Professional Documents

Culture Documents

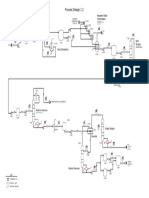

Process Design 1.2: Repeated Batch Fermentation

Uploaded by

Elzubair EljaaliOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Process Design 1.2: Repeated Batch Fermentation

Uploaded by

Elzubair EljaaliCopyright:

Available Formats

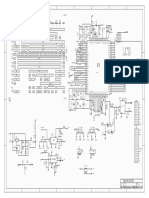

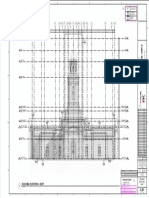

Process Design

1.2 Repeated Batch

Fermentation

R-201a Total ABE 19.2 g/L

ABE Productivity 0.42 g/L

Clostridium A:B:E 2:95:3

147

acetobutylicu R-201b

1.01

m PCSIR-10

1191 72.4

Molasses 1

34.9

R-201c 33.05

1.01

3.5

4 CO2

11 R-201d

P-101

0.016 1191

25 25

HE-101 H2 39

1.01 3.5 103.7

1191

CSW 5 13 34.9

1.5

2 8

FeSO4.7H2O 1033 P-102 7

HPS 12 1.01

T-301

H2 O 25 6

P-104 1191 P-105 Beer

1.01

V-101

9 V-102

25 Stripper

121.8

A-101

1140

3.5 33.05

1.01 10

98.5% Water Removal

20 22 1140

100% Biomass Removal

3 33.05

P-103

10 Feed Sterilization CW

1.5

1191

P-204 24

130 23

3.5 R-202

V-201 P-205

1.1 1101

25 111.8

1.01 CO2 1.5

H2

37.

25

9

27 H2O and

1.01

26 Biomass

to Waste Water

28 Treatment

F-301

CW

32

3.3

79.5

0.9

Waste Stream (CO2 and Acetone)

37.9 40

25

1.1

103.3

29 30

31 Acetone Recovery 4.1

76.5

0.5

99.9% Acetone Recovery

40

P-302

P-301

V-301 CW

34.6 34.6

V-302 15.1

T-302 HPS 25

93.45 20

0.9

1.1 1.5

D- 20

34 30 38

1.01

Water Stripper

33

1

HE-301 37

36

35

43

Decanter

HPS

T-304

15.9

T-303 81.25

33.8

0.5

H2 O

97 41 to Waste Water

1.5 Treatment

20 Purity 99.17%

42

18.7

25

P-305 45 1.01

18.7

49

47 1.01

Pressure (bar) Mass Flow (tonne/h)

y V-303 V-304

18.7

44

128.9

Buta 1.5

46

nol

KEY Rec 48

Temperature (○C) over

P-306 Butano

50 51

l

P

u

V-305 r

i

t

P-307 y

9

9

.

0

5

%

O

v

e

r

a

l

l

R

e

c

o

v

e

r

y

9

5

.

6

2

%

You might also like

- Process Design 1.2: Repeated Batch FermentationDocument1 pageProcess Design 1.2: Repeated Batch FermentationElzubair EljaaliNo ratings yet

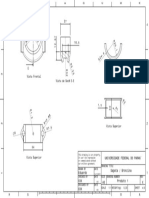

- Sapata Sheet 4Document1 pageSapata Sheet 4Dejan AntanasijevicNo ratings yet

- Roof Framing Plan Purlin Connections: A' B C D E ADocument1 pageRoof Framing Plan Purlin Connections: A' B C D E ATrisha Marie Bustria MartinezNo ratings yet

- e - Hakko - fx951 - ADocument2 pagese - Hakko - fx951 - ARizky WijayaNo ratings yet

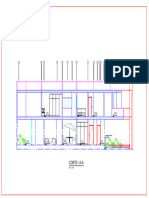

- Saldaña Ejercicio 7-Corte AaDocument1 pageSaldaña Ejercicio 7-Corte Aaalexsaldana.ruagNo ratings yet

