Professional Documents

Culture Documents

Hydraulic Calculation Procedures for Automatic Sprinkler Systems

Uploaded by

ahmad adnanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydraulic Calculation Procedures for Automatic Sprinkler Systems

Uploaded by

ahmad adnanCopyright:

Available Formats

Section 22.

4 ● Hydraulic Calculation Procedures 845

The 1966 edition of NFPA 13 was the first to include a chapter that dealt with hydraulic cal-

culations. The following sentence is from that edition: “The design area shall be the hy-

draulically most remote area and shall include all sprinklers on both sides of the cross main.”

This sentence meant that, if the system shown in Figure A.22.3.2(b) were to be calculated, the

10 sprinklers on the end of the system (five on each side of the cross main), plus two on the

next branch line, would be included in the calculation.

However, under certain conditions, such as where sprinklers were spaced 13 ft (3.96 m)

apart on a branch line and the branch lines were spaced 10 ft (3.05 m) apart, and where the

design area included 12 sprinklers, some designers were calculating 3 sprinklers on a branch

line [3 ⫻ 13 ft = 39 ft (3 ⫻ 3.96 m = 11.9 m)] over four branch lines [4 ⫻ 10 ft = 40 ft (4 ⫻

3.05 m = 12.2 m)]. This approach resulted in a design area that was nearly a perfect square.

The square shape for the design area would be inadequate if 4 sprinklers operated on the

branch line. Therefore, the requirement that the area of operation take the form of a rectan-

gle, with the length of the longer side having a dimension of 1.2⻫A, was eventually added.

Gridded systems, along with the specification of a square-shaped design area, first ap-

peared in the 1975 edition of NFPA 13 as follows: “For gridded systems, the design area shall

be the hydraulically most remote area which approaches a square.” This requirement was

adopted because it did not seem logical to calculate all of the sprinklers on one line of a grid,

which had been done for tree systems since 1966.

In later editions of NFPA 13, the characteristic square design area was changed to a rec-

tangular area. The longer side of the rectangle must be at least 1.2 times greater in length than

its shorter side. The dimension of the rectangle that is parallel to the branch lines must be the

longer dimension to account for the possibility that a fire could spread in that direction and

open multiple sprinklers on a single branch line before opening sprinklers on other branch

lines. To require more water to flow through a smaller number of individual branch lines is

hydraulically more demanding than to require the same demand to be supplied by more

branch lines with fewer operating sprinklers. Obviously, a worst-case scenario would be to

make the designer calculate all of the sprinklers on the remote branch line. However, at a cer-

tain point, the fire is much more likely to spread to areas under adjacent branch lines than to

spread entirely under one branch line. Part of the rationale behind design areas is an attempt

to predict where heat from a fire will travel. To provide an even greater factor of safety, some

insurance companies require the longer side of the design area to have a dimension of 1.4⻫A.

This more conservative approach, however, is not considered necessary by NFPA 13.

It should be noted that the design area is not always a single rectangle. The design area

can consist of two rectangles when the number of sprinklers on the branch line closest to the

water supply is less than the number of sprinklers on the most remote branch line. This situ-

ation frequently occurs when 1 or 2 sprinklers need to be added to the design area to ensure

that the number of sprinklers is sufficient to physically cover the area requirement.

The number of sprinklers for the design area can be calculated using the area of cover-

age for the sprinklers where the sprinklers are installed with relatively uniform spacing. For

example, for a design area of 1500 ft2 (139 m2) and an area of coverage of 130 ft2 (12 m2) per

sprinkler, the total number of sprinklers to be considered in the design area is 1500 ft2 divided

by 130 ft2 (139 m2 divided by 12 m2), which results in a total of 12 sprinklers (the actual num-

ber of 11.5 is rounded up to the next whole number).

The number of sprinklers along a branch line can be determined by dividing the length

of the design area’s longer side by the spacing of the sprinklers along the branch line where

the sprinklers are relatively uniform in their spacing. For example, with a design area of 1500

ft2 (139 m2) and a sprinkler spacing of 13 ft (3.96 m) along the branch lines and 10 ft (3.05

m) between branch lines, the number of sprinklers in the design area along the branch line is

4 — that is, (1.2⻫1500 ft2)/13 ft or (1.2⻫139 m2)/3.96 m. With a total of 12 sprinklers to be

considered and 4 sprinklers required per branch line, a total of three branch lines must be con-

sidered in the design area — that is, 12 divided by 4 equals 3. This technique applies only

where all sprinklers are uniformly spaced.

Automatic Sprinkler Systems Handbook 2010

846 Chapter 22 ● Plans and Calculations

FAQ 䊳 Where sprinklers are not uniformly spaced, the same general rules apply, but there are no

How are design areas neat formulas for determining the number of sprinklers in the design area or the maximum

determined where sprinklers are number of sprinklers to include on any single branch line. Instead, the length of the design

not uniformly spaced?

area needs to be determined (using the rule of 1.2 times the square root of the design area),

and all of the sprinklers that cover any part of the design area length need to be included in

the design area. Once the sprinklers on the most remote branch line have been established,

adjacent sprinklers on additional branch lines closer to the water supply need to be added until

the area encompassed by the sprinklers exceeds the total design area. Then, on the branch line

closest to the water supply, sprinklers can be dropped from the design area if they are the least

demanding sprinklers on the branch line and still allow the remaining sprinklers to physically

cover the required design area.

An example illustrating nonuniform sprinkler spacing requirements follows. Sprinklers

are located in an ordinary hazard occupancy in accordance with the spacing rules of Chapter

8, but, due to the location of walls and potential obstructions, the spacing is not uniform.

