Professional Documents

Culture Documents

T2 Selection and Installation Guide

Uploaded by

Samer ChahroukOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

T2 Selection and Installation Guide

Uploaded by

Samer ChahroukCopyright:

Available Formats

T2 Selection and Installation Guide

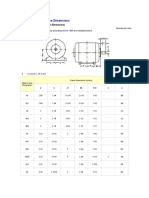

1) Select valve body and orifice size 2) Assemble the orifice and valve body and install into system

T2 type expansion valves are designed for flare connections. To make a functioning valve, Orifice and System Installation

pair the appropriate valve body and orifice using the charts below. 1) Slide the orifice into the valve body and secure using liquid line flare nut.

IF THE EXACT SYSTEM CAPACITY CANNOT BE FOUND, USE THE NEXT LARGER ORIFICE. 2) Attach evaporator inlet or distributor assembly to valve outlet flare nut.

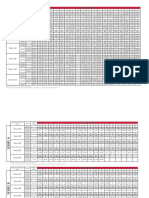

R22 Evap. Temperature (°F) Tighten both flare nuts to 26 - 33 ft lbs.

1 Orifice Code 45 35 25 0 -10 -20 -30 -40

Valve Body

Size Number Rated Capacity in Tons (TR)2

1/10 1/10 1/10 1/10 1/10 1/10 1/10 1/10

0x 068-2002

1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 Torque Requirements

1/6 1/6 1/6 1/6 1/6 1/6 1/6 1/6 26-33 ft-lb

00 068-2003

1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4

(35-45Nm)

1/2 1/2 1/2

01 068-2010 1/2 1/2 1/2 1/4 1/4

TX 2 TEX 2 3/4 3/4 3/4

068Z3206 068Z3209 02 068-2015 1 1 1 3/4 3/4 3/4 1/2 1/2

1 3/4 3/4

03 068-2006 2 2 2 1 1

1 1/2 1 1

Superheat Adjustment

04 068-2007 3 3 3 2 2 2 1 1/2 1 1/2

05 068-2008 4 4 3 1/2 3 2 1/2 2 1/2 2 2 1) Remove the cap.

06 068-2009 5 5 4 1/2 3 1/2 3 3 2 1/2 2 1/2 2) Make superheat adjustments ¼ turn at a time (1 turn=7°F). Turning clockwise

increases superheat. Turning counter-clockwise decreases superheat.

R404A / R507 Evap. Temperature (°F)

3) Reinstall the cap.

