Professional Documents

Culture Documents

Changes in GSM of Grey Knitted Fabric from Pretreatment to Finishing

Uploaded by

Black SoulOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Changes in GSM of Grey Knitted Fabric from Pretreatment to Finishing

Uploaded by

Black SoulCopyright:

Available Formats

136 K. M.

Faridul Hasan: Study on the Changes of GSM (Gm/m2) of Grey Knitted Fabric from Pretreatment to Finishing

3.1. Cares that should be Taken for GSM Measurement All most all the GSM values found are near about to

To collect two or more sample from different parts of acceptable limit. When we observed more than one GSM

the fabric of same lot & same order no. to get accurate values for same fabric & same processes we did not get

result. larger difference.

To ensure the sample is accurately dried. To ensure that More research and development is required to monitor the

no pressure is applied to the sample before cutting by Change of GSM in different processes.

the GSM cutter.

To measure the GSM before absorbing the moisture to

get accurate result.

To ensure that the sample is cut by GSM cutter REFERENCES

accurately. [1] E.P.G. Ghol & L.D. Vilensky, Textile Science (1983), CBS

To ensure that the blade is sharp enough to cut the Publishers & Distributors, 41-42.

sample for GSM.

[2] S. Gordon and Y-L. Hsies, Cotton: Science and technology

To make sure that the Rubber pad is plane but not

(2007), Woodhead Publishing Ltd, 3-5.

rough.

To apply uniform Tension. [3] A.D. Broadbent, Basic Principle of Textile Coloration9201),

To ensure that there’s not any yarn of sample to be cut SDC, 72.

later. [4] E.R. Troatman, Dyeing & Chemical technology of Textile

Numbering of sample for specific process is to be Fibers (1975), Charles Giffin & Company Ltd, 44.

done. [5] Postle, R. (1990) "Fabric Objective Measurement

To measure the GSM accurately. Technology: Present Status and Future Potential",

To clean the Balance properly International Journal of Clothing Science and Technology,

To make zero the Electric balance reading. Vol. 2 No: 3, pp.7 – 17

When the sample is put in the balance its covered with [6] Ukponmwan J. O. (1988). Correlation Between Objective and

the head. Subjective Methods of Assessing Fabric Handle, Journal of

The reading is taken & multiplied by 100 Textile Institute, No 4, 1988, pp 580-587.

[7] Kawabata S. (1989). Fabric Performance in Clothing and

3.2. Faults that may Arise during GSM Measurement Clothing Manufacture, Journal of Textile Institute, Vol 80,

GSM may vary due to existing dirt variation in different No 1, pp 19-50

parts of the fabric Grey Stage). [8] Chen, Y., and Collier, B. J, (1997). Characterising Fabric End

If Pretreatment is not proper in all parts of the fabric. Use by Fabric Physical Properties, Textile Research Journal,

If GSM of Uneven shade (fabric) is taken. Vol 67, No 4, pp 247-252.

To take improper Weight. [9] BS (1979). Methods of Test for Textiles (British Standard

To cut the sample improperly. Handbook No. 11), British Standards Institution, Revised

To take the Stentering sample which is not properly Edition.

gripped? [10] Gong R.H. and Mukhopadhyay S.K. (1993). Fabric Objective

To take the measurement after long time Measurement: A Comparative Study of Fabric Characteristics,

If the fiber is immature in some particular places. Journal of Textile Institute, Vol 84, No 2, pp 192-198.

If the Electric balance exist any dirt or dust. [11] Roshan L. S. (1995), Importance of Mechanical and Physical

If the sample is remained rough through any pressure Properties of Fabrics in the Clothing Manufacturing Process.

applied directly or indirectly to it before cutting by International Journal of Clothing Science and Technology,

GSM cutter. Vol 7, No 2/ 3, pp 35-42.

