Professional Documents

Culture Documents

Table 21: Material Balance of All Inputs in Fertilzer Sector

Table 21: Material Balance of All Inputs in Fertilzer Sector

Uploaded by

sagar dasguptaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Table 21: Material Balance of All Inputs in Fertilzer Sector

Table 21: Material Balance of All Inputs in Fertilzer Sector

Uploaded by

sagar dasguptaCopyright:

Available Formats

Table 21: Material balance of all inputs in Fertilzer sector

Sr. Item Unit Received at Allocated Allocated Difference Remarks

No. plant battery for urea for other if any

limit production products

1.0 Purchased items

1.1 Purchased power MWh

1.2 Natural gas MMSCMD

1.3 Naphtha

a Volume Kl

b Weight MT

1.4 Diesel Kl

1.5 Furnace oil /LSHS etc.

a Volume Kl

b Weight MT

1.6 Coal MT

1.7 Any other fuel

2.0 Steam

2.1 Production

2.1.1 Boiler ( Individual) MT

2.1.2 GTG/HRU MT

2.1.3 Service/auxiliary boiler MT

2.1.4 Others MT

2.2 Consumption MT

2.2.1 Steam turbo generator MT

2.2.2 Ammonia plant MT

2.2.3 Urea plant MT

2.2.4 Others MT

3.0 Power

3.1 Generation MWh

3.1.1 GTG MWh

3.1.2 Others MWh

3.2 Consumption

3.2.1 Ammonia plant MWh

3.2.2 Urea plant MWh

3.2.3 Others MWh

3. Pro-forma i. Plant capacity, production & capacity

a. Pro-forma utilization

Under the PAT scheme, all DCs are • Installed capacity

required to fill-in and submit to BEE, Pro- • Production

forma, which is mandatory, with following • Capacity utilization

salient features:

Monitoring & Verification Guidelines 89

ii. Purchased electricity – Purchased ii. Calorific value of fuel

quantity, cost, consumption In fertilizer sector, all the energy

iii. Generated electricity through DG/ calculations are based on net calorific

turbo gen/gas turbine/co-generation value (NCV) of fuel. NCV will also be

iv. Fuels – Gaseous (NG, LNG), Liquid furnished along with GCV.

(Naphtha, fuel oil, diesel) solid (coal, iii. Total inputs at plant battery limit

coke) – Purchased quantity, calorific In the existing Pro-forma, only the

value (GCV). inputs, which are allocated for urea

v. Consumption of energy input for production, are furnished. Modified

• Power generation Pro-forma, provides for furnishing

total inputs at plant battery limit in

• Process raw material addition to the inputs allocated for

• Process heating urea product.

vi. Using waste as fuel iv. Quantity of natural gas

vii. Use of non-conventional energy Presently, natural gas is being received

(Solar, wind, etc) from a number of sources. Instead of

giving quantity of natural gas received

ix. Total energy input at BL

from different sources separately,

b. Sector Specific Pro-forma total quantity shall be furnished at one

Keeping in view the special requirements place only. However break up of this

in fertilizer sector, the Pro-forma has been quantity may be furnished for Feed

modified with following changes:- and fuel along with respective NCV.

Other fuels which are not in use in

i. Plant capacity is reported in fertilizer sector have been removed.

following formats:-

4. Annexure to Pro-forma

1. Name plate capacity: The original

name plate capacity at the time of The Pro-forma being of generic nature

installation of plant. does not contain information specific to

fertilizer sector. Therefore, additional

2. Re-assessed capacity: As revised by technical information is furnished through

“Fertilizer Industry Coordination “Annexure to Pro-forma. Information

Committee (FICC) “ in the year 2002. furnished in Annexure to Pro-forma is as

3. Baseline production: As worked out following:

(for urea product only) under PAT A. Installed capacity, production, CU,

scheme. It is an average of production on-steam days for ammonia / urea for

for three baseline years viz 2007-08, base 5 years.

08-09, 09-10.

B. Installed capacity has been substituted

4. Re-vamp capacity: Subsequent to with re-assessed capacity.

baseline period i.e. 2007-10, some

plants carried out major revamp to C. Inputs to Ammonia Plant

enhance capacity further. The capacity • NG/RLNG/LNG/PMT ( Feed,

is as reported by DCs to Department fuel) – Quantity, NCV

of Fertilizers. • Naphtha ( Feed, fuel) – Quantity,

NCV

90 Monitoring & Verification Guidelines

• Steam / power – Quantity, • Credits/debits– DM Water

conversion factor heating, LP steam export etc.

• Credits / debits – DM Water E. Conversion factor for power

heating, LP steam export etc. generated.

• Ammonia production F. Heat value of steam generated.

D. Inputs to Urea Plant G. Information available in log sheets,

• Ammonia consumption for urea log books, data logger print outs and

other plant documents need to be

• Power/steam verified with appropriate references.

5. Plant battery limit block diagram

6. Data not available in Pro-forma and • Calculations for conversion factors of

Annexure – 1 steam/power.

a. Additional information in Block

• Fuel input to boilers

diagram

• Waste gases available from ammonia/ The illustrative block diagram in

urea plants and fed to boilers. sections - 5 above, when, filled

adequately, incorporates missing

• Quantity of steam produced.

information.

• Other energy inputs like pre-heated i. It depicts all inputs at plant

DM water battery limit, which may be

Monitoring & Verification Guidelines 91

consumed for production of urea a. Allocation of fuel for production of

as well as other products. ammonia, power/steam and other

ii. It also depicts all inputs allocated for products/facilities (wherever applicable).

urea production. b. Calculation of conversion factor for power

iii. Gives details on various imports/ generated (Kcal/Kwh) and its distribution.

exports, debit/credit etc. c. Conversion factor for purchased power

iv. One set of sample calculations of gate- (taken as 2860 Kcal/Kwh).

to-gate energy balance to be furnished d. Calculation of heat value of steam

by DC. produced (Kcal/Kg) and its distribution.

v. Basis of calculations, conversion e. Calculation of SEC for ammonia by

factors, assumptions, import/export, considering the following:-

credit/debit etc; to be mentioned i. Feed & fuel energy input to ammonia

specifically. plant directly

7. Procedure for calculation of specific ii. Allocation of steam/power to

energy consumption (SEC) ammonia plant along with conversion

factors.

