Professional Documents

Culture Documents

Talan Test Report Model 182

Uploaded by

Victor PerezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Talan Test Report Model 182

Uploaded by

Victor PerezCopyright:

Available Formats

www.tuv.

com

Seite 2 von 17

Prüfbericht - Nr.: 21177740 006 Page 2 of 17

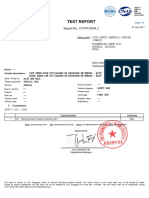

Test Report No.: 556-12-0517

Equipmentlist

Messung/Measuring Gerätenummer/ nächste

Ident.-Nummer Kalibrierung/

Barcode-Nummer Überwachung

Equipment number next calibration/

surveillance

Marking Expert ---

Information to be supplied Expert ---

Test results of accredited laboratories of competent subcontractor are marked with /*.

/*1 test results of test report 21177740 001 f (556-11-1495), 08.12.2017

/*2 test results of test report 21177740 002 f (556-12-0149), 05.12.2017

/*3 test results of test report 21177740 003 (556-12-0362), 30.12.2017

/*4 test results of test report 21177740 005 (556-12-0397), 03.12.2017

Rev. 1 2010-01-01 / approved: D. Knape

12-0517.docErstelldatum 07.12.2017 13:42:00

www.tuv.com

Seite 3 von 17

Prüfbericht - Nr.: 21177740 006 Page 3 of 17

Test Report No.: 556-12-0517

Article description

Item SE/2M0182/3

Sizes 38 – 47

Category / Symbols S3 SRA

Design C

Picture

Collar material

---

Insert material

---

Upper material

- Leather Barton X

Vamp lining

- fleece grey X

Quarter lining

- Non Woven fabric.ibiline 720 col.91 X

Back lining

--- ---

Tongue lining

- Non Woven fabric.ibiline 720 col.91 X

Tongue

- leather board .salmandra thread X

Inlay sole

- Ibitech 222 A20 014 2,5 mm X

Insole

- Ibiaoam 9605 3,0 mm ST TT4 X

Penetration proof insert

- Steal midsole Art. 1604 SMAL X

Rev. 1 2010-01-01 / approved: D. Knape

12-0517.docErstelldatum 07.12.2017 13:42:00

www.tuv.com

Seite 4 von 17

Prüfbericht - Nr.: 21177740 006 Page 4 of 17

Test Report No.: 556-12-0517

Article description

Item SE/2M0182/3

Sizes 38 – 47

Category / Symbols S3 SRA

Design C

Picture

Outsole

- dual density PU-PU system

Toe cap

- Steal 6522 SMAL X

Overcap

---

Rev. 1 2010-01-01 / approved: D. Knape

12-0517.docErstelldatum 07.12.2017 13:42:00

www.tuv.com

Seite 5 von 17

Prüfbericht - Nr.: 21177740 006 Page 5 of 17

Test Report No.: 556-12-0517

Marking - Meaning of the symbols:

P : Penetration resistance

C . Electrical resistance, conductive footwear

A : Electrical resistance, antistatic footwear

I : Electrically insulating footwear

HI : Heat insulation of sole complex

CI : Cold insulation of sole complex

E : Energy absorption of seat region

WR : Water resistant

M : Metatarsal protection

AN : Ankle protection

WRU : Water penetration and water absorption

CR : Resistance of upper to cutting

HRO : Resistance to hot contact

SRA : slip resistance on ceramic tile floor/ cleaning agent

SRB : slip resistance on steel plate/glycerine

SRC : slip resistance on ceramic tile floor/ cleaning agent and steel plate/glycerine

Rev. 1 2010-01-01 / approved: D. Knape

12-0517.docErstelldatum 07.12.2017 13:42:00

www.tuv.com

Seite 6 von 17

Prüfbericht - Nr.: 21177740 006 Page 6 of 17

Test Report No.: 556-12-0517

Test results

/4 20345/ 4 Footwear shall be classified as

Classification Tab. 1 follows:

classification I Footwear made from leather and X

other materials, excluding all-rubber

or all-polymeric footwear

classification II all-rubber (i.e. entirely vulcanized) or

all-polymeric (i.e. entirely moulded)

footwear

/5.2

Form Bild 3

General requirements Design

/5.2.1 20344/ 6.2 --- N/A

Height of upper size height [mm]

design: A ≤ 36 < 103

37/ 38 < 105

39/ 40 < 109

41/ 42 < 113

43/ 44 < 117

45 and bigger < 121

design: B size height [mm] --- N/A

≤ 36 at least 103

37/ 38 at least 105

39/ 40 at least 109

41/ 42 at least 113

43/ 44 at least 117

45 and bigger at least 121

design: C size height [mm] size [mm] P/*4

≤ 36 at least 162

37/ 38 at least 165 38 224

39/ 40 at least 172

41/ 42 at least 178 42 238

43/ 44 at least 185

45 and bigger at least 192

47 263

design: D size height [mm] --- N/A

≤ 36 at least 255

37/ 38 at least 260

39/ 40 at least 270

41/ 42 at least 280

43/ 44 at least 290

45 and bigger at least 300

design: E size height [mm] --- N/A

≤ 36 at least 255

37/ 38 at least 260

39/ 40 at least 270

41/ 42 at least 280

43/ 44 at least 290

45 and bigger at least 300

Rev. 1 2010-01-01 / approved: D. Knape

12-0517.docErstelldatum 07.12.2017 13:42:00

www.tuv.com

Seite 7 von 17

Prüfbericht - Nr.: 21177740 006 Page 7 of 17

Test Report No.: 556-12-0517

Parameter according to Tested acc. to EN ISO Test result Remark

EN ISO 20345 P F N/A N/T

/5.2.2 20345/ 5.2.2 P/*4

Seat region -

design A closed

design B closed

design C closed closed

design D closed

design E

/5.3 General requirements /5.3.1 Outsole properties

/5.3.1.1 20345/ 5.3.1.1 Insole (if used) not removable without given P/*1

Construction damage of the shoe

/5.3.1.2 20344/ 5.2 at least 4,0 size bond strength P/*1

Upper/ outsole bond * at least 3,0 N/mm at material break 38 7,3*

strength 42 6,6*

47 4,2*

General requirements /5.3.2

Toe protection

/5.3.2.1 20345/ toe cap not removable without given P/*1

General 5.3.2.1 damage of the shoe;