- Gambar Kerja Product Sesi 1Document2 pagesGambar Kerja Product Sesi 1Muhamad Eko FebriansyahNo ratings yet

- MHI2023 E HYDRO Low 1221Document34 pagesMHI2023 E HYDRO Low 1221Miguel FranciscoNo ratings yet

- Villancico Baritono IDocument1 pageVillancico Baritono IJohnny CerónNo ratings yet

- Group Vii HalogenDocument17 pagesGroup Vii HalogenIftitahur Rohmah -No ratings yet

- GROUND FLOOR PLANS 3-ModelDocument1 pageGROUND FLOOR PLANS 3-ModelOmar YassenNo ratings yet

- Schematic Rockola Expandable 2022-11-18Document1 pageSchematic Rockola Expandable 2022-11-18luckyNo ratings yet

- Schematic Rockola Expandable 2022-11-18Document1 pageSchematic Rockola Expandable 2022-11-18Linkon BiswasNo ratings yet

- Bracket RWD RR Spring (Machining)Document1 pageBracket RWD RR Spring (Machining)Very BagusNo ratings yet

- Pefd Fixx 3Document1 pagePefd Fixx 3Rafi Theda PrabawaNo ratings yet

- Lamento Náufrago: PorroDocument2 pagesLamento Náufrago: PorroJefferson GuerreroNo ratings yet

- MARINES CORPS CORPORAL Homenagem Aos Cabos Da Banda Marcial Do CFN-Trombone - 2Document1 pageMARINES CORPS CORPORAL Homenagem Aos Cabos Da Banda Marcial Do CFN-Trombone - 2Rosinaldo Araújo LimaNo ratings yet

- Foundation Plan Roof Framing Plan: K & M Design and StandardsDocument1 pageFoundation Plan Roof Framing Plan: K & M Design and StandardsSabrex MacadatoNo ratings yet

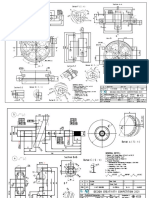

- Housing RinDocument2 pagesHousing RinRinaldi PraharsaNo ratings yet

- E03 For PitDocument1 pageE03 For Pitsebastian0210_401439No ratings yet

- 2sd1867, 2sd1980, 2sd2195 RohmDocument5 pages2sd1867, 2sd1980, 2sd2195 RohmMohammad kazem DehghaniNo ratings yet

- A F C D H E G A F: Denah Lantai Dasar KALA 1:100 Denah Lantai 1 SKALA 1:100Document1 pageA F C D H E G A F: Denah Lantai Dasar KALA 1:100 Denah Lantai 1 SKALA 1:100fadjarwNo ratings yet

- Baterias SanitariasDocument1 pageBaterias SanitariasAlex Carrasco DelgadoNo ratings yet

- MarchasDocument15 pagesMarchasEDWARD STALIM LAZARO HINOJOSANo ratings yet

- Korek 2Document1 pageKorek 2PenerbangNo ratings yet

- AstragDocument4 pagesAstragCampean-Craciun CristianNo ratings yet

- Periodic Table of Elements W Chemical Group Block PubChemDocument1 pagePeriodic Table of Elements W Chemical Group Block PubChemRoy BibanoNo ratings yet

- SplitOneFile 1666274379Document2 pagesSplitOneFile 1666274379EDWARD STALIM LAZARO HINOJOSANo ratings yet

- Arquitectura 01Document1 pageArquitectura 01Cabello Huacho PercyNo ratings yet

- Skye Boat Parts-Bb - Trumpet - 1 PDFDocument1 pageSkye Boat Parts-Bb - Trumpet - 1 PDFKatie BirtNo ratings yet

- Skye Boat Parts-Bb - Trumpet - 1Document1 pageSkye Boat Parts-Bb - Trumpet - 1Katie BirtNo ratings yet

- Los Mejores Planos Del MundoDocument1 pageLos Mejores Planos Del MundoPaula AndreaNo ratings yet

