Professional Documents

Culture Documents

Advantages of Pre-Engineered Building Over Conventional Building

Uploaded by

Maricar GaculaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Advantages of Pre-Engineered Building Over Conventional Building

Uploaded by

Maricar GaculaCopyright:

Available Formats

International Journal of Innovative Technology and Exploring Engineering (IJITEE)

Advantages of Pre-Engineered Building overISSN: 2278-3075,Building

Conventional Volume-9 Issue-3, January 2020

Advantages of Pre-Engineered Building over

Conventional Building

Rajnandan Verma, Raghvendra Singh

Dr.Raghvendra Singh Professor of Civil Engineering Department,

Abstract: In these days, the cost and time of construction is in Ujjain Engineering College, Ujjain, M.P. India,

more priority for the client with the large working area for

various uses. For the economically and minimum loss

of material, pre-engineered building system (PEBs) has

many advantage, because it gives more column free space at low

cost. Pre-engineered metal buildings are more reliable for various

uses like complex industrial facilities, warehouses

and distributioncenters, stock-house, shopping malls, resort,

motor court, office, cabin, service complex, aircraft-hanger,

athletics and fun stadium, study places, temples, hospitals, and

any types of industrial structures. In the pre-engineered metal

building system, the rigid frame consists of slab, wall are

connected with primary member (beam and column). This frame

can spanlarge spacing without any intermediate columns. The

frameswidths are spaced at spacing between 15 m to 60 m and

span can increase with column-free up to 300 m in proposed

building structures. Therefore in this paper, an attempt has been

made to analyze a pre-engineered metal building with a span of

40 m with the help of finite element based software ETABS

(2013). For the comparison, for the same span of 40 m

length a conventional steel building is analyzed in same

software. The results were found from both analysis

indicated the pre-engineered steel building is economic with

the conventional steel building as well as stablealso.

Keywords: Pre-engineered metal building,

Conventional building, ETAB

I. INTRODUCTION

The efficient and economic construction over conventional

method of building construction Pre-engineered building

(PEB) system were induced. the concept of pre-engineered

steel metal building systemmade over all

structural component like, beam, column, purlin, rafter as

well as roof wall sheeting, primary members, secondary

members, connected with each other and different

structural components [Ref.8 and 9]. Thistechnology is

a built, structure with precast and prefabricated members

which are erected at site. Pre-engineered steel buildings are

mainly low height buildings which are useful for

residential building, show-rooms, shopping malls etc.

[Ref.2].The PEBs system are very economical and faster

to application for the low height buildings, with this

system the construction time is reduced about half than

conventional Steel building. Although pre- engineered

steel building are widely used for any industrial purpose

building or non-residential building construction

globalized, In India, it is now new structural concept.

[Ref.3and4].Now a days, large spaced area is the

uttermost requirement for any type of industry and with the

approach of computer software’s it is now easily possible.

Revised Manuscript Received on January 05, 2020.

Correspondence Author

Rajnandan Verma,Computer Aided Structural Designing and Drafting,

Civil Engineering Department, Ujjain Engineering College, Ujjain,

M.P. India,

Retrieval Number: C8954019320/2020©BEIESP Published By:

DOI: 10.35940/ijitee.C8954.019320 Blue Eyes Intelligence Engineering

2564 & Sciences Publication

International Journal of Innovative Technology and Exploring Engineering (IJITEE)

Advantages of Pre-Engineered Building overISSN: 2278-3075,Building

Conventional Volume-9 Issue-3, January 2020

With the improvement in technology, computer

software’s have contributed immensely to the

enhancement of quality of life through new researches.

Pre-engineered building (PEB) is one of such revolution.

“Pre-engineered buildings” are fully fabricated in the factory

in the robotic manner after designing, then transported to the

site directly in completely knocked down (CKD) condition

and all components are assembled and erected with

connection like, nut-bolts, hence it reducing the time of

completion[Ref.1 and 7].