edge covering at least 5 mm beneath

and at least 10 mm in the opposite

direction;

scuff resistant coverings at least

1 mm thick

/5.3.2.2 4.3.2.2 size internal length [mm] Size P/*1

Internal length ≤ 36 at least 34

37/ 38 at least 36 38 38/39

39/ 40 at least 38

41/ 42 at least 39 42 42/42

43/ 44 at least 40

45 and bigger at least 42 47 45/45

/5.3.2.3 20344/ 5.4 size rest height [mm] Size

Impact resistance ≤ 36 at least 12,5

(minimum clearance) 37/ 38 at least 13,0 38 14,0 P/*2

39/ 40 at least 13,5

41/ 42 at least 14,0 42 14,0 P/*2

43/ 44 at least 14,5

45 and bigger at least 15,0 47 19,5 P/*3

/5.3.2.4 20344/ 5.5 size rest height [mm] Size

Compression resistance ≤ 36 at least 12,5

(minimum clearance) 37/ 38 at least 13,0 38 14,0 P/*2

39/ 40 at least 13,5

41/ 42 at least 14,0 42 14,0 P/*2

43/ 44 at least 14,5

45 and bigger at least 15,0 47 18,0 P/*3

/5.3.2.5.1 20344/ 5.6.2 classification I: (48 h) given P/*1

Corrosion resistance of - no more as 5 areas of corrosion;

metal toe cap - none of which shall exceed 2,5 mm²

20344/ 5.6.1 classification II: (168 h) --- N/A

- no more as 5 areas of corrosion;

- none of which shall exceed 2,5 mm²

Rev. 1 2010-01-01 / approved: D. Knape

12-0517.docErstelldatum 07.12.2017 13:42:00

www.tuv.com

Seite 8 von 17

Prüfbericht - Nr.: 21177740 006 Page 8 of 17

Test Report No.: 556-12-0517

Parameter according to Tested acc. Requirement Test result Remark

EN ISO 20345 to EN ISO P F N/A N/T

/5.3.2.5.2 EN 12568/ 4.3 Following requirements should be --- N/A

Toe Caps made of other fulfilled

materials

- impact resistance after EN 12568/ size rest height [mm] --- N/A

influence of higher 7.1.5.1 ≤5 at least 19,5

temperatures 6 at least 20,0

(minimum clearance) 7 at least 20,5

8 at least 21,0

9 at least 21,5

≥ 10 at least 22,0

- impact resistance after EN 12568/ size rest height [mm] --- N/A

influence of lower 7.1.5.2 ≤5 at least 19,5

temperatures 6 at least 20,0

(minimum clearance) 7 at least 20,5

8 at least 21,0

9 at least 21,5

≥ 10 at least 22,0

- impact resistance after EN 12568/ size rest height [mm] --- N/A

influence of acid 7.1.5.3 ≤5 at least 19,5

(Minimum Clearance) 6 at least 20,0

7 at least 20,5

8 at least 21,0

9 at least 21,5

≥ 10 at least 22,0

- impact resistance after EN 12568/ size rest height [mm] --- N/A

influence of lye 7.1.5.4 ≤5 at least 19,5

(Minimum Clearance) 6 at least 20,0

7 at least 20,5

8 at least 21,0

9 at least 21,5

≥ 10 at least 22,0

- impact resistance after EN 12568/ size rest height [mm] --- N/A

influence of fuel 7.1.5.5 ≤5 at least 19,5

(Minimum Clearance) 6 at least 20,0

7 at least 20,5

8 at least 21,0

9 at least 21,5

≥ 10 at least 22,0

/5.3.3 20344/ 5.7 no air bubbles --- N/A

Leak proofness

/5.3.4 20344/ 5.1 The following ergonomic requirements are fulfilled if answered with P/*4

Ergonomic features „Yes“:

Is the inside surface of the footwear free from rough, sharp or YES

hard areas that caused you irritation or injury?

Are there no pinch points caused by the toecap or the edge YES

covering of the toecap?

Is the footwear free of features that you consider to make wearing YES

the footwear hazardous?

Can the fastening be adequately adjusted? (if necessary) YES

Can the following activities be performed without problems? YES

- walking (5 min bei 6 km/h)

- climbing stairs (during 1 min 17 ± 3 stairs up and down)

- kneeling/ crouching (acc. picture 1 DIN EN ISO 20344)