- +VDC +VDC: Quasi NPN Rockola ExpandableDocument1 page+VDC +VDC: Quasi NPN Rockola ExpandableDeepak AnandNo ratings yet

- A C D E F G A': Gspublisherversion 0.5.100.100Document1 pageA C D E F G A': Gspublisherversion 0.5.100.100Moisil EmanuilNo ratings yet

- Cimentaciones EstructurasDocument1 pageCimentaciones EstructurasRené Paricahua SánchezNo ratings yet

- Ma 149B V4 2000Document1 pageMa 149B V4 2000Antonio CarlosNo ratings yet

- Allegretto Rit. Lento: GuitarDocument1 pageAllegretto Rit. Lento: GuitarКалин КалинNo ratings yet

- Plano 03Document1 pagePlano 03ERICK ORDOÑEZNo ratings yet

- WB97S-2 SF10001 електросхемиDocument13 pagesWB97S-2 SF10001 електросхемиVan AvaksNo ratings yet

- Preliminary, For Reference or Quotation Purposes Only. Do Not ManufactureDocument1 pagePreliminary, For Reference or Quotation Purposes Only. Do Not Manufactureoflorez72No ratings yet

- Poz.2 Kuciste Donji Dio Reduktor Model SFSBDocument1 pagePoz.2 Kuciste Donji Dio Reduktor Model SFSBJosip BriškiNo ratings yet

- Periodic Table of Elements W Chemical Group Block PubChemDocument1 pagePeriodic Table of Elements W Chemical Group Block PubChemAnnu AkNo ratings yet

- Honda K20A Conrod PDFDocument1 pageHonda K20A Conrod PDFJohnJulienGraymondNo ratings yet

- Soed Ebs eDocument1 pageSoed Ebs eВікторіяNo ratings yet

- SC-2100 Feed Gas Slug Catcher V-2401 Inlet Gas SeparatorDocument2 pagesSC-2100 Feed Gas Slug Catcher V-2401 Inlet Gas SeparatorMidha NeerNo ratings yet

- Periodic Table of ElementsDocument1 pagePeriodic Table of Elementsteknologipangan bthNo ratings yet

- Bienvenidos - No Huyas de Mí - Electric BassDocument3 pagesBienvenidos - No Huyas de Mí - Electric BassVane MBNo ratings yet

- Issued For Production: Rev. DateDocument1 pageIssued For Production: Rev. DateKaramjit SinghNo ratings yet

- Tasha Modul3Document1 pageTasha Modul3Aqsal FahrizqaNo ratings yet

- Edc17c11 Part 1 and 2Document1 pageEdc17c11 Part 1 and 2greemaxNo ratings yet

- Periodic Table of Elements W Melting Point PubChemDocument1 pagePeriodic Table of Elements W Melting Point PubChemHuey KaNo ratings yet

- Architectural 3Document1 pageArchitectural 3Cendrix PayaoNo ratings yet

- Drawing1.Dwg - Diagrama Unifilar - Ka Net-ModelDocument1 pageDrawing1.Dwg - Diagrama Unifilar - Ka Net-Modelacsabraga3No ratings yet

- Periodic Table of Elements W Chemical Group Block PubChemDocument1 pagePeriodic Table of Elements W Chemical Group Block PubChemClick LinkNo ratings yet

- CC1300 4812112482 Rev - DDocument7 pagesCC1300 4812112482 Rev - DsandroNo ratings yet

- Generac's Position in The Market: Derate DataDocument2 pagesGenerac's Position in The Market: Derate DataJuly E. Maldonado M.No ratings yet

- Cabaña QQWE12 OctDocument1 pageCabaña QQWE12 OctMiiguel Hdez MariinNo ratings yet

- Return RollersDocument1 pageReturn RollersHO Minh TuanNo ratings yet

- Fiesta Del Dolor Trumpet in BBDocument3 pagesFiesta Del Dolor Trumpet in BBJavier ZambranoNo ratings yet