With increased significance on the green buildings ensuring

sustainable construction, the PEB structures are designed

with a high proportion of recycled content making

them lighter in weight by about 30% to 40% than

the conventional steel buildings (CSB). Since the PEB

system based construction technique is contributing the

ultimate modernization with high-technology and faster

methods of construction ensuring efficient, cost

effectiveness and speedy completion of projects [Ref.3, 4

and 6]. As a result today the PEB system is the most favored

choice among the consultant, architects, builders,

developers, and industrialists.

A. PEBs Structural Members Concept

Pre-engineered buildings use a prearranged supply of

raw materials in lighter weight that has verified over

time to satisfy a broad range of structural and unique

esthetic design requirements. This flexibility allows PEBs

to fulfill and almost unlimited range of building

configurations, custom design, requirements and

applications. The pre-engineered steel building is a

building shell utilizing three distinct product categories

as:

Built-up “I” shaped primary structural

framing members(columns and rafters) Refer fig. 1 Cold-

formed “Z” and “C” shaped secondary structural members

(roof purlin, eave struts and wall grits) Refer fig. 2Roll

formed profiled sheeting (roof and wall panels) Refer fig 3

...

Retrieval Number: C8954019320/2020©BEIESP Published By:

DOI: 10.35940/ijitee.C8954.019320 Blue Eyes Intelligence Engineering

2565 & Sciences Publication

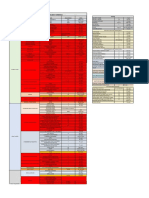

B. Comparison Between Pre-Engineered Building

System And Conventional Building System (Table

1 and fig.4)

Fig.4 Difference between PEBs and Conventional steel

building

Table 1: Comparison between PEBs and Conventional

steel building

Function Pre-engineered Conventionalbuilding

Type Building system

system(PEBs) (CSBs)

Fig.1 Built-up “I” shaped primary structural framing Cost and time of They are 20% more

members. construction are expensive than PEBs.

calculated based Building construction

1.Construction upon extensive cost and time are not

cost and time experience with estimated accurately in

similar building. advance.

30% cost is

reduced in

overall.

In PEBs, Section and members

Primary framing have constant cross-

member are section, are selected

Fig.2 cold-formed “Z” and “C” tapered, so the from standard hot

system is about rolled I-section as the

30 to 40% Primary steel members

advantages for so they are heavier

2.Building the main rigid than what is actually

weight frame than required

conventional hot

rolled section as

primary member

3.Delivery to Approx.42 to 56 Approx. 140 to 182

site days days.

designis Simple Extensive, foundation

and easily required is heavy in

4.Foundation

constructed with weight

light weight

foundation

Fig.3 Roll-formed profiled sheeting Shaped secondary

member

Retrieval Number: C8954019320/2020©BEIESP Published By:

DOI: 10.35940/ijitee.C8954.019320 Blue Eyes Intelligence Engineering

2565 & Sciences Publication

International Journal of Innovative Technology and Exploring Engineering (IJITEE)

Advantages of Pre-Engineered Building overISSN: 2278-3075,Building

Conventional Volume-9 Issue-3, January 2020

The less-weight Do not perform well in Importance factor 1.5

5.Eartquake flexible frames seismic zones because

Response reduction factor 5

resistance produced higher of heavy in weight and

resistance rigid

seismic forces.

Aesthetic Architectural design

6.Architectural architectural required for each

design and project in the

appearance appearancecan consideration of

be achieved at esthetic appearance.

low cost.

Building is Many source of supply

supplied is required to co-

7.Source of

complete with ordinates suppliers and

material and

cladding and all contractors.

component

accessories,

from one single Fig.5 Pre-engineered building with tapered member

source

It is not possible to Table3:Pre-engineered building members

Designed and

8.Quality fabricated at control the quality S.no Structural steel member Section

control single in-house because there are properties

unit with strict many sources and

1 Frame rafter Tapered I

quality control many manufactures.

