Professional Documents

Culture Documents

Slew Ring: 1 - You Will Need

Uploaded by

Escandon Vicario LinoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Slew Ring: 1 - You Will Need

Uploaded by

Escandon Vicario LinoCopyright:

Available Formats

Lubrication-Tightening-Clearance check

Slew ring

M005

Lubrication-Tightening-Clearance check

Slew ring

1- You will need

• Standard tool kit

• Steel shims • Place barriers around the perimeter of the

• Protective goggles work area

• Gloves

2- Preliminary procedure

1. Place the machine in maintenance configuration. Refer to Section B 1.1 - Maintenance imple-

mentation.

3- Lubrication

The illustrations in this paragraph do not necessarily correspond to the range of products designated in the

manual.

The maintenance of the slew ring is essential for the safety of the machine and to guarantee its service life. Whatever

the type of system installed on the machine, interior or external teeth, follow the recommendations of greasing as

indicated in the program.

1. Check for the presence of all the locating bolts.

2. Check that the accessible screws are not loosened. If nec-

essary, tighten the screws(Refer to the "tightening torque"

table).

3. Visually check the presence of the teeth and gear (if pos-

sible).

4. Check the appearance of the teeth.

5. Grease the (internal and external) crown gear teeth.

6. Grease the raceways (access to greasers via the holes

situated on the turntable, until the oil escapes from the

crown lip seal).

4000790800 E 11.20 USA / GB 71

Lubrication-Tightening-Clearance check

Slew ring

M005

4- Tightening

Machine type Metric Imperial

HA16PE 21,5 daN.m (158 lbf.ft)

HA12IP - HA33JE 9 daN.m (66 lbf.ft)

HA15IP - HA43JE 9 daN.m (66 lbf.ft)

HA12CJ - HA32CJ 9 daN.m (66 lbf.ft)

HA12CJ+ - HA32CJ+ 9 daN.m (66 lbf.ft)

HA120PX (N/A) 9 daN.m (66 lbf.ft)

HA16X (N/A) 21,5 daN.m (158 lbf.ft)

HA16SPX - HA46SJRT 21,5 daN.m (158 lbf.ft)

HA16PX - HA46JRT 21,5 daN.m (158 lbf.ft)

HA18SPX - HA51SJRT 21,5 daN.m (158 lbf.ft)

HA18PX - HA51JRT 21,5 daN.m (158 lbf.ft)

HA20PX - HA61JRT 21,5 daN.m (158 lbf.ft)

HA260PX - HA80JRT 21,5 daN.m (158 lbf.ft)

HA32RTJ PRO - HA100RTJ PRO 21,5 daN.m (158 lbf.ft)

HA41RTJ PRO - HA130RTJ PRO 21,5 daN.m (158 lbf.ft)

H14TX - HB40 8,7 daN.m (64 lbf.ft)

H16TPX - HB44J 8,7 daN.m (64 lbf.ft)

H21TX - HB62 21,5 daN.m (158 lbf.ft)

H23TPX - HB68J 32 daN.m (236 lbf.ft)

H25TPX - HB76J 21,5 daN.m (158 lbf.ft)

H28TJ+ - HB86TJ+ 21,5 daN.m (158 lbf.ft)

HT43RTJ PRO - HT132RTJ PRO 21,5 daN.m (158 lbf.ft)

STAR 8 - STAR 22J - Ring on plate 13.5 daN.m (100 lbf.ft)

STAR 8 - STAR 22J - Plate on mast foot 19.5 daN.m (144 lbf.ft)

STAR 8 - STAR 22J - Ring on chassis 13.5 daN.m (100 lbf.ft)

STAR 10 - STAR 26J - Ring on plate 13.5 daN.m (100 lbf.ft)

STAR 10 - STAR 26J - Plate on mast foot 19.5 daN.m (144 lbf.ft)

STAR 10 - STAR 26J - Ring on chassis 13.5 daN.m (100 lbf.ft)

72 4000790800 E 11.20 USA / GB

Lubrication-Tightening-Clearance check

Slew ring

M005

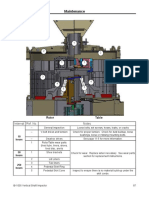

5- Criteria of replacement

Check the slewing system every 500 h or each major intervention done on the machine.