Rev. 1 2010-01-01 / approved: D. Knape

12-0517.docErstelldatum 07.12.2017 13:42:00

www.tuv.com

Seite 9 von 17

Prüfbericht - Nr.: 21177740 006 Page 9 of 17

Test Report No.: 556-12-0517

Parameter according to Tested acc. Requirement Test result Remark

EN ISO 20345 to EN ISO P F N/A N/T

/5.3.5 20345 P/*1

Slip resistance Annex A symbol SRA

Sliding friction coefficient

- ceramic tile floor/ heel A ≥ 0,28 µ

cleaning agent outsole B ≥ 0,32 µ

symbol SRA

- steel plate/ glycerine heel C ≥ 0,13 µ

outsole D ≥ 0,18 µ

symbol SRB

- ceramic tile floor/ Size 38 42 47

cleaning agent and heel A ≥ 0,28 µ 0,31 0,32 0,34

steel plate/ glycerine outsole B ≥ 0,32 µ 0,40 0,42 0,45

heel C ≥ 0,13 µ 0,04 0,10 0,08

outsole D ≥ 0,18 µ 0,09 0,11 0,18

symbol SRC

/5.4 Height of inserts/ collar materials

Shoe upper

/5.4.1 20345/ 5.4.1 size height [mm] --- N/A

General – Design A ≤ 36 at least 44

37/ 38 at least 46

39/ 40 at least 48

41/ 42 at least 50

43/ 44 at least 52

≥ 45 at least 53

General – Design B 20345/ 5.4.1 size height [mm] --- N/A

≤ 36 at least 64

37/ 38 at least 66

39/ 40 at least 68

41/ 42 at least 70

43/ 44 at least 72

≥ 45 at least 73

General – Design C 20345/ 5.4.1 size height [mm] --- N/A

≤ 36 at least 113

37/ 38 at least 115

39/ 40 at least 119

41/ 42 at least 123

43/ 44 at least 127

≥ 45 at least 131

General - Design D 20345/ 5.4.1 size height [mm] --- N/A

≤ 36 at least 172

37/ 38 at least 175

39/ 40 at least 182

41/ 42 at least 188

43/ 44 at least 195

≥ 45 at least 202

General – Design E 20345/ 5.4.1 size height [mm] --- N/A

≤ 36 at least 265

37/ 38 at least 270

39/ 40 at least 280

41/ 42 at least 290

43/ 44 at least 300

≥ 45 at least 310

Collar/ material insert if collar and material inserts are tested only for

above the set heights, it will be tested as upper material specification /*1

acc. to clause 5.5.1 und 5.5.2 and

below as upper material (all

properties)

Rev. 1 2010-01-01 / approved: D. Knape

12-0517.docErstelldatum 07.12.2017 13:42:00

www.tuv.com

Seite 10 von 17

Prüfbericht - Nr.: 21177740 006 Page 10 of 17

Test Report No.: 556-12-0517

Parameter according to Tested acc. Requirement Test result Remark

EN ISO 20345 to EN ISO P F N/A N/T

Collar/ material inserts Lining properties

/5.5.1 20344/ 6.3 leather ≥ 30 N --- N/A

Tear strength woven fabric/ textil ≥ 15 N

/5.5.2 20344/ 6.12 dry 25.600 cycles --- N/A

Abrasion resistance wet 12.800 cycles

no hole formation

/5.4.7 20344/ 6.9 at least 3,2 --- N/A

pH-value < 0,7 (if pH-value < 4,0)

differce number

/5.4.9 20344/ 6.11 not detectable (< 3 mg/ kg) --- N/A

Chromium VI – conent

Collar/ material inserts Upper properties leather board salmandra thread

/5.4.2 20344/ 6.1 rubber ≥1,5 mm --- N/A

Thickness classification II polymer ≥1,0 mm

/5.4.3 20344/ 6.3 leather ≥ 120 N direction I P/*3

Tear strength woven fabrics/ textil ≥ 60 N 204 175 209

direction II

216 247 251

/5.4.4 20344/ 6.4 split leather ≥ 15 N/ mm² --- N/A

Tensile properties

rubber ≥ 180 N

polymer

at 100 % 1,3 - 4,6 N/ mm²

stretching

streching at ≥ 250 %

break

/5.4.5 20344/ 6.5 no cracking at less than --- N/A

Flexing resistance rubber: 125.000 cycles

polymer: 150.000 cxcles

/5.4.6 20344/ 6.6 at least 0,8 mg/cm²h 2,8 3,0 2,4 P/*3

Water vapour permeability

Water vapour absorption 20344/ 6.7 mg/cm² x 8h 13,0 14,0 13,0 only for

calculation

Water vapour coefficient 20344/ 6.8 at least 15 mg/cm² 35,5 37,5 32,0 P/*3

/5.4.7 20344/ 6.9 at least 3,2 4,4 P/*1

pH-value < 0,7 (if pH-value < 4,0)

difference number

/5.4.8 20344/ 6.10 after 150.000 flexing cycles: --- N/A

Hydrolysis no cracks

/5.4.9 20344/ 6.11 not detectable (< 3 mg/kg) not detectable P/*1

Chromium VI- content

Rev. 1 2010-01-01 / approved: D. Knape

12-0517.docErstelldatum 07.12.2017 13:42:00

www.tuv.com

Seite 11 von 17

Prüfbericht - Nr.: 21177740 006 Page 11 of 17

Test Report No.: 556-12-0517

Parameter according to Tested acc. Requirement Test result Remark

EN ISO 20345 to EN ISO P F N/A N/T

Upper leather Barton

/5.4.2 20344/ 6.1 rubber ≥1,5 mm --- N/A

Thickness classification II polymer ≥1,0 mm

/5.4.3 20344/ 6.3 leather ≥ 120 N 203 308 308 P/*1

Tear strength woven fabrics/ textil ≥ 60 N 307 232 309

/5.4.4 20344/ 6.4 split leather ≥ 15 N/ mm² --- N/A

Tensile properties

rubber ≥ 180 N

polymer

at 100 % 1,3 - 4,6 N/ mm²

stretching

streching at ≥ 250 %

break

/5.4.5 20344/ 6.5 no cracking at less than --- N/A

Flexing resistance rubber: 125.000 cycles

polymer: 150.000 cxcles

/5.4.6 20344/ 6.6 at least 0,8 mg/cm²h 13,1 15,4 14,8 P/*1

Water vapour permeability

Water vapour absorption 20344/ 6.7 mg/cm² x 8h 0,8 0,9 0,8 only for

calculation

Water vapour coefficient 20344/ 6.8 at least 15 mg/cm² 105 124 119 P/*1

/5.4.7 20344/ 6.9 at least 3,2 4,5 P/*1

pH-value < 0,7 (if pH-value < 4,0)