1 Orifice Code 45 35 25 0 -10 -20 -30 -40

Valve Body

Size Number Rated Capacity in Tons (TR)2

1/10

0x 068-2002 1/10 1/10 1/10 1/10 1/10 1/10 1/15

1/8

1/6 1/8 1/8 1/8 1/8 1/8 1/8 1/10

00 068-2003

1/4 1/6 1/6 1/6 1/6 1/6 1/6 1/8

1/4

01 068-2010 1/2 1/4 1/4 1/4 1/4 1/4 1/6

1/2

TS2 TES 2

02 068-2015 3/4 1/2 1/2 1/2 1/4 1/4 1/4 1/4

068Z3400 068Z3403

3/4 3/4 1/2

03 068-2006 1 3/4 1/2 1/2 1/2

1 1 3/4

3/4 1) Thermostatic element with

04 068-2007 2 2 1 1/2 1 1 3/4 3/4

1 diaphragm

05 068-2008 2 1/2 2 2 1 1/2 1 1/2 1 1 1 2) Interchangeable orifice

06 068-2009 3 3 2 1/2 2 1 1/2 1 1/2 1 1 assembly

3) Valve body

R134a Evap. Temperature (°F) 4) Setting spindle for adjustment

Orifice Code 45 35 25 0 -10 -20 -30 -40 of static superheat SS

1

Valve Body

Size Number Rated Capacity in Tons (TR)2

1/10 1/10 1/10

0x 068-2002 1/10 1/10 1/10 1/10 1/10

1/8 1/8 1/8

1/6 1/6 1/6 1/6 1/6 1/6

00 068-2003 1/6 1/6

1/4 1/8 1/8 1/8 1/8 1/8

1/4

01 068-2010 1/2 1/4 1/4 1/4 1/4 1/6 1/6

TN 2 TEN 2 1/2

068Z3346 068Z3348 02 068-2015 3/4 1/2 1/2 1/2 1/4 1/4 1/4 1/4

1/2

03 068-2006 1 3/4 1 3/4 1 3/4 1/2 1/2 1/2

3/4

04 068-2007 2 1 1/2 1 1/2 1 1 3/4 3/4 3/4

05 068-2008 2 1/2 2 2 1 1/2 1 1 1 1

06 068-2009 3 2 1/2 2 1/2 2 1 1/2 1 1/2 1 1

1

Valve Body - Internal: 3/8" X 1/2" ODF - External: 3/8" X 1/2" w/ 1/4" ODF Equalizer USCO.PI.AA0.A1.22 / 521U0165 ©Danfoss 2010

2

Capacities are based on a condensing temperature of 90 °F and a vapor free liquid temperature of 80 °F ahead of the expansion valve.

You might also like

- Fishing ManualDocument152 pagesFishing Manualnabi100% (1)

- Everything You Need to Know About Steel WashersDocument2 pagesEverything You Need to Know About Steel WashersTarunNo ratings yet

- MKT-001 Rev 02 Rotary Shoulder Handbook RSDocument116 pagesMKT-001 Rev 02 Rotary Shoulder Handbook RSArsalan AhmadNo ratings yet

- Stud Bolt ChartDocument2 pagesStud Bolt ChartDI DI100% (1)

- Driscal-D Polymer QMAXDocument1 pageDriscal-D Polymer QMAXAnonymous vSLFJCNNo ratings yet

- Oil Field Data HandbookDocument148 pagesOil Field Data HandbookUnknowneon100% (2)

- Flange Data: Bolt Reference Charts For ASME B16.5 FlangesDocument4 pagesFlange Data: Bolt Reference Charts For ASME B16.5 FlangesMilena Lemus FonsecaNo ratings yet

- Quotation Form KAESER SC2IOM-1: Device DescriptionDocument1 pageQuotation Form KAESER SC2IOM-1: Device DescriptionSamer ChahroukNo ratings yet

- 3G Antenna TypeDocument5 pages3G Antenna TypeynsmekalNo ratings yet

- NH3 Process DescriptionDocument8 pagesNH3 Process DescriptionMusa KaleemNo ratings yet

- Cold Room CalculatorDocument3 pagesCold Room CalculatorSamer ChahroukNo ratings yet

- Lab Report Spray DryerDocument4 pagesLab Report Spray DryerOh Hui XuanNo ratings yet

- 300# RF Piping Dimensions ChartDocument148 pages300# RF Piping Dimensions Chartrerezhassan100% (1)

- Oil / Chemical Tanker Instruction Manual: Controlled Copy #03Document381 pagesOil / Chemical Tanker Instruction Manual: Controlled Copy #03Nikita GalinNo ratings yet

- API_Specification_7-1_Addendum_1_20201221Document11 pagesAPI_Specification_7-1_Addendum_1_20201221deepeshtNo ratings yet

- AcopleDocument5 pagesAcoplecesarNo ratings yet

- Appendix C' Continuous Welding Rail Thermal Expansion: The City of Winnipeg Bid Opportunity No. 712-2013Document2 pagesAppendix C' Continuous Welding Rail Thermal Expansion: The City of Winnipeg Bid Opportunity No. 712-2013didbeauNo ratings yet

- 4140 Prehard/Annealed: AlloyDocument2 pages4140 Prehard/Annealed: AlloyJason CarterNo ratings yet

- Sch80ctech SDL80C TDocument9 pagesSch80ctech SDL80C Thumberto.aranguiz2715No ratings yet

- Litek Product Catalogue - ANSI - 2018Document24 pagesLitek Product Catalogue - ANSI - 2018prateekmuleNo ratings yet

- 8.13 - Glycol Heat Tracing 11Document1 page8.13 - Glycol Heat Tracing 11Greg EverettNo ratings yet

- Conversion: Nozzle KitDocument2 pagesConversion: Nozzle Kitdonhan91No ratings yet

- Inspection Reports Against TESCO PO No. 483-89Document16 pagesInspection Reports Against TESCO PO No. 483-89Farhan IlyasNo ratings yet