[12] Prof. V.A. shenai, Technology of Textile Processing (Vol II):

Chemistry of Dyes and Principles of Dyeing (1993), Sevak

4. Conclusions Publications, 519-522.

I tried my best to find out the Change of GSM of different [13] John shore, Cellulosic Dyeing (19950, SDC, 212-213.

fabrics (mentioned in the experimental data) from [14] John Shore, Colorants and Auxiliaries (Vol II): Chemistry of

Pretreatment to finishing both in dyeing & finishing section. Dyes and Principles of Dyeing (1993), Sevak publications,

For this purpose, I had to collect the sample of each & 519-522.

every processes for GSM measurement. For some fabrics we [15] Prof. V.A. shenai, Technology of Textile Processing (Vol II):

took more than one or two sample for accuracy of the result. Chemistry of Dyes and Principles of Dyeing (1993), Sevak

Through this measurement of GSM, I got the GSM of Publications, 519-523.

different fabrics for different processes & I was able to [16] Hassan B. A. (2003). Effect of Mechanical and Physical

compare these GSM values for different fabric for different Properties on Fabric Hand. Wood Head Publishing Limited,

processes. New York, pp 447 – 447.

You might also like

- 5 SularDocument2 pages5 SularAniket MahajanNo ratings yet

- Comparison of Regression and Adaptive Neuro-Fuzzy Models For Predicting TheDocument5 pagesComparison of Regression and Adaptive Neuro-Fuzzy Models For Predicting TheDr. Zulfiqar AliNo ratings yet

- 24 996.fullDocument8 pages24 996.fullpriyaNo ratings yet

- Durability Utilizing Abrasion of Seamed Laser Faded DenimDocument6 pagesDurability Utilizing Abrasion of Seamed Laser Faded DenimijsretNo ratings yet

- Paper (Total Appearance Value)Document8 pagesPaper (Total Appearance Value)ravibabayNo ratings yet

- 43 ADocument2 pages43 AMohamed EsithNo ratings yet

- Assessment of Laboratory Sample Preparation For Fibre Reinforced SandsDocument11 pagesAssessment of Laboratory Sample Preparation For Fibre Reinforced SandsPinak RayNo ratings yet

- Determination of Pore Size Porosity and Pore Size Distribution of Wovenstructures by Image Analysis Techniques 2165 8064 1000314Document9 pagesDetermination of Pore Size Porosity and Pore Size Distribution of Wovenstructures by Image Analysis Techniques 2165 8064 1000314miloNo ratings yet

- Studies On Cotton Acrylic Bulked Yarns Produced From Different Spinning Technologies Part II Fabric CharacteristicsDocument11 pagesStudies On Cotton Acrylic Bulked Yarns Produced From Different Spinning Technologies Part II Fabric CharacteristicsHarun VenkateshNo ratings yet

- Weft & Warp TensionDocument8 pagesWeft & Warp Tensionnemat2008No ratings yet

- Performanceanalysisofspandex Incorporatedsinglejerseyfabricsfor Sportswear-MinDocument12 pagesPerformanceanalysisofspandex Incorporatedsinglejerseyfabricsfor Sportswear-MinNasrin AkterNo ratings yet

- Effect of Twist Multiplier On Air Permeability of Single Jersey and 1x1 Rib FabricsDocument8 pagesEffect of Twist Multiplier On Air Permeability of Single Jersey and 1x1 Rib FabricsAndrian WijayonoNo ratings yet

- Investigation of Performance Properties of Graphene Coated FabricsDocument6 pagesInvestigation of Performance Properties of Graphene Coated FabricsIjmret JournalNo ratings yet

- Mechanical Properties of 3D Woven Basalt Fiber Composite Materials: Experiment and FEM SimulationDocument7 pagesMechanical Properties of 3D Woven Basalt Fiber Composite Materials: Experiment and FEM SimulationmithileshmaverickNo ratings yet

- Fabric and Garment Drape Measurement - Part 2: Reham Sanad, Tom Cassidy, Vien Cheung, Elaine EvansDocument22 pagesFabric and Garment Drape Measurement - Part 2: Reham Sanad, Tom Cassidy, Vien Cheung, Elaine EvansFashionnift NiftNo ratings yet

- Influence of fabric architecture on dry fabric contact behaviorDocument13 pagesInfluence of fabric architecture on dry fabric contact behaviorranim najibNo ratings yet

- Investigation of Air Permeability of Cotton & Modal Knitted FabricsDocument6 pagesInvestigation of Air Permeability of Cotton & Modal Knitted FabricsAhmad SamerNo ratings yet

- Cotton AgeingDocument6 pagesCotton AgeingSubba RaoNo ratings yet

- The Effect of Fibre Blend On Comfort Characteristics of ElasticDocument7 pagesThe Effect of Fibre Blend On Comfort Characteristics of ElasticGeotamNo ratings yet

- Is 6668Document8 pagesIs 6668Muthukumaar GanapathisamyNo ratings yet

- The Stress Analysis Method For Three-Dimensional Composite MaterialsDocument20 pagesThe Stress Analysis Method For Three-Dimensional Composite Materialsم.احمدالربيعيNo ratings yet

- Effect of Stitch Per Inch (SPI) and Yarn Count On Seam Strength of Twill FabricDocument7 pagesEffect of Stitch Per Inch (SPI) and Yarn Count On Seam Strength of Twill FabricAbhishek KumarNo ratings yet

- Research ArticleDocument11 pagesResearch ArticlesagarkanzarkarNo ratings yet

- 01 NiromiDocument3 pages01 NiromiShanmugeshwari MuthiahNo ratings yet

- 1 PBDocument14 pages1 PBZalam ZimbooNo ratings yet

- Studying Effects of Fabric Thickness, Loop Shape Factor, Fabric Tightness Factor and Aerial Weight On Thermal Conductivity of Plain Single Jersey Cotton Knitted Fabric Using Box Behnken DesignDocument8 pagesStudying Effects of Fabric Thickness, Loop Shape Factor, Fabric Tightness Factor and Aerial Weight On Thermal Conductivity of Plain Single Jersey Cotton Knitted Fabric Using Box Behnken DesignIJEACS UKNo ratings yet

- Behaviour of Sand Confined With Single and Multiple GeocellsDocument14 pagesBehaviour of Sand Confined With Single and Multiple Geocellssundeep48100% (1)

- Geocell Confinement Improves Sand Strength StiffnessDocument14 pagesGeocell Confinement Improves Sand Strength StiffnessManaswini VadlamaniNo ratings yet

- Parative FullDocument10 pagesParative FullTJPRC PublicationsNo ratings yet

- Bagging Behavior of Different Fabric Structures Knitted From Blended Yarns Using Image ProcessingDocument8 pagesBagging Behavior of Different Fabric Structures Knitted From Blended Yarns Using Image ProcessingskgolbanNo ratings yet

- Air-Jet Texturing PDFDocument0 pagesAir-Jet Texturing PDFNessre ZeineNo ratings yet

- SYF Notes P 1Document9 pagesSYF Notes P 1Ashish MohapatraNo ratings yet

- Experimental Verification of Free Vibration Analysis of Stiffened Plate Considering - FSDT and HSDTDocument6 pagesExperimental Verification of Free Vibration Analysis of Stiffened Plate Considering - FSDT and HSDTSuresh Kumar V ce21g514No ratings yet

- Modelling Ballistic Impact On Woven Fabric With Ls-DynaDocument6 pagesModelling Ballistic Impact On Woven Fabric With Ls-DynaburakNo ratings yet

- Manufacturing and Sewing Performance of Polyurethane and Polyurethane Silicone Coated FabricsDocument7 pagesManufacturing and Sewing Performance of Polyurethane and Polyurethane Silicone Coated FabricsAbhishek KumarNo ratings yet

- Materials: A Comprehensive Study On The Mechanical Properties of Different 3D Woven Carbon Fiber-Epoxy CompositesDocument13 pagesMaterials: A Comprehensive Study On The Mechanical Properties of Different 3D Woven Carbon Fiber-Epoxy CompositesBharani MurugesanNo ratings yet

- Mechanical Properties of Flax Fiber Reinforced Composites Manufactured Using Hand Layup and Compression Molding-A ComparisonDocument9 pagesMechanical Properties of Flax Fiber Reinforced Composites Manufactured Using Hand Layup and Compression Molding-A ComparisonsriyajambukarNo ratings yet

- Determination of Length and Width of Woven Fabrics - MethodsDocument9 pagesDetermination of Length and Width of Woven Fabrics - Methodsanuragbhattacharjee56No ratings yet

- Accepted Manuscript: Composite StructuresDocument33 pagesAccepted Manuscript: Composite StructuresDwitiya D TihataNo ratings yet

- Riginal Rticles A Study of The Effects of Machine Gauge and Some Knit Structures On The Physical Properties of Weft Knitted FabricsDocument7 pagesRiginal Rticles A Study of The Effects of Machine Gauge and Some Knit Structures On The Physical Properties of Weft Knitted Fabricserica_burton8232No ratings yet

- Measurement of Fabric GSM Using Non Destructive MethodDocument6 pagesMeasurement of Fabric GSM Using Non Destructive MethodsentyNo ratings yet

- DSDDocument4 pagesDSDIshwar DudagiNo ratings yet

- An Investigation On The Effect of Top Roller Cot Grinding and Its Pressure On Yarn QualityDocument11 pagesAn Investigation On The Effect of Top Roller Cot Grinding and Its Pressure On Yarn QualityInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Analysis The Influenced of Plain and Twill StructuDocument7 pagesAnalysis The Influenced of Plain and Twill StructuMuhammad MustahsinNo ratings yet

- Performance Evaluation of Cotton Yarn Sized With Natural Starches Produced From Native Corn Cassava and Potato StarchesDocument5 pagesPerformance Evaluation of Cotton Yarn Sized With Natural Starches Produced From Native Corn Cassava and Potato StarchesAnkush JainNo ratings yet

- Allaoui 2012Document13 pagesAllaoui 2012ranim najibNo ratings yet

- Air Permeability Test ResultDocument4 pagesAir Permeability Test Resultritesh0raj-2No ratings yet

- Effects of Combed and Carded Yarn On Weft Knitted Finished Quality-MinDocument5 pagesEffects of Combed and Carded Yarn On Weft Knitted Finished Quality-MinNasrin AkterNo ratings yet

- Effect of Yarn Count On Single Jersey Knitted Fabric PropertiesDocument5 pagesEffect of Yarn Count On Single Jersey Knitted Fabric PropertiesGOPINo ratings yet

- Cross Woven Glass FibreDocument9 pagesCross Woven Glass FibreUmair KhalidNo ratings yet

- Abrasion Resistance Property of Woven FabricsDocument3 pagesAbrasion Resistance Property of Woven FabricsJothi Vel Murugan100% (1)

- Frost Park 2003Document14 pagesFrost Park 2003akshayNo ratings yet

- Study of Woven Fabric Shear BehaviourDocument11 pagesStudy of Woven Fabric Shear Behaviourasebaei95No ratings yet

- Seam Performance Evaluation of Plain Fabric UsingDocument9 pagesSeam Performance Evaluation of Plain Fabric UsingMd NurunnabiNo ratings yet

- Specific Surface Area of Some Standard Cotton Fiber and Its Relation To Physical PropertiesDocument3 pagesSpecific Surface Area of Some Standard Cotton Fiber and Its Relation To Physical PropertiesJackeline Carneiro CornelsenNo ratings yet

- Thermal Comfort Properties of Bifacial FabricsDocument9 pagesThermal Comfort Properties of Bifacial FabricspriyaNo ratings yet

- Effect of Machine Parameters On Knit Fabric SpecificationsDocument5 pagesEffect of Machine Parameters On Knit Fabric SpecificationsGarmentLearnerNo ratings yet

- Effect of Weave Structures and Thread Densities On The Cover FactorDocument12 pagesEffect of Weave Structures and Thread Densities On The Cover Factormohammadi.m1324No ratings yet

- OP-01 Bikini A BODY YDDocument1 pageOP-01 Bikini A BODY YDBlack SoulNo ratings yet

- Op-01 Bikini B InnerDocument1 pageOp-01 Bikini B InnerBlack SoulNo ratings yet

- OP-01 Bikini A BODYDocument1 pageOP-01 Bikini A BODYBlack SoulNo ratings yet

- RVM231PB64 A Body Width MeshDocument1 pageRVM231PB64 A Body Width MeshBlack SoulNo ratings yet

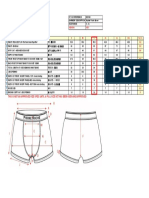

- BKB Szorty Y-A 1wayDocument1 pageBKB Szorty Y-A 1wayBlack SoulNo ratings yet

- 49713-S S Tee C NK TapeDocument1 page49713-S S Tee C NK TapeBlack SoulNo ratings yet

- RVM231PB64 A Body Width Out MeshDocument1 pageRVM231PB64 A Body Width Out MeshBlack SoulNo ratings yet

- BKM Classic Kids - Brief-D BottomDocument1 pageBKM Classic Kids - Brief-D BottomBlack SoulNo ratings yet

- Pieces Per Set: 1 Material Per Set: 0.9707inch Material Per Dozen: 11.6480inch Total Material: 38.8268Document1 pagePieces Per Set: 1 Material Per Set: 0.9707inch Material Per Dozen: 11.6480inch Total Material: 38.8268Black SoulNo ratings yet

- BKB Szorty-B FR CroseDocument1 pageBKB Szorty-B FR CroseBlack SoulNo ratings yet

- RVM231PB64 A Body 30-9-22Document1 pageRVM231PB64 A Body 30-9-22Black SoulNo ratings yet

- Updated GA21SSM036BTT 031615091276 - TfileDocument7 pagesUpdated GA21SSM036BTT 031615091276 - TfileBlack SoulNo ratings yet

- 49713-S S Tee A BodyDocument1 page49713-S S Tee A BodyBlack SoulNo ratings yet

- Pieces Per Set: 1 Material Per Set: 0.9707inch Material Per Dozen: 11.6480inch Total Material: 38.8268Document1 pagePieces Per Set: 1 Material Per Set: 0.9707inch Material Per Dozen: 11.6480inch Total Material: 38.8268Black SoulNo ratings yet

- Mens Boxer A BodyDocument1 pageMens Boxer A BodyBlack SoulNo ratings yet

- Girls Jersey Trousers Measurement ChartDocument4 pagesGirls Jersey Trousers Measurement ChartBlack SoulNo ratings yet

- Brief A BODYDocument1 pageBrief A BODYBlack SoulNo ratings yet

- PSF Vertbaudet 70013-0990 94642 Dors Bien D 20211029Document15 pagesPSF Vertbaudet 70013-0990 94642 Dors Bien D 20211029Black SoulNo ratings yet

- BLS Nov2021 JP04 BlissDocument34 pagesBLS Nov2021 JP04 BlissBlack SoulNo ratings yet

- Style File: C:/Users/jubayer - sabuj/Desktop/2XU Pattern PDF/COMP DESIGN/BLS NOV2021 JP04 BLISS - PDS Global InfoDocument10 pagesStyle File: C:/Users/jubayer - sabuj/Desktop/2XU Pattern PDF/COMP DESIGN/BLS NOV2021 JP04 BLISS - PDS Global InfoBlack SoulNo ratings yet

- CH+GE21FWF063JKT Size Set Sample-Production MEASURMENTDocument1 pageCH+GE21FWF063JKT Size Set Sample-Production MEASURMENTBlack SoulNo ratings yet

- Global Info:: Base 0.0130 47.34Document2 pagesGlobal Info:: Base 0.0130 47.34Black SoulNo ratings yet

- Sports design pattern fileDocument6 pagesSports design pattern fileBlack SoulNo ratings yet

- w23 4055 Cost A BodyDocument1 pagew23 4055 Cost A BodyBlack SoulNo ratings yet

- Aero Mid-Rise Comp Shorts - Style #WA6684bDocument16 pagesAero Mid-Rise Comp Shorts - Style #WA6684bBlack SoulNo ratings yet

- Ga21fwf005jkt Measurment ChartDocument1 pageGa21fwf005jkt Measurment ChartBlack SoulNo ratings yet

- BLC Nov2021 JP04Document77 pagesBLC Nov2021 JP04Black SoulNo ratings yet

- Baum Trading Size Specfication: A B C D E F I J M N O P QDocument1 pageBaum Trading Size Specfication: A B C D E F I J M N O P QBlack SoulNo ratings yet

- GE+CH21SSF013BRA Production MeasureDocument1 pageGE+CH21SSF013BRA Production MeasureBlack SoulNo ratings yet

- GA-SS21 Mens T-Shirt Fit SpecsDocument1 pageGA-SS21 Mens T-Shirt Fit SpecsBlack SoulNo ratings yet

- A Review of The Success and Failure Characteristics of Resin-Bonded BridgesDocument10 pagesA Review of The Success and Failure Characteristics of Resin-Bonded BridgesMichael XuNo ratings yet

- Republic of the Philippines College Research Methods AssignmentDocument13 pagesRepublic of the Philippines College Research Methods AssignmentNecy Mae U. YponNo ratings yet

- 52-Using Building Information Modeling (BIM) For Estimating and Scheduling, Adoption BarriersDocument9 pages52-Using Building Information Modeling (BIM) For Estimating and Scheduling, Adoption BarriersJean-paul AgbohNo ratings yet

- Management Science or Art PDFDocument9 pagesManagement Science or Art PDFHakim Jan33% (3)