difference number

/5.4.8 20344/ 6.10 after 150.000 flexing cycles: --- N/A

Hydrolysis no cracks

/5.4.9 20344/ 6.11 not detectable (< 3 mg/kg) not detectable P/*1

Chromium VI- content

/5.5

Lining

Quarter lining non woven fabric.ibiline 720 col.91

/5.5.1 20344/ 6.3 leather ≥ 30 19 15 16 P/*1

Tear strength woven fabrics/ textil ≥ 15 26 17 16

/5.5.2 20344/ 6.12 dry 25.600 cycles no hole formation P/*1

Abrasion resistance wet 12.800 cycles no hole formation

no hole formation

/5.5.3 20344/ 6.6 at least 2,0 mg/cm²h 9,5 10,4 8,8 P/*1

Water vapour permeability

Water vapour absorption 20344/ 6.7 mg/cm² x 8h 3,3 3,0 3,8 only for

calculation

Water vapour coefficient 20344/ 6.8 at least 20 mg/cm² 79 87 74 P/*1

/5.5.4 20344/ 6.9 at least 3,2 --- N/A

pH-value < 0,7 (if pH-value < 4,0)

difference number

/5.5.5 20344/ 6.11 not detectable (< 3 mg/kg) --- N/A

Chromium VI- content

Vamp lining fleece grey

/5.5.1 20344/ 6.3 leather ≥ 30 68 94 85 P/*1

Tear strength woven fabrics/ textil ≥ 15 69 75 65

/5.5.2 20344/ 6.12 dry 25.600 cycles no hole formation P/*1

Abrasion resistance wet 12.800 cycles no hole formation

no hole formation

/5.5.3 20344/ 6.6 at least 2,0 mg/cm²h 13,1 15,4 14,8 P/*1

Water vapour permeability

Water vapour absorption 20344/ 6.7 mg/cm² x 8h 0,8 0,9 0,8 only for

calculation /*1

Water vapour coefficient 20344/ 6.8 at least 20 mg/cm² 105 124 119 P/*1

/5.5.4 20344/ 6.9 at least 3,2 --- N/A

pH-value < 0,7 (if pH-value < 4,0)

difference number

/5.5.5 20344/ 6.11 not detectable (< 3 mg/kg) --- N/A

Chromium VI- content

Rev. 1 2010-01-01 / approved: D. Knape

12-0517.docErstelldatum 07.12.2017 13:42:00

www.tuv.com

Seite 12 von 17

Prüfbericht - Nr.: 21177740 006 Page 12 of 17

Test Report No.: 556-12-0517

Parameter according to Tested acc. Requirement Test result Remark

EN ISO 20345 to EN ISO P F N/A N/T

/5.6

Tongue leather board .salmandra thread

/5.6.1 20344/ 6.3 leather ≥ 36 N 105 101 99 P/*1

Tear strength woven fabrics/ textil ≥ 18 N 88 93 83

/5.6.2 20344/ 6.9 at least 3,2 4,4 P/*1

pH-value < 0,7 (if pH-value < 4,0)

difference number

/5.6.3 20344/ 6.11 not detectable (< 3 mg/kg) not detectable P/*1

Chromium VI content

/5.7 Ibiaoam 9605 3,0 mm ST TT4/

Lasting insole/ insock/ Ibitech 222 A20 014 Industrie Biagioli SpA

Water permeability 20344/ 7.2 ≥ 60 s non permeable permeable only for

(insock) < 60 s permeable specification

/5.7.1 20344/ 7.1 at least 2,0 mm 3,0 P/*3

Thickness

(lasting insole)

/5.7.2 20344/ 6.9 at least 3,2 --- N/A

pH-value < 0,7 (if pH-value < 4,0)

difference number

(lasting insole and insock)

/5.7.3 20344/ 7.2 at least 70 mg/cm² 153 143 154 P/*1

Water absorption at least 80 % 110 119 109

Water desorption

(lasting insole)

/5.7.5 20344/ 6.11 not detectable (< 3 mg/kg) --- N/A

Chromium VI- content

(lasting insole and insock)

/5.7.4.2 20344/ 6.12 dry 25.600 cycles no hole formation P/*3

Abrasion resistance wet 12.800 cycles no hole formation

(insock) no hole formation

/5.7.4.1 20344/ 7.3 after 400 cycles not bad as reference not bad as reference sample P/*1

Abrasion resistance sample

(insole - not for leather

insole)

/5.8

outsole dual density PU-PU system

/5.8.1 20344/ 8.1 ≥ 6,0 mm --- N/A

Thickness of outsoles

(non cleated)

/5.8.2 20344/ 8.2 density tear strength density 1,17 g/cm3 P/*1

Tear strength ≤ 0,9 g/cm³ ≥ 5,0 kN/ m

> 0,9 g/cm³ ≥ 8,0 kN/ m 12,0 16,8 24,4

5.8.3 20344/8.3 density abrasion resistance density 1,17 g/cm3 P/*1

Abrasion resistance ≤ 0,9 g/cm³ max. 250 mm³

> 0,9 g/cm³ max. 150 mm³ 124 131 75

/5.8.4 20344/ 8.4.1 if the flexing of the outsole is > 45° at 43 only for

Rigidity test of the whole 30 N testing of flexing resistance is specification

shoe required

/5.8.4 20344/ 8.4.2 cut growth --- N/A

Flexing resistance after 30.000 flexing cycles ≤ 4,0 mm

/5.8.5 20344/ 8.5 cut growth 0,0 0,0 0,0 P/*1

Hydrolysis after 150.000 flexing cycles at –5°C

≤ 6,0 mm

/5.8.6 20344/ 5.2 ≥ 4,0 N/ mm 3,1* 4,7* 4,5* P/*1

Interlayer bond strength *at material break at least 3,0 N/ mm

/5.8.7 20344/ 8.6.1 volume increase ≤ 12 % 1 2 2 P/*1

Resistance to fuel oil

20344/ 8.6.2 cut growth --- N/A

after 150.000 flexing cycles ≤ 6,0 mm

(if volume decrease > 0,5% or if

increase of hardness > 10 Shore-A-

hardness-units)

Rev. 1 2010-01-01 / approved: D. Knape

12-0517.docErstelldatum 07.12.2017 13:42:00

www.tuv.com

Seite 13 von 17

Prüfbericht - Nr.: 21177740 006 Page 13 of 17

Test Report No.: 556-12-0517

Parameter according to Tested acc. Requirement Test result Remark

EN ISO 20345 to EN ISO P F N/A N/T

Additional requests Whole footwear

/6.2.1.1 20344/ 5.8.2 at least 1100 N size

Penetration resistance measured at 0 mm nail penetration 38 1279 P/*3

42 1271 P/*1

46 1111 P/*1

/6.2.1.2 20344/ 6.2.1.2 The penetration-resistant insert shall given P/*1

- Construction be built into the bottom of the shoe in

such a manner that it cannot be

removed without damaging the

footwear.

