Professional Documents

Culture Documents

Experimental Study and Performance Analysis of Solar Air Heaters With Different Parameters

Uploaded by

IRJMETS JOURNALOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Experimental Study and Performance Analysis of Solar Air Heaters With Different Parameters

Uploaded by

IRJMETS JOURNALCopyright:

Available Formats

e-ISSN: 2582-5208

International Research Journal of Modernization in Engineering Technology and Science

( Peer-Reviewed, Open Access, Fully Refereed International Journal )

Volume:03/Issue:09/September-2021 Impact Factor- 6.752 www.irjmets.com

EXPERIMENTAL STUDY AND PERFORMANCE ANALYSIS OF SOLAR AIR

HEATERS WITH DIFFERENT PARAMETERS

Sunil Kumar Patel*1, Dr. M.K. Chopra*2

*1,2Department Of Mechanical Engineering, RKDF Engineering College, SRK

University, Bhopal (M.P.) India.

ABSTRACT

Energy is the foundation of sustainability and quality of life. In different structures, we need energy to meet our

needs. The rate of energy consumption is a pattern or gradual lifestyle. Extensive energy sources can be

organized into two categories: regular and irregular. Conventional energy sources include petroleum products

(coal, crude oil and flammable gas), which are highly accurate and limited in use and practical. Previous studies

have found that irregular roughness of various shapes without airflow changes their laminar behavior to a

turbulent shape. The turbulent effect of the flow inside the solar air heater duct disturbs the boundary layer

formed near the hot surface.

Keywords: Experimental Study; Solar Energy; Performance Analysis.

I. INTRODUCTION

There is no electricity grid in most parts of the country, so one of the first uses of solar energy was to pump

water to replace India's 1 million diesel water pumps, each 3.5 watt-kilowatt-hours. The sun is the best source

of energy. With solar energy coming from Earth, a small portion of the light is enough to survive. This light is

converted into different types of energy which is useful for many types of experiments. In addition to nuclear

energy from various energy sources, it is also generated from the sun. Because of the benefits of the sun, many

researchers around the world are looking for financial resources to control their energy.

India is blessed with abundant sunshine, rain and biomass. The last two decades of hard work has paid off as

people in all walks of life realize the benefits of renewable energy, particularly with the need for alternatives to

electricity if needed in cities or suburbs. The government created the Extraordinary Energy Resources Service

(DNES) in 1982. Ships and grenades were built using wind energy before 7000 BC. The use of electric motors

from water treatment plants or irrigation systems has speeded things up. With the advent of the revolution, as

oil began to rise, the amount of energy used increased. This happened in stages from the discovery of coal

mines to the discovery of real oil and gas. Only half a century ago, nuclear power was first introduced as an

energy source. Over the past century, it has become increasingly clear that uncontrolled use of energy is

causing more harm to the environment.

Table 1: Current renewable energy scenarios in India

Sl. No. Sources Approximate Potential Potential Harnessed

(MW) (MW)*

1 Wind Power 45219 17967.15

2 Small Hydro(upto 25 MW) 15000 3434.07

3 Biomass Power (Agro residues) 16881 1209.60

4 Cogeneration bagasse 5000 2109.73

5 Waste to Energy 2700 93.68

6 Solar Power 6X108 1044.16

Total 84776 25858.39

www.irjmets.com @International Research Journal of Modernization in Engineering, Technology and Science

[288]

e-ISSN: 2582-5208

International Research Journal of Modernization in Engineering Technology and Science

( Peer-Reviewed, Open Access, Fully Refereed International Journal )

Volume:03/Issue:09/September-2021 Impact Factor- 6.752 www.irjmets.com

Measuring Units Of Energy

A unit of energy measurement is called a BTU or British thermal unit. BTU refers to the amount of heat energy

required to increase the temperature of one pound of sea water by one degree Fahrenheit.

Energy can be measured in joules. The amount of energy required to weight 1 pound is about an inch. It

requires 1,000 joules equivalent to one British thermal unit. Joule is named after the British scientist James

Prescott Joule, who was 90 years old. Until he discovered that heat is a form of energy.

Scientists orbit the earth to measure energy in joules rather than BTUs. It seems that people around the world

use metric systems, meters and kilograms, as well as metric systems. You get kilojoules: kilojoules mean 1000,

so 1000 joules = 1 kilogram = BTU.

Basic Applications Of Solar Energy

There are many domestic and industrial forms of solar thermal systems. Some of the main uses of solar energy

are crop drying, irrigation, chemical rehabilitation, heating and cooling, water/air heating and much more. The

biggest problem with solar energy is its construction. Different types of solar collectors are used to collect the

sun's rays, which can be used to provide a drinking experience for drinkers and which are used in many

domestic and industrial applications. It is the number one component of any solar system.