1(prismatic1200_750mm) section

2 Frame Tapered I

II. PROCESS OF MODELLING

rafter2(prismatic750_900mm) section

In the present attempted a three dimensional single

3 Frame Tapered I

storey industrial frame havingsymmetry along X and Y

rafter3(prismatic900_750mm) section

direction and rectangle (110m X 40m) in shape is considered

(Table

2: Description of building). Steel frame having tapered “I” 4 Frame rafter4 I section

section is used in pre-engineered frame model 750mm

(Table 3:Pre-engineered building members)and standard hot 5 Frame purlin and gable end purlin ISMC_350

rolled “I section” constant cross section are used in

6 End column(prismatic350_900mm) Tapered I

conventional steel frame model (Table 4: Conventional steel

section

building members).For the bracings (X-type) 25mm

diameter of steel rod is used in both of the model. The 7 Centre column ISMB350

structure having fixed support and all joints 8 Bracings (X-Type) 25mm dia of

designed asperfectly rigid.IS: 875-1987 (Parts – I to steel rod

V),IS: 1893-

2002, andIS: 800-2007 are used in the process of calculating

forces and load (national codes).

Table 2:Description of building

Location Ujjain

Length 110m

Width 40

Eave height 9

Seismic zone II

Wind speed 39m/s

Wind terrain category 2

Wind class C Fig.6 conventional steel building

Life span 50years

Slope of roof 1 in 10

Soil type Medium

Retrieval Number: C8954019320/2020©BEIESP Published By:

DOI: 10.35940/ijitee.C8954.019320 Blue Eyes Intelligence Engineering

2566 & Sciences Publication

Table 4: Conventional steel building members purlin

S.no Structural steel member Section properties Outer 184.9 1015.902 26 26413.452

1 Frame rafter ISLB900 frame

column

2 Purlin ISLB500

Center 101.2 714.891 13 9293.583

3 End column ISWB6002 frame

4 Centre column ISWB450 column

5 Bracings (X-Type) 25x200mm Rec. Gable 101.2 579.856 4 2319.424

steel Plate end

column1

LOAD COMBINATIONS Gable 101.2 659.288 4 2637.154

end

In the limit state design of steel structure, load combination column2

istaken as per clause no. 6.3.1.1of IS 1893(Part I):2002 and

IS800:2007. Gable 95.5 374.791 6 2248.751

end

(DL+LL) (DL+WL/EL)

purlin1

(DL+0.8LL+0.8WL/EL)

1.5(DL+LL) Gable 95.5 378.142 4 1512.570

1.5(DL+WL/EL) end

(0.9DL+1.5WL/EL) purlin2

1.2(DL+LL)+0.6WL/EL Gable 95.5 375.631 4 1502.526

1.2(DL+LL+WL/EL) end

(1.2DL+0.5LL+2.5EL) purlin3

(0.9DL+2.5EL)

1.7 (DL+LL) Gable 95.5 451.991 4 1807.966

1.3 (DL+LL +EL_X) end

1.3 (DL+ LL –EL_X) rafter 1

1.3 (DL+ LL +EL_Y) Gable

1.3 (DL+ LL –EL_Y) 95.5 527.324 8 4218.598

end

1.7 (DL+EL_X) rafter 2

1.7 (DL–EL_X) Bracings 50 - - 27022.68

1.7 (DL+EL_Y)

1.7 (DL–EL_Y) Truss 83.1+21.1 1831.691 22 40297.20

(DL denotes (Dead Load) and EL_X/EL_Y denotes

Earthquake load in X-direction and Y-direction

Total weight (kg) 311879.68

WL, wind load respectively

Table 6:Pre-engineered building steel take off

III. RESULTS AND DISCUSSION Structure Cross Weight Number Cumulative

Member Section Of

Table5 and table6 shows the design weight of structure and Of Weight

Area Single

total steel take off and reduction of steel in pre-engineered 2 Member (Kg)

(cm ) Member

building(Table 6:Pre-engineered building steel take (kg)

off)comparison with conventional steel building(Table 5:

Conventional building steel take off). Tapered 295.25 1552.447 22 34153.836

rafter 1

Table 5:Conventional building steel take off

Tapered 275.75 1449.914 22 31898.121

Structure Cross Weight Number Cumulative rafter 2

Member Section Of Of Weight

Area Single Tapered 275.75 725.065 22 15951.441

Member (kg)