Except for the non-metallic inserts

sewn in as part of the strobel stiched

construction, the insert shall not lie

about the flange of the safety toecap

and shall not be attached to it.

/6.2.1.3 20344/ 5.8.1 Distance between the line of the last given P/*3

- Dimensions and the egde of the penetration

resistant insert

circumference max. 6,5 mm

heel region max. 17 mm

- Design 20345/ figure not more than 3 holes of max. given P/*1

4 diameter 3 mm in the shaded area

/6.2.1.4 20344/ 5.9 no cracks after 1 x 106 flexing cycles no cracks P/*1

- Flexing resistance

/6.2.1.5.1 20344/ 5.6.1 classification I: (48 h) given P/*1

- Corrosion resistance of - not more than 5 areas with corrosion

penetration resistant - no one of this areas > 2,5 mm²

inserts made of metal

20344/ 5.6.2 classification II: (168 h) --- N/A

- not more than 5 areas with corrosion

- no one of this areas > 2,5 mm²

Rev. 1 2010-01-01 / approved: D. Knape

12-0517.docErstelldatum 07.12.2017 13:42:00

www.tuv.com

Seite 14 von 17

Prüfbericht - Nr.: 21177740 006 Page 14 of 17

Test Report No.: 556-12-0517

Parameter according to Tested acc. Requirement Test result Remark

EN ISO 20345 to EN ISO P F N/A N/T

/6.2.1.5.2 20345/ at 1100 N for 10 s no nail penetration --- N/A

- Non metallic inserts 6.2.1.5.2; measured

EN 12568/ 5.2

after influence of higher EN 12568/

temperatures 7.1.5.1

after influence of lower EN 12568/

temperatures 7.1.5.2

after influence of acid EN 12568/

7.1.5.3

after influence of leach EN 12568/

7.1.5.4

after influence of fuel EN 12568/

7.1.5.5

/6.2.2 20345/ 6.2.2

Electrical properties

/6.2.2.1 20344/ 5.10 ≤ 105Ω --- N/A

- Conductive footwear

dry atmosphere

/6.2.2.2 20344/ 5.10 105 - 109Ω left/right

- Antistatic footwear with insock P/*3

dry atmosphere 38 4,2x108/5,6x108

42 4,9x108/7,3x108

47 4,4x108/3,8x108

wet atmosphere with insock P/*1

38 9,1x106/9,4x106

42 9,2x106/1,4x107

46 1,4x107/1,4x107

/6.2.2.3 20344/ 5.11 electrical class 00 --- N/A

- Isulating footwear electrical class 0

(classification II)

/6.2.3 20345/ 6.2.3

Adverse conditions

/6.2.3.1 20344/ 5.12 ≤ 22 °C --- N/A

Heat insulation of

sole complex

(increase of temperature)

/6.2.3.2 20344/ 5.13 ≤ 10 °C --- N/A

Cold insulation of

sole complex

(decrease of temperature)

/6.2.4 20344/ 5.14 at least 20 J size left/right

Energy absorption of seat 38 33/31 P/*3

region 42 35/35 P/*3

46 34/34 P/*1

47 39/38 P/*3

/6.2.5 20344/ 5.15.1 --- N/A

Water resistance after 1000 steps: area of water

trough test penetration < 3 cm2

brushing 20344/ 5.15.2 no water penetration before 15 min

Rev. 1 2010-01-01 / approved: D. Knape

12-0517.docErstelldatum 07.12.2017 13:42:00

www.tuv.com

Seite 15 von 17

Prüfbericht - Nr.: 21177740 006 Page 15 of 17

Test Report No.: 556-12-0517

Parameter according to Tested acc. Requirement Test result Remark

EN ISO 20345 to EN ISO P F N/A N/T

/6.2.6 20345/ 6.2.6

Metatarsal protection

/6.2.6.1 20345/ 6.2.6.1 - shall have made from suitable --- N/A

- construction materials

- shall be attached to the footwear in

such a manner that it cannot be

removed without damaging the

footwear

- shall fit the shape of the footwear

and shall be designed so as not to

impair normal foot movement

/6.2.6.2 20344/ 5.16 size min. clearance after impact --- N/A

- impact resistance ≤ 36 at least 37,0

37/ 38 at least 38,0

39/ 40 at least 39,0

41/ 42 at least 40,0

43/ 44 at least 40,5

≥ 45 at least 41,0

/6.2.7 20344/ 5.17 average value ≤ 20 kN --- N/A

Ankle protection several value ≤ 30 kN

Additional requirements /6.3

upper

/6.3.1 20344/ 6.13 water penetration: after 60 min ≤ 0,2 g 0,01 0,00 0,01 P/*1

water penetration and water absorption: ≤ 30 % 5,6 12,0 6,2

water absorption

/6.3.2 20345/ 6.3.2 non functional and decorative given P/*3

construction stichings are not allowed

/6.3.3 --- N/A

cut resistance of upper

/6.3.3.1 20344/ 6..3.1 design B, C, D, E

design

/6.3.3.2 20344/

construction 6.3.3.2; Bild 5

cut 20344/ 6.14 factor I: not less than 2,5

Additional requirements /6.4

outsole

/6.4.1 20344/ 6.4.1; With exception of the region under --- N/A

Cleated area picture 6 the flange of the toe cap, at least the

shaded area as shown in following

picture shall have cleats which are

open to the side.