Solar Collectors

Renewable energy has seen unprecedented improvements due to reduced demand for oil terminals that

provide valuable energy sources. Solar energy is an important source of energy due to its size. The easiest and

most efficient way to use solar energy is to convert it into solar energy. A nuclear solar system must convert

solar energy into solar energy on average. Solar collectors use the energy they generate to convert energy from

solar radiation into hot air and transfer the energy emitted from the collector.

II. LITERATURE REVIEW

The wings were shown just to give a sense of proportion. Many thin shapes increase the surface area, including

the exposed conjunctival area, increasing heat transfer from the hot surface to the moving fluid. The closed

surface increases the heat transfer rate with the negative effect of limiting fluid flow. Wavy V by Sebai et al.

Several studies have been carried out to design efficient corrugated surfaces to increase heat transfer with

minimal damage.

Roughness components can be separated into two-dimensional or three-dimensional ribs, transverse or

oblique ribs, broken ribs with or without holes, or without shape. Rough components can be bent wire, cut,

perforated or composite rib. Ribs are generally square, but unique shapes such as circular, semi-circular and

beveled are also taken into account when examining the application of heat pressure.

The effect of roughness on the contact factor and velocity assignment was first studied by Ncordse, who led the

sequence of analyzes in solid sand grains. Early tests, starting with the Neckards test, tried to produce speed

and heat dissipation at some level. The use of artificial heaters using small diameter wire attached to the

suction plate was first developed by Prasad and Malik to improve the efficiency of solar heat conduction. Prasad

and Sini were studied experimentally under a magnetic field in the form of small thermal conduction edges of

total fluid flow in the path of a solar heater. Verma and Prasad verified the inclusion of steel cables on three

sides of the rectangular tunnel at room temperature and fluid flow. Gupta also studied the effects of flexible

wire wool under the suction plate at different stages of operation.

Gupta and his colleagues examined the roughness of the oblique transverse rib. Ahrwal etc. Adjust the

continuous slope of the bevel rib, providing the maximum roughness difference and increasing the heat transfer

coefficient of the solar air heater. They study several approximate coefficients for correction. Later, Kumar etc.

He also studied the summary of diagonal sides with different operating parameters.

Formulations

The layer acts as a conductive coating for heat transfer. As a result, the rough effects irritate the boundary layer

and increase the rate of heat transfer. The roughness also increases the pressure drop inside the channel, to

reduce its effect, it is necessary to create a turbulent flow near the surface. The effect of tilt has not yet been

studied explicitly and in combination with the phase factor. Therefore, the main purpose of the present work is

www.irjmets.com @International Research Journal of Modernization in Engineering, Technology and Science

[289]

e-ISSN: 2582-5208

International Research Journal of Modernization in Engineering Technology and Science

( Peer-Reviewed, Open Access, Fully Refereed International Journal )

Volume:03/Issue:09/September-2021 Impact Factor- 6.752 www.irjmets.com

to increase the rate of heat transfer capacity of the solar air heater using a specific slope with the roughness of

the ribs stuck in the absorbent plate. The current study was conducted with different engineering criteria used

in the roughness and affecting the generation number and thermal performance. Copper wires of different

diameters (such as coarse heights) and different shapes are commonly used to drive heat transfer.

III. METHODOLOGY

Before starting the experiments, make sure the tools are connected and positioned correctly. Keep connections

free of air leaks, check all connections and start blower. Check the U-tube gauge level as zero and adjust the

airflow through the control valve to set the preset airflow rate. The experiment was carried out to collect data

on heat transfer coefficient and friction flux under steady state conditions. It takes about 40-45 minutes for the

system to reach steady state. The temperature relative to the plate in the different airflow range was taken only

to obtain the steady state condition assumed to be reached when the plate temperature and the exhaust air

temperature did not deviate by 15 min. of time.

Procedure followed to conduct experiment

1. Make all gaskets leak-proof to eliminate errors and connect the instruments correctly with the experimental

mounted for correct operation, after checking all connections the blower is then turned on.

2. Before adjusting the control valve, make sure the micrometer and the U-tube manometer are level. The

preset mass flow rate is then adjusted for the test section.

3. The experiment is conducted to collect data concerning heat transfer coefficient and friction flux under

steady state condition. With each change in airflow rate, the system must reach a steady state and it takes a

minimum of 1 hour before data is recorded.

4. The temperature relative to the plate in different airflow ranges was reached after reaching the steady state

condition. Inlet, outlet air temperature and board temperature are recorded using thermocouple wires via the

data logger.

5. The pressure drop in the duct and the pressure drop in the orifice plate are obtained using a

micromanometer and a U-tube manometer.