Sprinklers are located as shown in the plan view in Exhibit 22.4. For the sake of this exam-

ple, only the sprinklers, cross main, and branch lines near the design area are shown.

EXHIBIT 22.4 Design Area

Example with Nonuniform 2 ft

Spacing of Sprinklers.

10 ft

4 ft 6 ft 8 ft 10 ft 6 ft 4 ft 6 ft 8 ft 6 ft 2 ft

12 ft

10 ft

For SI units, 1 ft = 0.3 m.

If the ceiling in the building is 20 ft (6.1 m) in height, a density/area can be selected from

the curves in Figure 11.2.3.1.1, and the area can be reduced by 25 percent if quick-response

sprinklers are installed. Therefore, the final design area for this example is 1125 ft2 (104.25

m2) [1500 ft2 ⫻ 0.75 = 1125 ft2 (139 m2 ⫻ 0.75 = 104.25 m2)]. Using the rule for 1.2 times

the square root of the design area, the length of the design area parallel to the branch lines

needs to be at least 40.25 ft (12.3 m) long [1.2 times the square root of 1125 ft2 (104.25 m2)].

The design area needs to start in the northwest corner of the building (most remote from the

water supply) and continue to the east, picking up all sprinklers that cover territory within

40.25 ft (12.3 m) of the corner, as shown in Exhibit 22.5. Note that the design area has to in-

clude the five sprinklers labeled as A, B, C, D, and E. Sprinkler F is not included in the de-

sign area, because sprinkler E is permitted to cover 2.25 ft (0.69 m) to its east. This raises an

2010 Automatic Sprinkler Systems Handbook

Section 22.4 ● Hydraulic Calculation Procedures 839

the actual length of pipe attached to the fitting. To correctly add the equivalent pipe length to

the actual pipe length, the two pipes need to be of the same material and of the same internal

diameter, and they must have the same C factor.

Table 22.4.3.1.1 contains equivalent lengths for various types of fittings and valves for

Schedule 40 pipe with a C factor of 120. Where other types of pipe are used, the length of

pipe needed to create the same amount of friction loss will be different. The formula in

22.4.3.1.3.1 is used to adjust for different pipe diameter (other schedules of pipe), and

22.4.3.2, including Table 22.4.3.2, is used to adjust for differing C factors.

The example that follows illustrates the effect of differing C factors. The base formula for

friction loss through a given length of pipe using the Hazen–Williams approach is as follows:

4.52Q1.85

Pf = L ⫻

(C1.85)(d4.87)

where:

Pf = friction loss (psi)

L = length (ft)

Q = flow (gpm)

C = friction loss coefficient

d = actual internal diameter of pipe (in.)

The example illustrates why an adjustment is needed and considers a 2 in. (50 mm),

Schedule 40, 10 ft (3 m) length of steel pipe with a C factor of 100 when 135 gpm (511

L/min) is flowing through the pipe. The actual internal diameter of the pipe must be used.

Table A.6.3.2 and Table A.6.3.5 provide information in this regard. When the C factor is 100,

the friction loss is as follows:

4.52(1351.85)

Pf(100) =10

[

(1001.85)(2.0674.87) ]

= 2.7 psi

From Table 22.4.3.2, the multiplier for pipe having a C value of 100 is 0.713. The cor-

rection to the friction loss value is as follows:

Pf(100) = 2.7 psi ⫻ 0.713 = 1.9 psi

When the C factor is 120, the friction loss is as follows:

4.52(1351.85)

Pf(120) = 10

[ (1201.85)(2.0674.87) ]

= 1.9 psi

Therefore, the values from Table 22.4.3.1.1 need to be adjusted accordingly when C factors

other than 120 are used.

Another example specifically considers the adjustment needed for a fitting. Determine

the equivalent length of a 11/4 in. (32 mm) 90 degree elbow used in a system employing Sched-

ule 10 steel pipe on a dry pipe system.

In Step 1, determine the internal diameter of Schedule 10 and Schedule 40 steel pipe. From

Table A.6.3.2, Schedule 10 is 1.442 in. (36.6 mm) and Schedule 40 is 1.380 in. (35.1 mm).

In Step 2, derive the factor using the following equation (see also 22.4.3.1.3.1):

4.87

factor = (

1.442 in.

1.380 in. ) = 1.2387

In Step 3, establish the equivalent length of a 11/4 in. pipe obtained from Table 22.4.3.1.1

for a 11/4 in. (32 mm), Schedule 40, 90 degree elbow by the factor determined in Step 2, as

follows:

3 ft (0.9 m) ⫻ 1.2387 = 3.716 ft (1.13 m)

Automatic Sprinkler Systems Handbook 2010

844 Chapter 22 ● Plans and Calculations

System A in Figure A.22.4.4.1(a) shows the design area for 12 sprinklers with three branch

lines and 4 sprinklers per branch line. However, all sprinkler systems don’t end up with per-

fectly rectangular design areas as shown in system A. Frequently, an extra sprinkler or two

needs to be added to the design area to make sure that it covers the right size space, and Fig-

ure A.22.4.4.1.1.1 was added in the 2010 edition to show such an example. In these cases, the

design area becomes two rectangles, one smaller and one larger.

Systems B and C in Figure A.22.4.4.1(a) are examples of two such rectangular design

areas, with the location of the extra sprinkler on the fourth branch line.

System D in Figure A.22.4.4.1(a) illustrates the situation described in 22.4.4.1.1.3, with

an insufficient number of sprinklers on the branch lines to meet the rule for 1.2 times the

square root of the area. In this case, additional sprinklers on additional branch lines are added

to maintain the minimum design area.

System E in Figure A.22.4.4.1(a) illustrates that sprinklers on both sides of the cross

main can be used to achieve the required design area and the rule for 1.2 times the square root

of the design area.