/6.4.2 20344/ 8.1.2 [mm] --- N/A

Thickness d1 (direct-injected, not less

vulcanized or cemented) than 4,0

d1 (multilayered outsoles) not less

than 4,0

d1 (all-rubber or all- not less

polymeric footwear) than 3,0

d3 (all-rubber or all- not less

polymeric footwear) than 6,0

Rev. 1 2010-01-01 / approved: D. Knape

12-0517.docErstelldatum 07.12.2017 13:42:00

www.tuv.com

Seite 16 von 17

Prüfbericht - Nr.: 21177740 006 Page 16 of 17

Test Report No.: 556-12-0517

Parameter according to Tested acc. Requirement Test result Remark

EN ISO 20345 to EN ISO P F N/A N/T

/6.4.4 20344/ 8.1 [mm] --- N/A

Cleat height d2 (direct-injected, not less

vulcanized or cemented) than 2,5

d2 (multilayered outsoles) not less

than 2,5

d2 (all-rubber or all- not less

polymeric footwear) than. 4,0

/6.4.4 20344/ 8.7 rubber and polymeric outsoles: --- N/A

Resistance to hot contact - shall not melt

- shall not develop any cracks when

bent around the mandrel

leather outsoles:

- shall develop no cracks or charring

which extend into the corium when

bent around the mandrel

Marking and Information to be supplied

/7 20345/ 7 given P

Marking

size

manufacturer’s identification mark

manufacturer’s type designation

year of manufacture and at least

quarter

number and year of European

standard: EN ISO 20345: 2007

category and symbols

/8 20345/ 8 - name and full address of the given P/*4

Users Information 20345/ 8.1 manufacturer and/ or his authorized

General representative

- notified body, involved in type

examination (for category III –products

the notified body involved with article

11)

- number and year of standard

- explanation of any pictograms,

markings and performance levels; a

basic explanation of the tests that

have been applied to the footwear

- instruction for use

- tests to be carried out by the

wearer before use

- fitting, how to put on and take

off the footwear, if relevant

- application; basic information on

possible uses

- limitations of use

- instructions for storage and

maintenance

- instructions for cleaning and/ or

decontamination

- obsolescence deadline or period

of obsolescence

- if appr., warnings against

problems likely to be encountered

- reference to accessories and spare

parts

- type of packaging suitable for

transport

Rev. 1 2010-01-01 / approved: D. Knape

12-0517.docErstelldatum 07.12.2017 13:42:00

www.tuv.com

Seite 17 von 17

Prüfbericht - Nr.: 21177740 006 Page 17 of 17

Test Report No.: 556-12-0517

Parameter according to Tested acc. Requirement Test result Remark

EN ISO 20345 to EN ISO P F N/A N/T

/8.2 20345/ 8.2 in acc. to properties of the footwear: --- N/A

Electrical properties 20345/ 8.2.1 - leaflet for conductive footwear

20345/ 8.2.2 - leaflet for shoes with antistatic given P/*4

properties

20345/ 8.2.3 - leaflet for electrically insulating shoes --- N/A

/8.3 20345/ 8.3 If the footwear is supplied with a given P/*4

Insocks removable insock it should be made

clear in the leaflet that testing was

carried out with the insock in place.

A warning shall be given that the foot-

wear shall only be used with the

insock in place and that the insock

shall only be replaced by a

comparable insock supplied by the

original footwear manufacturer.

If the footwear is supplied without an

insock it should be made clear in

leaflet that testing was carried out with

no insock present. A warning shall be

given that fitting an insock can affect

the protective properties of the

footwear.

Rev. 1 2010-01-01 / approved: D. Knape

12-0517.docErstelldatum 07.12.2017 13:42:00

You might also like

- Safety Compliance Testing For Fmvss No. 218 Motorcycle HelmetsDocument5 pagesSafety Compliance Testing For Fmvss No. 218 Motorcycle HelmetsLiliana GonzálezNo ratings yet

- Steel Toe Cap 459 CertificateDocument3 pagesSteel Toe Cap 459 CertificatelufvijpharmaNo ratings yet

- Ich 3300 DotDocument4 pagesIch 3300 DotOscar Rafael Romero LópezNo ratings yet

- Nova-Eh Saso en P GZHT90868086Document11 pagesNova-Eh Saso en P GZHT90868086arivazhagan aNo ratings yet

- Xone 500GT Dot PDFDocument5 pagesXone 500GT Dot PDFFlor Viviana CASTAÑO VELANDIANo ratings yet

- Safety 60950 Move2500Document224 pagesSafety 60950 Move2500vishalvsinghonlineNo ratings yet

- Actuator Maintenance ServicesDocument7 pagesActuator Maintenance ServicesKevin MuhalingNo ratings yet

- 5ST3740 Datasheet enDocument4 pages5ST3740 Datasheet endanielNo ratings yet

- Dirt SeperatorsDocument46 pagesDirt SeperatorsCletus GonsalvesNo ratings yet

- Casing Stabbing BoardDocument1 pageCasing Stabbing BoardRanjithNo ratings yet

- Packaging Details: Vendor Name & AddressDocument4 pagesPackaging Details: Vendor Name & AddressPk NimiwalNo ratings yet

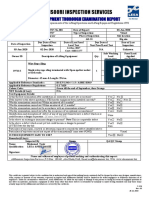

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument2 pagesAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- FORFLEX® 7AI 00 D65-EnDocument2 pagesFORFLEX® 7AI 00 D65-EnRonaldo CamargoNo ratings yet

- Pressure Vessel - Inspectin CertificateDocument3 pagesPressure Vessel - Inspectin CertificateSpectex dubaiNo ratings yet

- Index of Revisions Rev. Description And/Or Revised Sheets: I-PR-3010.94-1400-910-JHB-046Document13 pagesIndex of Revisions Rev. Description And/Or Revised Sheets: I-PR-3010.94-1400-910-JHB-046ThiagoNo ratings yet