6. For each roughness, six different airflow rates in relation to the Reynolds number were conducted.

Experimental setup

To control the improvement of the solar air heater using the artificial roughness of the inclined split rib with

slits, data on the heat transfer coefficient, friction factor and thermal efficiency are obtained using an

experimental setup. The characteristic slope with graded rib roughness is fabricated with various geometric

parameters such as the degree of relative roughness (P/e), the number of cracks at half the slope (Ng) and the

relative crack size (g/e). To explore the combined effect of the Nusselt number and the friction factor, the

thermo-hydraulic performance variables of the current roughness, which is the discrete slope with gap rib

roughness, were also studied.

A pilot duct with a width of 200 mm and a height of 30 mm is obtained. The flow section includes an inlet

section for fluid flow at atmospheric temperature, a test section for a separate study of the slope with uneven

roughness and an outlet section for calculating the outlet temperature. The channel is made of wooden boards

with internal dimensions of 2000 mm x 200 mm x 30 mm. The inlet section provides a fully developed flow to

the test section and measures the temperature of the inlet air. In the exit area, the mixing section is provided to

properly mix the air leaving the test area to obtain a uniform exit temperature, i.e., the average block

temperature.

www.irjmets.com @International Research Journal of Modernization in Engineering, Technology and Science

[290]

e-ISSN: 2582-5208

International Research Journal of Modernization in Engineering Technology and Science

( Peer-Reviewed, Open Access, Fully Refereed International Journal )

Volume:03/Issue:09/September-2021 Impact Factor- 6.752 www.irjmets.com

Figure 1: Experimental setup

The pressure drop created in the test section during the experiment was measured with a micronometer. The

absorbent plate is made of GI plate (galvanized iron plate) with dimensions of 1500 mm x 200 mm x 1.5 mm

and is provided using coarse copper wire with a height of 1.5 mm. The top of the absorbent plate is coated with

black paint to increase its ability to absorb heat. Both sides of the absorbent plate, namely the air inlet section

and the duct outlet section are covered with 8 mm thick plywood and the entire outer surface of the

configuration is covered with 25 mm thick polystyrene foam with thermal conductivity 0.037 W / mK

insulation.

Table 2: System and roughness parameters

Sl.No. Roughness parameters Range

1. Roughness height (e) 1.5 mm

2. Angle of attack (α) 30o, 45o and 60o

3. Width of duct (W) 200 mm

4. Height of duct (H) 25 mm

5. Aspect ratio (W/H) 8

6. Relative roughness pitch (P/e) 6, 8, 10 and 12

7. Number of gaps on half of inclination (Ng) 1, 2 and 3

www.irjmets.com @International Research Journal of Modernization in Engineering, Technology and Science

[291]

e-ISSN: 2582-5208

International Research Journal of Modernization in Engineering Technology and Science

( Peer-Reviewed, Open Access, Fully Refereed International Journal )

Volume:03/Issue:09/September-2021 Impact Factor- 6.752 www.irjmets.com

8. Relative gap size (g/e) 1, 2 and 3

9. Reynolds number (Re) 4000-12000

The plate is fabricated by using copper wires of small diameter (1mm and 1.5mm) and it is sticking over the

surface of GI sheet to get the required geometry with predefined parameters.

IV. RESULTS AND DISCUSSION

Table 3: Experimental and theoretical Nusselt number of smooth surface

Sl.No. Reynolds number Experimental (Nus) Theoretical (Nus) Error in (Nus) in %

1 4000 18.56 15.35 0.13

2 6000 23.56 21.23 0.10

3 8000 28.26 27.15 0.04

4 10000 32.56 32.62 -0.02

5 12000 36.42 37.85 -0.04

0.016 Theorectical f smooth

0.014 Experimental f smooth

0.012

0.01

Friction factor

0.008

0.006

0.004

0.002

0

0 2000 4000 6000 8000 10000 12000 14000

Reynolds Number

Figure 2: Plot between theoretical and experimental Nusselt number of smooth plate

Table 4: Experimental and theoretical friction factor of smooth surface

Reynolds number Experimental (fs) Theoretical (fs) Error in (fs) in %

4000 0.014 0.01065 0.24

6000 0.012 0.009557 0.20

8000 0.01 0.008917 0.11

10000 0.0092 0.008426 0.08

12000 0.0089 0.008046 0.10

www.irjmets.com @International Research Journal of Modernization in Engineering, Technology and Science

[292]

e-ISSN: 2582-5208

International Research Journal of Modernization in Engineering Technology and Science

( Peer-Reviewed, Open Access, Fully Refereed International Journal )

Volume:03/Issue:09/September-2021 Impact Factor- 6.752 www.irjmets.com

40

35

Nusselt Number

30

25

20

15

Theoretical Nu smooth

10

2000 4000 6000 8000 10000 12000 14000

Reynolds Number

Figure 3: Plot between theoretical and experimental Friction factor of smooth plate

V. CONCLUSION

The results obtained from the correlation and the results of the experimental data for the Nusselt number and

the friction factor were compared as shown in the Table. 3, 4 respectively. The experimental and theoretical

results of the Nusselt number and the friction factor are shown in Figures 2 and 3, respectively. From the graph,

the deviation in the theoretical and experimental Nusselt number of the flat plate shows that the results are in

the considerable range and therefore the available test facility is authenticated. From the graph, the deviation in

the theoretical and experimental friction factor of the flat plate shows that the results are in the considerable

range and therefore the available testing facility is authenticated.