Figure A.22.4.4.1(b) illustrates the design area for looped systems with various riser lo-

cations and branch line configurations.

22.4.4.1.1 Density/Area Method.

22.4.4.1.1.1* Where the design is based on the density/area method, the design area shall be

a rectangular area having a dimension parallel to the branch lines at least 1.2 times the square

root of the area of sprinkler operation (A) used, which shall permit the inclusion of sprinklers

on both sides of the cross main.

A.22.4.4.1.1.1 The word “rectangular” in this section is not meant to imply that the design

area always has to be a rectangle. Instead, the intent is to require a design area with sides that

meet at right angles and the longer side parallel to the branch lines. In many cases, this will

be a perfect rectangle with four sides. However, in some cases with multiple sprinklers on

multiple branch lines within the design area, the design area can be satisfied with fewer sprin-

klers on the last branch line than on the first, resulting in a design area that is a rectangle with

the corner cut out as shown in Figure A.22.4.4.1.1.1.

10 ft

10 ft

Design area

Discharge criteria: 0.45 gpm²/2000 ft²

20 sprinklers in design area 1.2(2000)0.5/10 = 5.3 rounded up to

6 sprinklers per branch line

Note that the design area is not a perfect rectangle. The 2000 ft²

requirement can be met with fewer sprinklers on the fourth branch

line back, so there is no need to include the additional four sprinklers

on the fourth branch line.

FIGURE A.22.4.4.1.1.1 Example of Nonsymmetrical

Hydraulically Most Demanding Area.

22.4.4.1.1.2 Any fractional sprinkler shall be carried to the next higher whole sprinkler.

22.4.4.1.1.3 In systems having branch lines with an insufficient number of sprinklers to ful-

fill the 1.2 requirement, the design area shall be extended to include sprinklers on adjacent

branch lines supplied by the same cross main.

2010 Automatic Sprinkler Systems Handbook

Section 22.4 ● Hydraulic Calculation Procedures 841

Calculated area A 2 12 ft between sprinklers

1 x x x x x x

10 ft between lines

2 x x x x x x

3 x x x x x x

4 x x x x x x

A B C D E F

Notes:

1. For gridded systems, the extra sprinkler (or sprinklers) on branch

line 4 can be placed in any adjacent location from B to E at the

designer’s option.

2. For tree and looped systems, the extra sprinkler on line 4

should be placed closest to the cross main.

Assume a remote area of 1500 ft2 with sprinkler coverage of 120 ft2

Design area

Total sprinklers to calculate =

Area per sprinkler

1500

= = 12.5, calculate 13

120

1.2÷ A

Number of sprinklers on branch line =

S

Where:

A = design area

S = distance between sprinklers on branch line

1.2÷1500 = 3.87

Number of sprinklers on branch line =

12

For SI units, 1 ft = 0.3048 m; 1 ft2 = 0.0929 m2.

FIGURE A.22.4.4 Example of Determining the Number of

Sprinklers to Be Calculated.

lated on the second branch line. Hydraulic calculations for the first branch at point A indicate

a demand of 37 gpm (140.1 L/min) at 15 psi (1.0 bar). This demand includes discharge

through sprinklers 1 and 2 and the associated pressure and elevation losses. Hydraulic calcu-

lations for the second branch line when sprinkler 3 is operating indicate a demand of 18 gpm

(68.1 L/min) at 12 psi (0.8 bar) at point A. Because only one pressure can exist at point A, the

higher pressure of 15 psi (1.0 bar) will need to be provided, so that the proper discharge from

sprinklers 1 and 2 is obtained. Supplying a pressure of 12 psi (0.8 bar) will result in less than

1

37 gpm (140.1 L/min) through the first branch line. At point A, 15 psi (1.0 bar) will create a 2

waterflow in excess of 18 gpm (68.1 L/min) through the second branch line to sprinkler 3.

The increased flow can be calculated by determining a K-factor at point A, using the demand 3

information for sprinkler 3 at point A of 18 gpm (68.1 L/min) at 12 psi (0.8 bar) and rear-

ranging the formula Q = K⻫P to solve for K. This equation yields a K-factor of K-5.2, as fol-

lows:

(18 gpm)

A

⻫12 psi

The K-factor is used to determine the flow at sprinkler 3 if the pressure is increased to 15 psi EXHIBIT 22.3 Branch Line

(1.0 bar) with the formula Q = K⻫P. In this case, Q = 5.2⻫15 psi (1.0 bar) = 20 gpm (75.7 Schematic.

Automatic Sprinkler Systems Handbook 2010

Section 22.4 ● Hydraulic Calculation Procedures 843

Paragraph 22.4.4.1 clarifies that the water supply must be capable of handling the most de-

manding situation faced by the system. The most demanding situation may not be the most

remote from the water supply if situations closer to the water supply are more hazardous or

have larger areas protected by individual sprinklers. For example, an office building might be

sprinklered as a light hazard occupancy, with sprinklers spaced 14 ft ⫻ 14 ft (4.3 m ⫻ 4.3 m)

in the rooms remote from the water supply and extended coverage sprinklers covering 20 ft

⫻ 20 ft (6.1 m ⫻ 6.1 m) close to the water supply. The extended coverage sprinklers are closer

to the water supply, but they may produce a demand greater than the sprinklers on 14 ft ⫻ 14

ft (4.3 m ⫻ 4.3 m) spacing far from the water supply. Calculations need to be performed for

verification. Where multiple areas are being calculated, it is possible that one area will have

a higher pressure demand and the other area will have a higher flow demand. In these cir-

cumstances, adding the demands together is not necessary. It is also not necessary to ensure X X X X X X

