrow FoxNo ratings yet

- Progress Structural Eng Maths - 2001 - Hu - Vibration Serviceability of Timber Floors in Residential ConstructionDocument10 pagesProgress Structural Eng Maths - 2001 - Hu - Vibration Serviceability of Timber Floors in Residential ConstructionMohammed IbrahimNo ratings yet

- Evaluacion Del Amortiguamiento de Puente Carretero Por Medio de Vibraciones Forzadas y AmbientalesDocument12 pagesEvaluacion Del Amortiguamiento de Puente Carretero Por Medio de Vibraciones Forzadas y AmbientalesSebastian Contreras ContrerasNo ratings yet

- Justification of ACI 446 Proposal For Updating ACI CodeDocument10 pagesJustification of ACI 446 Proposal For Updating ACI Codemcivil 9No ratings yet

- Defect Types and Non-Destructive Testing Techniques For Composites and Bonded JointsDocument19 pagesDefect Types and Non-Destructive Testing Techniques For Composites and Bonded JointsShanker PandeyNo ratings yet

- Effect of Synthetic Fibers On Structural Behavior of Concrete Slabs On GroundDocument9 pagesEffect of Synthetic Fibers On Structural Behavior of Concrete Slabs On GroundJuanCarlos MendozaNo ratings yet

- Allen, D.E., Murray, T.M. - Design Criterion For Vibrations Due To WalkingDocument15 pagesAllen, D.E., Murray, T.M. - Design Criterion For Vibrations Due To WalkingHugo VerissimoNo ratings yet

- Assessing The Strength of Reinforced Concrete Structures Through Ultrasonic Pulse Velocity and Schmidt Rebound Hammer Tests-LibreDocument8 pagesAssessing The Strength of Reinforced Concrete Structures Through Ultrasonic Pulse Velocity and Schmidt Rebound Hammer Tests-LibremingNo ratings yet

- Impact Echo MethodDocument19 pagesImpact Echo Methodjs kalyana ramaNo ratings yet

- Jte10561j DL.1415051 1 PDFDocument8 pagesJte10561j DL.1415051 1 PDFpaolaNo ratings yet

- Effects of Increasing Allowable Compressive Stressat Prestress TransferDocument11 pagesEffects of Increasing Allowable Compressive Stressat Prestress TransferProfessor Dr. Nabeel Al-Bayati-Consultant EngineerNo ratings yet

- Introduction To Acoustic Emission Testing 2Document20 pagesIntroduction To Acoustic Emission Testing 2Ashutosh SinghNo ratings yet

- Vibration Mechanisms and Controls of Long-Span Bridge - ReviewDocument21 pagesVibration Mechanisms and Controls of Long-Span Bridge - ReviewDionysius Siringoringo100% (1)

- Frictional Forces Related To Self-Ligating Brackets: Luca Pizzoni, Gert Ravnholt and Birte MelsenDocument9 pagesFrictional Forces Related To Self-Ligating Brackets: Luca Pizzoni, Gert Ravnholt and Birte MelsenGoutamNo ratings yet

- 8 - Wang 2016Document8 pages8 - Wang 2016mohammadali nasiroleslamiNo ratings yet

- Introduction To Acoustic Emission TestingDocument19 pagesIntroduction To Acoustic Emission TestingkingstonNo ratings yet

- A Comparative Study of Scarfed Nozzle For Jet Installation Noise ReductionDocument26 pagesA Comparative Study of Scarfed Nozzle For Jet Installation Noise ReductionSKataNo ratings yet

- Bracind of Steel Beams in Bridges PDFDocument96 pagesBracind of Steel Beams in Bridges PDFAndré Luiz NogueiraNo ratings yet

- Acoustic and Ow Fields of An Excited High Reynolds Number Axisymmetric Supersonic JetDocument23 pagesAcoustic and Ow Fields of An Excited High Reynolds Number Axisymmetric Supersonic Jetpuneshwarverma8128No ratings yet

- Abstract ManuelMonteiroDocument10 pagesAbstract ManuelMonteiroGANESHNo ratings yet

- A Case of Vibro Compaction Vibration Monitoring in A Reclaimed SiteDocument6 pagesA Case of Vibro Compaction Vibration Monitoring in A Reclaimed Sitemennahossam8820No ratings yet

- STP 571-1975Document294 pagesSTP 571-1975Tim SchouwNo ratings yet

- NDT Lecture Notes-5Document23 pagesNDT Lecture Notes-5JpNo ratings yet

- VIBRATORY STRESS RELIEF: A FUNDAMENTAL STUDY OF ITS EFFECTIVENESSDawson MoffatDocument9 pagesVIBRATORY STRESS RELIEF: A FUNDAMENTAL STUDY OF ITS EFFECTIVENESSDawson MoffatgreatsteelNo ratings yet

- Mechanics of Rubber Bearings for Seismic and Vibration IsolationFrom EverandMechanics of Rubber Bearings for Seismic and Vibration IsolationNo ratings yet

- Mechanics and Fatigue in Wheel/Rail ContactFrom EverandMechanics and Fatigue in Wheel/Rail ContactS.L. GrassieNo ratings yet

- B. Shield, J. Roberts & M. VuillermozDocument1 pageB. Shield, J. Roberts & M. VuillermozsnailbookNo ratings yet