VI. REFERENCES

[1] Dipprey DF, Sabersky RH. Heat and momentum transfer in smooth and rough tubes at various prandtl

numbers. International Journal of Heat and Mass Transfer, 1963, 6(5):329-332.

[2] Prasad K, Mullick SC. Heat transfer characteristics of a solar air heater used for drying purposes.

Applied Energy. 1983 Feb 1;13(2):83-93.

[3] Prasad BN, Saini JS. Effect of artificial roughness on heat transfer and friction factor in a solar air heater.

Solar energy. 1988 Dec 31;41(6):555-60.

[4] Verma SK, Prasad BN. Investigation for the optimal thermo-hydraulic performance of artificially

roughened solar air heaters. Renewable Energy. 2000 May 31;20(1):19-36.

[5] Gupta D, Solanki SC, Saini JS. Heat and fluid flow in rectangular solar air heater ducts having transverse

rib roughness on absorber plates. Solar Energy. 1993 Jul 1;51(1):31-7.

[6] Sahu MM, Bhagoria JL. Augmentation of heat transfer coefficient by using 90 broken transverse ribs on

absorber plate of solar air heater. Renewable Energy. 2005 Oct 31;30(13):2057-73.

[7] Gupta D, Solanki SC, Saini JS. Thermohydraulic performance of solar air heaters with roughened

absorber plates. Solar Energy. 1997 Jul 31;61(1):33-42.

[8] Aharwal KR, Gandhi BK, Saini JS. Experimental investigation on heat transfer enhancement due to a gap

in an inclined continuous rib arrangement in a rectangular duct of solar air heater. Renewable energy.

2008 Apr 30;33(4):585-96.

[9] Aharwal KR, Gandhi BK, Saini JS. Heat transfer and friction characteristics of solar air heater ducts

having integral inclined discrete ribs on absorber plate. Int J Heat Mass Transf 2009;52:5970–7.

[10] Kumar TS, Mittal V, Thakur NS, Kumar A. Second law analysis of a solar air heater having 60 inclined

discrete rib roughness on absorber plate. African Journal of Environmental Science and Technology.

2010;4(13):913-29.

www.irjmets.com @International Research Journal of Modernization in Engineering, Technology and Science

[293]

You might also like

- Chapter 1: ProposalDocument15 pagesChapter 1: ProposalNabil MuhaiminNo ratings yet

- Review On Development of Mechanical Tracking System For Solar Water HeaterDocument8 pagesReview On Development of Mechanical Tracking System For Solar Water HeaterIJRASETPublicationsNo ratings yet

- JETIR2303159Document5 pagesJETIR2303159Sidhu SidhuNo ratings yet

- Power Generation Efficiency and Prospects of Floating Photovoltaic SystemsDocument7 pagesPower Generation Efficiency and Prospects of Floating Photovoltaic SystemsリズキーNo ratings yet

- 3D - A Power PDFDocument12 pages3D - A Power PDFElmin OmicNo ratings yet

- Solar System - A Case StudyDocument28 pagesSolar System - A Case Studykmahesh526No ratings yet

- Krishnaprasad ReportDocument20 pagesKrishnaprasad ReportVA CreationsNo ratings yet

- MJ Thesis Fina Na Final!!!Document15 pagesMJ Thesis Fina Na Final!!!Michael John SantiagoNo ratings yet

- A Review On Performance of Solar Powered Air Conditioning SystemDocument8 pagesA Review On Performance of Solar Powered Air Conditioning SystemIJRASETPublicationsNo ratings yet

- Ijert Ijert: Maximum Power Point Tracking (MPPT) of Solar Cell Using Buck-Boost ConverterDocument13 pagesIjert Ijert: Maximum Power Point Tracking (MPPT) of Solar Cell Using Buck-Boost ConverterAHMAD SOHAIBNo ratings yet

- Performance Study of Latest Technology in Parabolic Trough Collector For Maximum Energy Utilization From The Solar Energy IJERTV4IS010780Document3 pagesPerformance Study of Latest Technology in Parabolic Trough Collector For Maximum Energy Utilization From The Solar Energy IJERTV4IS010780India In NewsNo ratings yet

- IRJET-A Review On Power Electronics in Renewable Energy SystemsDocument7 pagesIRJET-A Review On Power Electronics in Renewable Energy Systemsبشرى جودةNo ratings yet