- LOAD AND TORQUE CHART FOR BOLTS AND STUDSDocument6 pagesLOAD AND TORQUE CHART FOR BOLTS AND STUDSlucianaNo ratings yet

- TorqueDocument6 pagesTorquelucianaNo ratings yet

- Fig. Ptp-1: Short Variable SpringDocument1 pageFig. Ptp-1: Short Variable Springali murtadhoNo ratings yet

- As SPT FS Sy EqrDocument2 pagesAs SPT FS Sy EqrAndreyNo ratings yet

- Pneumatic Components OverviewDocument8 pagesPneumatic Components OverviewHernandez Rodriges Alexis BryamNo ratings yet

- Feeder "Te" Rotary (Airlock) : ApplicationDocument5 pagesFeeder "Te" Rotary (Airlock) : ApplicationzementheadNo ratings yet

- Tube OD NPT Size Basic Ordering Number: 1 In./25 MM and UnderDocument1 pageTube OD NPT Size Basic Ordering Number: 1 In./25 MM and UnderLeonardNo ratings yet

- Patton Line Size - 2014Document6 pagesPatton Line Size - 2014Rocky James AsildoNo ratings yet

- Nema Electrical Motors FrameDocument11 pagesNema Electrical Motors FrameLuckie IbrahimNo ratings yet

- Manual Processing Methods and Times for TRI-X 400 FilmDocument4 pagesManual Processing Methods and Times for TRI-X 400 FilmAnaNo ratings yet

- PTP Hd-1: Hold Down (Anchor Type)Document1 pagePTP Hd-1: Hold Down (Anchor Type)bayzuraNo ratings yet

- Anchor Type PTP HD-1Document1 pageAnchor Type PTP HD-1ELINo ratings yet

- Slip On Flange RTJ GasketDocument2 pagesSlip On Flange RTJ GasketEDAC RFCLNo ratings yet

- Wire Rope CapacitiesDocument1 pageWire Rope CapacitiesJose DiazNo ratings yet

- Catalogo UniflexDocument8 pagesCatalogo UniflexsetsuNo ratings yet

- Thermal Expansion Valves GuideDocument3 pagesThermal Expansion Valves GuidercbandeiraNo ratings yet

- World Flange StandardsDocument10 pagesWorld Flange StandardsIsaac KendallNo ratings yet

- L6004DDocument8 pagesL6004DmaldomattNo ratings yet

- Thermoplastic Flanges: Technical Information Weights & DimensionsDocument11 pagesThermoplastic Flanges: Technical Information Weights & DimensionsANDERSON NERESNo ratings yet

- Fig100 TPI UboltDocument1 pageFig100 TPI UboltYotselys LópezNo ratings yet

- 1.4 Male Tube Adapter 12mmOD X 0.25 Inchi NPT SS316 SwagelokDocument2 pages1.4 Male Tube Adapter 12mmOD X 0.25 Inchi NPT SS316 SwagelokumarNo ratings yet

- Plus X 125 Manual Processing Small-Tank Processing (8-Or 16-Ounce Tank)Document3 pagesPlus X 125 Manual Processing Small-Tank Processing (8-Or 16-Ounce Tank)AnaNo ratings yet

- Bearings - Boston GearDocument7 pagesBearings - Boston GearJames GreenNo ratings yet

- Piping Valve Flange DimensionsDocument270 pagesPiping Valve Flange DimensionschadNo ratings yet

- Turftech Turf Ovr T Ettf-1 TDocument7 pagesTurftech Turf Ovr T Ettf-1 TSony CNo ratings yet

- Ser & TSRDocument8 pagesSer & TSRSAMO THERMALNo ratings yet

- l19146 Xa02uen E1 CombinedDocument41 pagesl19146 Xa02uen E1 CombinedErik HansonNo ratings yet

- T-Seals: Product DescriptionDocument5 pagesT-Seals: Product DescriptionHamdi SaidNo ratings yet

- ASME and ANSI B16.5 Flanges and Bolt Dimensions Class 150 To 2500Document8 pagesASME and ANSI B16.5 Flanges and Bolt Dimensions Class 150 To 2500elias2505No ratings yet