- Fluid Lab Services Fluid Preparation Compositional Analysis PsDocument1 pageFluid Lab Services Fluid Preparation Compositional Analysis PsElzubair EljaaliNo ratings yet

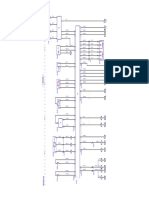

- HEN For Problem 7.3Document1 pageHEN For Problem 7.3Elzubair EljaaliNo ratings yet

- Hfe ch12 Pivot TablesDocument6 pagesHfe ch12 Pivot TablesElzubair EljaaliNo ratings yet

- Oil Stabilization With Optimization 1Document16 pagesOil Stabilization With Optimization 1Elzubair EljaaliNo ratings yet

- MSC Business Analytics Course Structure 2019 20Document1 pageMSC Business Analytics Course Structure 2019 20Elzubair EljaaliNo ratings yet

- Tut 1Document3 pagesTut 1Elzubair EljaaliNo ratings yet

- CPLX Tuts SolutionsDocument12 pagesCPLX Tuts SolutionsElzubair EljaaliNo ratings yet

- In en 924233 08 Ac 101Document10 pagesIn en 924233 08 Ac 101Elzubair EljaaliNo ratings yet

- Null 5Document2 pagesNull 5Elzubair EljaaliNo ratings yet

- TUT (4) Q1: Choose The Best AnswerDocument3 pagesTUT (4) Q1: Choose The Best AnswerElzubair EljaaliNo ratings yet

- Logbook StandardDocument1 pageLogbook StandardElzubair EljaaliNo ratings yet

- HSE in Short NotesDocument12 pagesHSE in Short NotesElzubair EljaaliNo ratings yet

- Page 1 of 4Document4 pagesPage 1 of 4Elzubair EljaaliNo ratings yet

- Com BrownDocument1 pageCom BrownElzubair EljaaliNo ratings yet

- Material BalanceDocument43 pagesMaterial BalanceElzubair EljaaliNo ratings yet

- Great Ways To StudyDocument70 pagesGreat Ways To StudyElzubair EljaaliNo ratings yet

- Pro MB (AutoRecovered)Document12 pagesPro MB (AutoRecovered)Elzubair EljaaliNo ratings yet

- Tut4 Q3Document9 pagesTut4 Q3Elzubair EljaaliNo ratings yet

- متغيرات العمليات الكيميائيةDocument31 pagesمتغيرات العمليات الكيميائيةElzubair EljaaliNo ratings yet

- CIL Control-1Document6 pagesCIL Control-1Elzubair EljaaliNo ratings yet

- Ayman Hnyde: Work ExperienceDocument4 pagesAyman Hnyde: Work ExperienceElzubair EljaaliNo ratings yet

- الأبعاد والنظم الأساسيةDocument28 pagesالأبعاد والنظم الأساسيةElzubair EljaaliNo ratings yet

- Assignment: Q M CP ( T 1 T 2)Document3 pagesAssignment: Q M CP ( T 1 T 2)Elzubair EljaaliNo ratings yet

- Win The Morning Win The Day!Document14 pagesWin The Morning Win The Day!Elzubair EljaaliNo ratings yet

- Speak Better EnglishDocument25 pagesSpeak Better EnglishElzubair EljaaliNo ratings yet

- Tutorial ERP StudentsDocument2 pagesTutorial ERP StudentsHariz MiorNo ratings yet

- Stainless Steel Putty (ST) : Technical Data SheetDocument2 pagesStainless Steel Putty (ST) : Technical Data SheetSreenivasNo ratings yet

- 3 Effects of Electric Current Physics ProjectDocument20 pages3 Effects of Electric Current Physics ProjectAkshatNo ratings yet

- Extintor CO2 B10V-1 - BADGER PDFDocument2 pagesExtintor CO2 B10V-1 - BADGER PDFCoordinador TecnicoNo ratings yet

- Produktblatt Auruna 215 en Screen 20190416Document2 pagesProduktblatt Auruna 215 en Screen 20190416Abdulrahman JradiNo ratings yet