X

X X

X

X

X

X X X X X X

that the higher flow is available at the higher pressure. Instead, the water supply only needs X X X X X X X X X

X X X X X X X X X

to be verified as being capable of handling each individual demand situation. X X X X X X X X X

Paragraph 22.4.4.1 also recognizes that the design areas are not always in the shape of a X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

rectangle. For example, in a design involving listed residential sprinklers, the design area of X X X X X X X X X

four sprinklers might be a perfect square, depending on the branch line locations and the room X X

X X

configuration. X X

The storage discharge requirements are broken out of Chapter 12 and into their own X X

X X

chapters. These requirements are located in Chapters 13 to 20. However, since the general X X

rules remained in Chapter 12, 22.4.4.1 only references Chapter 12. But, by inference, all of X

X

X

the rules in Chapters 13 through 20 are referenced in Chapter 12.

A

A.22.4.4.1 See Figure A.22.4.4.1(a) and Figure A.22.4.4.1(b). X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X X X X X X X X X

X X X X X X X X X

X X X X X X X

X X X X X X X X X

X X X X X X X

X X X X X X X X

X

X X

X X X X X X X

X X X X X X X X

X

X X X X X X X X

X

X X X

X X X X X X

X X X X X X X

A

X X X X X X X

X X X X X X

X X X

A X X X X

X X X X X X

X X X X X X

X

X

X

X X X X X X

X

X

X

X

X

X

X

X

X X X X X X

X

X

X

X

X

X X X X X X

1

X

X

X

X

X

X X X X X X

X

X

X

X

X

X

X

X X X X X X

X

X

X

X

X

X

X X

B

X

X

X

X X

B X X

X X

X X

X X

X X

X X X X X X

X X X X X X

C D

X X X X X X

X

X

X

X X X X X X

X

X

X

X X X X X X

X

X

X

X X

B

X

X

X

X X

X

X

X

X X

X X

X X

E

FIGURE A.22.4.4.1(b)

1 This sprinkler is not in the selected area of operation. Example of Hydraulically

Most Demanding Area

FIGURE A.22.4.4.1(a) Example of Hydraulically Most for Various Piping

Demanding Area. Arrangements.

Automatic Sprinkler Systems Handbook 2010

840 Chapter 22 ● Plans and Calculations

In Step 4, make a final adjustment for the different C factor for a dry pipe system. From

Table 22.4.4.7, the C value for a dry system using black steel is 100. From Table 22.4.3.2, the

multiplier for pipe with a C value of 100 is 0.713. Therefore, the equivalent length of a 11/4 in.

(32 mm) 90 degree elbow used in a system employing Schedule 10 steel pipe on a dry pipe

system is as follows:

0.713 ⫻ 3.716 ft (1.13 m) = 2.6495 ft (808 mm)

FAQ 䊳 The values in Table 22.4.3.1.1 are not friction losses. They are the lengths of straight pipe

Why are the equivalent lengths that have the same friction loss as the fittings or valves. Pipes with C factors greater than 120

multiplied by numbers greater

have less friction loss per foot of pipe, therefore it takes more pipe to get to the same friction

than 1.0 for C factors better

than 120 and less than 1.0 for C loss of a fitting than it does for pipe with a C factor of 120. Likewise, pipes with a C factor

factors less than 120 when C less than 120 take less pipe to achieve the same friction loss as it does pipe with a C factor of

factors less than 120 have a 120.

worse friction loss?

22.4.3.3 Valves. Specific friction loss values or equivalent pipe lengths for alarm valves, dry

pipe valves, deluge valves, strainers, and other devices shall be made available to the author-

ity having jurisdiction.

22.4.3.4 Differing Values. Specific friction loss values or equivalent pipe lengths for listed

fittings not in Table 6.4.1 shall be used in hydraulic calculations where these losses or equiv-

alent pipe lengths are different from those shown in Table 22.4.3.1.1.

Specially listed products that do not conform to the ASTM pipe sizes are addressed in

22.4.3.4. A number of special fittings that are listed for various pipe types are available on the

market. These fittings often have friction loss values that differ from the values given in Table

22.4.3.1.1. Although these fittings tend to facilitate the installation of a system, they do come

with a pressure penalty that must be accounted for in the hydraulic calculations. As indicated

in 22.1.3, the working plans are required to include manufacturer’s instructions and informa-

tion on these specially listed fittings.

22.4.4* Calculation Procedure.

A.22.4.4 See Figure A.22.4.4.

Details on how to properly calculate the water demand of a sprinkler system are provided in

22.4.4. The various concepts and equations described throughout Chapters 11 through 22 to

hydraulically design a system are tied together in 22.4.4.

The concepts in Chapters 11 through 21 are used to determine the amount of water each

sprinkler will need to discharge, the pressure necessary to achieve this flow, the number of

sprinklers to calculate, the duration of the water supply, and the existence and demand of hose

connections. Hydraulic calculations are then typically performed by starting with the flow

and pressure demand at the most hydraulically demanding single point in the system, which

is usually the most distant sprinkler from the water supply. Working back toward the water

supply, pressure losses and additional flows are added to determine the total water demand.

At some points within a system, the waterflow will split and travel in two or more direc-

tions. This flow split happens on cross mains with multiple branch lines, at connections to

lines supplying in-rack sprinklers, and at connections to hose stations. When this type of flow

split occurs, the demand for each leg of the split needs to be calculated independently. Be-

cause only one pressure reading can exist at a single point in the system, the more demand-

ing pressure reading is used at the point of separation. Therefore, the flow through the line

that requires less pressure needs to be adjusted to the higher pressure. This adjustment results

in a greater waterflow because of the greater amount of pressure. The adjustment is accom-

plished using a combined K-factor, as shown in the example that follows, and as permitted by

22.4.2.4.3. (See the commentary following 22.4.2.4.3.)