- Service Quality - Customer Satisfaction: Mrs.P.TamilselviDocument3 pagesService Quality - Customer Satisfaction: Mrs.P.TamilselviClaire BacligNo ratings yet

- Dark Therapy: A Famous CaseDocument2 pagesDark Therapy: A Famous CaseJP BeausoleilNo ratings yet

- Research Methods: Chapter Seven (Research Report Writing andDocument13 pagesResearch Methods: Chapter Seven (Research Report Writing andbojaNo ratings yet

- Research Proposal For Climate Change Using SWMMDocument17 pagesResearch Proposal For Climate Change Using SWMMVimala ThentuNo ratings yet

- BASM 523 - Management Consulting and Corporate Decision Support 2Document10 pagesBASM 523 - Management Consulting and Corporate Decision Support 2uygh gNo ratings yet

- National Benchmark Survey on Quality of Work Life in Service SectorDocument14 pagesNational Benchmark Survey on Quality of Work Life in Service SectorMatthew HughesNo ratings yet

- MarketingDocument2 pagesMarketingSuryam GNo ratings yet

- MTH3003 tutorial 5 problems on sampling distribution of means and proportionsDocument3 pagesMTH3003 tutorial 5 problems on sampling distribution of means and proportionsNur Arisya AinaaNo ratings yet

- Final Final ReportDocument38 pagesFinal Final Reporttrisha sinhaNo ratings yet

- Contoh Table 1 JorcDocument12 pagesContoh Table 1 JorcHardiyanto HardiyantoNo ratings yet

- Effects of Marungko Approach in Improving The Reading Ability of Grade 3 PupilsDocument24 pagesEffects of Marungko Approach in Improving The Reading Ability of Grade 3 PupilsJoel E. LiongNo ratings yet

- Statistics For Business and Economics 13th Edition McClave Test Bank DownloadDocument37 pagesStatistics For Business and Economics 13th Edition McClave Test Bank DownloadFreddie Cherry100% (20)

- Lesson 12 - Summarizing FindingsDocument22 pagesLesson 12 - Summarizing FindingsLudovina Calcaña100% (2)

- One of The Fundamental Shifts in Organizational Management in The Last 10 Years Has Been The PurposefulDocument1 pageOne of The Fundamental Shifts in Organizational Management in The Last 10 Years Has Been The PurposefulLinggar Amanda KamaNo ratings yet

- Placement BrochureDocument44 pagesPlacement BrochureJaya GummalaNo ratings yet

- The Level of EvidanceDocument6 pagesThe Level of EvidanceyoezufNo ratings yet

- Unit-III Data CollectionDocument82 pagesUnit-III Data CollectionSaravanan ShanmugamNo ratings yet

- Southeast Asia Psychology Journal Vol.6, (2018) 16-25Document10 pagesSoutheast Asia Psychology Journal Vol.6, (2018) 16-25Viqih AryanataNo ratings yet

- Integer Programming Part 2Document41 pagesInteger Programming Part 2missMITNo ratings yet

- Competitive Intelligence of Law Firms and Lawyers From Big DataDocument7 pagesCompetitive Intelligence of Law Firms and Lawyers From Big DataMellwyn JosephNo ratings yet

- Baum - An Introduction To Modern Econometrics Using StataDocument376 pagesBaum - An Introduction To Modern Econometrics Using StataVelichka Dimitrova100% (1)

- The Cracked Mirror, Karen KernbergDocument10 pagesThe Cracked Mirror, Karen Kernbergjuaromer100% (1)

- Qam601 - Statistics For Management CASE STUDY of The Kolkata DigestDocument9 pagesQam601 - Statistics For Management CASE STUDY of The Kolkata DigestAdwait DeNo ratings yet

- Educ 6 Prelim MidtermDocument8 pagesEduc 6 Prelim Midtermskye.business2022No ratings yet

- Strategy Through Innovative Behaviors, Actions, and Risk-Taking That Drive Towards and Can Be Measured Through Improved Metrics of Success."Document2 pagesStrategy Through Innovative Behaviors, Actions, and Risk-Taking That Drive Towards and Can Be Measured Through Improved Metrics of Success."Simran RaiNo ratings yet

- Insecticidal Activity of Extracts of Makahiya Leaves and StemsDocument35 pagesInsecticidal Activity of Extracts of Makahiya Leaves and StemsAnonymous G1ZHMFvNo ratings yet