In general specific energy consumption (SEC)

is calculated by dividing total energy input at iii. Credit/debit of energy at ammonia

battery limit by final product. However, in case plant battery limit like pre-heating

of ammonia / urea complex, part of the input of DM water, burning ‘Off gases” in

energy is utilized for manufacturing ammonia boiler furnace etc.

wherein Carbon-di-oxide (CO2) is also f. Calculation of SEC for urea by considering

produced as by-product. Ammonia and CO2 the following:-

are then reacted to produce urea. Part of the

i. Allocation of ammonia, separately as

steam/power energy is consumed in urea plant.

manufactured or purchased, for urea

Further, full quantity of ammonia produced is

production.

not necessarily consumed for urea manufacture.

Part of ammonia may go to storage or export. ii. Allocation of steam/power to

Similarly, part of steam / power may be either ammonia plant along with conversion

exported or imported. Therefore, in fertilizer factors.

sector, SEC of urea cannot be calculated directly iii. Credit/debit of energy by way of

by dividing total energy input by urea product. export of steam, burning vent gases

Following procedure is to be adopted for etc.

calculating SEC:-

Sr. No. Description Unit Illustrative figures Actual for 2014-15 Remarks

1.0 Overall plant battery limit

1.1 Inputs

1.1.1 Natural gas ( NG)

a Quantity MMSCM

b NCV of NG Kcal/SCM

1.1.2 Naphtha

a Quantity kl

92 Monitoring & Verification Guidelines

Sr. No. Description Unit Illustrative figures Actual for 2014-15 Remarks

b NCV of naphtha Kcal/lit

Kcal/kg

c Density of naphtha gm/cc

1.1.3 Grid power MWh

1.1.4 Steam MT

1.1.5 Ammonia MT

1.2 Output

Urea MT

Power export kWh

2.0 CPP/HRU

2.1 Input

2.1.1 Natural gas MMSCM

2.2 Output

2.2.1 Power MkWh

Heat rate Kcal/kWh

2.2.2 Steam MT

Heat content Kcal/kg

3.0 Ammonia Plant

3.1 Input

3.1.1 NG feed MMSCM

3.1.2 NG fuel MMSCM

3.1.3 Naphtha feed kl

3.1.4 Naphtha fuel kl

3.1.5 Steam MT

3.1.6 Power MkWh

3.2 Output

3.2.1 Ammonia product MT

4.0 Urea Plant

4.1 Input

4.1.1 Ammonia MT

4.1.2 Steam MT

4.1.3 Power MkWh

4.2 Output

4.2.1 Urea product MT

5.0 Service boiler / Utilities

5.1 Input

5.1.1 NG Fuel MMSCM

5.1.2 Naphtha fuel kl

Monitoring & Verification Guidelines 93

8. Gate to Gate specific energy consumption (SEC)

i. Overall material & energy balance

An illustrative material & energy flow diagram of an ammonia/urea fertilizer complex is

given below

Total Energy /

feed Input Plant Fuel: 69 MM SCM Power Export

CPP & HRU (Colony+ GAIL)

6.4MkWh

Grid Power0.0 Steam Generated Power Generated

kWh 178 MkWh

Steam0.0 MT

1211950 MT

82346 MT

102 MkWh

62.15MkWh

1129604 MT

Feed: 485 KL

NG

7.0 MkWh

Urea

752 MM SCM,

1230715 MT

NCV: 8412 Urea Plant

Ammonia

Kcal/SCM

Feed: 490 MM SCMPlant

Ammonia

Naphtha 702170 MT

Ammonia Ammonia Import

701574 MT

4352 KL

596 MT

NCV:

7466Kcal/L

Fuel: 3867 KL

Fuel:193 MM SCM

Service Boiler Other Utilities

Figure 16: Overall Material and Energy balance. Figures mentioned above are indicative and used for representational purpose only . The

actual data will Figure

vary from unit toMaterial

16: Overall unit . and Energy balaance

II. CALCULATION OF SPECIFIC ENERGY CONSUMPTION (SEC) OF AMMONIA

(a) Material balance of Natural Gas

Description Quantity NCV Heat content Remarks

(MM SCM) ( Kcal/SCM) (Gcal) 2 x 3

1 2 3 4

Total input

752 8412 6325824

Distribution

CPP/HRU 69 8412 580428

Reformer feed 490 8412 4121880

Reformer fuel 193 8412 1623516

94 Monitoring & Verification Guidelines

(b) Material balance of Naphtha

Description Quantity (KL) NCV (Kcal/ L) Heat content (Gcal) 2 x 3 Remarks

1 3 2 4 5

Total input

4352 7466 32492

Distribution

Reformer feed 485 7466 3621

Service boiler 3867 7466 28871

c) Energy balance in Ammonia Plant

Item Unit Quantity NCV/ Heat Heat content Specific energy

value Gcal consumption

Ammonia production MT

NG feed MM SCM

NG fuel MM SCM

Naphtha feed MT

Naphtha fuel MT

Steam MT

Power MkWh

Total feed energy Gcal

Total fuel energy Gcal

Power + steam Gcal

Total SEC Gcal/MT

Non plant energy Gcal/MT

SEC including non-plant energy Gcal/MT

(d) Energy balance in Urea Plant

Item Unit Quantity NCV/ Heat Heat content Specific energy

value Gcal consumption

Urea

production MT 1230715

Ammonia feed MT 701574 7.691 5395806 4.384

Steam MT 1129604 743 839295 0.682

Power MkWh 62150 511 31759 0.026

Total energy Gcal 6266860

Total SEC Gcal/MT 5.092

Non plant energy Gcal/MT 0.079

SEC including non plant Gcal/MT 5.171

energy

Monitoring & Verification Guidelines 95

9. Computing Baseline data a. Production

Under first cycle of PAT scheme, the Baseline production of urea is obtained

baseline period constitutes the years 2007- by averaging urea production for three

08, 08-09 and 2009-10. Urea product has baseline years i.e. 2007-08, 08-09, 09-10.

been taken as basis for calculating Specific Production during target year (2014-15) is

energy consumption “SEC”. reported in the following table.