Step 1 : Visual and sound check :

Replace slew ring in the following cases :

• Abnormal noise during the turret rotation.

• Movement jolts during the rotation of the turret.

• Gear teeth missing or damaged.

• Presence of metal particles in the grease.

• Wear on gear teeth.

Step 2 : Measurement of the clearance :

Place the machine in the following conditions :

• On flat ground, Set up barriers to define the test area.

• No load in the platform.

• From the ground control box, align the turret at 90 ° to the chassis.

• Lift the boom approximatively 30 ° from the ground.

• Completely retract the boom.

• Jib in horizontal position(if fitted).

From the magnetic comparator, note the clearance ( J1) between chassis (or turret) and the slew ring.

Clearance between chassis (or turret) and slew ring

J1

4000790800 E 11.20 USA / GB 73

Lubrication-Tightening-Clearance check

Slew ring

M005

After having carried out the measurement :

• Lower the boom at horizontal position.

• Lift the arm (if exists) as its maximum position. Don’t extend the telescopic boom.

• The telescopic boom should be fully extended and in the horizontal position..

• Jib in horizontal position(if fitted).

In its new configuration, note the clearance ( J1) between chassis (or turret) and the slew ring as previously.

• If the difference between two measurements does not exceed 2 mm : the test validates correct operation.

• Otherwise, contact HAULOTTE Services® to repair the system.

6- Clearance check

Consult the After-Sales Service HAULOTTE Services®.

7- Additional operation

1. Place the machine in its operating configuration. Refer to Section B 1.1 - Maintenance imple-

mentation.

2. Rotate the slew ring by one complete turn.

A tight spot or grinding sound during rotation or the presence of metal particles escaping from the lip seal are

signs of abnormal wear in the raceway (Contact HAULOTTE Services®).

74 4000790800 E 11.20 USA / GB

You might also like

- F1-F5 Adj FRD PDFDocument21 pagesF1-F5 Adj FRD PDFNguyễn Quang HưngNo ratings yet

- 50 Series Mechanical - Pins and BushingsDocument55 pages50 Series Mechanical - Pins and BushingsLuis Torres100% (1)

- SKI Chaincase - 4-Stroke (Line-Up) - Supplement mmr2017-119Document12 pagesSKI Chaincase - 4-Stroke (Line-Up) - Supplement mmr2017-119Erne Lange OlsenNo ratings yet

- F1-F5 Adj PDFDocument21 pagesF1-F5 Adj PDFtpedrosa22No ratings yet

- General Information: Instruction Manual Portable Static Cone PenetrometerDocument4 pagesGeneral Information: Instruction Manual Portable Static Cone PenetrometerAbdelhamid ElgasaierNo ratings yet

- A900099 PC10 15-28UU Track ShoeDocument6 pagesA900099 PC10 15-28UU Track Shoejoaquin suarezNo ratings yet

- Manual - Tong XQ6B RDCDocument26 pagesManual - Tong XQ6B RDCJavier Danilo Aranda PinzonNo ratings yet

- Operating Manual of XYQ6B TongDocument26 pagesOperating Manual of XYQ6B TongV.D. J.No ratings yet

- M-S-215 Static Cone PenetrometerDocument4 pagesM-S-215 Static Cone PenetrometerJunpieter GultomNo ratings yet

- Replace Cylinder Gland SealsDocument10 pagesReplace Cylinder Gland Sealshuguer1No ratings yet

- Alternator: SpecificationsDocument4 pagesAlternator: SpecificationsjogremaurNo ratings yet

- Ключ Гідравлічний Xq114-6bDocument26 pagesКлюч Гідравлічний Xq114-6bЮрчик ПерчукNo ratings yet

- 7HB (A, B, C, D, E, X) Assembly-Disassembly ManualDocument33 pages7HB (A, B, C, D, E, X) Assembly-Disassembly ManualYavuz Ercanli100% (1)

- S2000 SOS Supercharger Install ManualDocument43 pagesS2000 SOS Supercharger Install ManualMatthew Chtchavlinski100% (4)

- 126e PTP Shale Shaker Operations ManualDocument13 pages126e PTP Shale Shaker Operations ManualAndrew GoadNo ratings yet

- Workshopmanual xl500r 1982 Multi 09062014 2148Document100 pagesWorkshopmanual xl500r 1982 Multi 09062014 2148daqyou daqNo ratings yet

- Westco Product Catalog 2019Document16 pagesWestco Product Catalog 2019DiegoCaicedo1982100% (2)

- Vsi 2Document9 pagesVsi 2Vivek AgrawalNo ratings yet

- FloorHand BLOHM BOSSDocument4 pagesFloorHand BLOHM BOSSCarlosSantamariaNo ratings yet

- GROUP 11 FRONT AXLE REMOVALDocument61 pagesGROUP 11 FRONT AXLE REMOVALChristian VicenteNo ratings yet

- 2.staad Output ReportDocument23 pages2.staad Output Reportsamir bendreNo ratings yet

- Champ Ion PackerDocument2 pagesChamp Ion PackerCHO ACHIRI HUMPHREYNo ratings yet

- 105 MaintenanceDocument29 pages105 MaintenanceokovalskiNo ratings yet

- Group 10 TransmissionDocument54 pagesGroup 10 TransmissionDado OgameNo ratings yet

- Nowosci 1.03.07Document18 pagesNowosci 1.03.07andrzejNo ratings yet

- Checklist RigDocument104 pagesChecklist RigKiryaki Francis100% (2)

- Manual Mantenimiento Mission 40Document8 pagesManual Mantenimiento Mission 40Daygor Martinez SabucoNo ratings yet

- Bof 1.5 inDocument5 pagesBof 1.5 inDurvis RomeroNo ratings yet

- Maintain Rail Coach Draw GearDocument8 pagesMaintain Rail Coach Draw Gearanunay kumarNo ratings yet

- Workshop Manual: TBR SeriesDocument60 pagesWorkshop Manual: TBR Seriesfrankhil ramosNo ratings yet

- A Complete Guide To Spiratec™ Rotor (Cs41018/Cs41019/Cs41011) & Remote Centrifuge Product Benefits Installation InstructionsDocument7 pagesA Complete Guide To Spiratec™ Rotor (Cs41018/Cs41019/Cs41011) & Remote Centrifuge Product Benefits Installation InstructionsCarlos MeztNo ratings yet

- TONGS: Large-Capacity, Self-Locking Wrenches Used To Grip Drill String Components and Apply Torque. As WithDocument4 pagesTONGS: Large-Capacity, Self-Locking Wrenches Used To Grip Drill String Components and Apply Torque. As WithAhmed AmirNo ratings yet

- Spanco Freestanding Jib Cranes ManualDocument40 pagesSpanco Freestanding Jib Cranes ManualMarceloPolicastro100% (1)

- 2013 Fork Rockshox Service ManualDocument83 pages2013 Fork Rockshox Service ManualXc Cristi0% (1)

- Group 11 Front AxleDocument27 pagesGroup 11 Front AxleHậu MinhNo ratings yet

- Maintenance Operating and Service ManualDocument16 pagesMaintenance Operating and Service ManualsaritasohamNo ratings yet

- Maintenance: Rotor Interval Ref. No. NotesDocument11 pagesMaintenance: Rotor Interval Ref. No. NotesEduardo AcostaNo ratings yet

- 203-10 Tds Rev B Halbrite No-Turn ToolDocument3 pages203-10 Tds Rev B Halbrite No-Turn ToolBledarNo ratings yet

- Torque-Hub Planetary Final Drive 7HA00/7HB00 Series Service ManualDocument46 pagesTorque-Hub Planetary Final Drive 7HA00/7HB00 Series Service ManualMonty100% (1)

- Washpipe WPT00070 (NOV Etc.7.50 Inch Thread X 4 Tapered To 3 Inch Bore)Document12 pagesWashpipe WPT00070 (NOV Etc.7.50 Inch Thread X 4 Tapered To 3 Inch Bore)osvaldoNo ratings yet

- 2001 Headshok Bearing Migration Inspection Instructions enDocument2 pages2001 Headshok Bearing Migration Inspection Instructions enMohamed Abdel HamidNo ratings yet

- Low Speed MotorDocument12 pagesLow Speed MotorZoran JankovNo ratings yet

- Technical Services Tel: (800) 381-9312 / Fax: (800) 791-5500Document8 pagesTechnical Services Tel: (800) 381-9312 / Fax: (800) 791-5500RobertoNo ratings yet