- Design Parameters of 10Kw Floating Solar Power Plant: November 2015Document6 pagesDesign Parameters of 10Kw Floating Solar Power Plant: November 2015Narasimha DvlNo ratings yet

- Designing and Fabrication of Double Pass Solar Air Heater Integrated With Thermal StorageDocument7 pagesDesigning and Fabrication of Double Pass Solar Air Heater Integrated With Thermal StorageM. RazaNo ratings yet

- 2015 - O Joneydi Shariatzadeh - Modelingandoptimizationofanovelsolarchimneycogener (Retrieved 2019-10-30)Document10 pages2015 - O Joneydi Shariatzadeh - Modelingandoptimizationofanovelsolarchimneycogener (Retrieved 2019-10-30)Min YikaiNo ratings yet

- FHT SsDocument6 pagesFHT SsharishNo ratings yet

- Solar and wind powered multigeneration system analyzedDocument17 pagesSolar and wind powered multigeneration system analyzedMeral SüzerNo ratings yet

- Assignment 1 - Wind EnergyDocument17 pagesAssignment 1 - Wind EnergySyenHong Nik100% (1)

- Wind EnergyDocument10 pagesWind EnergyYahia AltalhiNo ratings yet

- Rotating GateDocument34 pagesRotating GateAlex MartynNo ratings yet

- Design and Development of Heat ExchangerDocument6 pagesDesign and Development of Heat ExchangerInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Analysis of Electricity Generation With Combined Power Systems For Residential BuildingsDocument21 pagesAnalysis of Electricity Generation With Combined Power Systems For Residential Buildingsboforo3821No ratings yet

- Ijett V38P207Document6 pagesIjett V38P207Ahmed Mohamed AhmedNo ratings yet

- Analysis of A Vacuum-Based Photovoltaic Thermal Collector: SciencedirectDocument7 pagesAnalysis of A Vacuum-Based Photovoltaic Thermal Collector: Sciencedirecthansel huacasiNo ratings yet

- Irjet V7i5215Document3 pagesIrjet V7i5215muhyideen6abdulganiyNo ratings yet

- Energy, Exergyand Energy Audit Analysis of Vijayawada Thermal Power StationDocument8 pagesEnergy, Exergyand Energy Audit Analysis of Vijayawada Thermal Power Stationjhugo_mirandaNo ratings yet

- DESIGN OF WATER HEATING SYSTEM IN SWIMMING POOL Ijariie16549Document4 pagesDESIGN OF WATER HEATING SYSTEM IN SWIMMING POOL Ijariie16549Dynamic HVAC ConsultantsNo ratings yet

- Analisis Pembangkit Listrik Hybrid Tenaga Nuklir Dan MatahariDocument3 pagesAnalisis Pembangkit Listrik Hybrid Tenaga Nuklir Dan Mataharifauzi handyNo ratings yet

- Transient Analysis of Solar Flat Plate Collector Applied in Computational Fluid DynamicsDocument9 pagesTransient Analysis of Solar Flat Plate Collector Applied in Computational Fluid DynamicsAntonio FIFANo ratings yet

- Designing Large Solar Power PlantsDocument52 pagesDesigning Large Solar Power PlantsmujeebNo ratings yet

- Ventilator Fan in The Kitchen To Produce Power For Home AppliancesDocument20 pagesVentilator Fan in The Kitchen To Produce Power For Home Appliancesdurga prasadNo ratings yet

- Solar Gas Turbine Systems: April 2017Document14 pagesSolar Gas Turbine Systems: April 2017julienjoyet6524No ratings yet

- Power Generation From Wind TourbineDocument11 pagesPower Generation From Wind TourbineKireNo ratings yet

- Floating Solar Power PlantDocument5 pagesFloating Solar Power Plantpothugunta charanNo ratings yet

- balijepalli2017.pdf سولر جديدDocument12 pagesbalijepalli2017.pdf سولر جديدAmmar Al-KindyNo ratings yet

- Ijert Ijert: Modelling of Non-Conventional Energy Sources-Solar and Wind Hybrid ModelDocument9 pagesIjert Ijert: Modelling of Non-Conventional Energy Sources-Solar and Wind Hybrid Modelsrinureddy2014No ratings yet

- JETIR2303159Document5 pagesJETIR2303159Sidhu SidhuNo ratings yet

- HeatpipeDocument21 pagesHeatpipeNuleivNo ratings yet

- Design Parameters of 10Kw Floating Solar Power Plant: November 2015Document6 pagesDesign Parameters of 10Kw Floating Solar Power Plant: November 2015JobNo ratings yet

- Development of Water Pipelines Energy Harvesting System: Journal of Physics Conference Series February 2021Document13 pagesDevelopment of Water Pipelines Energy Harvesting System: Journal of Physics Conference Series February 2021raja maneNo ratings yet