Consider the portion of a sprinkler system shown in Exhibit 22.3. The flow through sprin-

klers 1 and 2 is calculated on the first branch line, and the flow through sprinkler 3 is calcu-

2010 Automatic Sprinkler Systems Handbook

842 Chapter 22 ● Plans and Calculations

L/min). The total demand at point A becomes 57 gpm (216 L/min) [37 gpm ⫹ 20 gpm (140

L/min ⫹ 76 L/min)] at 15 psi (1.0 bar).

Calculations at the point of connection of the line that supplies in-rack sprinklers are

done as indicated in the preceding example. At the point of connection to the ceiling sprin-

kler system, the two demands are evaluated, with the higher pressure demand selected and the

flow at the lower demand adjusted to the higher pressure. For some specific commodities

stored in racks, the protection criteria do not require the in-rack sprinkler water demand to be

added to the ceiling system demand. One example includes combustible liquids in plastic con-

tainers protected in accordance with NFPA 30, Flammable and Combustible Liquids Code.

The protection criteria for this commodity employ ceiling sprinklers, in-rack sprinklers, and

solid barriers throughout the rack. In this circumstance, only the most demanding flow from

either the ceiling sprinkler system or the in-rack sprinkler system needs to be met. Unless the

standard prescribing the sprinkler requirements expressly permits the water supply to satisfy

only the more demanding of the two systems (ceiling sprinklers or in-rack sprinklers), the two

demands need to be added together after balancing them to the higher pressure demand as

shown in the previous example.

Hose connections to sprinkler systems that are part of a standpipe system required to

meet NFPA 14, Standard for the Installation of Standpipe and Hose Systems, also may need

to be adjusted as described in the previous example. The requirements of NFPA 14 for com-

bined systems provide more information on this piping arrangement.

Hose connections to sprinkler systems that are not part of a standpipe system, such as

those installed for first aid in warehouses, are not required to follow the adjustments described

in the previous example. Instead, the flow demand is added to the sprinkler demand at the

point of connection using the pressure available in the system at that point. In effect, no min-

imum pressure requirement exists for hose connections that are not part of a standpipe sys-

tem.

Figure A.22.4.4 illustrates how to determine the number of sprinklers in a gridded sys-

tem’s area of operation and how to determine the number of sprinklers on each branch line in

the area of operation. Note that the formulas used in Figure A.22.4.4 only work where using

relatively uniform spacing of sprinklers and where placement of sprinklers is approximately

half the distance to the wall with respect to the location of the next sprinkler in the opposite

direction. In Figure A.22.4.4, the design area physically needs to cover 1500 ft2 (139 m2). If

the sprinklers are not uniformly spaced at 10 ft ⫻ 12 ft (3 m ⫻ 3.7 m) coverage, additional

sprinklers might need to be added, so that the design area is at least 1500 ft2 (139 m2).

Similarly, if the sprinklers on the most remote branch line are close to the wall, the 13

sprinklers shown in the design area in Figure A.22.4.4 might not cover 1500 ft2 (139 m2), and

additional sprinklers would be needed. For example, if the sprinklers on the most remote

branch line were 1 ft (0.3 m) away from the wall, the 13 sprinklers shown would only phys-

ically cover 1368 ft2 (127 m2) [26 ft2 ⫻ 48 ft2 (2.4 m2 ⫻ 4.5 m2) for the large rectangle plus

the 120 ft2 (11.1 m2) covered by sprinkler B]. Adding an additional sprinkler (sprinkler C in

Figure A.22.4.4) would only increase the covered area to 1488 ft2 (138 m2), so an additional

sprinkler (sprinkler D) would be needed to ensure that the design area covered at least 1500

ft2 (139 m2).

If the sprinkler system in Figure A.22.4.4 were a tree or loop system, the branch line

would terminate at the last sprinkler on the right in the calculated area, and the cross main

would probably be to the left. In this situation, the extra sprinkler on branch line 4 would have

to be sprinkler B for tree and loop systems, because it is closest to the supply and would be

the hydraulically most demanding on that branch line. Tree and loop systems do not have the

freedom implied by note 1 to Figure A.22.4.4.

22.4.4.1* For all systems the design area shall be the hydraulically most demanding based on

the criteria of Chapter 11, Chapter 12, or the special design approaches in accordance with

the requirements of Chapter 21.

2010 Automatic Sprinkler Systems Handbook

You might also like

- 14Document16 pages14Ahmad mkNo ratings yet

- Extended Coverage Sprinkler SpacingDocument13 pagesExtended Coverage Sprinkler Spacingm.sofiqur rahmanNo ratings yet

- Obstructions and Extended Coverage Sprinklers-The "Four Times Rule"Document11 pagesObstructions and Extended Coverage Sprinklers-The "Four Times Rule"m.sofiqur rahmanNo ratings yet

- 13Document13 pages13Ahmad mkNo ratings yet

- Hydraulic Calculations For Small RoomsDocument4 pagesHydraulic Calculations For Small RoomsAnonymous qrSsYuxyoYNo ratings yet

- 18-Duct DesignDocument6 pages18-Duct Designpryor.lamarioNo ratings yet

- Fire Sprinkler System - Article ObstructionDocument5 pagesFire Sprinkler System - Article ObstructionKarthikeyan VeerasamyNo ratings yet

- Determining Remote AreaDocument5 pagesDetermining Remote AreaSdwise100% (1)

- Pipe Expansion Support MethodsDocument6 pagesPipe Expansion Support MethodsTeeranai ThaiteamsingNo ratings yet