Sr. No. Description Unit Baseline data Assessment year

2007-08 2008-09 2009-10 Average 2014-15

1.0 Urea product

1.1 Installed capacity MT n.a.

1.2 Actual production MT

1.3 Capacity Utilization % n.a.

b. Specific energy consumption (SEC) for three baseline years i.e. 2007-08, 08-09,

Baseline specific energy consumption (SEC) 09-10. Specific energy consumption (SEC)

of urea is obtained by weighted average during target year (2014-15) is reported in

the following table.

Sr. No. Description Unit Baseline data Assessment year

2007-08 2008-09 2009-10 Total 2014-15

1.0 Urea production Tonnes n.a.

1.1 SEC Gcal/ MT n.a.

1.2 Total energy Gcal

1.3 Weighted average Gcal/MT n.a n.a n.a

10. Normalization factors (i) Forced shut down of the plant and

subsequent Cold start up

PAT procedure provides for “Normalization” (ii) List of critical equipment, which on failure,

of reported data based on capacity utilization cause forced shut down.

factor, when plant load factor (PLF) has a

deviation of more than 30%. The PAT procedure (iii) Plant operation at low load

also provides for normalization by statistical (iv) Reduction of ammonia synthesis and CO

analysis methods. In fertilizer sector, apart shift catalyst

from capacity utilization, there are some other

(vi) Use of naphtha due to non-availability of

important factors viz. number of forced shut

gas

down of the plant, use of naphtha due to

unavailability of natural gas, quality of coal (vi) Deterioration in quality of coal

and commissioning period after major revamp For calculating the unproductive energy

of the plant, which also affect specific energy consumption against individual factor,

consumption of product. Identified causes of formats were developed showing

un-productive energy consumption on account illustrative calculations.

of factors, which are beyond the control of the

plant are as follows:

96 Monitoring & Verification Guidelines

a. Low capacity utilization utilization will be considered only in

In addition to the reasons for lower one of the plants i.e. either ammonia

capacity as given in PAT document, lower or urea.

capacity utilization due to following 5. Subsequent to the baseline year i.e.2007-10,

reasons has also been considered for some DCs have carried out major revamp

normalization(i) shortage of raw material of their plant for capacity enhancement

including feed, fuel, water, electricity etc. in line with New Investment Policy for

(ii) high cost of inputs leading to unviable urea notified by the Govt. in 2008. Govt.

urea production beyond certain capacity recognized enhanced capacity, while

( iii) major equipment failure ( iv) force reimbursing cost of production under the

majeure. pricing policy. The enhanced capacity shall

Factors like shortage of raw materials be considered, while calculating capacity

(mainly the gas), decline in market demand, utilization for normalization, subject to

change in Govt. policy etc. are beyond the confirmation from DoF, Government

control of DCs. These factors may force of India and also verification certificate

the plant to be operated at lower capacity, issued by an Accredited Energy Auditor to

thus causing adverse effect on energy DC which seek to declare their enhanced

consumption. In such cases, normalization installed capacities, production and energy

shall be allowed as follows. use. Cost of this audit will be borne by the

DC. Check tests of such verification could

i. Pre-requisites for Normalization be carried out by BEE, if needed.

1. A DC shall furnish detailed and 6. Some plants are having ammonia plant

convincing reasons with supporting capacity higher than the quantity of

documents for reduction in capacity ammonia required for urea production

utilization, due to factors, beyond and thus, diverting surplus ammonia for

their control. production of other products or direct

2. Following criteria shall be adopted:- sales. In such cases, due to Govt. policy

and/or market conditions, consumption of

a) No compensation shall be allowed

surplus ammonia for production of other

if the capacity utilization of urea

products becomes unviable and under

plant on annual basis is 95% or

these circumstances, ammonia plant is

above.

operated at lower capacity, thus resulting

b) Compensation shall be allowed in higher energy consumption per MT of

for capacity utilization between ammonia, which also get transferred to

70-95%. urea, even if the urea plant is operated at

c) Below 70%, the data shall be full load; Normalization shall be allowed.

discarded. 7. In case of ammonia / urea complex having

3. The claim will be based on Technical ammonia capacity matching with urea

operating data (TOP), which is production, capacity utilization of urea

being reported to Fertilizer Industry plant shall be considered.

Coordination Committee (FICC) of ii. Calculation of normalization factor

Department of Fertilizers, Govt. of

1. Based on the operating data collected

India.

from plants at 100%, 85% and 70%

4. Normalization due to low capacity plant load, average normalization

Monitoring & Verification Guidelines 97

factor works out to be 0.02 Gcal per a. Maximum permissible value ( Gcal/

MT of urea per percentage reduction MT ammonia) = (95 - % Capacity

in plant load below 95% up to 70%. utilization of ammonia plant) * 0.02

2. Impact of Lower Capacity utilization Gcal.

shall be worked out as follows:- b. Actual unproductive energy (Gcal/

a. Maximum permissible value MT urea) = Annual Energy, Gcal/

(Gcal/ MT urea) = (95 - % Capacity MT of ammonia - Weighted Average

utilization) * 0.02. of Monthly Energy Consumptions

for the months with ammonia plant

b. Actual unproductive energy Capacity Utilization of 100% or more

(Gcal/ MT urea) = Annual Energy,

Gcal/MT of Urea - Weighted c. Lowest of the above two shall be

Average of Monthly Energy considered for allowing the impact

Consumptions for the months of lower capacity utilization. In such

with Capacity Utilization of 100% cases, normalization due to low

or more capacity utilization (i.e. <95%) will be

allowed only in one of the plants i.e.

c. Lowest of the either (a) or (c) either ammonia or urea.

shall be considered for allowing

the impact of lower capacity 4. Capacity utilization for urea plant will

utilization. be calculated based on “Baseline urea

Production”.