- Physics Investigatory ProjectDocument12 pagesPhysics Investigatory ProjectHarsh Mande100% (2)

- Analysis of Solar-Assisted Cooling ChamberDocument7 pagesAnalysis of Solar-Assisted Cooling Chambermouloud tizzaouiNo ratings yet

- Physics Investigatory Project CompletedDocument12 pagesPhysics Investigatory Project CompletedHarsh MandeNo ratings yet

- Factors affecting power production from wind turbines and solar cellsDocument6 pagesFactors affecting power production from wind turbines and solar cellsreemNo ratings yet

- Generate Electricity From Park Revolving DoorDocument39 pagesGenerate Electricity From Park Revolving Doortariq7660% (5)

- ThermoelectricgenerationDocument8 pagesThermoelectricgenerationsatyaprakash kumawatNo ratings yet

- My Published Paper 3Document6 pagesMy Published Paper 3Badadmasi MaiwdaNo ratings yet

- IJETT-V28P223Document8 pagesIJETT-V28P223Build ItNo ratings yet

- Analysis of Energy, Exergy, Environmental, and Economics (4E) On Photovoltaic-Thermal Collector SystemDocument15 pagesAnalysis of Energy, Exergy, Environmental, and Economics (4E) On Photovoltaic-Thermal Collector SystemafshooabadaniNo ratings yet

- Investigation of Thermal Performance and Energy Savings in Solar Water HeatersDocument11 pagesInvestigation of Thermal Performance and Energy Savings in Solar Water HeatersInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Mini steam power plant modelDocument12 pagesMini steam power plant modelaniket bobadeNo ratings yet

- Improving Efficiency of Flat Plate Solar Collectors Using CuO-Water NanofluidDocument12 pagesImproving Efficiency of Flat Plate Solar Collectors Using CuO-Water Nanofluidsebastian perez murilloNo ratings yet

- Agra SanjeyDocument11 pagesAgra SanjeyafshooabadaniNo ratings yet

- Desarrollo de Un Sistema Integrado de Energia Termosolar Hibrida Con Generador Termoelectrico para Desalinización y Producción de EnergíaDocument14 pagesDesarrollo de Un Sistema Integrado de Energia Termosolar Hibrida Con Generador Termoelectrico para Desalinización y Producción de EnergíaDairo Ruiz-LogreiraNo ratings yet

- Solar Stirling EngineDocument23 pagesSolar Stirling EngineDnalzir MontanteNo ratings yet

- Study Of Replicating Kapagene Generator For Higher EfficiencyDocument8 pagesStudy Of Replicating Kapagene Generator For Higher EfficiencySenki AlphonsNo ratings yet

- Wind Turbine DesignDocument7 pagesWind Turbine DesignJia Le ChowNo ratings yet

- Effect of Roughness Parameters in Solar Air Heater Duct A ReviewDocument12 pagesEffect of Roughness Parameters in Solar Air Heater Duct A ReviewInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- A Review On Wind Energy Conversion System and Enabling TechnologyDocument7 pagesA Review On Wind Energy Conversion System and Enabling Technologybastian MNo ratings yet

- Automatic Irrigation System Design and Implementation Based On Iot For Agricultural DevelopmentDocument21 pagesAutomatic Irrigation System Design and Implementation Based On Iot For Agricultural DevelopmentIRJMETS JOURNALNo ratings yet

- Effect of Wind Loads On High Rise Building in Different Seismic ZonesDocument6 pagesEffect of Wind Loads On High Rise Building in Different Seismic ZonesIRJMETS JOURNALNo ratings yet

- Stochastic Epidemic ModellingDocument15 pagesStochastic Epidemic ModellingIRJMETS JOURNALNo ratings yet

- Training Needs Analysis Among Grassroots Entrepreneurs: Basis For The Implementation of A University of Makati-Based Training Program On Financial Literacy and Entrepreneurial SkillsDocument18 pagesTraining Needs Analysis Among Grassroots Entrepreneurs: Basis For The Implementation of A University of Makati-Based Training Program On Financial Literacy and Entrepreneurial SkillsIRJMETS JOURNALNo ratings yet

- Nanoprobiotics - An Innovative Trend in Probiotic WorldDocument10 pagesNanoprobiotics - An Innovative Trend in Probiotic WorldIRJMETS JOURNALNo ratings yet

- Wireless Energy TransmissionDocument8 pagesWireless Energy TransmissionIRJMETS JOURNALNo ratings yet

- Astrobiology: Exploring Life Beyond EarthDocument6 pagesAstrobiology: Exploring Life Beyond EarthIRJMETS JOURNALNo ratings yet

- A Review of Nano Additives For Performance Enhancement of LubricantDocument5 pagesA Review of Nano Additives For Performance Enhancement of LubricantIRJMETS JOURNALNo ratings yet