- Insertion Losses of Acoustic Louvers: Articles You May Be Interested inDocument2 pagesInsertion Losses of Acoustic Louvers: Articles You May Be Interested insnailbookNo ratings yet

- The Ultimate Deck Pedestal SolutionDocument1 pageThe Ultimate Deck Pedestal SolutionsnailbookNo ratings yet

- Some Objective and Subjective Aspects of Three Acoustically Variable HallsDocument1 pageSome Objective and Subjective Aspects of Three Acoustically Variable HallssnailbookNo ratings yet

- Emotional Abuse ChecklistDocument1 pageEmotional Abuse Checklistsnailbook100% (1)

- Calculation of Road Traffic Noise (Size Reduced) 1988Document100 pagesCalculation of Road Traffic Noise (Size Reduced) 1988edNo ratings yet

- (123doc) - De-Thi-Thu-So-9Document12 pages(123doc) - De-Thi-Thu-So-9Xoăn TrầnNo ratings yet

- Kustom Sienna 30 Manuel Utilisateur en 28764Document4 pagesKustom Sienna 30 Manuel Utilisateur en 28764NPUIUNo ratings yet

- Noise and Vibration Get Your Own Project Buda: GIL Power Generation KilkennyDocument14 pagesNoise and Vibration Get Your Own Project Buda: GIL Power Generation KilkennyMina EliasNo ratings yet

- Reviewed of Noise Control in Ic EngineDocument3 pagesReviewed of Noise Control in Ic Engineijsret100% (1)

- Design For ComfortDocument50 pagesDesign For ComfortPai Lang ZhenNo ratings yet

- ANC Using DSP ProcessorDocument5 pagesANC Using DSP ProcessorSahil “Sapdon” PalaskarNo ratings yet

- Navy Supplement To The DOD Dictionary of Military and Associated Terms, 2011Document405 pagesNavy Supplement To The DOD Dictionary of Military and Associated Terms, 2011bateljupko100% (1)

- Audiometric Booths 1.2.1Document5 pagesAudiometric Booths 1.2.1Harish MelkaniNo ratings yet

- CAT Power Plants Layout CATDocument280 pagesCAT Power Plants Layout CATburcin GozalNo ratings yet

- 545WKS 2 Building and Construction Provision of Facilities and SafetyDocument68 pages545WKS 2 Building and Construction Provision of Facilities and SafetyAlexNo ratings yet

- Chapter 1 Thesis NoiseDocument11 pagesChapter 1 Thesis NoiseJorge Bagwak100% (1)

- Speaker Application Guide 1Document68 pagesSpeaker Application Guide 1Ravinder Gu100% (1)

- Case Mounted Accelerometers Datasheet - 124M2609Document18 pagesCase Mounted Accelerometers Datasheet - 124M2609Viet DinhTrongNo ratings yet

- AerzenDocument20 pagesAerzenmih4iNo ratings yet

- Lab 6 - Work Environment Design (Sound Level) (Samahat)Document6 pagesLab 6 - Work Environment Design (Sound Level) (Samahat)AfafNo ratings yet

- Study of Noise Pollution and Its Effects in Selective Rail Stations in BangladeshDocument9 pagesStudy of Noise Pollution and Its Effects in Selective Rail Stations in Bangladesh2rmjNo ratings yet

- Noise Hazard Identification Checklist PDFDocument2 pagesNoise Hazard Identification Checklist PDFaffeenaNo ratings yet

- Carrier Slot DiffusersDocument96 pagesCarrier Slot DiffusersPanagiotis CvNo ratings yet

- Wg20 1c ZLN SeriesDocument96 pagesWg20 1c ZLN SeriesBENHOUDNo ratings yet

- Bridge and Gantry Crane Drivers Guide 0001Document72 pagesBridge and Gantry Crane Drivers Guide 0001John Henry SinuratNo ratings yet

- Series: 973 - 1327 KWM (Gross) at 1500 RPMDocument18 pagesSeries: 973 - 1327 KWM (Gross) at 1500 RPMlahcen boudaoudNo ratings yet

- Manual Bomba CPXDocument36 pagesManual Bomba CPXRolando Felipe Tapia Moyano100% (1)

- Twin Screw PumpsDocument56 pagesTwin Screw PumpsAyman MedaneyNo ratings yet

- Assessment and Management of Environment Noise Regulations.Document8 pagesAssessment and Management of Environment Noise Regulations.cikkuNo ratings yet

- Batching Plant ActivityDocument5 pagesBatching Plant ActivityPrabu LingamNo ratings yet

- Celebration of Ganesh Festival: Environmental Issues in The State of Maharashtra, IndiaDocument7 pagesCelebration of Ganesh Festival: Environmental Issues in The State of Maharashtra, IndiaAakashNo ratings yet

- BS EN 60534-8-4-2005 (2007) - Control Valves-Noise GeneratedDocument30 pagesBS EN 60534-8-4-2005 (2007) - Control Valves-Noise GeneratedPraveenKatkooriNo ratings yet

- Phonak Audeo P 210x280 EN V1.00 027-0602-02Document2 pagesPhonak Audeo P 210x280 EN V1.00 027-0602-02Melson RequinoNo ratings yet