- Technical-Guides Shackle Inspection Spa 2003Document1 pageTechnical-Guides Shackle Inspection Spa 2003israel11288No ratings yet

- ASME and ANSI B16.5 Flanges and Bolt Dimensions Class 150 To 2500Document8 pagesASME and ANSI B16.5 Flanges and Bolt Dimensions Class 150 To 2500Swaminathan ThayumanavanNo ratings yet

- Technical Bulletin: Hydraulic SnubbersDocument5 pagesTechnical Bulletin: Hydraulic SnubbersDavid Luna MolinaNo ratings yet

- L Series BrochureWebDocument16 pagesL Series BrochureWebmadhavikNo ratings yet

- XR734Document4 pagesXR734kohilanrkNo ratings yet

- Blind RTJ FlangeDocument7 pagesBlind RTJ FlangeAMIRHUSAIN MOMINNo ratings yet

- FKC Lake Shore Rope AttDocument8 pagesFKC Lake Shore Rope AttFelipe SantibáñezNo ratings yet

- P 1483 BG - pg10 16Document7 pagesP 1483 BG - pg10 16Larry Vilca DelgadoNo ratings yet

- Par de Apriete en BridasDocument1 pagePar de Apriete en BridasJose Humberto ArandaNo ratings yet

- Orifice Flange Set: Flow Measurement DevicesDocument1 pageOrifice Flange Set: Flow Measurement DevicesDavigote Focker LeeNo ratings yet

- Torque (N-M) For Class 150 Asme B16.5 Raised Face Flanges (Sheet Gaskets - Ptfe Fluoropolymer Coated Fasteners)Document2 pagesTorque (N-M) For Class 150 Asme B16.5 Raised Face Flanges (Sheet Gaskets - Ptfe Fluoropolymer Coated Fasteners)vesselyNo ratings yet

- Flange Size TableDocument1 pageFlange Size Tablediana.isbalNo ratings yet

- Fine Particle (2.5 microns) Emissions: Regulations, Measurement, and ControlFrom EverandFine Particle (2.5 microns) Emissions: Regulations, Measurement, and ControlNo ratings yet

- KS75 40Document5 pagesKS75 40Samer ChahroukNo ratings yet

- Service Manual for Classic Control WashersDocument76 pagesService Manual for Classic Control WashersSamer ChahroukNo ratings yet

- Model:AJE4519ZFZ (CAJ4519Z) : Technical Data SheetDocument1 pageModel:AJE4519ZFZ (CAJ4519Z) : Technical Data SheetSamer ChahroukNo ratings yet

- Doc348350573022 PDFDocument24 pagesDoc348350573022 PDFZahir KhiraNo ratings yet

- Parts Customization - Ice Making Machine 175/75 Top Cover of Ice Making Machine 84X84 CM To Ply and Fill With Thermal Isolation FoamDocument1 pageParts Customization - Ice Making Machine 175/75 Top Cover of Ice Making Machine 84X84 CM To Ply and Fill With Thermal Isolation FoamSamer ChahroukNo ratings yet

- DSE60xx MKII Operators ManualDocument100 pagesDSE60xx MKII Operators ManualJan AhmedNo ratings yet

- DS Download Instructions PDFDocument8 pagesDS Download Instructions PDFShaikh DanishNo ratings yet

- Technical Data SheetDocument1 pageTechnical Data SheetSamer ChahroukNo ratings yet

- Caterpillar ElectricalDocument17 pagesCaterpillar ElectricalJuanDiegoNo ratings yet

- Technical Data SheetDocument1 pageTechnical Data SheetSamer ChahroukNo ratings yet

- Module Configuration Parameters OverviewDocument2 pagesModule Configuration Parameters Overviewedgarcoo100% (1)

- Js Series: 1 Pole-8 ADocument8 pagesJs Series: 1 Pole-8 ASamer ChahroukNo ratings yet

- Calculate Capacitor Size to Improve Power FactorDocument2 pagesCalculate Capacitor Size to Improve Power FactorSamer ChahroukNo ratings yet

- Cable Size CalculatorDocument13 pagesCable Size CalculatorSamer ChahroukNo ratings yet