- Field Assembly Manual: Dump TruckDocument67 pagesField Assembly Manual: Dump TruckWilson JhNo ratings yet

- Caterpillar 3508, 3508B, 3508CDocument11 pagesCaterpillar 3508, 3508B, 3508CGazNo ratings yet

- Toyota Tercel 1986Document885 pagesToyota Tercel 1986yorgo7002No ratings yet

- CHAMP® XHP PackerDocument2 pagesCHAMP® XHP PackerservicemenruNo ratings yet

- 5 Wheel: Installation, Maintenance & Service BulletinDocument7 pages5 Wheel: Installation, Maintenance & Service Bulletinrmj68900No ratings yet

- Crusher House OperationDocument21 pagesCrusher House Operationratan das0% (1)

- Alimak Passenger Hoist Mast ConnectionDocument3 pagesAlimak Passenger Hoist Mast ConnectionPraveen KumarNo ratings yet

- Long Term Storage Cautions For AC MotorsDocument12 pagesLong Term Storage Cautions For AC MotorsAlexNo ratings yet

- Sebf 8054 Обмеры и Правка КвDocument33 pagesSebf 8054 Обмеры и Правка КванджелаNo ratings yet

- Smi 292Document28 pagesSmi 292Sourav NandiNo ratings yet

- Operations and Parts Manual - Vanoil 3 1/16" - 10ksi Quad Bop MAN P306QB00-A, REV. 0Document18 pagesOperations and Parts Manual - Vanoil 3 1/16" - 10ksi Quad Bop MAN P306QB00-A, REV. 0dowel hernandezNo ratings yet

- Instructions For The Safe Use of P-Quip Liner Retention Systems - Pt. No. 80000111 Revision Date August 9, 2006Document7 pagesInstructions For The Safe Use of P-Quip Liner Retention Systems - Pt. No. 80000111 Revision Date August 9, 2006Heri VillaNo ratings yet

- Torque Specifications (Ka/Kc Models)Document5 pagesTorque Specifications (Ka/Kc Models)paniyaNo ratings yet

- Standard Design Features: All Plenty Side Entry Mixers Incorporate The FollowingDocument1 pageStandard Design Features: All Plenty Side Entry Mixers Incorporate The FollowingAw HvNo ratings yet

- Isuzu D-Max 2011 Axle Service ManualDocument162 pagesIsuzu D-Max 2011 Axle Service ManualWilmer Huanga0% (1)

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)

- DS PRIAMOS DC-1 Digital Speed Control eDocument4 pagesDS PRIAMOS DC-1 Digital Speed Control eEscandon Vicario LinoNo ratings yet

- SQ1120 SQ1150 SQ3140 SQ3200 SQ3300Document63 pagesSQ1120 SQ1150 SQ3140 SQ3200 SQ3300Escandon Vicario LinoNo ratings yet

- Serial Number Range Parts ManualDocument140 pagesSerial Number Range Parts ManualWagner BernardinaNo ratings yet

- User'S Manual: Model 29840Document18 pagesUser'S Manual: Model 29840Escandon Vicario LinoNo ratings yet

- Operator's Manual Supplement: GS - 30 GS - 32 GS - 46 GS - 47Document20 pagesOperator's Manual Supplement: GS - 30 GS - 32 GS - 46 GS - 47Escandon Vicario LinoNo ratings yet

- User'S Manual: Model 29840Document18 pagesUser'S Manual: Model 29840Escandon Vicario LinoNo ratings yet

- 216767e Smartlink Software InstallationDocument11 pages216767e Smartlink Software InstallationEscandon Vicario LinoNo ratings yet

- AllisonDocument9 pagesAllisonDaniel Castillo Peña100% (6)

- 01 GMK3050 3 00 May2021Document20 pages01 GMK3050 3 00 May2021Escandon Vicario LinoNo ratings yet

- AllisonDocument9 pagesAllisonDaniel Castillo Peña100% (6)

- Laboratory Report Torsion TestDocument36 pagesLaboratory Report Torsion Testfaruq haziqNo ratings yet

- NRC Generic Fundamentals Examination Question Bank - PWR February 2016Document65 pagesNRC Generic Fundamentals Examination Question Bank - PWR February 2016Iqbal HayatkhanNo ratings yet