- Glass Ceramics QuizDocument3 pagesGlass Ceramics QuizRon Pascual100% (1)

- Chemistry: Section I - Part B (Continued)Document21 pagesChemistry: Section I - Part B (Continued)Anonymous QE45TVC9e3No ratings yet

- Realistic Well Planning With Dynamic Well Control ModellingDocument7 pagesRealistic Well Planning With Dynamic Well Control ModellingAoun MuhammadNo ratings yet

- Chemistry Investigatory ProjectDocument19 pagesChemistry Investigatory ProjectDivya Vatsa50% (4)

- Chem Academy: Enolate ChemistryDocument13 pagesChem Academy: Enolate ChemistryHamit RanaNo ratings yet

- Protein MetabolismDocument6 pagesProtein MetabolismGeline Dela RosaNo ratings yet

- UV VIS CaffeineDocument15 pagesUV VIS CaffeineTinuviele EsguerraNo ratings yet

- Module 7 LipidsDocument3 pagesModule 7 Lipidsgarciamigueld23No ratings yet

- Metabolism Exam 2 - GIFT - Spring 2016Document9 pagesMetabolism Exam 2 - GIFT - Spring 2016shafa_nathani100% (2)

- Accc/Tw Prague (700) : Data SheetDocument1 pageAccc/Tw Prague (700) : Data SheetkmiqdNo ratings yet

- Analysis Synthesis and Design of Chemical Processes Third Edition T LDocument5 pagesAnalysis Synthesis and Design of Chemical Processes Third Edition T LUzair Wahid0% (1)

- Renderoc SP40: Constructive SolutionsDocument2 pagesRenderoc SP40: Constructive SolutionsSathiyaseelan SubramaniNo ratings yet

- Pacing Guide: Inspire ChemistryDocument6 pagesPacing Guide: Inspire Chemistryjsencion977No ratings yet

- Color, Solubility, and Complex Ion Equilibria of Nickel (11) Species in Aqueous SolutionDocument2 pagesColor, Solubility, and Complex Ion Equilibria of Nickel (11) Species in Aqueous SolutionManuel OrihuelaNo ratings yet

- Numerical Investigation On Freezing in Ballast Tank of Ship Navigating in Ice-Bound SeaDocument8 pagesNumerical Investigation On Freezing in Ballast Tank of Ship Navigating in Ice-Bound SeaAlexander ProkhorenkoNo ratings yet

- Formation of PrecipitationDocument2 pagesFormation of PrecipitationArianne May Amosin50% (2)

- Crack Identification in Reinforced Concrete Beams Using ANSYS SoftwareDocument13 pagesCrack Identification in Reinforced Concrete Beams Using ANSYS SoftwarethaibinhkxNo ratings yet

- Lai BinglinDocument22 pagesLai BinglinNicholas Chin Yong LekNo ratings yet

- Design of FRP-Profiles & All-FRP-Structures (2009) - Presentation PDFDocument67 pagesDesign of FRP-Profiles & All-FRP-Structures (2009) - Presentation PDFJulio Humberto Díaz RondánNo ratings yet

- Lenovo ThinkCentre M58 M58p ES50Document6 pagesLenovo ThinkCentre M58 M58p ES50Anthony P MadambaNo ratings yet

- Case Hardening SteelsDocument52 pagesCase Hardening SteelsGururaja TantryNo ratings yet

- CHAPTER 7 Solid Waste ManagementDocument28 pagesCHAPTER 7 Solid Waste Managementdaabgchi67% (3)

- Pulp Mill Odor ControlDocument6 pagesPulp Mill Odor Controlalakazum28No ratings yet

- 4CH1 2C Que 20211120Document24 pages4CH1 2C Que 20211120Fazal AhmedNo ratings yet

- Used Oil Recycling and Treatment in The United AraDocument11 pagesUsed Oil Recycling and Treatment in The United AraEssam AlharthyNo ratings yet