2

(cm ) Member rafter 3

(kg) Tapered 266 699.428 22 15387.428

Frame 335.5 1764.084 44 77619.726 rafter 4

Rafter1

Frame 53.7 421.49 90 37934.444

Frame 335.5 882.174 44 38815.656 purlin

Rafter2

Tapered 151.14 830.413 26 21590.750

Frame 95.5 749.58 90 67462.55 outer

Retrieval Number: C8954019320/2020©BEIESP Published By:

DOI: 10.35940/ijitee.C8954.019320 Blue Eyes Intelligence Engineering

2567 & Sciences Publication

International Journal of Innovative Technology and Exploring Engineering (IJITEE)

ISSN: 2278-3075, Volume-9 Issue-3, January 2020

column IV. CONCLUSION

Basically in pre- engineered building the sections used

are built up sections and built-up member are specified by

Center 89.4 631.534 13 8209.946 the designer when the desired properties or configuration

column cannot be obtained in a single hot-rolled section. In this

pre- engineered steel building 38.47% steel weight is

Gable 266 1258.950 4 5035.802 reduced. Built-up section can be bolted or Welded, in

end

general it is less expensive because much less handling is

rafter1

required in the shop and because of more efficient

Gable 266 1468.779 8 11750.233 utilization ofmaterial. The clean lines of welded members

end also produce a better appearance.

rafter

REFERENCES

Gable 89.4 512.24 4 2048.97 1. Anderson J.P & MARC, “Guide for the Design &construction of Pre-

end engineered Building”, The Association for Iron & steel Technology,

coulmn1 2003, technical report 13.

2. Anbuchezian A, Dr. Baskar. G, “Experimental Study on Cold Formed

Gable 89.4 582.414 4 2329.659 Steel Purlin Section”, IRACST-Engineering Science and Technology:

end An International journal (ESTIJ), ISSN: 2250-3498, Vol.3, No.2,

April 2013

coulmn2 3. Bradley A.k, “pre-engineered building”, JFE Civil Engineering &

Gable Construction, Vol-2, 1970, pp. 25-46.

53.7 210.746 6 1264.481 4. G. Sai Kiran, A. Kailasa Rao, R. Pradeep Kumar- “Comparison

end of

purlin1 Design Procedure for PEBs”.

5. Muhammad Umair Saleem, “Minimum Weight Design of

Gable 53.7 212.630 4 850.523 Pre- engineered steel building structures using Built-up Section and

end Cold Formed Sections”, Advanced Material Research Vol 684

purlin2 (2013) PP

125-129

Gable 53.7 211.218 4 844.875 6. Lipson S.L, “History of Pre-engineered Building”, JFE Civil

end Engineering & construction, Vol-1, 1962,pp. 9-25.

purlin3 7. Wei-Wen Yu , “Cold Form Steel Structure”, Mc Graw Hill

Book

Company, 1973,pp.25-46.

8. C.M. Meera, “Pre-engineered building Design of an Industrial

Warehouse”, International Journal of Engineering & Emerging

Bracings 4.9 - - 2647.901 Technologies, June 2013 Volume 5, issue 2, pp 75-82

9. Dr. A. N. Sarkar “Innovations in designing Pre- engineered Building

Total weight (kg) 191898.41 part 1” Asia-Pacific Institute of Management, New Delhi.

The structural design and comparative analysis of a

industrial steel frame has been done with very effective and NATIONAL CODES

1. IS: 875-1987 (Parts – I to V), Indian Code of Practice for

user friendly software ETAB. A typical steel frame is

evaluating loads excepting earthquake load, BIS New

analysed with both the concept (PEBs and CSB) in all Delhi.

structural and loading criteria and the results were obtained 2. IS: 1893-2002, Criteria for the Seismic design of

as following in table7. structures subjected to earthquake loads, BIS New Delhi.

3.IS: 800-2007, Indian Code of Practice for general construction in steel,

Table 7: ETAB Software analysis results comparison BIS New Delhi.