- Production and Performance Study of Biogas From Areca WasteDocument4 pagesProduction and Performance Study of Biogas From Areca WasteIRJMETS JOURNALNo ratings yet

- Design and Analysis of Three Rotor Rotary EngineDocument10 pagesDesign and Analysis of Three Rotor Rotary EngineIRJMETS JOURNALNo ratings yet

- Biomedical Applications of The Graphene-Based NanomaterialsDocument11 pagesBiomedical Applications of The Graphene-Based NanomaterialsIRJMETS JOURNALNo ratings yet

- Comparative Analysis of Local Binary & Non Binary Descriptors For Gender ClassificationDocument5 pagesComparative Analysis of Local Binary & Non Binary Descriptors For Gender ClassificationIRJMETS JOURNALNo ratings yet

- Best Modulation Technique and Most Efficient Carrier Number For Getting Maximum SNR and Minimum Ber For Ofdm Generated Signal Over Rayleigh DistributionDocument8 pagesBest Modulation Technique and Most Efficient Carrier Number For Getting Maximum SNR and Minimum Ber For Ofdm Generated Signal Over Rayleigh DistributionIRJMETS JOURNALNo ratings yet

- Comparative Analysis Using Machine Learning Algorithms For Predicting Heart DiseaseDocument5 pagesComparative Analysis Using Machine Learning Algorithms For Predicting Heart DiseaseIRJMETS JOURNALNo ratings yet

- Biofuel Manufacturing and Characterization From Waste Cooking Oil Using Batch Transesterification ProcessDocument16 pagesBiofuel Manufacturing and Characterization From Waste Cooking Oil Using Batch Transesterification ProcessIRJMETS JOURNALNo ratings yet

- Geopolymer Pavement Block Using M-SandDocument7 pagesGeopolymer Pavement Block Using M-SandIRJMETS JOURNALNo ratings yet

- Design Analysis of Rigid Flange Coupling by Usingcae and CadDocument11 pagesDesign Analysis of Rigid Flange Coupling by Usingcae and CadIRJMETS JOURNALNo ratings yet

- Comparative Study Between Regular Concrete and Light Weight Concrete To Be Used in Concreting of Shear WallDocument7 pagesComparative Study Between Regular Concrete and Light Weight Concrete To Be Used in Concreting of Shear WallIRJMETS JOURNALNo ratings yet

- Recommendation of Agricultural Farms From Satellite Mental Imagery Victimization Deep LearningDocument3 pagesRecommendation of Agricultural Farms From Satellite Mental Imagery Victimization Deep LearningIRJMETS JOURNALNo ratings yet

- Analytical Calculation of Automatic Sprinkler Fire Extinguishing System (Sfes)Document20 pagesAnalytical Calculation of Automatic Sprinkler Fire Extinguishing System (Sfes)IRJMETS JOURNALNo ratings yet

- Probabilistic Analysis of Indian Covid-19 Data With Interactive Real Time Augmented RealityDocument5 pagesProbabilistic Analysis of Indian Covid-19 Data With Interactive Real Time Augmented RealityIRJMETS JOURNALNo ratings yet

- Comparative Analysis of Machine Learning Models For Predicting Bitcoin Price RateDocument5 pagesComparative Analysis of Machine Learning Models For Predicting Bitcoin Price RateIRJMETS JOURNALNo ratings yet

- Usage of Flyash and Jute Fiber Collectively For Stabilization of Soil - A ReviewDocument5 pagesUsage of Flyash and Jute Fiber Collectively For Stabilization of Soil - A ReviewIRJMETS JOURNALNo ratings yet

- Design Stratigies of Low Power Voltage Level Shifter Circuits For Multi Supply SystemsDocument6 pagesDesign Stratigies of Low Power Voltage Level Shifter Circuits For Multi Supply SystemsIRJMETS JOURNALNo ratings yet

- Distributed Denial of Service (Ddos) Attacks Detection MechanismDocument7 pagesDistributed Denial of Service (Ddos) Attacks Detection MechanismIRJMETS JOURNALNo ratings yet

- Mechanical Recycling of CFRP Along With Case Study of Bicycle FrameDocument8 pagesMechanical Recycling of CFRP Along With Case Study of Bicycle FrameIRJMETS JOURNALNo ratings yet

- Role of (E-Hr) Electronic Human Resource in Telecom SectorDocument5 pagesRole of (E-Hr) Electronic Human Resource in Telecom SectorIRJMETS JOURNALNo ratings yet

- Design Stratigies of Low Power Voltage Level Shifter Circuits For Multi Supply SystemsDocument6 pagesDesign Stratigies of Low Power Voltage Level Shifter Circuits For Multi Supply SystemsIRJMETS JOURNALNo ratings yet

- Social Distancing Detection Using TensorflowDocument4 pagesSocial Distancing Detection Using TensorflowIRJMETS JOURNALNo ratings yet