3. Impact of Lower Capacity utilization

of plants where ammonia is surplus iii. Supporting data / documentation

than required for urea production, Data shall be maintained in the

shall be worked out as follows: following formats:-

A. Month-wise production & energy consumption during the year

Sr. No. Month Ammonia Urea

On stream production CU SEC On stream production CU SEC

days MT % Gcal/MT days MT % Gcal/MT

1 April

2 May

3 June

4 July

5 August

6 September

7 October

8 November

9 December

10 January

11 February

12 March

98 Monitoring & Verification Guidelines

B. Data for best operating months

Sr. No. Best operating Ammonia CU Urea CU SEC SEC Urea Reference

month production production Ammonia

MT % MT % Gcal/ MT Gcal/ MT

(i) Take the month in which , plants have 11. Utility boiler furnace

run for all the calendar days. 12. Gas turbine/HRSG

(ii) Capacity utilization during the month 13. Cooling Tower

should be equal to or above 100%.

14. Major Fire leading to complete

b. Cold startup of the plant after forced shut shutdown of plant and cold

down startup

In case of sudden failure of a critical 15. Turbo generator along with GTG

equipment as per the list below, or external

16. Purifier

factors (as notified), ammonia plant

undergoes a forced shut down. Restarting 17. CO Shift Converter

the plant from cold conditions (Cold start B. The Designated Consumer (DC) shall

up) , consumes unproductive energy and furnished a detailed report on failure of

shall be normalized. such equipment and its impact on energy

i. Pre-requisites for Normalization consumption.

A. The list of critical equipment failure C. The Designated Consumer shall declare

of which leads to complete shutdown with back up documentation, what portion

of plant and consequent cold start of such unproductive consumption during

up, allowed under this normalization the month is due to cold shutdown and

factor is given below :- startup activity.

1. Primary Reformer D. This actual energy loss due to shut down

and cold startup in Gcal/MT of Urea shall

2. Secondary Reformer

be compensated, subject to maximum of

3. Heat Exchange Reformer 0.03 Gcal/MT of Urea.

4. Reformed Gas Boiler ii. Calculation of normalization factor

5. Carbon dioxide absorber and A. Energy loss during the month(s) for

stripper which additional cold startup is being

6. Air, Refrigeration and synthesis claimed shall be calculated as follows:-

compressors (i) (Monthly Energy per MT of

7. Synthesis converters Ammonia during the month–

Weighted Average Monthly

8. Synthesis Gas Waste Heat Boilers Energy Consumption for the

9. High pressure urea reactor, months with 100% on-stream

stripper and carbamate condenser days) X Monthly Ammonia

production for the month of

10. Carbon dioxide compressor

Startup.

Monitoring & Verification Guidelines 99

(ii) This Energy Loss shall be divided down and cold startup in Gcal/

by Annual Urea Production to MT of Urea shall be compensated,

identify total unproductive subject to maximum of 0.03 Gcal/

loss in a month. MT of Urea.

(iii) The Designated Consumer shall (v) The failure of critical equipment

declare what portion of such leading to complete shutdown of

unproductive consumption plant and consequent cold

during the month is due to cold start up, allowed under this

shutdown and startup activity. normalization factor is given at

(iv) This actual energy loss due to shut Annexure -

iii. Documentation

Sr. No. Description Unit 2007-08 2008-09 2009-10 2014-15

1 Ammonia production MT

2 Urea production MT

3 Total no of cold start up Nos

4 Cold start up due to failure of major Nos

equipment

5 For each start up

a Duration hours

b Energy consumed Gcal

Note: For each shut down / cold start up, information to be filled-in separately.

c. Use of naphtha A. As per directives from Department

A. Using part naphtha involves additional of Fertilizers, Govt. of India, use of

energy consumption as follows:- naphtha is to be discontinued

in phased manner. As such, use of

a) For each startup of facilities to use naphtha is not foreseen. However,

naphtha as feed including pre- provision is being made, in case

reformer naphtha has to be used due to

b) For the period of use of naphtha shortage of natural gas in future, with

as feed permission from DoF.

c) For the period of use of naphtha B. In case of use of naphtha, DC will

as fuel furnish details regarding non-

availability of gas, leading to use of

B. DCs shall furnish detailed and convincing

naphtha.

reasons with supporting documents

for use of naphtha due to non-availability ii. Calculation of normalization factor

of gas on account of factors, beyond their A. Following formula shall be used

control.

Energy loss (Gcal/MT Urea) = (185*S + 0.625 *

i. Pre-requisites for Normalization Nfeed + 0.443 * Nfuel) / urea production in MT

100 Monitoring & Verification Guidelines

S= 1 if naphtha is used as feed in startup

S= 0 if naphta is not used as feed in startup

NFeedc= quantity of naphtha used as feed in MT.

NFuelc= quanity of naphtha/LSHS/FO used as fuel in MT.

iii. Documentation

Sr. No. Description Unit 2007-08 2008-09 2009-10 2014-15

1 Ammonia production MT

2 Urea production MT

3 NG consumption MMSCMD

4 Shortfall in NG MMSCMD

5 Equivalent naphtha kl

6 Actual naphtha used kl

d. Catalyst reduction B. This will be considered subject to

Fresh catalyst is in oxidized form and certification by DCs and furnishing to

needs to be reduced with synthesis gas, BEE information as follows:

wherein hydrogen reacts with oxygen and (i) Year in which the catalyst were last changed

gets converted into water. Whole plant along with copies of purchase order,

is operated at 60-80% load for around 48 last placed with the vendor , time taken

to 120 hours, depending upon type and in commissioning of catalyst , facts and

quantity of catalyst. Thus, replacement / figures clearly indicating and quantifying

reduction of ammonia synthesis and CO rise in the energy consumption of plant

shift catalysts consumes large amount due to the replacement of this catalyst.

of unproductive energy. Therefore,

normalization due to replacement / (ii) Copies of purchase orders placed by

reduction of these catalysts will be allowed. units with the vendors for supply of fresh

catalysts.