- Test Report: Applicant: Kai Li Xin Toys Factory Address: Chenghai District, Shantou City, Guangdong Province, ChinaDocument12 pagesTest Report: Applicant: Kai Li Xin Toys Factory Address: Chenghai District, Shantou City, Guangdong Province, ChinaEdwing Francisco100% (1)

- NFPL D23 09Document2 pagesNFPL D23 09harun bdNo ratings yet

- Ich 3110 DotDocument4 pagesIch 3110 DotAlvaro Ricardo Vargas GutierrezNo ratings yet

- Fenestration Standard/Specification For Windows, Doors, and SkylightsDocument13 pagesFenestration Standard/Specification For Windows, Doors, and SkylightsAndrea Nicola TurcatoNo ratings yet

- 3SB38010AB3 Datasheet enDocument4 pages3SB38010AB3 Datasheet enChineslmNo ratings yet

- Actuator Maintenance ServicesDocument7 pagesActuator Maintenance ServicesKevin MuhalingNo ratings yet

- SCMH 3.2.4 Tie Rod Assembly FAIR Rev New Dated 9AUG2023Document6 pagesSCMH 3.2.4 Tie Rod Assembly FAIR Rev New Dated 9AUG2023GÜRHAN EMİNNo ratings yet

- Testcoo Sample Report-BagDocument20 pagesTestcoo Sample Report-BagraulNo ratings yet

- Has Been Renewed On 17 Jan 2024 For Information Only: Type Approval CertificateDocument4 pagesHas Been Renewed On 17 Jan 2024 For Information Only: Type Approval CertificateDuongthithuydungNo ratings yet

- MI Plan For NDC Expected Order Date 05-06-2018 Rev 1 With VF50 - String 3Document29 pagesMI Plan For NDC Expected Order Date 05-06-2018 Rev 1 With VF50 - String 3EduardNo ratings yet

- 3SU18010AA000AB1 Datasheet enDocument3 pages3SU18010AA000AB1 Datasheet enPeterNo ratings yet

- Document Title: Revision: Vendor Rev.: Facility Identifier: Discipline: Document Type: Project Doc. Number: Vendor Doc. NumberDocument7 pagesDocument Title: Revision: Vendor Rev.: Facility Identifier: Discipline: Document Type: Project Doc. Number: Vendor Doc. Numberrajindo1No ratings yet

- 28399-A-002 Super Sack (00160570)Document1 page28399-A-002 Super Sack (00160570)RanjithNo ratings yet

- Webbing Sling VisualDocument8 pagesWebbing Sling VisualRanjithNo ratings yet

- Pressure Vessel InspectionDocument3 pagesPressure Vessel InspectionSpectex dubaiNo ratings yet

- 3RV19331DA00 Datasheet enDocument2 pages3RV19331DA00 Datasheet enAtlanta BoliviaNo ratings yet

- Safety Harness-2Document15 pagesSafety Harness-2Shirley Sofia Yancapallo CruzNo ratings yet

- 3NA3817 Datasheet enDocument5 pages3NA3817 Datasheet enIrineuNo ratings yet

- Digitron Single Connectors Rev10Document50 pagesDigitron Single Connectors Rev10zym3344No ratings yet

- 150.72-RP1 Ylaa 2Document54 pages150.72-RP1 Ylaa 2José RamosNo ratings yet

- Pgca MR D06 005 - C1 - 2Document90 pagesPgca MR D06 005 - C1 - 2Ami PutraNo ratings yet

- NFPL D23 08Document2 pagesNFPL D23 08harun bdNo ratings yet

- DCL Test Report - Size 12.7 MM - 18-2-2020Document2 pagesDCL Test Report - Size 12.7 MM - 18-2-2020docpt76No ratings yet

- Ylaa0070 - Ylaa0120Document108 pagesYlaa0070 - Ylaa0120Juan David Hurtado CuencaNo ratings yet

- Certificaciones Segpro ArnesDocument17 pagesCertificaciones Segpro ArnesJazmin GonzalesNo ratings yet

- Boil Test 3 Ply GlassDocument6 pagesBoil Test 3 Ply Glassy2kareinNo ratings yet

- Big Bag Ring VisualDocument1 pageBig Bag Ring VisualRanjithNo ratings yet

- P1814AB-F17C1-RVQ-I&A-MST-23-0001-R1 - Installation Cable TrayDocument14 pagesP1814AB-F17C1-RVQ-I&A-MST-23-0001-R1 - Installation Cable TrayAshafik SihapNo ratings yet

- jsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiDocument6 pagesjsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiMon Trang NguyễnNo ratings yet

- CHECKLIST - FORK LIFT UpdatedDocument4 pagesCHECKLIST - FORK LIFT UpdatedAkhilNo ratings yet

- Turn Buckle VisualDocument8 pagesTurn Buckle VisualRanjithNo ratings yet

- Man Rider Winch VisualDocument6 pagesMan Rider Winch VisualRanjithNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument1 pageAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- SCMH 3.2.5 Tie Rod Detail FAIR Rev New Dated 10AUG2023Document9 pagesSCMH 3.2.5 Tie Rod Detail FAIR Rev New Dated 10AUG2023GÜRHAN EMİNNo ratings yet

- Data Sheet281-665 281-400Document9 pagesData Sheet281-665 281-400bala sonyNo ratings yet

- Five Finger Scratch Resistance Test Method: 1.0 GeneralDocument3 pagesFive Finger Scratch Resistance Test Method: 1.0 GeneralJuliano DepetrisNo ratings yet

- J1037 - 201504-Windshield Washer TubingDocument5 pagesJ1037 - 201504-Windshield Washer TubingJicheng PiaoNo ratings yet

- G4Q-0802-01 CLVE of Rubber Expansion Joints & Repair - August 2013Document3 pagesG4Q-0802-01 CLVE of Rubber Expansion Joints & Repair - August 2013prathapNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument1 pageAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- EXXI-4130-00-00-VD-MAN-5251 - 00x-Sellos MecanicosDocument33 pagesEXXI-4130-00-00-VD-MAN-5251 - 00x-Sellos MecanicosrodolfostiNo ratings yet