Sl. Structural PEBs CSBs AUTHORS PROFILE

No. description

1 Total steel take off 191898.41 311879.68 Rajnandan verma, PG Scholar, Doing his

Master of Engineering (ME) in Computer Aided

(kg) Structural Design & Drafting (CASDD) at

2 Maximum Ujjain Engineering, College, Ujjain. Teaching

5.2 9.4 Experience 2years, Research paper:1 national

deflection (mm) conference, Email id: rv51364@gmail.com

3 Maximum shear 463.23 546.41 Dr Raghvendra Singh (M Tech, PhD (Geotechnical

force (kN) Engg.), IIT Kharagpur)

Professor, Department of Civil Engineering

4 Maximum moment 160.45 204.71 22 years teaching experience, 12 year research

(kN-m) experience, Guide: 20 B Tech., 20 M Tech., 02 PhD

students, Research papers: 25 national & international journal, 35 national

5 Axial force (kN) 387.78 542.43 & international conferences.

One ASCE paper was nominated for final selection.

6 Maximum storey 13445.72 16762.54 Email id:raghvendr@gmail.com

force (kN)

7 Maximum column 342.94 573.88

force (kN)

Retrieval Number: C8954019320/2020©BEIESP Published By:

DOI: 10.35940/ijitee.C8954.019320 Blue Eyes Intelligence Engineering

2568 & Sciences Publication

You might also like

- Analysis Design of Pre-Engineered Building Using Is 8002007 International Standards-00Document40 pagesAnalysis Design of Pre-Engineered Building Using Is 8002007 International Standards-00PRATIK ATWALNo ratings yet

- 'Analysis, Design and Comparison of Composite Material Decking System Use in Building''Document31 pages'Analysis, Design and Comparison of Composite Material Decking System Use in Building''PRATIK ATWALNo ratings yet

- A Comparative Study of Conventional Steel Building and Pre-Engineered Steel Building Structure Using STAAD PRODocument7 pagesA Comparative Study of Conventional Steel Building and Pre-Engineered Steel Building Structure Using STAAD PROIJRASETPublicationsNo ratings yet

- Slender Column Design PDFDocument12 pagesSlender Column Design PDFwerdubob8944No ratings yet

- Pre Engineered BuildingsDocument10 pagesPre Engineered BuildingsVelu KaruppiahNo ratings yet

- Sample Actual Estimates Proposed 2 Storey Residential Dwelling (Final)Document41 pagesSample Actual Estimates Proposed 2 Storey Residential Dwelling (Final)Jomar RoblesNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Engg. Build. DesignDocument67 pagesEngg. Build. DesignAyon SenguptaNo ratings yet

- Identify and Interpret Drawing and PlansDocument55 pagesIdentify and Interpret Drawing and Plansflaviano p tabotada jrNo ratings yet

- Architecture Standard Rooms SizeDocument9 pagesArchitecture Standard Rooms SizeJaved Zakhil0% (1)

- V2 I8 39 PDFDocument6 pagesV2 I8 39 PDFRamachandra Sahu100% (1)

- Bhanu PEBDocument27 pagesBhanu PEBBhanuprakash KumbarNo ratings yet

- Optimum Design of An Industrial Ware House: Kankuntla Ashok Y., Nirantar Shalaka R., Rajgiri Dinesh NDocument5 pagesOptimum Design of An Industrial Ware House: Kankuntla Ashok Y., Nirantar Shalaka R., Rajgiri Dinesh NAkbar Hamid100% (1)

- Design and Analysis of Prefabricated Structure Using E TABDocument12 pagesDesign and Analysis of Prefabricated Structure Using E TABInternational Journal of Application or Innovation in Engineering & Management100% (1)

- A State of Art Review On Analysis and Design of Pre 2023 Materials Today PRDocument7 pagesA State of Art Review On Analysis and Design of Pre 2023 Materials Today PRdawiw18153No ratings yet

- Comparative Study of Pre Engineered and Conventional Industrial BuildingDocument6 pagesComparative Study of Pre Engineered and Conventional Industrial BuildingCIVIL ENGG. SVESNo ratings yet

- Comparative Analysis of Pre-Engineered Building and Conventional Steel Building by Staad ProDocument9 pagesComparative Analysis of Pre-Engineered Building and Conventional Steel Building by Staad Prodawiw18153No ratings yet