- Technical Data MJC SeriesDocument4 pagesTechnical Data MJC SeriesBenjamin MurphyNo ratings yet

- Aerzen Blowers 054-08 2223Document5 pagesAerzen Blowers 054-08 2223Jon SmithNo ratings yet

- Pressure Fluid Regulator Airmix Instructions Manual Sames Kremlin 582092110 UkDocument19 pagesPressure Fluid Regulator Airmix Instructions Manual Sames Kremlin 582092110 UkEneias FreireNo ratings yet

- ZDEV Electromagnetic Safety ValvesDocument2 pagesZDEV Electromagnetic Safety ValvesŠime RončevićNo ratings yet

- GLV-Catalogue - Botil IndiaDocument18 pagesGLV-Catalogue - Botil IndiaHamza LamamraNo ratings yet

- Recomended Volume of Chain Locker PDFDocument1 pageRecomended Volume of Chain Locker PDFMayank DixitNo ratings yet

- Pressure Reducing Valve Pilot Operated VP-DRP10: Subplate To ISO 5781Document2 pagesPressure Reducing Valve Pilot Operated VP-DRP10: Subplate To ISO 5781Felipe Pisklevits LaubeNo ratings yet

- P&id - ChillerDocument1 pageP&id - ChillerMeryemNo ratings yet

- Calculating Spring Wire Diameter from Given DataDocument7 pagesCalculating Spring Wire Diameter from Given Dataomkar digamabar sononeNo ratings yet

- Visual rope inspection optimizationDocument88 pagesVisual rope inspection optimizationAlex CallisayaNo ratings yet

- Propped Cantilever With UdlDocument5 pagesPropped Cantilever With UdlIqbal Hossain50% (4)

- General Instructions - Daily CheckDocument8 pagesGeneral Instructions - Daily Checkrama AmeesNo ratings yet

- Globe Valves Explained: Types and UsesDocument4 pagesGlobe Valves Explained: Types and UsesMohamed AtefNo ratings yet

- Innovair PEK 60Hz R410a Commercial Package Brochure EnglishDocument12 pagesInnovair PEK 60Hz R410a Commercial Package Brochure Englishcris melos100% (1)

- Pressure Balanced Elbow Expansion JointDocument2 pagesPressure Balanced Elbow Expansion JointlishiqianNo ratings yet

- Drive Belt Troubleshooting GuideDocument12 pagesDrive Belt Troubleshooting GuideQuang Nguyen HuynhNo ratings yet

- Mat - No. 1.1181, DIN Ck35, AISI 1035: Designation by StandardsDocument2 pagesMat - No. 1.1181, DIN Ck35, AISI 1035: Designation by StandardsBill MurrayNo ratings yet

- ISJ HEX COMMONALITY CHART AKH00001-UP (MACHINE) (SEBP5600 - 00) - DocumentaciónDocument8 pagesISJ HEX COMMONALITY CHART AKH00001-UP (MACHINE) (SEBP5600 - 00) - DocumentaciónLeo Perez100% (1)

- Diaphragm Pump FinalDocument2 pagesDiaphragm Pump FinalBHUSHAN CRNo ratings yet

- CoroPlusToolGuide Report 2023-01-12Document5 pagesCoroPlusToolGuide Report 2023-01-12FEL EmpiresNo ratings yet

- Technical Data: TimberjackDocument4 pagesTechnical Data: TimberjackOgnjen KovacevicNo ratings yet

- CH 08Document47 pagesCH 08Symphony DreamsNo ratings yet

- Machine Tools Design: InstructorsDocument31 pagesMachine Tools Design: InstructorsAladdin AdelNo ratings yet

- Load Calculation in A BuildingDocument7 pagesLoad Calculation in A BuildingBaharulHussainNo ratings yet

- Servall Engineering Works PVT LTDDocument7 pagesServall Engineering Works PVT LTDRaghulNo ratings yet

- ESP X-mastree Well Head DiagramDocument2 pagesESP X-mastree Well Head DiagramHafidz AmrillahNo ratings yet

- Control Valve SpoolDocument3 pagesControl Valve SpoolManuel felipe PalmaNo ratings yet

- LTAFDocument16 pagesLTAFİ. Çağlar YILDIRIMNo ratings yet