i. Pre-requisites for Normalization

ii. Calculation of normalization factor

A. In case of ammonia synthesis catalyst,

in the older plants, oxidized form Adjustment shall be allowed on the basis

of the catalyst is used which takes of actual plant data, subject to a maximum

around 4-5 days for reduction, causing of 0.04 Gcal/MT of Urea.

corresponding un-productive energy e. Deterioration in quality of coal

consumption. Presently, “ Pre-reduced

The quality of indigenous coal has been

catalyst” is also available, which is

deteriorating gradually, thus affecting

expansive but takes around 48 hours

boiler efficiency adversely. The reduction

for reduction, thus consuming lesser

in boiler efficiency due to poor quality of

un-productive energy. This aspect

coal shall be compensated.

will be taken care , while calculating

normalization factor. i. Pre-Requisites for Normalization

Monitoring & Verification Guidelines 101

Weighted average of three years A = Ash content of coal (%)

data shall be worked out. In case M = Moisture (%)

there is significant variation, then

normalization factor shall be applied H = Hydrogen ( %)

based on the actual impact due to the GCV = Kcal/Kg

variation.

B. Boiler efficiency shall be converted into

ii. Calculation of normalization factor specific energy consumption, as follows:

A. Quality of coal affects boiler efficiency, Additional Energy Consumption, Gcal/

which shall be calculated by following MT of Urea = Energy of Coal per MT of

empirical formula:- Urea in Target Year, Gcal/MT of Urea

Boiler Efficiency = 92.5 – ((50*A+630 * (Boiler Efficiency in Base Year – Boiler

(M+9H)) / GCV. Efficiency in Target Year)/Boiler Efficiency

in Target Year.

Where

iii. Documentation

A. Coal consumption and analysis

Sr. No. Parameters Unit 2007-08 2008-09 2009-10 2014-15

1 Quantity of coal used MT

2 GCV (Weighted average) Kcal/kg

3 NCV (Weighted average) Kcal/kg

4 Proximate analysis

A Fixed carbon %

B Volatile matter %

C Moisture %

D Ash %

5 Ultimate analysis

A Carbon %

B Hydrogen %

C Sulphur %

D Nitrogen %

E Oxygen %

f. Additional provisions under PAT scheme. Therefore DC should

i. Normalization factors to be applied seek normalization only when specified

during assessment year, shall also be energy saving target is not met due to

applied on baseline data for 2007-10. reasons beyond control of DCs.

B. Provision of normalization factors is C. DC’s claim will be examined based on

intended solely to save plants from Technical operating data (TOP), which

penalties for non-achieving the saving is being reported to Fertilizer Industry

targets, for reasons which are beyond the Coordination Committee ( FICC) of

control of DCs. However, availing of any Department of Fertilizers, Govt. of India as

of the normalization factors shall render the well as by auditors designated by Bureau

DC ineligible for issuance of E-certificates of Energy Efficiency ( BEE).

102 Monitoring & Verification Guidelines

7.5. Annexure V: Aluminium Load and Turbine Heat Rate PLF

1. The energy required to transport mined normalization. Equivalent capacity HMBD

bauxite to refining operations with inthe or characteristics curve shall be used, if

plant boundary, alumina to smelting OEM data is not available with the DC

operations, ingots to metal processors, 8. In case of addition of new Potline, a DC

and scrap from collection to melting is shall submit all relevant design data of

accounted as inside transportation and new Pot line to EmAEA for inclusion in the

consider as energy used in plant. verification report

2. Plant stoppages and start due to external 9. The baseline SEC factor used for product

factor: Necessary documents has to be equivalent will be used for assessment year

provided by DC product equivalent. The major product of

3. Proper documents on Bauxite Quality for the baseline period will be considered in

the purpose of normalization have to be the assessment year. In case if any new

maintained and submitted to EmAEA. product is introduced in the assessment

year the SEC factor of assessment year will

4. Refinery Mass Balance (Bauxite to alumina be used for converting to equivalent major

ratio): The DC has to provide necessary product for the assessment period.

calculation document to EmAEA during

M&V for verification of alumina product 10. For Import or Export of Carbon Anode,

ratio. DC shall be required to fill the Pro-forma

the type of anode (i.e., Green Anode,

5. Smelter Mass Balance (Alumina to Molten Baked Anode or Rodded Anode) exported

Aluminium ratio): The DC has to provide or imported in the Remarks Column.

necessary calculation document to EmAEA The SEC shall be for the type of Carbone

during M & V for verification of Molten Anode i.e., SEC up to the type of Carbon

Aluminium product ratio Anode produced. Generally for importing

6. In Smelter Plant EmAEA has to verify or exporting anodes, the energy shall be

BusBar Voltage drop and Anode-Cathode booked till the energy of baked anodes

Distance in reduction cell.

1. Refinery

7. DC needs to submit HMBD of Turbine

system or characteristics curve between 11. Review of Section wise Specific Energy

Consumption

Table 22: Section wise Energy Consumption details

S. No Section Thermal energy Electrical Energy kWh/tone kWh/tone of Remarks

Consumption Consumption of Alumina Aluminium

1 Grinding

2 Digestion

3 Clarification

4 Precipitation

5 Calcination

Monitoring & Verification Guidelines 103

12. Plant Boundary export, Colony power, Construction

Demarcation of plant boundary is required power, power supplied to other ancillary

with clear understanding of raw material unit outside of the plant boundary. Typical

input, energy input, power import/ plant boundary conditions are produced

export, Intermediary product import/ below.