- Design & Analysis of Pre-Engieered Building StructureDocument3 pagesDesign & Analysis of Pre-Engieered Building StructureShubhamNo ratings yet

- Comparative Study of Pre Engineered and Conventional Industrial BuildingDocument6 pagesComparative Study of Pre Engineered and Conventional Industrial BuildingTauseef AhmadNo ratings yet

- Alternative Designs For Gable Industrial Structure: (Irjet)Document7 pagesAlternative Designs For Gable Industrial Structure: (Irjet)Sinius InfracomNo ratings yet

- PreEngineered BuildingsDocument21 pagesPreEngineered BuildingsAli Imran HaveriNo ratings yet

- Peb B D0513243Document16 pagesPeb B D0513243Daniyal AhmedNo ratings yet

- Wang 2020 IOP Conf. Ser. Mater. Sci. Eng. 768 052090Document7 pagesWang 2020 IOP Conf. Ser. Mater. Sci. Eng. 768 052090Ghian Carlo Garcia CalibuyotNo ratings yet

- "Analysis and Cost Comparative Study of Conventional IndustrialDocument4 pages"Analysis and Cost Comparative Study of Conventional IndustrialSandeep SolankiNo ratings yet

- Analysis and Design of Pre - Engineered Building For Vehicle Parking ShedDocument23 pagesAnalysis and Design of Pre - Engineered Building For Vehicle Parking ShedEr S Thirumarai NathanNo ratings yet

- Chapter-1: 1.1 Tapered Steel MembersDocument11 pagesChapter-1: 1.1 Tapered Steel MembersKulal SwapnilNo ratings yet

- A Comparative Study Between The Pre Engineered Structur - 2021 - Materials TodayDocument7 pagesA Comparative Study Between The Pre Engineered Structur - 2021 - Materials Todaydawiw18153No ratings yet

- Study and Analysis of Pre-Engineering Building Structure: Sunil Kumar, Assit. Prof. G.B. BhaskarDocument3 pagesStudy and Analysis of Pre-Engineering Building Structure: Sunil Kumar, Assit. Prof. G.B. Bhaskarshashank adigaNo ratings yet

- International Journal of Technical Innovation in Modern Engineering & Science (IJTIMES)Document8 pagesInternational Journal of Technical Innovation in Modern Engineering & Science (IJTIMES)Parth DaxiniNo ratings yet

- Enginering Since To BIMDocument7 pagesEnginering Since To BIMFreizerNo ratings yet

- Ijirt142565 PaperDocument6 pagesIjirt142565 PaperGuru Prasad KarriNo ratings yet

- Comparative Analysis of Pre-Engineered Steel Building and Conventional Steel Building Using Etab-A ReviewDocument7 pagesComparative Analysis of Pre-Engineered Steel Building and Conventional Steel Building Using Etab-A Reviewdawiw18153No ratings yet

- Pre Engineered Buildings 410 PDFDocument7 pagesPre Engineered Buildings 410 PDFDrGanesh KameNo ratings yet

- IJCRT2306026Document8 pagesIJCRT2306026pankaj645924No ratings yet

- Economic Analysis of Prefabricated Buildings BasedDocument10 pagesEconomic Analysis of Prefabricated Buildings BasedSàrthàk SrìvàstàvàNo ratings yet

- 1 Review of Precast Concrete Technology in India IJERTV10IS060400Document6 pages1 Review of Precast Concrete Technology in India IJERTV10IS060400Mohd SaleemNo ratings yet

- Pre-Engineered Construction Analysis and Design of Portal FrameDocument7 pagesPre-Engineered Construction Analysis and Design of Portal FrameDimpesh SolankiNo ratings yet

- IJERDSEP1547Document10 pagesIJERDSEP1547wkh331985No ratings yet

- Steel Concrete Composite Systems For Modular Construction of High-Rise BuildingsDocument15 pagesSteel Concrete Composite Systems For Modular Construction of High-Rise Buildings박지훈No ratings yet