- NS 6145 Modern Phys and X-RaysDocument55 pagesNS 6145 Modern Phys and X-RaysMeesixNo ratings yet

- 80-98ME ME-C Engines MaintenaceDocument9 pages80-98ME ME-C Engines MaintenaceLeonid KolesnikovNo ratings yet

- Q400.amm (76) .Amm05 11 00 992 802Document11 pagesQ400.amm (76) .Amm05 11 00 992 802Naresh Kumar5No ratings yet

- Bme001 - Advanced Internal Combustion EnginesDocument2 pagesBme001 - Advanced Internal Combustion Engineskannurunani2004No ratings yet

- JIS B 8265-2010 Errata 2013Document11 pagesJIS B 8265-2010 Errata 2013nanotech123No ratings yet

- NL1150D 24Document1 pageNL1150D 24carolinammiyashiroNo ratings yet

- Nipcxf 000013Document654 pagesNipcxf 000013Arron ChanNo ratings yet

- IEC60896 (FTHT Battery) Test ReportDocument13 pagesIEC60896 (FTHT Battery) Test ReportVictor PerezNo ratings yet

- TES-K-100.01-R0 HVAC DesignDocument89 pagesTES-K-100.01-R0 HVAC DesignSalmanEjazNo ratings yet

- Calibración Motor s4D106Document2 pagesCalibración Motor s4D106mrcruzito_2099No ratings yet

- Settima GR 90 SMT16B L: DimensionsDocument1 pageSettima GR 90 SMT16B L: Dimensionsmahan moradiNo ratings yet

- 2PX4 Table Staad Report DocumentsDocument23 pages2PX4 Table Staad Report DocumentsEr Prabhanjan ChigareNo ratings yet

- Growatt MIN 2500-6000TL-X CE LVDDocument2 pagesGrowatt MIN 2500-6000TL-X CE LVDpatchqvjkNo ratings yet

- MSN 778 LH Side Engine SN Ed0364Document4 pagesMSN 778 LH Side Engine SN Ed0364Budi PrayitnoNo ratings yet

- Arc Flash Hazard Reduction at Incoming Terminals of LV Equipment - Maurice D'Mello (IEEE)Document11 pagesArc Flash Hazard Reduction at Incoming Terminals of LV Equipment - Maurice D'Mello (IEEE)Ezequiel Juarez BenítezNo ratings yet

- Emergency Air Compressor Type Wp-22l - 110413Document59 pagesEmergency Air Compressor Type Wp-22l - 110413Aswin MohanNo ratings yet

- Issue 72 September 2018Document12 pagesIssue 72 September 2018Amila BalasooriyaNo ratings yet

- Unit 5 - Mineral Resources What Are Minerals?: Pakistan StudiesDocument13 pagesUnit 5 - Mineral Resources What Are Minerals?: Pakistan StudiesTaha YousafNo ratings yet

- Cat De88 GC: ® Diesel Generator SetsDocument2 pagesCat De88 GC: ® Diesel Generator SetsApo ghasan Al shargapiNo ratings yet

- Manual de Instrucciones - Autoclave Tuttnauer 3870EL-DDocument103 pagesManual de Instrucciones - Autoclave Tuttnauer 3870EL-DMARIA ALEJANDRA SIERRA GILNo ratings yet

- BP DieselDocument3 pagesBP Dieselariyamanjula2914No ratings yet

- Powin Stacks Product Line 2021Document2 pagesPowin Stacks Product Line 2021melihguneriNo ratings yet

- Waste Heate Reocvery, ASME ChE - 2013 - 01Document68 pagesWaste Heate Reocvery, ASME ChE - 2013 - 01Steve WanNo ratings yet

- Power Boost BulletinDocument3 pagesPower Boost BulletinBrianHazeNo ratings yet

- ZX 470Document13 pagesZX 470Mohammed Shaheeruddin100% (1)

- Parts List V-480 Engine (Job No-11436) - CWS PropsalDocument4 pagesParts List V-480 Engine (Job No-11436) - CWS PropsalSandeep NikhilNo ratings yet

- Daily News Simplified - DNS Notes 18 Dec 2020Document14 pagesDaily News Simplified - DNS Notes 18 Dec 2020NitinNo ratings yet

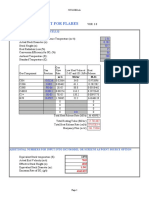

- Calculation Sheet For Flares: User Supplied Inputs (Grey Cells)Document1 pageCalculation Sheet For Flares: User Supplied Inputs (Grey Cells)Евгений ПищаевNo ratings yet

- Journal of Energy StorageDocument14 pagesJournal of Energy StorageLuis Antonio CNo ratings yet

- Hokkaido Airconditioner Service ManualDocument47 pagesHokkaido Airconditioner Service ManualrodrigoNo ratings yet