- Sprinkler System Design CapacityDocument14 pagesSprinkler System Design Capacityisaacodi100% (1)

- Drainage Systems Design GuideDocument64 pagesDrainage Systems Design GuideRichardLaraMedinaNo ratings yet

- Module 4 - Hydraulic CalculationDocument42 pagesModule 4 - Hydraulic CalculationJoseph Ryan Manandeg100% (1)

- Design Guide: Hunter Rainwater SystemsDocument5 pagesDesign Guide: Hunter Rainwater SystemsTransgulfNo ratings yet

- Drainagesystemslecturei 091022013358 Phpapp02Document62 pagesDrainagesystemslecturei 091022013358 Phpapp02Abdul Raoof100% (1)

- Heating and Cooling Load CalculationDocument7 pagesHeating and Cooling Load Calculationirsalan_shahidNo ratings yet

- Design Rules Low Speed TunnelsDocument11 pagesDesign Rules Low Speed TunnelsJaideep PanditNo ratings yet

- Example 21Document2 pagesExample 21RamosPeterNo ratings yet

- 10Document19 pages10Ahmad mkNo ratings yet

- Pipes and Pipe Sizing - International Site For Spirax SarcoDocument19 pagesPipes and Pipe Sizing - International Site For Spirax Sarcokarthikraja21100% (1)

- بتول ماجد سعيد (التقرير النهائي)Document20 pagesبتول ماجد سعيد (التقرير النهائي)Batool MagedNo ratings yet

- Wind Tunnel Designs and Their Diverse Engineering Applications 14Document2 pagesWind Tunnel Designs and Their Diverse Engineering Applications 14Dang Tien PhucNo ratings yet

- Ponding On The Flat RoofsDocument4 pagesPonding On The Flat RoofsthirumalaichettiarNo ratings yet

- NFPA 13 Sprinkler System Layout and Design RequirementsDocument24 pagesNFPA 13 Sprinkler System Layout and Design RequirementsAnonymous qrSsYuxyoYNo ratings yet

- Proper Gutter and Downspout Sizing Design of Roof Drainage Systems Roof DrainageDocument4 pagesProper Gutter and Downspout Sizing Design of Roof Drainage Systems Roof DrainageEhman TarosaNo ratings yet

- Ventilator FanDocument6 pagesVentilator FanloqNo ratings yet

- Atmospheric Boundary Layer Wind Tunnel DesignDocument6 pagesAtmospheric Boundary Layer Wind Tunnel DesignYadvender SinghNo ratings yet

- Car Park Ventilation System DesignDocument16 pagesCar Park Ventilation System DesignSopi Labu100% (1)

- TDP 504 - Duct Design Level 1 Fundamentals - QuizDocument3 pagesTDP 504 - Duct Design Level 1 Fundamentals - QuizSuthi Sae DanNo ratings yet

- Nfpa 13 Sprinkler DesignDocument42 pagesNfpa 13 Sprinkler Designdaves guron0% (1)

- Shell and Tube Heat Exchanger Design PreparedDocument6 pagesShell and Tube Heat Exchanger Design PreparedEmebu SamuelNo ratings yet

- 10 - Air Distribution SystemDocument7 pages10 - Air Distribution SystemZeeshan HasanNo ratings yet

- Case StudyDocument33 pagesCase StudyDaryl Gomez TimatimNo ratings yet

- Eurovent 2.3Document24 pagesEurovent 2.3pipipopo75100% (1)

- Low-Speed Wind TunnelDocument32 pagesLow-Speed Wind TunnellucioctsicilNo ratings yet

- Chapter 4 Design of Sewers 4 1 Design ofDocument11 pagesChapter 4 Design of Sewers 4 1 Design ofSuchitra PandaNo ratings yet

- Sieve Tray ExtractorDocument12 pagesSieve Tray ExtractorCris-Anne Juangco III100% (2)

- Differential Head Flowmeters (Usbr - Gov) (ISO-5167 Stolz Equation) .HTMLDocument7 pagesDifferential Head Flowmeters (Usbr - Gov) (ISO-5167 Stolz Equation) .HTMLempanadaNo ratings yet

- Roof Drains Tech DataDocument19 pagesRoof Drains Tech DataperezismaelNo ratings yet

- Percolation TestDocument3 pagesPercolation TestKothiyal MukeshNo ratings yet

- Car Park Ventilation System DesignDocument13 pagesCar Park Ventilation System Designnakul4491_88890127100% (1)

- Steam Distribution Essentials: Mains, Drainage and WaterhammerDocument11 pagesSteam Distribution Essentials: Mains, Drainage and Waterhammerhej hejNo ratings yet

- VESDA Air Sampling Pipe NetworkDocument3 pagesVESDA Air Sampling Pipe Networksamir rabiaNo ratings yet

- Workshop 1 - Dewatering Questions (Solutions)Document4 pagesWorkshop 1 - Dewatering Questions (Solutions)guanglichen0No ratings yet

- Car Parking CalclulationDocument9 pagesCar Parking CalclulationVishnu PrajapatiNo ratings yet

- Sprinkler Sloped - Ceilings - 2010 PDFDocument7 pagesSprinkler Sloped - Ceilings - 2010 PDFnrodinis7No ratings yet

- Car Park Ventilation System DesignDocument15 pagesCar Park Ventilation System DesignAlvaajid SaleemNo ratings yet

- BD Prelim 1Document14 pagesBD Prelim 1Julia KirstenNo ratings yet

- Underground Facilities for Better Environment and Safety - India Ventilation of long tunnelsDocument13 pagesUnderground Facilities for Better Environment and Safety - India Ventilation of long tunnelsClifford Allen CooperNo ratings yet