- Cost Reduction Effects of In-Situ PC Production For Heavily Loaded Long-Span BuildingsDocument18 pagesCost Reduction Effects of In-Situ PC Production For Heavily Loaded Long-Span BuildingsRene Rodrigues O. SilvaNo ratings yet

- Rotational Sti Ness of Inter-Module Connection in Mid-Rise Modular Steel BuildingsDocument14 pagesRotational Sti Ness of Inter-Module Connection in Mid-Rise Modular Steel BuildingsBobby CurrieNo ratings yet

- Pre Engineered Buildings 410Document8 pagesPre Engineered Buildings 410Vinit KondapureNo ratings yet

- A Review Paper On Comparative Analysis On RCC Structure With Energy Dissipation Device and Composite StructureDocument8 pagesA Review Paper On Comparative Analysis On RCC Structure With Energy Dissipation Device and Composite StructureIJRASETPublicationsNo ratings yet

- A Study On Design of Industrial Building-A Review: K.Prabin Kumar, D.Sunny PrakashDocument6 pagesA Study On Design of Industrial Building-A Review: K.Prabin Kumar, D.Sunny PrakashShubhamNo ratings yet

- E3sconf Icemee2021 03020Document4 pagesE3sconf Icemee2021 03020Akanksha PendharkarNo ratings yet

- 9 Optimization of Bill of Quantities For Construction of Pre-Engineered BuildingsDocument3 pages9 Optimization of Bill of Quantities For Construction of Pre-Engineered BuildingsdhanarajNo ratings yet

- Analysis of Pre-Engineered Buildings With Different Types of Bracings - IJAS - Volume 12 - Pages 4236-4244Document9 pagesAnalysis of Pre-Engineered Buildings With Different Types of Bracings - IJAS - Volume 12 - Pages 4236-4244Fateh QuadriNo ratings yet

- Researchpaper Design of Steel Frame Industrial Building Compared With ReinforcedDocument5 pagesResearchpaper Design of Steel Frame Industrial Building Compared With Reinforcedbasanth babuNo ratings yet

- Fin Irjmets1682867109Document5 pagesFin Irjmets1682867109B45Raj Kumar ThakurNo ratings yet

- Advantages of Pre-Engineered Building Over Conventional Steel BuildingsDocument9 pagesAdvantages of Pre-Engineered Building Over Conventional Steel Buildingsdawiw18153No ratings yet

- 11chapter 1Document3 pages11chapter 1Wai Yann ZawNo ratings yet

- A Comparative Study Between The Pre Engineered Building and Conventional Steel BuildingDocument9 pagesA Comparative Study Between The Pre Engineered Building and Conventional Steel Buildingdawiw18153No ratings yet

- Precast PDFDocument5 pagesPrecast PDFAMAL JAMAL BITNo ratings yet

- Nuclear Engineering and Design: A A A B BDocument12 pagesNuclear Engineering and Design: A A A B BAssia Ben AhmedNo ratings yet

- Peb 2Document6 pagesPeb 2Ayush GargNo ratings yet

- Overview of Pre-Engineered BuildingsDocument6 pagesOverview of Pre-Engineered BuildingsGhaneshwar ThangjamNo ratings yet

- Assessment and Design of Steel Frame Structure, Consists Performance of Connection Joints With Tekla & Staad ProDocument8 pagesAssessment and Design of Steel Frame Structure, Consists Performance of Connection Joints With Tekla & Staad ProaeoiuNo ratings yet

- A Study On Cold-Formed Steel Frame Connection A ReDocument8 pagesA Study On Cold-Formed Steel Frame Connection A Resozha phdauNo ratings yet

- Case Studies in Modular Prefabrication: Comparative Analysis and DiscoveriesDocument7 pagesCase Studies in Modular Prefabrication: Comparative Analysis and DiscoveriesC08vikram sawantNo ratings yet

- Optimization of Industrial BuildingDocument18 pagesOptimization of Industrial BuildingEr S Thirumarai NathanNo ratings yet

