0% found this document useful (0 votes)

657 views1 pageMethod Statement Concrete Coring

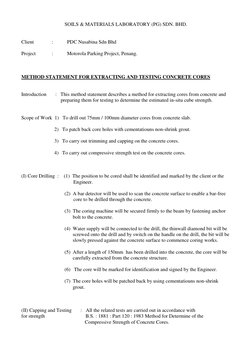

This document provides a method statement for extracting concrete cores from a parking structure project in Penang, Malaysia and testing them to determine the in-situ concrete strength. It involves drilling 75mm or 100mm cores from the slab, patching the holes, trimming and capping the cores, and conducting compressive strength testing according to British standards. The method statement outlines using a coring machine, diamond bit, extracting the core, marking it for identification, and patching the hole with non-shrink grout.

Uploaded by

Rosdin Bin IsmailCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

657 views1 pageMethod Statement Concrete Coring

This document provides a method statement for extracting concrete cores from a parking structure project in Penang, Malaysia and testing them to determine the in-situ concrete strength. It involves drilling 75mm or 100mm cores from the slab, patching the holes, trimming and capping the cores, and conducting compressive strength testing according to British standards. The method statement outlines using a coring machine, diamond bit, extracting the core, marking it for identification, and patching the hole with non-shrink grout.

Uploaded by

Rosdin Bin IsmailCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd