Professional Documents

Culture Documents

IEC60896 (FTHT Battery) Test Report

Uploaded by

Victor PerezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IEC60896 (FTHT Battery) Test Report

Uploaded by

Victor PerezCopyright:

Available Formats

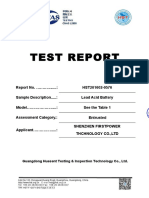

TEST REPORT

Report No. ………….....: HST201802-0576

Sample Description.....: Lead Acid Battery

Model…………………...: Motorcycle Battery See the Table 1

Assessment Category.: Entrusted

Applicant……………....: QINGDAO PUREGAIN TIRE CO., LTD.

Guangdong Huesent Testing & Inspection Technology Co., Ltd.

Add:No.163, Dongguanzhuang Road, Guangzhou, Guangdong, China

http://www.hst.org.cn E-mail:hst@hst.org.cn

Tel: +86-20-28263230 Fax: +86-20-28263237

TRF:HST-F-Q071 B/0 Page 1 of 13

Report No. : HST201802-0576

TEST REPORT

Sample Description Lead Acid Battery Trademark QUEIPA

Model See the Table 1 Specification Motorcycle Battery See the Table 1

Assessment Category Entrusted Sample Quantity 3 Piece

QINGDAO PUREGAIN TIRE The samples are sound,

Applicant Sample Status

CO., LTD. intact and fit for test.

Sample Received Date 2018.03.02 Test Date 2018.03.02-2018.03.16

Manufacturer QINGDAO PUREGAIN TIRE CO., LTD.

Address IND. PARK, ZHANGJIALOU TOWN, QINGDAO, SHANDONG, CHINA

Factory QINGDAO PUREGAIN TIRE CO., LTD.

Address IND. PARK, ZHANGJIALOU TOWN, QINGDAO, SHANDONG, CHINA

Test address No.163, Dongguanzhuang Road, Guangzhou, Guangdong, China

Test Items See the Table 2

IEC 60896-21:2004 Lead-acid batteries – Methods of test

Test standard

IEC 60896-22:2004 Lead-acid batteries – Requirements

The results conform to the requirements of standards with respect to the test

items.

Test Conclusion

(Stamp of Test Unit)

There are sixteen (See theTable 1) for application, shown in this report, with the

difference being the outer sizes and capacity. All of the tests were performed on

Remarks GEL-12N14-BS (12V14) Ah . The items of Protection a ainst internal ignition

from external spark sources and Protection against ground short propensity

are beyond the scope of our CNAS recognition.

Tested by :Ben Sign:

Reviewed by:Terry Sign:

Approved by:Louis Sign:

TRF:HST-F-Q071 B/0 Page 2 of 13

Report No. : HST201802-0576

Table 1: Models for application

No. Models Specification

1 GEL-12N6.5-BS 12V 6.5Ah

2 GEL-12N7A-BS 12V 7Ah

3 GEL-12N7B-BS 12V 7Ah

4 GEL-12N9-BS 12V 9Ah

5 GEL-YT7-BS 12V 7Ah

6 GEL-12N12-BS 12V 12Ah

7 GEL-YT9-BS 12V 9Ah

8 GEL-YT4L-BS 12V 4Ah

9 GEL-12N5-BS 12V 5Ah

10 GEL-12N14-BS 12V 14Ah

TRF:HST-F-Q071 B/0 Page 3 of 13

Report No. : HST201802-0576

Table 2:Test item

Test Clause Measures Purpose

6.1 Gas emission To determine the emitted gas volume

To verify the adequacy of current conduction

6.2 High current tolerance

cross-sections

Short circuit current and d.c. internal To provide data for the sizing of fuses in the

6.3

resistance exterior circuit

Protection against internal ignition from

6.4 To evaluate the adequacy of protective features

external spark sources

Protection against ground short To evaluate the adequacy of design features

6.5

propensity

Content and durability of required To evaluate the quality of the markings and the

6.6

markings content of the information

To ensure the presence of material identification

6.7 Material identification

markings

6.8 Valve operation To ensure the correct opening of safety valves

6.9 Flammability rating of materials To verify the fire hazard class of battery materials

To verify the maximum surface temperatures of

6.10 Intercell connector performance

the connectors during high rate discharges

To verify the available capacities at selected

6.11 Discharge capacity

discharge rates or discharge durations.

6.12 Charge retention during storage To provide storage duration data

To determine cyclic performance under float

6.13 Float service with daily discharge

charge conditions

To determine the recovery of capacity or autonomy

6.14 Recharge behaviour

time after a power outage

Service life at an operating temperature To determine the operational life at elevated

6.15

of 40 °C temperatures

Impact of a stress temperature of 55 °C To determine the influence of high stress

6.16

or 60 °C temperatures on cell or monobloc battery life

To determine the expected behaviour when

6.17 Abusive over-discharge

excessive capacity is discharged

To determine the expected times to establish a

6.18 Thermal runaway sensitivity

condition of escalating current and temperature

To determine the sensitivity toward damage

6.19 Low temperature sensitivity

induced by electrolyte freezing

To determine the propensity of the cell or

Dimensional stability at elevated internal

6.20 monobloc battery to be deformed by internal

pressure and temperature

pressure and at elevated temperature

Stability against mechanical abuse of Determine the propensity of the cell or monobloc

6.21

units during installation battery to fracture or leak when dropped.

TRF:HST-F-Q071 B/0 Page 4 of 13

Report No. : HST201802-0576

TEST RESULT

IEC 60896-21:2004, IEC 60896-22:2004

Items Requirement – Test Result - Remark Verdict

Gas emission:

At the rated float charge voltage

The test methods are according to clause 6.1.1 to Uflo=2.25V/(Ah*h*cell) at 25°C:

6.1.14 which are stated in the standard IEC 60896-21 1#: Ge=0,0019ml/hour/Ah

Requirement and application: Measure gas volumes 2#: Ge=0,0018ml/hour/Ah

State

(At the rated float charge voltage; At 2,40 Vpc 3#: Ge=0,0019ml/hour/Ah

6.1 the

overcharge voltage conditions). At 2,40 Vpc overcharge voltage

value

State data for all applications: ml gas per cell, h and conditions at 25°C:

Ah at 20° or 25 °C; ml gas per cell, h and Ah at 20° or 1#: Ge=0,0024ml/hour/Ah

25 °C. 2#: Ge=0,0022ml/hour/Ah

3#: Ge=0,0024ml/hour/Ah

High current tolerance:

The test methods are according to clause 6.2.1 to

6.2.6 which are stated in the standard IEC 60896-21 It has no any damage after 30 s

Requirement and application: Measure unit voltage, of high current flow.

inspect and document the status of the top-lead and Voltage after open circuit for

6.2 terminals of each unit after 30 s current flow. 5min: P

Pass for all applications: Voltage of unit >2,0 Vpc; 1#: U=12.61V

Show evidence of no incipient melting or of no loss of 2#: U=12.59V

electrical continuity after 30 s of high current flow 3#: U=12.59V

(value to be stated).

Short circuit current and d.c. internal resistance:

The test methods are according to clause 6.3.1 to 1#: Isc=4680.0A

6.3.6 which are stated in the standard IEC 60896-21 Ri =0.32mΩ

Requirement and application: Define prospective

State

short-circuit value Isc and internal resistance Ri of all 2#: Isc=4830.0A

6.3 the

units of a type range. Ri =0.31mΩ

value

State data for all applications: Short-circuit current

(Isc) in A; Internal resistance (Ri) in ohms. 3#: Isc=4680.0A

Ri =0.32mΩ

TRF:HST-F-Q071 B/0 Page 5 of 13

Report No. : HST201802-0576

IEC 60896-21:2004, IEC 60896-22:2004

Items Requirement – Test Result - Remark Verdict

Requirement for protection against internal

ignition from external spark sources No rapid combustion, No

The test methods are according to clause 6.4.1 to explosion

6.4 6.4.6 which are stated in the standard IEC 60896-21 P

Requirement and application: see table 7 in the Conformity

standard IEC 60896-22

Requirement for protection against internal

ignition from external spark sources

No ground short, No leakage

Requirement and application: see table 8 in the

6.5 P

standard IEC 60896-22

Conformity

The test methods are according to clause 6.5.1 to

6.5.9 which are stated in the standard IEC 60896-21

Content and durability of required markings:

The durability of the marking shall be tested according

to clause 1.7.13 of IEC 60950-1 and the content of

marking shall meet the requirement of IEC 60896-22

Information remain readable after

Requirement and application: Expose information to

test and content meet requirement

6.6 chemicals. P

Pass all substances for all applications: Information

shall remain readable after exposure to chemicals and

remain in place

Requested information to be present for all

See the ANNEX A

applications.

Material identification:

The test methods are according to clause 6.7.1 to

6.7.4 which are stated in the standard IEC 60896-21

Requirement and application: Inspect case and/or

cover for ISO 1043-1 materials symbol. Expose to

chemicals. All the symbol remain readable;

6.7 P

Pass for all applications: ISO symbol present on the ABS plastic

outside of the cover or/and case. Symbol shall remain

readable after exposure to chemicals and remain in

place. (NOTE If the material of the case differs from

the material of the cover, then a material identification

symbol should also be present on the case. Otherwise

one symbol on the cover is sufficient.)

TRF:HST-F-Q071 B/0 Page 6 of 13

Report No. : HST201802-0576

IEC 60896-21:2004, IEC 60896-22:2004

Items Requirement – Test Result - Remark Verdict

Valve operation:

The test methods are according to clause 6.8.1 to

6.8.3 which are stated in the standard IEC 60896-21 The valve adequate opening

Gas release detected before and

6.8 Requirement and application: Overcharge units and P

after stress temperature impact

detect gas flow from the valve.

test

Pass for all applications: Gas release detected before

and after stress temperature impact test

Flammability rating of materials:

The test methods are according to clause 6.9.1 to

6.9.4 which are stated in the standard IEC 60896-21 The flammability rating level for

State

samples of thickness equivalent

6.9 Requirement and application: Determine flammability the

to that of case and cover:

rating of case and cover material. level

HB 75, V-0

State data for all applications: State the flammability

rating level for samples of thickness equivalent to that

of case and cover

Intercell connector performance:

The test methods are according to clause 6.9.1 to

6.9.4 which are stated in the standard IEC 60896-21 State

The maximum temperature

6.10 Requirement and application: Measure and report the

reached: 56°C

maximum intercell connector temperature reached. value

State data for all applications: State maximum

temperature reached.

Discharge capacity:

The test methods are according to clause 6.11.1 to

6.11.12 which are stated in the standard IEC 60896-21

Requirement and application: Determine actual

capacity Ca. Ca to be at least X % of Crt with all units at

6.11 all rates shown below: See the ANNEX B P

10 h 1,80 Vpc; 8 h 1,75 Vpc; 3 h 1,70 Vpc; 1 h 1,60

Vpc; 0.25 h 1,60 Vpc.

Comply for all applications: Ca ≥ 95 % Crt

(NOTE The requirement of Ca ≥95 % Crt applies not to

the average but to each individual capacity of each of

the 6 units tested with a particular discharge rate.)

TRF:HST-F-Q071 B/0 Page 7 of 13

Report No. : HST201802-0576

IEC 60896-21:2004, IEC 60896-22:2004

Items Requirement – Test Result - Remark Verdict

Charge retention during storage

The test methods are according to clause 6.11.1 to

GEL-12N14-BS (12V 14Ah):

6.12 6.11.12 which are stated in the standard IEC 60896-21 P

Crf = 85.5%

Requirement and application: see table 16 in the

standard IEC 60896-22

Float service with daily discharges

GEL-12N14-BS (12V 14Ah):

The test methods are according to clause 6.13.1 to Cycle number=300

6.13.5 which are stated in the standard IEC 60896-21 Float charge:

6.13 P

Caf=79.7% Crt(3h rate)

Requirement and application: see table 17 in the

Boost charge:

standard IEC 60896-22

Cab=77.1% Crt(3h rate)

Recharge behavior:

The test methods are according to clause 6.14.1 to 1#: Rbf24h =101.0%

6.14.12 which are stated in the standard IEC Rbf168h =102.8%

60896-21

Requirement and application: Determine capacity 2#: Rbf24h =100.8%

6.14 P

after recharge; Rbf24h (24 h Recharge behaviour Rbf168h =102.6%

factor), Rbf168h (168 h Recharge behaviour factor).

Comply for all applications: ≥90 %, ≥98 % 3#: Rbf24h = 100.8%

(NOTE The requirement applies not to the average but Rbf168h =102.6%

to each of the individual tested units.)

service life at an operating temperature of 40 °C

The test methods are according to clause 6.15.1 to GEL-12N14-BS (12V 14Ah):

6.15 6.15.5 which are stated in the standard IEC 60896-21 P

T = 900 days

Requirement and application: see table 19 in the

standard IEC 60896-22

impact of a stress temperature of 55 ℃ or 60 ℃

At 55 °C:

The test methods are according to clause 6.16.1 to GEL-12N14-BS (12V 14Ah):

6.16 6.16.8 which are stated in the standard IEC 60896-21 P

Duration=320 days

Requirement and application: see table 20 in the C0.25h rate=0.79% Crt

standard IEC 60896-22

Abusive over-discharge:

Unbalanced string

The test methods are according to clause 6.17.1 to

over-discharge capacity Caod:

6.17.15 which are stated in the standard IEC

Caod =0.95 Crt(3h rate)

6.17 60896-21 P

Requirement and application: see table 21 in the Cyclic over-discharge capacity

standard IEC 60896-22 Caoc: Caoc =0.98 Crt(3h rate)

TRF:HST-F-Q071 B/0 Page 8 of 13

Report No. : HST201802-0576

IEC 60896-21:2004, IEC 60896-22:2004

Items Requirement – Test Result - Remark Verdict

information on thermal runaway sensitivity GEL-12N14-BS (12V 14Ah):

The test methods are according to clause 6.18.1 to Ultimate temperature after 168h

6.18.14 which are stated in the standard IEC at 2,45 Vpc:

6.18 60896-21 Ta=39 °C P

Ultimate temperature after 168h

Requirement and application: see table 22 in the at 2,60 Vpc:

standard IEC 60896-22 Tb=42 °C

impact of low temperature service on capacity

The test methods are according to clause 6.19.1 to

GEL-12N14-BS (12V 14Ah):

6.19.13 which are stated in the standard IEC

6.19 Cals =0.91 Crt (3h rate) P

60896-21

No mechanical damages

Requirement and application: see table 23 in the

standard IEC 60896-22

dimensional stability at elevated internal

GEL-12N14-BS (12V 14Ah):

pressures and temperatures Change in:

The test methods are according to clause 6.20.1 to Length:0,56% +3mm

6.20 P

6.20.6 which are stated in the standard IEC 60896-21 Width:0,80% +1mm

Requirement and application: see table 24 in the Height:0,65% +2mm

standard IEC 60896-22

stability against mechanical abuse of units during

installation - Cold star current

GEL-12N14-BS (12V 14Ah):

The test methods are according to clause 6.21.1 to

6.21 No leakage, No broken P

6.21.6 which are stated in the standard IEC 60896-21

T=12.1V 14Ah (-10 ºC)

Requirement and application: see table 25 in the

standard IEC 60896-22

TRF:HST-F-Q071 B/0 Page 9 of 13

Report No. : HST201802-0576

TEST RESULT

ANNEX A: 6.6-Requested markings information to be present

Technical information to be present

Polarity sign at the positive terminal(s) with a +

11 mm

symbol radius of at least 6 mm

Manufacturer and/or vendor name QINGDAO PUREGAIN TIRE CO., LTD.

Country of origin of unit Made in China

Type designation of unit GEL-12N14-BS

At least one rated capacity and its final voltage in Vpc

14Ah (End voltage 1.8Vpc 25°C)

or V per unit at a rate listed in 6.11 of IEC 60896-2-1

Rated temperature (20 °C or 25 °C) for the capacity

25°C

value

Cold start current temperature of -10 ªC 12.0/Unit~12.1V/Unit (-10°C)

Date of manufacture (see Note 1 below) in clear

01.2018

unequivocal mm.yyyy format

ISO warning symbols to be present with 11 mm diameter minimum size and in two contrasting colours

(See Note 2 and 3 below)

Warning P

Electrical danger P

No open fires and sparks P

Wear eye protection P

Read instructions P

Environmental protection and recycling symbols to be present

Recycling symbol P

Crossed out waste bin P

NOTE 1 For the purpose of this standard the “date of manufacture” is defined as the date of final inspection of

the units in the factory of origin.

NOITE 2 When the physical dimensions of the units do not allow to apply the symbols on the unit itself then a

separate label to be affixed near the battery or on the battery operating instructions is acceptable.

NOTE 3 The background colour is considered to be one colour.

TRF:HST-F-Q071 B/0 Page 10 of 13

Report No. : HST201802-0576

TEST RESULT

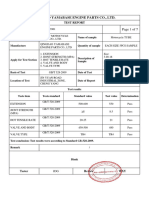

ANNEX B: 6.11-Discharge capacity(GNP250-12)

Capacity Crt= 14.0Ah Crt= 13.5Ah Crt= 12.5Ah Crt= 11.5Ah Crt=10.8Ah

C10 %of C8 %of C3 %of C1 %of C0.25 %of Remark

Sample No. (Ah) Crt (Ah) Crt (Ah) Crt (Ah) Crt (Ah) Crt

1# 14.0 101.8 13.8 118.7 12.5 1 23.2 11.9 S

121.6 10 .8 115.0

25°C

2# 14.1 102.7 13.2 117.2 12.2 1 22.7 11.6 120.7 10 .5 115.5

Ca≥95%Crt

3# 13.9 101.5 12.8 116.3 12.1 1 22.4 11.2 120.2 10 .1 114.0

TRF:HST-F-Q071 B/0 Page 11 of 13

Report No. : HST201802-0576

Photo(s) of the tested samples

SAMPLE PHOTO:

-- End of Report --

TRF:HST-F-Q071 B/0 Page 12 of 13

Report No. : HST201802-0576

Report Statement

1.This test report is invalid if altered, additions and deletions.

2.This test report is responsible for tested samples only .

3.Objections to the test report must be submitted to Guangdong Huesent

Testing & Inspection Technology Co., Ltd. within 15 days.

4.The test report is invalid without the signatures of tester,

reviewer ,approver ,and official stamp of test unit.

5.Without permission of Guangdong Huesent Testing & Inspection

Technology Co., Ltd., This report is not permitted to be duplicated in

extracts.

6.“P”=Pass=Test item conform to the requirement

“F”= Fail=Test item not conform to the requirement

“N”= Not Applicable =Test item Not Applicable to the test object

TRF:HST-F-Q071 B/0 Page 13 of 13

You might also like

- The Handbook of Lithium-Ion Battery Pack Design: Chemistry, Components, Types and TerminologyFrom EverandThe Handbook of Lithium-Ion Battery Pack Design: Chemistry, Components, Types and TerminologyRating: 3 out of 5 stars3/5 (7)

- Pipeline Integrity: Management and Risk EvaluationFrom EverandPipeline Integrity: Management and Risk EvaluationRating: 4.5 out of 5 stars4.5/5 (6)

- Resolución de Problema en FísicaDocument4 pagesResolución de Problema en FísicaCindy ChiribogaNo ratings yet

- MPM2D CPT: Knights of The Night Station: Include All Your Work For Each Part On Their Own .PDF File orDocument5 pagesMPM2D CPT: Knights of The Night Station: Include All Your Work For Each Part On Their Own .PDF File orKavya Pandya100% (2)

- Handbook on Battery Energy Storage SystemFrom EverandHandbook on Battery Energy Storage SystemRating: 4.5 out of 5 stars4.5/5 (2)

- Chapter7 DigitalData 2Document217 pagesChapter7 DigitalData 2orizaNo ratings yet

- IEC60896 (FTHT Battery) Test ReportDocument13 pagesIEC60896 (FTHT Battery) Test ReportMaxime SEHOU100% (1)

- IEC60896 DC 系列 - 瑞达DC12-260 HST201908-15631-1-WTDocument12 pagesIEC60896 DC 系列 - 瑞达DC12-260 HST201908-15631-1-WTAlvaro Cruz CáceresNo ratings yet

- Vkan Testing & Lab - Test ReportDocument13 pagesVkan Testing & Lab - Test ReportSrf SaharinNo ratings yet

- 301 CSBattery IEC60896-21 2004 OPZV 2V Test Report PDFDocument13 pages301 CSBattery IEC60896-21 2004 OPZV 2V Test Report PDFABID TRADERSNo ratings yet

- Informe Final 2012Document20 pagesInforme Final 2012Carlos GarcíaNo ratings yet

- Product Manual 3854 V2Document10 pagesProduct Manual 3854 V2amitonline09No ratings yet

- Type Test GN SeriesDocument20 pagesType Test GN SeriesMinh Chí NguyễnNo ratings yet

- EVVO 3-6KW-G2 - IP65 ReportDocument8 pagesEVVO 3-6KW-G2 - IP65 ReportUdara DissanayakeNo ratings yet

- Draft APpproval 1.0Document8 pagesDraft APpproval 1.0bharat singh koteriNo ratings yet

- Comparison of GBAnd International Standards For Electric Vehicle Secondary BatteriesDocument9 pagesComparison of GBAnd International Standards For Electric Vehicle Secondary BatteriesMohan KumarNo ratings yet

- Sabp G 006Document8 pagesSabp G 006Li PengNo ratings yet

- QP07.01 Testing Procedure For Ball ValveDocument15 pagesQP07.01 Testing Procedure For Ball ValveAnanm NaimNo ratings yet

- LR44 Battery MSDS For TP101Document9 pagesLR44 Battery MSDS For TP101Medina ElyNo ratings yet

- API API: ValvesDocument2 pagesAPI API: ValvesPrasad BondreNo ratings yet

- 01 Itp-380kv Gis - PlanDocument9 pages01 Itp-380kv Gis - PlanYahya SamaraNo ratings yet

- Product Manual IS 17397P 1Document6 pagesProduct Manual IS 17397P 1gsv988No ratings yet

- Kinder SchnitzmesserDocument8 pagesKinder SchnitzmesserTeam QuestInNo ratings yet

- Valves Cat 07Document2 pagesValves Cat 07Pacco HmNo ratings yet

- Saudi Aramco Test ReportDocument12 pagesSaudi Aramco Test ReportehteshamNo ratings yet

- Hydrostatic Test Procedure: Salalah Ammonia ProjectDocument6 pagesHydrostatic Test Procedure: Salalah Ammonia ProjectAbdelkhak KhallaNo ratings yet

- Indicating Wear Characteristics of Non-Petroleum and Petroleum Hydraulic Fluids in A Constant Volume Vane PumpDocument12 pagesIndicating Wear Characteristics of Non-Petroleum and Petroleum Hydraulic Fluids in A Constant Volume Vane PumpTarlan AllahverdiyevNo ratings yet

- Sabp-A-078 Htha PDFDocument28 pagesSabp-A-078 Htha PDFmalleshNo ratings yet

- Bghfy2018 0142Document39 pagesBghfy2018 0142Moataz Nazeem100% (1)

- CE-EN60065-130628020GZU-001 - Test Report Z2Document55 pagesCE-EN60065-130628020GZU-001 - Test Report Z2Yogesh PrajapatiNo ratings yet

- Oslon SSL White (CCT 2500 K - 6500 K) : IES LM-80-08 Test ReportDocument21 pagesOslon SSL White (CCT 2500 K - 6500 K) : IES LM-80-08 Test ReportAnonymous qD4jTcEXNo ratings yet

- Series GuideDocument7 pagesSeries Guidesukhvinder singhNo ratings yet

- ASTM D4180 Standard Test Method For Vibratory Packing Density of Formed Catalyst and PowderDocument3 pagesASTM D4180 Standard Test Method For Vibratory Packing Density of Formed Catalyst and PowderKumaresan LoganathanNo ratings yet

- 2B40208-2 Capacity TestDocument8 pages2B40208-2 Capacity Testameya gawadeNo ratings yet

- Batch Test Certificate: Date:23/06/2023 Product: ZP-4B Batch No:23F1019 Mfd. In: JUNE 2023Document3 pagesBatch Test Certificate: Date:23/06/2023 Product: ZP-4B Batch No:23F1019 Mfd. In: JUNE 2023venkiNo ratings yet

- Batch Test CertificateDocument3 pagesBatch Test Certificatekarthikeyan1003No ratings yet

- Ece R117Document9 pagesEce R117Özgür GözcüNo ratings yet

- Drain Pump, Data Sheet and Performance Curve: Genral Arrangement ofDocument11 pagesDrain Pump, Data Sheet and Performance Curve: Genral Arrangement ofAshish Gupta100% (1)

- Is 4985 StiDocument9 pagesIs 4985 StiraviNo ratings yet

- 170300917sha-001 1PDocument91 pages170300917sha-001 1PAlejandro Pedro Mundaca MalcaNo ratings yet

- Saudi Aramco Test ReportDocument12 pagesSaudi Aramco Test ReportTahir MubeenNo ratings yet

- 1676027749.battery Testing Guidelines - V3 - 9-2-23Document5 pages1676027749.battery Testing Guidelines - V3 - 9-2-23mohamed ibrahimNo ratings yet

- 300MAH-Bluetooth earphone-S03A21080160U01001 金宇宙 UN38.3 602030Document17 pages300MAH-Bluetooth earphone-S03A21080160U01001 金宇宙 UN38.3 602030Lee PeterNo ratings yet

- Batch Test Certificate: Date: 29/03/2019 Product: ZP-4 B Batch No: 19C1019 Mfd. In: March 2019Document3 pagesBatch Test Certificate: Date: 29/03/2019 Product: ZP-4 B Batch No: 19C1019 Mfd. In: March 2019அன்புடன் அஸ்வின்No ratings yet

- Agcl Ae Icda Pra Report 04inch Gas Line-6!01!25!05!2022-Cap CommentsDocument26 pagesAgcl Ae Icda Pra Report 04inch Gas Line-6!01!25!05!2022-Cap CommentsAnonymous AtAGVssJNo ratings yet

- Saudi Aramco Test Report: UPS/DC Vented Ni-Cad Wet Cell, Jobsite Acceptance Test SATR-P-3102 ElectDocument7 pagesSaudi Aramco Test Report: UPS/DC Vented Ni-Cad Wet Cell, Jobsite Acceptance Test SATR-P-3102 ElectehteshamNo ratings yet

- Saes-A-208 (2018)Document14 pagesSaes-A-208 (2018)Arjun RawatNo ratings yet

- Ekulama1 Hydrostatic Testing Procedure - Rev 2Document15 pagesEkulama1 Hydrostatic Testing Procedure - Rev 2eke23No ratings yet

- Pressure Testing Procedure A02Document11 pagesPressure Testing Procedure A02Toreson OfuafoNo ratings yet

- YKEPL MPI Procedure For A668 RMDocument4 pagesYKEPL MPI Procedure For A668 RMDeepak HoleNo ratings yet

- 1 - Lock CertificateDocument5 pages1 - Lock CertificateALENo ratings yet

- 7T04 MP 00 Po 041 1 B 006 - 0 - Pmi - Procedure - C2 - CDocument18 pages7T04 MP 00 Po 041 1 B 006 - 0 - Pmi - Procedure - C2 - CRamy OmarNo ratings yet

- OkDocument14 pagesOkresp-ectNo ratings yet

- Sabp G 013Document15 pagesSabp G 013Eagle Spirit100% (1)

- 10.COOPERHEAT HT ProcedureDocument16 pages10.COOPERHEAT HT Procedurethanga balanNo ratings yet

- HFY-GEN-CP-SPC-0009 - B Specification For Corrosion Coupon - Code-ADocument15 pagesHFY-GEN-CP-SPC-0009 - B Specification For Corrosion Coupon - Code-ATahir FadhilNo ratings yet

- Saes A 208Document14 pagesSaes A 208kjhdsjhdsuhj4321No ratings yet

- Xone 500GT Dot PDFDocument5 pagesXone 500GT Dot PDFFlor Viviana CASTAÑO VELANDIANo ratings yet

- PH12-3B-10-35-R708 11kV Load Shedding Panel (81UF) Protection Relay P141 - Rev ADocument11 pagesPH12-3B-10-35-R708 11kV Load Shedding Panel (81UF) Protection Relay P141 - Rev AratheeshkumardNo ratings yet

- © This Specification Must Not Be Copied or Communicated To A Third Party Without The Express Authorization of T307r6Document3 pages© This Specification Must Not Be Copied or Communicated To A Third Party Without The Express Authorization of T307r6조준장No ratings yet

- 17 ValvesDocument4 pages17 ValvesTrung NguyenNo ratings yet

- SC 69503Document6 pagesSC 69503sujatananasoNo ratings yet

- In Amenas Gas Project Algeria: 6877 TE XE 99 61 37470 P01Document17 pagesIn Amenas Gas Project Algeria: 6877 TE XE 99 61 37470 P01Daoued HaouesNo ratings yet

- EMC TEST - REPORT - FalcomDocument25 pagesEMC TEST - REPORT - FalcomVictor PerezNo ratings yet

- WINDFORCEDocument50 pagesWINDFORCEVictor PerezNo ratings yet

- Xingyuan AnnaiteDocument50 pagesXingyuan AnnaiteVictor PerezNo ratings yet

- 05 Pastillas FrenoDocument7 pages05 Pastillas FrenoVictor PerezNo ratings yet

- Test ReportDocument10 pagesTest ReportVictor PerezNo ratings yet

- Qingdao Yamabase Engine Parts CoDocument7 pagesQingdao Yamabase Engine Parts CoVictor PerezNo ratings yet

- Electrical Hazard Resistant Footwear ASTMF2413-11Document3 pagesElectrical Hazard Resistant Footwear ASTMF2413-11Victor PerezNo ratings yet

- Talan Test Report Model 182Document17 pagesTalan Test Report Model 182Victor PerezNo ratings yet

- Scale Drawing and Scale Models RubricDocument1 pageScale Drawing and Scale Models RubricArgoNavisNo ratings yet

- Engine Overhaul : Group 11BDocument80 pagesEngine Overhaul : Group 11BДмитрий100% (1)

- Conic SectionDocument9 pagesConic SectionJomana MacalnasNo ratings yet

- 2 Roisum ENDocument99 pages2 Roisum ENorhm100% (2)

- Warn 2013-2014 Application GuideDocument75 pagesWarn 2013-2014 Application Guideapi-238139220No ratings yet

- Notation Composer 3 Users GuideDocument690 pagesNotation Composer 3 Users GuideSvedot MakedonecNo ratings yet

- OneTen-Frontend Web Development FundamentalsDocument5 pagesOneTen-Frontend Web Development FundamentalsOkpetah Chioma christabelNo ratings yet

- Java Programming For BSC It 4th Sem Kuvempu UniversityDocument52 pagesJava Programming For BSC It 4th Sem Kuvempu UniversityUsha Shaw100% (1)

- Exploit Writing Tutorial Part 1 - Stack Based Overflows - Corelan TeamDocument54 pagesExploit Writing Tutorial Part 1 - Stack Based Overflows - Corelan Teamdamir_krstanovicNo ratings yet

- W12 1321 01 ADocument19 pagesW12 1321 01 ALucy SimmondsNo ratings yet

- PLC Programming With RSLogix 500Document132 pagesPLC Programming With RSLogix 500kemo_750252831No ratings yet

- Airbus A319/320/321 Notes: Welcome To The Airbus! Resistance Is Futile, You Will Be AssimilatedDocument128 pagesAirbus A319/320/321 Notes: Welcome To The Airbus! Resistance Is Futile, You Will Be Assimilatedejt01No ratings yet

- Invers Transf LaplaceDocument13 pagesInvers Transf LaplaceMeriska AhmadNo ratings yet

- B.S. in Electronics Engineering - BSECE 2008 - 2009Document2 pagesB.S. in Electronics Engineering - BSECE 2008 - 2009Vallar RussNo ratings yet

- Unit QuestionsDocument155 pagesUnit QuestionsSanya KhanNo ratings yet

- Sound Intensity Level CalculationDocument10 pagesSound Intensity Level CalculationvenkateswaranNo ratings yet

- Chapter 3 Digital ForensicsDocument5 pagesChapter 3 Digital ForensicsAbhinav GadekarNo ratings yet

- Siggberg WartsilaDocument27 pagesSiggberg WartsilaSenthil KumarNo ratings yet

- Life Sciences Grade 10 ATP 2024Document19 pagesLife Sciences Grade 10 ATP 2024olwe149No ratings yet

- Onion Ring Magic SquareDocument8 pagesOnion Ring Magic SquareMJ Foust100% (2)

- Bio Sem2 EssayDocument2 pagesBio Sem2 EssayEileen WongNo ratings yet

- Noise in Fiber Optic Communication LinksDocument14 pagesNoise in Fiber Optic Communication Linksian.maximillianNo ratings yet

- Struktur Baja 1Document33 pagesStruktur Baja 1Agung S NurcahyanaNo ratings yet

- Thông Gió Cho T - Pdfslide - Net - Electrical-Cabinet-Vbcm-The-Electrical-Cabinet-Ventilation-Serves-To-MaintainDocument26 pagesThông Gió Cho T - Pdfslide - Net - Electrical-Cabinet-Vbcm-The-Electrical-Cabinet-Ventilation-Serves-To-MaintainThành PhạmNo ratings yet

- Chemical Bonding and Molecular Structure: 2.1. Fundamental Concepts of Chemical BondsDocument47 pagesChemical Bonding and Molecular Structure: 2.1. Fundamental Concepts of Chemical BondsNguyễn Quốc HưngNo ratings yet

- A Detailed Lesson PlanDocument13 pagesA Detailed Lesson PlanReynaldo Quines Bohol100% (16)

- Created by C. Mani, Education Officer, KVS RO Silchar: ST ND RD ST ND RD ST ND RDDocument51 pagesCreated by C. Mani, Education Officer, KVS RO Silchar: ST ND RD ST ND RD ST ND RDjaindevansh100% (2)