- PrefabricationDocument11 pagesPrefabricationIqRa JaVedNo ratings yet

- 3170622Document3 pages3170622KSghNo ratings yet

- Structural Steel VolumeDocument19 pagesStructural Steel Volumedeepa lakshmiNo ratings yet

- Parul Pandey Dissertation PDFDocument36 pagesParul Pandey Dissertation PDFParul PandeyNo ratings yet

- Techniques of Wood Carving Applied in The Architectural Elements of Malay Vernacular BuildingsDocument5 pagesTechniques of Wood Carving Applied in The Architectural Elements of Malay Vernacular BuildingsNurul syara ainaa RahimNo ratings yet

- FloorsDocument19 pagesFloorsSaravanan KumarNo ratings yet

- DLC Vs PCCDocument7 pagesDLC Vs PCCSasanka SekharNo ratings yet

- Wenge Minimalist Luxury Interior Design Instagram StoryDocument3 pagesWenge Minimalist Luxury Interior Design Instagram StoryJustine PadillaNo ratings yet

- Rent To Own House and Lot For Sale Sta Elena Antipolo CityDocument11 pagesRent To Own House and Lot For Sale Sta Elena Antipolo Citymhyobispo100% (1)

- Listado de Materiales Disciplina Electrica Cybe 4 Nuevos Pozos 03-11-2020Document6 pagesListado de Materiales Disciplina Electrica Cybe 4 Nuevos Pozos 03-11-2020edwin cuellarNo ratings yet

- Brochure en MK4Document6 pagesBrochure en MK4AttallaEANo ratings yet

- Horizontal Seismic Band in Masonry StructuresDocument2 pagesHorizontal Seismic Band in Masonry StructuresSantosh YadavNo ratings yet

- BasementsDocument15 pagesBasementsMeshari FahimNo ratings yet

- Karl Friedrich SchinkelDocument18 pagesKarl Friedrich Schinkeltanie100% (7)

- List of Topics ForDocument4 pagesList of Topics ForPiyush BhandariNo ratings yet

- Waterstop InstallationDocument5 pagesWaterstop InstallationTefiloNo ratings yet

- Tomb of IltutmishDocument8 pagesTomb of Iltutmishname PPSNo ratings yet

- PHS Expansion JointsDocument4 pagesPHS Expansion JointsStephenNo ratings yet

- Material Portfolio: Name:Priyanka V Naik USN:1MS19AT042 Subject:Bmct-Iv Soa, BangaloreDocument10 pagesMaterial Portfolio: Name:Priyanka V Naik USN:1MS19AT042 Subject:Bmct-Iv Soa, Bangalore1MS19AT036 Hemanth kumarNo ratings yet

- B VEGADocument22 pagesB VEGAPetru CordosNo ratings yet

- Examples: Pre-Cast: Heydar Aliyev CenterDocument3 pagesExamples: Pre-Cast: Heydar Aliyev Centermarquezjohnmark101No ratings yet

- Lighting As Determinant of Form For ArchitectureDocument26 pagesLighting As Determinant of Form For Architecturefasi rahman100% (1)

- BLDG LAWS Pedro Assignment 5 - 6 BP 220 PD 957Document13 pagesBLDG LAWS Pedro Assignment 5 - 6 BP 220 PD 957Jofer PatenioNo ratings yet

- Comparison of GFRG With Conventional SystemsDocument83 pagesComparison of GFRG With Conventional Systemsarshivachandran0% (2)

- Constructs 2011 - Fall PDFDocument28 pagesConstructs 2011 - Fall PDFAlexandru PlesuNo ratings yet

- FlamingoDocument59 pagesFlamingoNone None NoneNo ratings yet

- Roofing and Waterproofing (US Army Mil TM 5-505-14) (1993) PDFDocument38 pagesRoofing and Waterproofing (US Army Mil TM 5-505-14) (1993) PDFbotchNo ratings yet

- BC Sheet 1 AasthaDocument4 pagesBC Sheet 1 AasthaajNo ratings yet

- Area Statement For Railway Terminus: Level Category Space Occupancy Area AdminDocument2 pagesArea Statement For Railway Terminus: Level Category Space Occupancy Area AdminMj ShobanaNo ratings yet