- LL Certificate PrototypeDocument1 pageLL Certificate Prototypetilakthakar1No ratings yet

- Manual BoschDocument74 pagesManual BoschSERTI S.A.SNo ratings yet

- 01-Flat Webbing 4Document1 page01-Flat Webbing 4Mohamed BarakaNo ratings yet

- EMC TEST - REPORT - FalcomDocument25 pagesEMC TEST - REPORT - FalcomVictor PerezNo ratings yet

- WINDFORCEDocument50 pagesWINDFORCEVictor PerezNo ratings yet

- Xingyuan AnnaiteDocument50 pagesXingyuan AnnaiteVictor PerezNo ratings yet

- Xingyuan AnnaiteDocument50 pagesXingyuan AnnaiteVictor PerezNo ratings yet

- Test ReportDocument10 pagesTest ReportVictor PerezNo ratings yet

- 05 Pastillas FrenoDocument7 pages05 Pastillas FrenoVictor PerezNo ratings yet

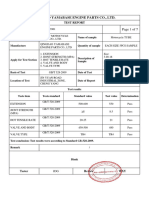

- Qingdao Yamabase Engine Parts CoDocument7 pagesQingdao Yamabase Engine Parts CoVictor PerezNo ratings yet

- Electrical Hazard Resistant Footwear ASTMF2413-11Document3 pagesElectrical Hazard Resistant Footwear ASTMF2413-11Victor PerezNo ratings yet

- IEC60896 (FTHT Battery) Test ReportDocument13 pagesIEC60896 (FTHT Battery) Test ReportVictor Perez100% (1)

- NIC Components NTC-T SeriesDocument10 pagesNIC Components NTC-T SeriesNICCompNo ratings yet

- SJ-20121112095141-003-LTE (V3.10.10) Alarm Handling (FDD) PDFDocument338 pagesSJ-20121112095141-003-LTE (V3.10.10) Alarm Handling (FDD) PDFRahul SharmaNo ratings yet

- Random PDFDocument15 pagesRandom PDFgreeblemeebleNo ratings yet

- DS Mod4Document32 pagesDS Mod4Nikhitha HBNo ratings yet

- LY IR9000 BGA Rework Station User GuideDocument4 pagesLY IR9000 BGA Rework Station User GuidemariabaccaroNo ratings yet

- H Beam Load Bearing CalculationDocument31 pagesH Beam Load Bearing CalculationMuhammad Attiq Ur RahmanNo ratings yet

- 9.shift RegistersDocument36 pages9.shift RegistersJagan GNNo ratings yet

- Modulation Reviewer For ECEDocument171 pagesModulation Reviewer For ECEianneanNo ratings yet

- LucasFilm Sound Effects Library - Track & Index ListDocument22 pagesLucasFilm Sound Effects Library - Track & Index ListKALFER0% (1)

- Alwasy Step Ahead in TechnologyDocument3 pagesAlwasy Step Ahead in TechnologyjtpmlNo ratings yet

- AC DC AcDocument3 pagesAC DC AcPhani KumarNo ratings yet

- Comparacion Planta Meg - TegpdfDocument18 pagesComparacion Planta Meg - TegpdfJulian RomeroNo ratings yet

- Sukrosa PDFDocument5 pagesSukrosa PDFSilvi TatianNo ratings yet

- Power Tool Switches: Catalog 1308650 Issued 1-01Document18 pagesPower Tool Switches: Catalog 1308650 Issued 1-01Gamal AhmadNo ratings yet

- Tally Erp 9.0 Material Control Centre in Tally Erp 9.0Document27 pagesTally Erp 9.0 Material Control Centre in Tally Erp 9.0Raghavendra yadav KMNo ratings yet

- Scania Jenerator DC1372A - 438-487kW PDFDocument2 pagesScania Jenerator DC1372A - 438-487kW PDFMehmet ErenNo ratings yet

- Profimat MT: United Grinding Technologies Blindtext Key DataDocument9 pagesProfimat MT: United Grinding Technologies Blindtext Key DataMiskoNo ratings yet

- SQAP For Pumps 2017Document79 pagesSQAP For Pumps 2017MukeshNo ratings yet

- KMJT's Goldfarming GuideDocument36 pagesKMJT's Goldfarming GuideAnonymous oe4U3HCcNo ratings yet

- The Punjab Factory RuleDocument313 pagesThe Punjab Factory Rulesafety_rliNo ratings yet

- HPSIM Command Line InterfaceDocument107 pagesHPSIM Command Line Interfacegverma80No ratings yet

- 3.re Situation in Suez Canal - M.V EVER GIVEN SUCCESSFULLY REFLOATEDDocument9 pages3.re Situation in Suez Canal - M.V EVER GIVEN SUCCESSFULLY REFLOATEDaungyinmoeNo ratings yet

- Automotive DevicesDocument152 pagesAutomotive DevicesLeticia PaesNo ratings yet

- 2014 - Solved Problems in Facility PlanningDocument135 pages2014 - Solved Problems in Facility Planninghshshdhd86% (7)

- Free and Forced Vibration of Repetitive Structures: Dajun Wang, Chunyan Zhou, Jie RongDocument18 pagesFree and Forced Vibration of Repetitive Structures: Dajun Wang, Chunyan Zhou, Jie RongRajesh KachrooNo ratings yet

- ReadingDocument3 pagesReadingAriana niurka torres arceNo ratings yet

- Traction Motors E WebDocument16 pagesTraction Motors E WebMurat YaylacıNo ratings yet

- Module 4Document8 pagesModule 4ABIGAIL OLAJUMOKE JOSEPHNo ratings yet

- Free Gear Calculator - KHK GearsDocument5 pagesFree Gear Calculator - KHK GearslawlawNo ratings yet

- Effect of Impurities On Freezing and Boiling PointsDocument6 pagesEffect of Impurities On Freezing and Boiling PointssakthivelNo ratings yet