Figure 17: Ex- GtG boundary for Aluminium (Refinery sub sector)

B. Smelter forma

13. Carbon Anode to Molten Aluminium 15. The additional cast house product shall be

ratio: The DC has to provide necessary converted into one product and inserted in

document to EmAEA during M & V. the Product “other” details in pro-forma

Approximately 0.45 kilograms of carbon 16. The energy used in smelter for imported

anode were needed to produce one scrap/ cold metal for production of finished

kilogram of aluminum products shall be considered for product

14. The smelter Energy consumption shall be equivalent hot metal SEC calculation

taken up to Molten Alumina in the pro-

Table 23: Section wise Energy Consumption details

S.No Section Thermal Energy Electrical Energy kWh/tone of kWh/tone of Remarks

Consumption Consumption Anode Aluminium

1 Pitch

2 Coke

3 Baking

104 Monitoring & Verification Guidelines

17. Electrolytic reduction energy consumption:

Table 24: Voltage Distribution

S.No Reduction Cell (Section wise) Voltage Distribution

1 External

2 Anode

3 Polarization

4 Bath

5 Reaction

6 Cathode

7 Other

18. Plant Boundary export, Colony power, Construction

Demarcation of plant boundary is required power, power supplied to other ancillary

with clear understanding of raw material unit outside of the plant boundary. Typical

input, energy input, power import/ plant boundary conditions are produced

export, Intermediary product import/ below

Figure 18: Ex- GtG boundary for Aluminium (Smelter sub sector)

Monitoring & Verification Guidelines 105

C. Cold Sheet 21. Plant Boundary

19. Necessary documents as per the instruction Demarcation of plant boundary is required

in Form 1 need to be provided by DC to with clear understanding of raw material

EmAEA for verification of section wise input, energy input, power import/

energy consumption and Specific Energy export, Intermediary product import/

Consumption. export, Colony power, Construction

20. Product equivalent of other cold rolled power, power supplied to other ancillary

products shall be calculated offline to unit outside of the plant boundary. Typical

to single cold rolled product through plant boundary conditions are produced

conversion from SEC of different cold below

rolled product.

Figure 19: Ex- GtG boundary for Aluminium (Cold Sheet sub sector)

7.6. Annexure VI: Pulp & Paper plant caters to two or more DCs for the

electricity and/or steam requirements. In

1. The boundary can be drawn virtually by such scenario, each DC shall consider such

including CPP or Cogen in the boundary captive power plant or cogeneration plant

limit of DCs, if nos DCs exist in a same in its boundary and energy consumed by

boundary limit. such captive power plant or cogeneration

2. The captive power plant (CPP) or cogen plant shall be included in the total energy

will be taken into the virtual boundary consumption. However, electricity in

of each DCs and accordingly import and terms of calorific value (as per actual heat

export of power and steam will be treated rate) and steam in terms of calorific value

as per Pro-forma data entry system. (as per steam enthalpy) exported to other

plants shall be subtracted from the total

3. If a captive power plant or cogeneration energy consumption.

106 Monitoring & Verification Guidelines

4. It is to be noted that the same fuel input in M&V format by mentioning the source

needs to be considered in case CPP is and document from where data is collected.

being taken into the boundary limit. Subsequently the data may be verified

By import and export of energy, the from the, data provided by the DC in sector

energy consumption from the CPP is specific Pro-forma for normalization.

automatically left out for the particular DC b. The information required is shown in the

for SEC calculation. flow chart for wood based pulp and paper

5. Mill wise verification data are required to mill

be included in the verification report c. List of documents required for monitoring

and verification

A. Wood Based Mills:-

a. The auditors may collect details required

Table 25: General details required in wood based Pulp and Paper Mills

A.1 Raw Material Details

Type of Wood:-

Sr No Name of the raw material Moisture, % Quantity, tonne/annum Source/ document

1

2

3

4

5

A.2 Wood Pulp Mill (Including Raw material, Chipper , Digester , WSC, ODL , Bleach Plant,

Recovery , WTP, and ETP)

i) Pulping Processes Used

Sr No Type of Capacity Production Total Yield (Including Source /

pulping tonne/annum tonne/annum screening losses) Document

1 Chemical

2 Semi Chemical

3 Chemi Thermo

Mechanical

4 Other

ii) Extended Delignification (ODL)

Sr No Item Unit Value Source / Document

1 Capacity tonne/ annum

2 Date of Installation of ODL Plant Date

Monitoring & Verification Guidelines 107

iii) Bleaching

Sr No Item Chemical Pulp Semi Chemical Chemical Thermo

Mechanical Pulp

1 Type of Bleaching ECF/conv. ECF/conv. ECF/conv.

2 Sequence Used

3 Bleaching Losses %

4 Bleached Pulp Yield %

5 Brightness of pulp, %

Sr No Item Unit Value Source / Document

1 Capacity Tonne/ annum

2 Date of Installation of ECL Plant Date

iv) Energy Consumption in Pulp Mill

Sr No Item Qty Source/ Document

1 Steam Consumption, LP/a

2 Steam Consumption, MP/a

3 Power Consumption, kWh/a

v) Pulp Dryer

Sr No Item Unit Qty Source / Document

1 Capacity Tonne/annum

2 Production of salable pulp, t/a Tonne/annum

3 Energy Consumption in pulp dryer kcal

4 LP Steam Consumption Tonne/annum

5 MP Steam Consumption Tonne/annum

6 Power Consumption kWh/annum

vi) Chemical Recovery

Sr No Item Unit Data Source / Document

1 Type of chemical recovery Conventional/Non-

Conventional

2 Total Black liquor Solids generated Tonnes

3 In Lime Kiln Installed Yes/No

4 Date of Installation of Lime Kiln I Date

5 Date of Installation of Lime Kiln II Date

6 Date of Installation of Lime Kiln III Date

108 Monitoring & Verification Guidelines

You might also like

- Introduction To Offshore Structures-PART-1Document22 pagesIntroduction To Offshore Structures-PART-1RUDHRA DHANASEKAR100% (1)

- Thermo Chemistry of Fuel-Air MixturesDocument34 pagesThermo Chemistry of Fuel-Air Mixturesmahmudul adilNo ratings yet

- Basics of OIl RefineryDocument28 pagesBasics of OIl RefineryDebasis Kumar Saha50% (2)

- POWER Power January 2023Document44 pagesPOWER Power January 2023Jose ArangoitiaNo ratings yet

- Boiler Operation Engineer (BOE) Viva QDocument12 pagesBoiler Operation Engineer (BOE) Viva QChetram Meena100% (1)