- Design and Operations Manual PressurizedDocument184 pagesDesign and Operations Manual PressurizedDu Tu LeNo ratings yet

- Design ApproachesDocument19 pagesDesign ApproachesJoseph Ryan Manandeg100% (1)

- GBD 112 THEME 4 Lecture NotesDocument5 pagesGBD 112 THEME 4 Lecture Notescorliavanz1303No ratings yet

- Perhitunga TalangDocument13 pagesPerhitunga Talangmuhammadudin1731No ratings yet

- Storm Water Drainage System-3Document24 pagesStorm Water Drainage System-3Abed BaayounNo ratings yet

- Roof Drain Sizing8Document8 pagesRoof Drain Sizing8Minh TranNo ratings yet

- CH 4 Sewers DesignDocument11 pagesCH 4 Sewers DesignmavessNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Steam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversFrom EverandSteam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversRating: 5 out of 5 stars5/5 (2)

- الأجهزة والآلات المستخدمه في النجارة-62-63Document2 pagesالأجهزة والآلات المستخدمه في النجارة-62-63ahmad adnanNo ratings yet

- الأجهزة والآلات المستخدمه في النجارة-29-30Document2 pagesالأجهزة والآلات المستخدمه في النجارة-29-30ahmad adnanNo ratings yet

- Topic 5-Fault Tree Analysis Part Two AudioDocument17 pagesTopic 5-Fault Tree Analysis Part Two Audioahmad adnanNo ratings yet

- الأجهزة والآلات المستخدمه في النجارة-51-54Document4 pagesالأجهزة والآلات المستخدمه في النجارة-51-54ahmad adnanNo ratings yet

- Topic 5-Fault Tree Analysis 1ST PART AUDIODocument25 pagesTopic 5-Fault Tree Analysis 1ST PART AUDIOahmad adnanNo ratings yet

- Topic 5-Fault Tree Analysis Part Three AudioDocument19 pagesTopic 5-Fault Tree Analysis Part Three Audioahmad adnanNo ratings yet

- Lecture One Brain Storming in Risk Assessment First Semester 2020-2021Document340 pagesLecture One Brain Storming in Risk Assessment First Semester 2020-2021ahmad adnanNo ratings yet

- Design of Fire Protection System 1 Dr. Abdullah Olimat First Semester 2015/2016 Subject 6: PumpsDocument66 pagesDesign of Fire Protection System 1 Dr. Abdullah Olimat First Semester 2015/2016 Subject 6: Pumpsahmad adnanNo ratings yet

- Topic 5-Fault Tree Analysis Part Two AudioDocument17 pagesTopic 5-Fault Tree Analysis Part Two Audioahmad adnanNo ratings yet

- Section 22.1 Working Plans: Automatic Sprinkler Systems Handbook 2010Document13 pagesSection 22.1 Working Plans: Automatic Sprinkler Systems Handbook 2010ahmad adnanNo ratings yet

- Lecture One Brain Storming in Risk Assessment First Semester 2020-2021Document340 pagesLecture One Brain Storming in Risk Assessment First Semester 2020-2021ahmad adnanNo ratings yet

- Lecture One Passive - Part Two AudioDocument405 pagesLecture One Passive - Part Two Audioahmad adnanNo ratings yet

- Hydraulic Calculation Procedures for Automatic Sprinkler SystemsDocument8 pagesHydraulic Calculation Procedures for Automatic Sprinkler Systemsahmad adnanNo ratings yet

- Sprinkler Spacing and ObstructionsDocument39 pagesSprinkler Spacing and Obstructionsahmad adnanNo ratings yet

- Design of Fire Protection System 1 Dr. Abdullah Olimat First Semester 2015/2016 Subject 6: PumpsDocument66 pagesDesign of Fire Protection System 1 Dr. Abdullah Olimat First Semester 2015/2016 Subject 6: Pumpsahmad adnanNo ratings yet

- Sprinkler Spacing and ObstructionsDocument39 pagesSprinkler Spacing and Obstructionsahmad adnanNo ratings yet

- Lecture One Passive - Part Two AudioDocument405 pagesLecture One Passive - Part Two Audioahmad adnanNo ratings yet

- Underground Piping RequirementsDocument18 pagesUnderground Piping Requirementsahmad adnanNo ratings yet

- Hydraulic Calculation Procedures for Automatic Sprinkler SystemsDocument8 pagesHydraulic Calculation Procedures for Automatic Sprinkler Systemsahmad adnanNo ratings yet

- Table 8.7.2.2.1: TABLE 8.7.2.2.1 Protection Areas and Maximum Spacing (Standard Sidewall SprayDocument24 pagesTable 8.7.2.2.1: TABLE 8.7.2.2.1 Protection Areas and Maximum Spacing (Standard Sidewall Sprayahmad adnanNo ratings yet

- Underground Piping RequirementsDocument18 pagesUnderground Piping Requirementsahmad adnanNo ratings yet

- Section 22.1 Working Plans: Automatic Sprinkler Systems Handbook 2010Document13 pagesSection 22.1 Working Plans: Automatic Sprinkler Systems Handbook 2010ahmad adnanNo ratings yet

- Table 8.7.2.2.1: TABLE 8.7.2.2.1 Protection Areas and Maximum Spacing (Standard Sidewall SprayDocument24 pagesTable 8.7.2.2.1: TABLE 8.7.2.2.1 Protection Areas and Maximum Spacing (Standard Sidewall Sprayahmad adnanNo ratings yet

- كتاب الثقافة الإسلامية المعتمد-2-81Document80 pagesكتاب الثقافة الإسلامية المعتمد-2-81ahmad adnanNo ratings yet