- Common Pharma Interview Questions For FreshersDocument6 pagesCommon Pharma Interview Questions For Freshersrameshwar9595kNo ratings yet

- TP-AATM 106b-A Moisture Karl Fischer MethodDocument2 pagesTP-AATM 106b-A Moisture Karl Fischer MethodRafael LugoNo ratings yet

- General Biology 1 (Factors Affecting Enzymes)Document4 pagesGeneral Biology 1 (Factors Affecting Enzymes)Jean Dacles100% (1)

- Pozzolanic Reactions of Six Principal Clay Minerals Activaction, Reactivity Assesments and Technological EffectsDocument12 pagesPozzolanic Reactions of Six Principal Clay Minerals Activaction, Reactivity Assesments and Technological EffectsDIAZCORDOBANo ratings yet

- 15B Le Chateliers PrincipleDocument2 pages15B Le Chateliers PrincipleJasmine KeirouzNo ratings yet

- Organic Spectroscopy and Chromatography by M Younas Third EditionDocument377 pagesOrganic Spectroscopy and Chromatography by M Younas Third EditionjoaoDjmsNo ratings yet

- Ftre 2023 Sample Paper Class X p2 PCMDocument19 pagesFtre 2023 Sample Paper Class X p2 PCMpriyagvspv100% (1)

- Enzymatic Assay of XYLANASE (EC 3.2.1.8) PrincipleDocument4 pagesEnzymatic Assay of XYLANASE (EC 3.2.1.8) Principlesyaza amiliaNo ratings yet

- Diagrama R 1234 YfDocument1 pageDiagrama R 1234 YfMaríaNo ratings yet

- BARIUM CHLORIDE GuideDocument5 pagesBARIUM CHLORIDE GuideDaphne Lianne DegayNo ratings yet

- Angus - Case - Ex20.003-E4 Dmmopa TDS 092519Document2 pagesAngus - Case - Ex20.003-E4 Dmmopa TDS 092519Mauro Di FraiaNo ratings yet

- Bmac4E02: Modern Analytical InstrumentationDocument22 pagesBmac4E02: Modern Analytical InstrumentationSachin ashokNo ratings yet

- Clinical Chemistry (Electrolytes)Document27 pagesClinical Chemistry (Electrolytes)2B SALVADOR Jamaica C.No ratings yet

- Choosing a Property Method for Distillation SimulationsDocument33 pagesChoosing a Property Method for Distillation SimulationsSheraz FiazNo ratings yet

- Pharmaceutical Process Scale Up Case StudyDocument8 pagesPharmaceutical Process Scale Up Case StudypratikNo ratings yet

- List of Koc STD RP 015 SeriesDocument5 pagesList of Koc STD RP 015 SeriesEr Md AamirNo ratings yet

- Myths Human GeneticsDocument72 pagesMyths Human GeneticsfukusacoNo ratings yet

- Guggenheim 1935Document57 pagesGuggenheim 1935Niraj ThakreNo ratings yet

- A Comparative Pharmaceutico-Analytical Study of Punarnasava and PunarnarishtaDocument5 pagesA Comparative Pharmaceutico-Analytical Study of Punarnasava and Punarnarishtaalnrmamckoppa19No ratings yet

- Molecular Basis of Inheritance: DNA Structure and ReplicationDocument31 pagesMolecular Basis of Inheritance: DNA Structure and ReplicationMamataMaharanaNo ratings yet

- Monday 4 May 2020: BiologyDocument20 pagesMonday 4 May 2020: Biologycye23No ratings yet

- Chemical Reaction - WikipediaDocument10 pagesChemical Reaction - WikipediaMala DeviNo ratings yet

- Year 9 Worksheet on Mixtures and Melting PointsDocument2 pagesYear 9 Worksheet on Mixtures and Melting PointsAlric DsouzaNo ratings yet

- Alumigrip 4400 Base Coat Application Process InstructionDocument4 pagesAlumigrip 4400 Base Coat Application Process InstructionLjubomirSinđelićNo ratings yet

- The Main Steps of The Manufacturing Process: Synthetic Rubber GlovesDocument3 pagesThe Main Steps of The Manufacturing Process: Synthetic Rubber GlovesLEE LEE LAUNo ratings yet