- Modular Hydrogen Plants: Hydro-ChemDocument12 pagesModular Hydrogen Plants: Hydro-ChemFahryPurnamaNo ratings yet

- Co-Gen BidDocument556 pagesCo-Gen BidManish ThakurNo ratings yet

- Valves Overview Service enDocument12 pagesValves Overview Service enBalraj PadmashaliNo ratings yet

- Technical Specifications For Sugauli CogenDocument558 pagesTechnical Specifications For Sugauli Cogenchaitanya_kumar_13No ratings yet

- Calc Ammonia Plant Energy ConsumptionDocument17 pagesCalc Ammonia Plant Energy ConsumptionDaniel Puello Rodelo100% (1)

- TATA Ammonia Plant: Design Features and Operating ExperienceDocument17 pagesTATA Ammonia Plant: Design Features and Operating Experiencevaratharajan g rNo ratings yet

- Final Spec Biomass PDFDocument21 pagesFinal Spec Biomass PDFRAM KrishanNo ratings yet

- 134 CHP Cogen at GPP by Fairos RoslanDocument32 pages134 CHP Cogen at GPP by Fairos RoslanAbu AbdullahNo ratings yet

- Questionnaire Cement Plants-01 (1) .8.04Document9 pagesQuestionnaire Cement Plants-01 (1) .8.04Debajit BurhagohainNo ratings yet

- 05-1-Collection of Problems PDFDocument15 pages05-1-Collection of Problems PDFFistia MaulinaNo ratings yet

- Biomass Power Plant in Indonesia (210408) -복사Document18 pagesBiomass Power Plant in Indonesia (210408) -복사sita deliyana FirmialyNo ratings yet

- P FD FileDocument13 pagesP FD FileNavanita Saikia MechNo ratings yet

- 45Document136 pages45odeinatusNo ratings yet

- Gas Tanker ProjectDocument40 pagesGas Tanker ProjectJudson FarrayNo ratings yet

- Chapter 2 Boiler Design PDFDocument6 pagesChapter 2 Boiler Design PDFFernando Sandoval RuedaNo ratings yet

- 00 VRMP OverallDocument11 pages00 VRMP OverallDeepak KatiyarNo ratings yet

- Iron and Steel 209 239 1 15 PDFDocument15 pagesIron and Steel 209 239 1 15 PDFmpNo ratings yet

- Energy Conservation FrameworkDocument8 pagesEnergy Conservation FrameworkdiebymyswordNo ratings yet

- Point Wise Compliance of Terms of Reference (Tor)Document14 pagesPoint Wise Compliance of Terms of Reference (Tor)OMSAINATH MPONLINENo ratings yet

- Form-1 Summary SheetDocument9 pagesForm-1 Summary SheetgireeshNo ratings yet

- Estimating Natural Gas Demand at A Petrochemical ComplexDocument4 pagesEstimating Natural Gas Demand at A Petrochemical ComplexJarodNo ratings yet

- Industry QuestionsDocument3 pagesIndustry Questionsakshay7573No ratings yet

- 0 - Kota Tharmal Plant New PDFDocument52 pages0 - Kota Tharmal Plant New PDFRahul LodhaNo ratings yet

- Considering Producting Alcohol From Potatoes Energy CalculusDocument7 pagesConsidering Producting Alcohol From Potatoes Energy CalculusLima CostaNo ratings yet

- Microsoft Word - MSERC MYT FORMATSDocument51 pagesMicrosoft Word - MSERC MYT FORMATSDebasish RoyNo ratings yet

- Microsoft Word - MSERC MYT FORMATS-1-9Document9 pagesMicrosoft Word - MSERC MYT FORMATS-1-9Debasish RoyNo ratings yet

- Information Required For ESIA - Gie - 2018!01!18Document11 pagesInformation Required For ESIA - Gie - 2018!01!18hassan zakwanNo ratings yet

- Prereforming: Based On High Activity Catalyst To Meet Market DemandsDocument8 pagesPrereforming: Based On High Activity Catalyst To Meet Market Demandsvaratharajan g rNo ratings yet

- Checklist For CCX 6MW Jocil Biomass Power PlantDocument21 pagesChecklist For CCX 6MW Jocil Biomass Power Plantapi-19973776No ratings yet

- Erp-Pe1 2020 PDFDocument106 pagesErp-Pe1 2020 PDFVictor FernandezNo ratings yet

- Rev-Updated Final Report - Conceptual Design AssessmentDocument45 pagesRev-Updated Final Report - Conceptual Design AssessmentLisbeth Roos RoosNo ratings yet

- Brief Summary of The ProjectDocument6 pagesBrief Summary of The ProjectNikunjNo ratings yet

- GSFC Thermal FinalDocument46 pagesGSFC Thermal FinalKuldeep RupareliaNo ratings yet

- Volume-IIIC Functional GuaranteeDocument54 pagesVolume-IIIC Functional GuaranteeVikas DwivediNo ratings yet

- Bulletin 14 - Replacement of Extraction Cum Condensing Turbine With Back Pressure Turbine PDFDocument2 pagesBulletin 14 - Replacement of Extraction Cum Condensing Turbine With Back Pressure Turbine PDFVikas NigamNo ratings yet

- UREA Data 1Document8 pagesUREA Data 1simaproindia4958No ratings yet

- Energy Audit Technical Detail FormatDocument6 pagesEnergy Audit Technical Detail FormatGreen BusinessNo ratings yet

- Section-III - CDU - Rev 1Document10 pagesSection-III - CDU - Rev 1adil khanNo ratings yet

- MC DE - EEC Form 4B AEUR Industrial DEsDocument6 pagesMC DE - EEC Form 4B AEUR Industrial DEsJohn Evan Raymund BesidNo ratings yet

- Barsingsar TPSDocument31 pagesBarsingsar TPSkarthik achudhanNo ratings yet

- Review of Energy Management at NoodsbergDocument3 pagesReview of Energy Management at Noodsbergbonginkosi mathunjwaNo ratings yet