- Underground Piping RequirementsDocument18 pagesUnderground Piping Requirementsahmad adnanNo ratings yet

- Section 22.1 Working Plans: Automatic Sprinkler Systems Handbook 2010Document13 pagesSection 22.1 Working Plans: Automatic Sprinkler Systems Handbook 2010ahmad adnanNo ratings yet

- Scanned Document CollectionDocument213 pagesScanned Document Collectionahmad adnanNo ratings yet

- Table 8.7.2.2.1: TABLE 8.7.2.2.1 Protection Areas and Maximum Spacing (Standard Sidewall SprayDocument24 pagesTable 8.7.2.2.1: TABLE 8.7.2.2.1 Protection Areas and Maximum Spacing (Standard Sidewall Sprayahmad adnanNo ratings yet

- كتاب الثقافة الإسلامية المعتمدDocument213 pagesكتاب الثقافة الإسلامية المعتمدahmad adnanNo ratings yet

- CS Fallback (ERAN12.1 03)Document314 pagesCS Fallback (ERAN12.1 03)CosminDNo ratings yet

- Intech200906 FocusDocument29 pagesIntech200906 FocusMauro Sánchez100% (1)

- MY ResumeDocument3 pagesMY ResumebbcemkeceNo ratings yet

- NTC Thermistors Type RL30: Uncoated Disc With Radial LeadsDocument2 pagesNTC Thermistors Type RL30: Uncoated Disc With Radial LeadsJonh G. GonzálezNo ratings yet

- Praktikum Akuntansi-BiayaDocument27 pagesPraktikum Akuntansi-BiayaK-AnggunYulianaNo ratings yet

- Dirtbag DeluxeDocument9 pagesDirtbag DeluxeRuben Malagon VargasNo ratings yet

- 3.6.3 Column and Beam Fire ProtectionDocument10 pages3.6.3 Column and Beam Fire Protectionodemircioglu2No ratings yet

- API 510 External Inspection ChecklistDocument3 pagesAPI 510 External Inspection ChecklistMetallurgist007100% (3)

- A17fo PDFDocument16 pagesA17fo PDFdivortiareNo ratings yet

- Manage inventory levels and reorder itemsDocument7 pagesManage inventory levels and reorder itemsSenior Clothing Production TrainorNo ratings yet

- 24 Useful Excel Macro Examples For VBA Beginners (Ready-To-use)Document24 pages24 Useful Excel Macro Examples For VBA Beginners (Ready-To-use)Shrinivasan ParthasarathyNo ratings yet

- Ansys CrackingDocument1 pageAnsys CrackingPiranha TourniquetNo ratings yet

- 2005 c230 Factory Approved Service PamphletDocument30 pages2005 c230 Factory Approved Service Pamphletsrikarmallampati100% (2)

- Associate JD - CL 10Document3 pagesAssociate JD - CL 10Chandan AnandNo ratings yet

- Post-Secondary Options Classroom Lesson PlanDocument3 pagesPost-Secondary Options Classroom Lesson Planapi-2522299320% (1)

- EMI Vs Veris ECDocument11 pagesEMI Vs Veris ECEzrin Mohd Husin100% (2)

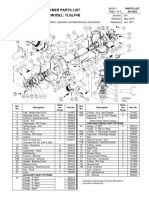

- Blackmer Parts List Pump Model: Tlglf4BDocument2 pagesBlackmer Parts List Pump Model: Tlglf4BRAUL ARMANDO PALOMO CAMPOSNo ratings yet

- RC Roof Beam DesignDocument5 pagesRC Roof Beam DesignSujay SantraNo ratings yet

- BSR330 Briefing IFP W1 - September 2019Document22 pagesBSR330 Briefing IFP W1 - September 2019Nur FatinahNo ratings yet

- M - SC - (CS) - 341 13 - Advaned Java ProgrammingDocument296 pagesM - SC - (CS) - 341 13 - Advaned Java ProgrammingRajee Ammayappan0% (1)

- India's Leading Infrastructure Services CompanyDocument25 pagesIndia's Leading Infrastructure Services CompanyArdhendu ShekharNo ratings yet

- DC DC Converter Simulation White PaperDocument12 pagesDC DC Converter Simulation White PaperGiulio Tucobenedictopacifjuamar RamírezbettiNo ratings yet

- Caregiving For Grades 7 To 10Document26 pagesCaregiving For Grades 7 To 10Yeshua YeshaNo ratings yet

- Understand Api PDFDocument332 pagesUnderstand Api PDFgopiipog786No ratings yet

- Taconic RF-35TC Technical Data SheetDocument4 pagesTaconic RF-35TC Technical Data SheetTato YudayanaNo ratings yet

- Islamic States in Java 1500-1700 Eight Dutch Books and Articles by Dr. H.J. de GraafDocument90 pagesIslamic States in Java 1500-1700 Eight Dutch Books and Articles by Dr. H.J. de GraafEwinNo ratings yet

- 5.syllabus - Deb1053 - Electronic WorkshopDocument8 pages5.syllabus - Deb1053 - Electronic WorkshopadibNo ratings yet

- 4-Sided Planer & Moulder Operation Manual: For Spares and Service ContactDocument48 pages4-Sided Planer & Moulder Operation Manual: For Spares and Service ContactAlfred TsuiNo ratings yet

- R5310206-Linear and Discrete Systems AnalysisDocument4 pagesR5310206-Linear and Discrete Systems AnalysissivabharathamurthyNo ratings yet

- Daily Drilling Report: Bha Tally Bit Record Mud Report Mud Pump Drilling InformationDocument25 pagesDaily Drilling Report: Bha Tally Bit Record Mud Report Mud Pump Drilling InformationHamed NazariNo ratings yet