- Indian Oil Corporation Limited: Certificate of Merit RefineryDocument5 pagesIndian Oil Corporation Limited: Certificate of Merit RefineryBadiuzzama AzmiNo ratings yet

- Boilers, Steam Generators, Dryers, and Process HeatersDocument2 pagesBoilers, Steam Generators, Dryers, and Process HeatersRed CrazyNo ratings yet

- (Please Enumerate Use Separate Sheet, If Necessary) : Petroleum Fuel Station ProjectsDocument4 pages(Please Enumerate Use Separate Sheet, If Necessary) : Petroleum Fuel Station ProjectsCharlotte Mae MartinezNo ratings yet

- ABB Turbocharging - Tips For Operators - July 2020Document30 pagesABB Turbocharging - Tips For Operators - July 2020Miguel BautistaNo ratings yet

- Clean Development Mechanism Project Design Document Form (CDM-SSC-PDD) Version 03 - in Effect As Of: 22 December 2006 IDocument26 pagesClean Development Mechanism Project Design Document Form (CDM-SSC-PDD) Version 03 - in Effect As Of: 22 December 2006 ImurugaraajNo ratings yet

- 1.1.4.2.2 Simple Cycle OperationDocument8 pages1.1.4.2.2 Simple Cycle Operationpramod_nandaNo ratings yet

- Cs Distr Steam Methane ReformDocument5 pagesCs Distr Steam Methane ReformJuan Antonio SánchezNo ratings yet

- SteamDocument7 pagesSteamarunrajmech09No ratings yet

- Is - 10000 (1) - 1980Document6 pagesIs - 10000 (1) - 1980sangita ghaisasNo ratings yet

- Fertilizer 86 120 1 15 1 7Document7 pagesFertilizer 86 120 1 15 1 7Chanakya KesaNo ratings yet

- NAWTEC13-3164: Optimizing Steam Turbine Generator OutputDocument14 pagesNAWTEC13-3164: Optimizing Steam Turbine Generator OutputAjiNo ratings yet

- Diesel EngineDocument9 pagesDiesel EngineAshwin BlasterNo ratings yet

- FilesDocument22 pagesFilesMahmoud ChihebNo ratings yet

- Adama ZLD Preliminary Energy Audit ReportDocument32 pagesAdama ZLD Preliminary Energy Audit Reportyalewlet tarekeggnNo ratings yet

- HVAC Ch10Document5 pagesHVAC Ch10Abdul RahmanNo ratings yet

- Chap 01 General and 02 Market PDFDocument12 pagesChap 01 General and 02 Market PDFWarlito BorneaNo ratings yet

- 3.0 Gas Turbine (For Printing)Document42 pages3.0 Gas Turbine (For Printing)yam3thebnyNo ratings yet

- Capex & Opex9834865Document32 pagesCapex & Opex9834865Farrah Taha AbdullahNo ratings yet

- Safety Case Questionnaire: Product CapacityDocument5 pagesSafety Case Questionnaire: Product Capacitydilip matalNo ratings yet

- BÀI TẬP ĐỌC HIỂU LỚP 7Document3 pagesBÀI TẬP ĐỌC HIỂU LỚP 7Thànhh LongNo ratings yet

- Explosive Gas That's Lighter Than Air The Squeaky Voice GasDocument8 pagesExplosive Gas That's Lighter Than Air The Squeaky Voice GasMatthew SmithNo ratings yet

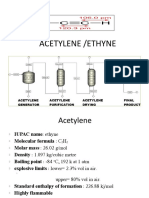

- Acetylene Production-2023 4Document31 pagesAcetylene Production-2023 4Divyansh NagarNo ratings yet

- Chapter 6 Chemical EquilibriumDocument74 pagesChapter 6 Chemical Equilibriumnoor syahirahNo ratings yet

- Lpgas: Northwest Europe Daily Assessments $/MTDocument5 pagesLpgas: Northwest Europe Daily Assessments $/MTMilkiss SweetNo ratings yet

- STAHL Poster Safety RealityDocument1 pageSTAHL Poster Safety Realityedwardesjr100% (1)

- 15701A03B1Document20 pages15701A03B1Suri VijayNo ratings yet

- CAClist 05072013Document108 pagesCAClist 05072013mahendraNo ratings yet

- Formation GroupDocument16 pagesFormation GroupAmar BenAmarNo ratings yet

- Green Building Imperative Panacea For en 8dd63a47Document15 pagesGreen Building Imperative Panacea For en 8dd63a47Kevin ChristianNo ratings yet

- Wind Farm DissertationDocument6 pagesWind Farm DissertationManchester100% (1)

- CHART INDUSTRIES INC 10-K (Annual Reports) 2009-02-25Document150 pagesCHART INDUSTRIES INC 10-K (Annual Reports) 2009-02-25http://secwatch.com100% (3)

- 2016 Paper 1 Oct & Nov QP 1Document16 pages2016 Paper 1 Oct & Nov QP 1LeniNo ratings yet

- Energy Profile EgyptDocument4 pagesEnergy Profile EgyptLe Diacre KNo ratings yet

- CL ALOX enDocument2 pagesCL ALOX enmikael8118No ratings yet

- 029 PDFDocument8 pages029 PDFkrishnaNo ratings yet

- HP Fuel Gas SystemDocument8 pagesHP Fuel Gas SystemAnonymous QSfDsVxjZNo ratings yet

- Advanced Separation-1Document44 pagesAdvanced Separation-1fekremariam AmbawNo ratings yet

- Chapter 17Document127 pagesChapter 17rkverm100% (2)

- Petronas Refinery & Petrochemical Corporation Sdn. BHDDocument4 pagesPetronas Refinery & Petrochemical Corporation Sdn. BHDMuhammad firdaus rusliNo ratings yet

- Present Scenario of Solar Energy in India and Scope in FutureDocument17 pagesPresent Scenario of Solar Energy in India and Scope in FutureAbhishek Ranjan100% (3)

- Tas Institute of OilDocument7 pagesTas Institute of OilSheena DovenantNo ratings yet